Mold Drawing

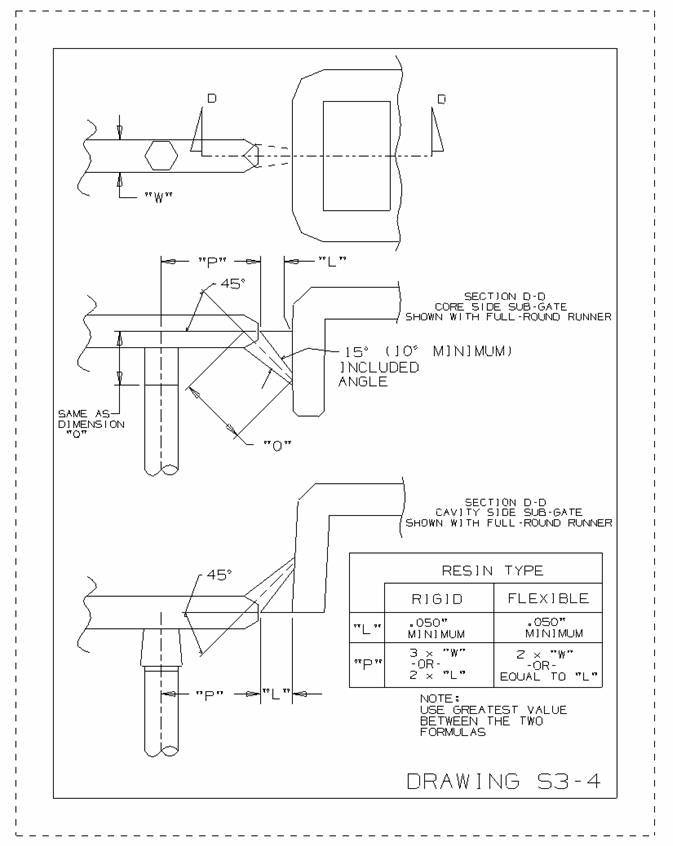

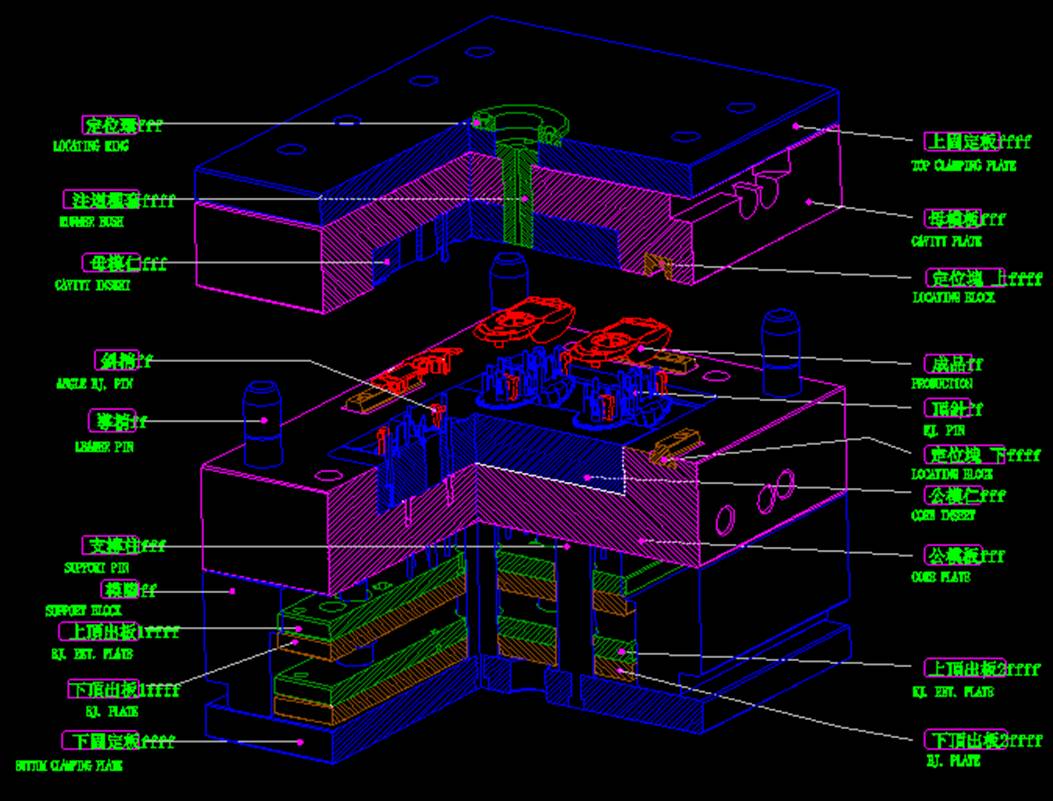

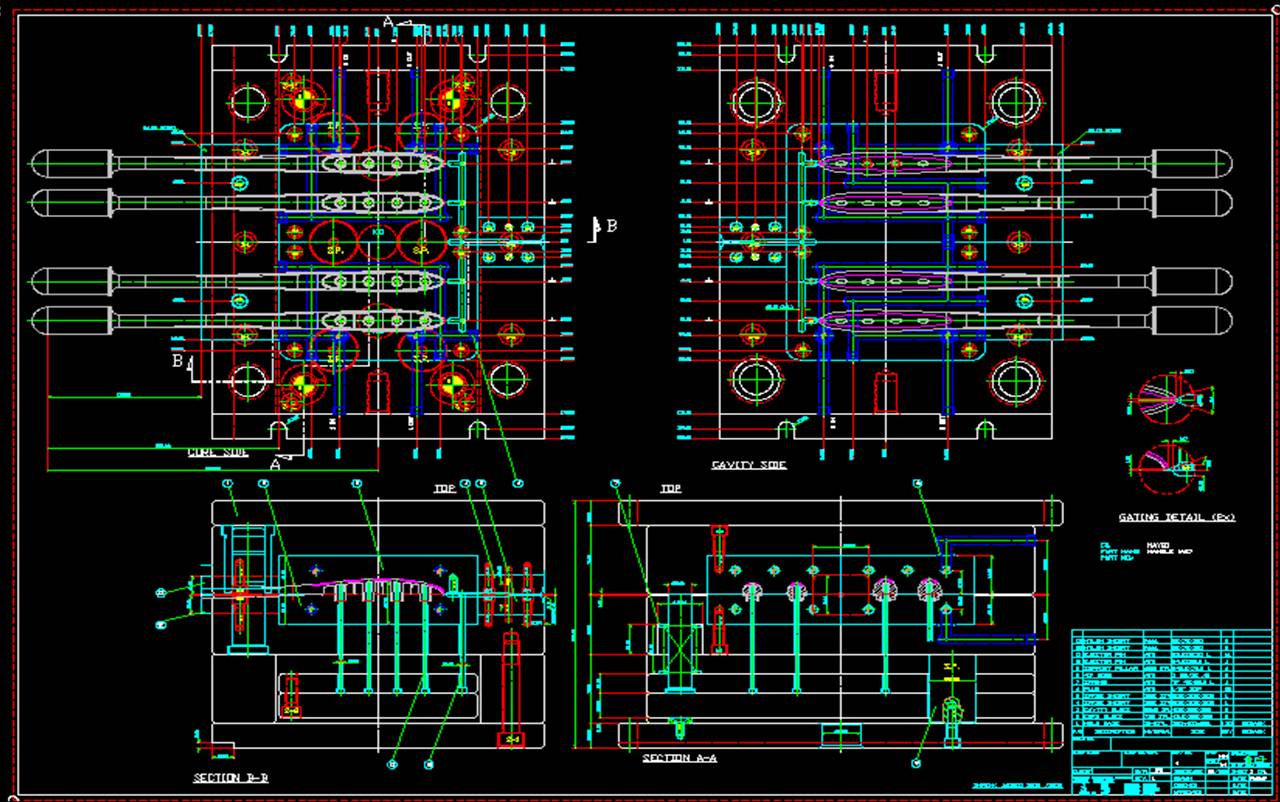

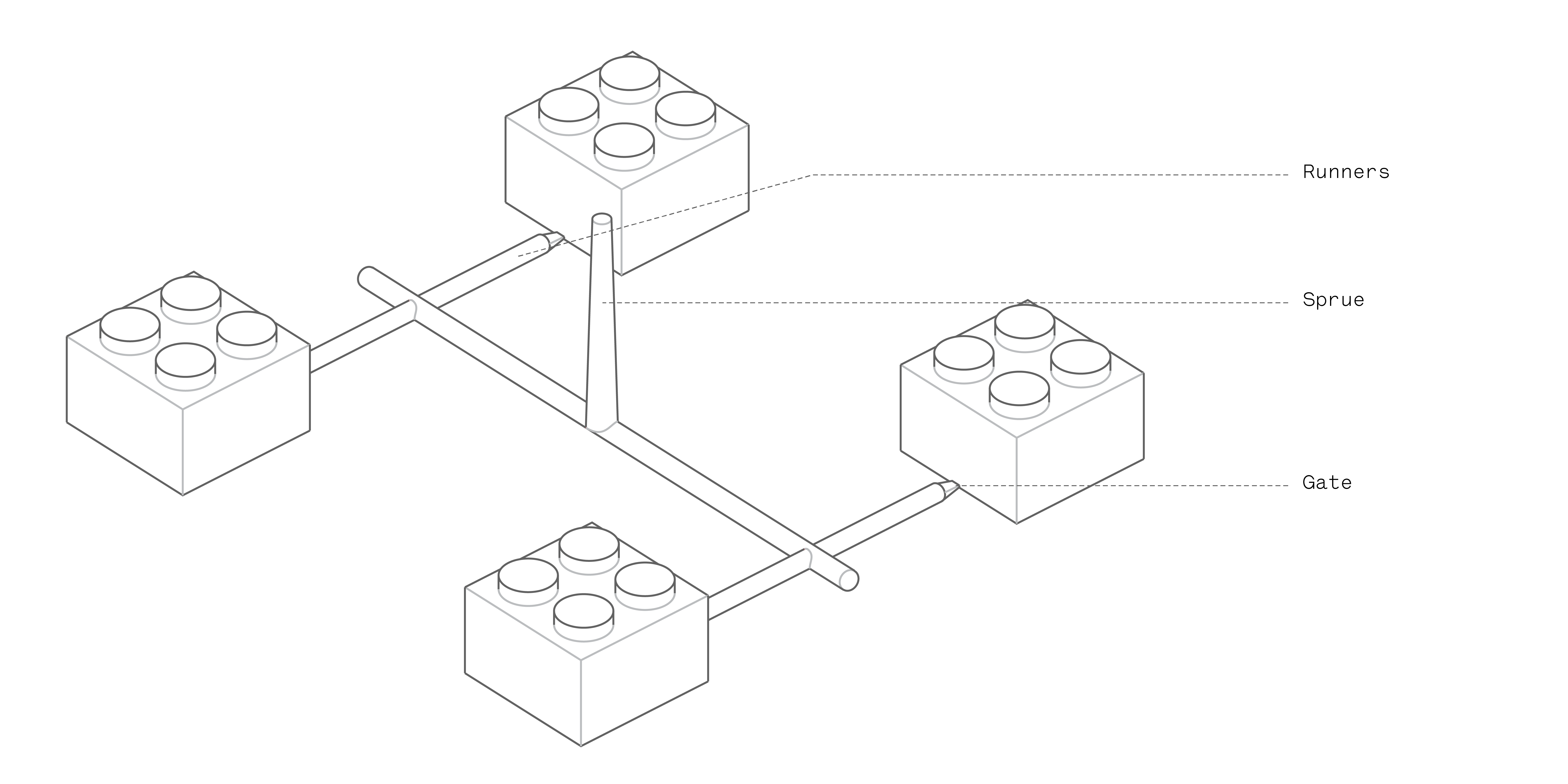

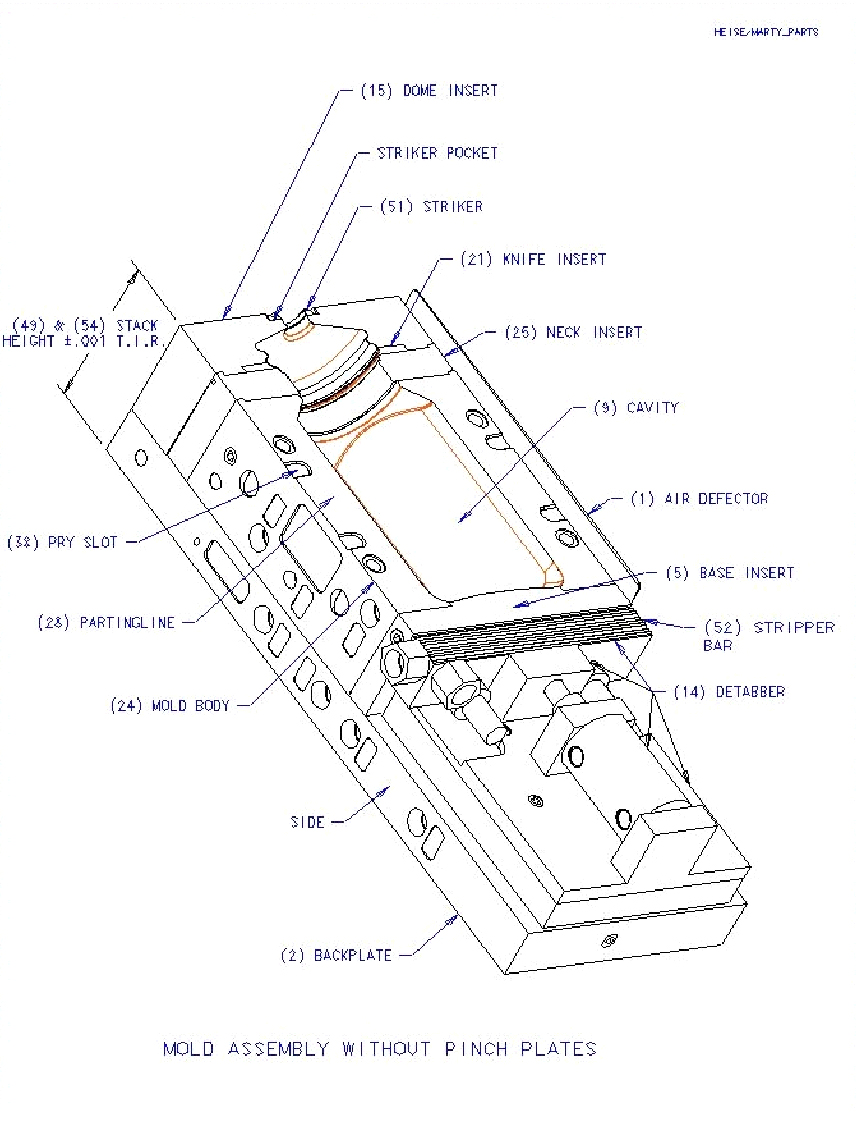

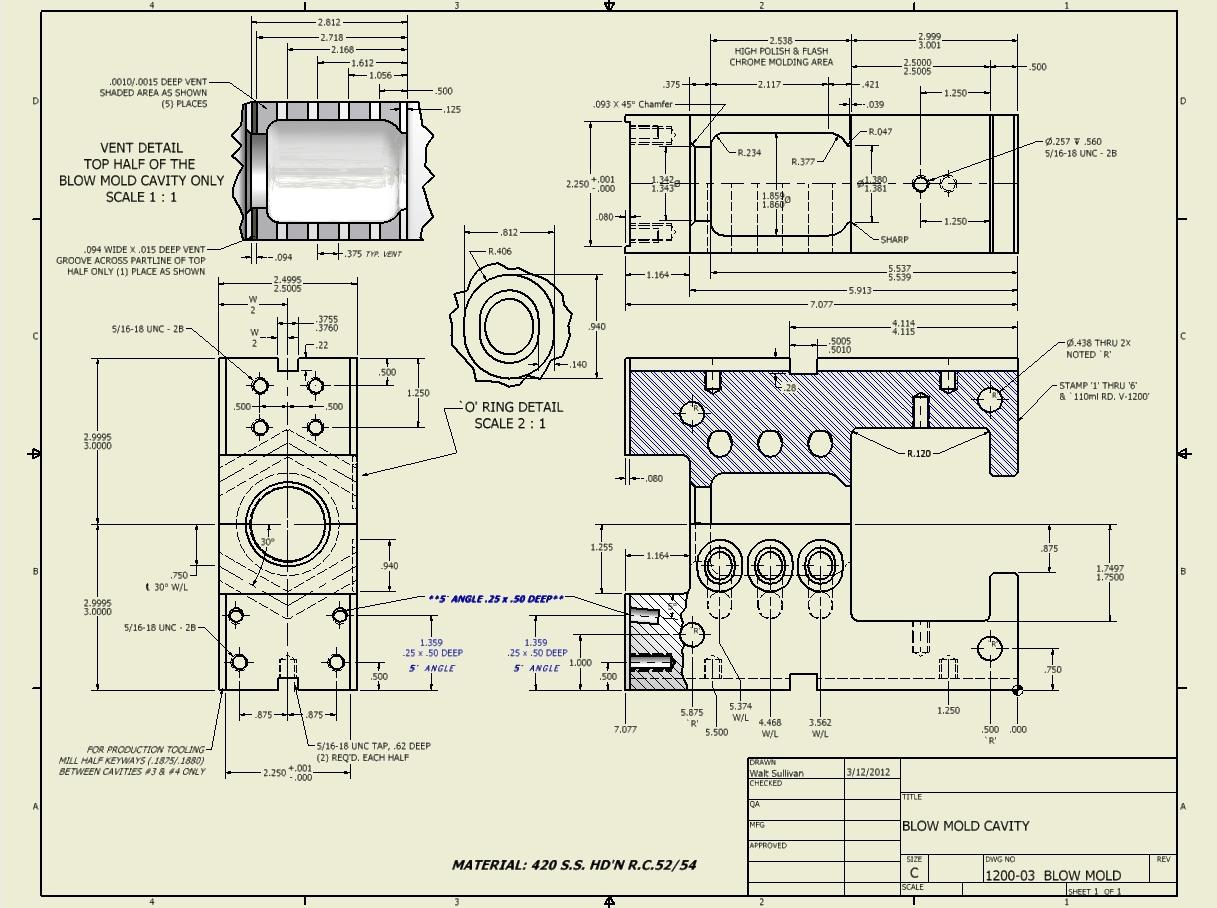

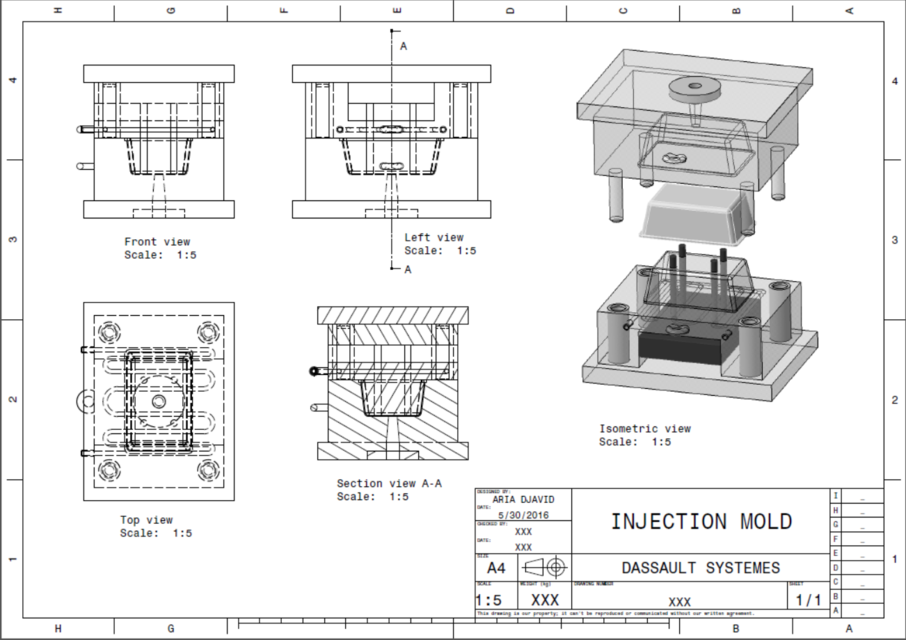

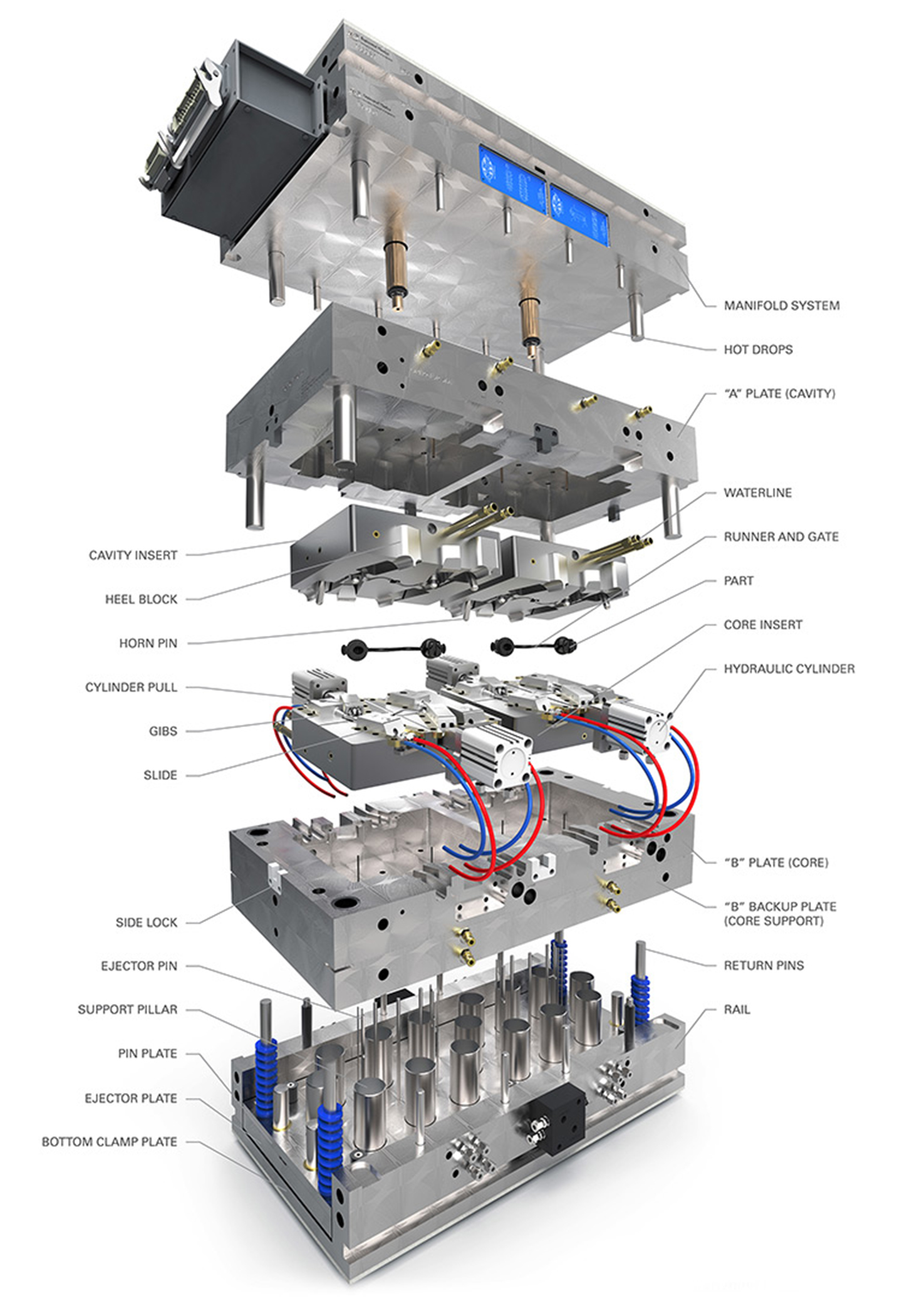

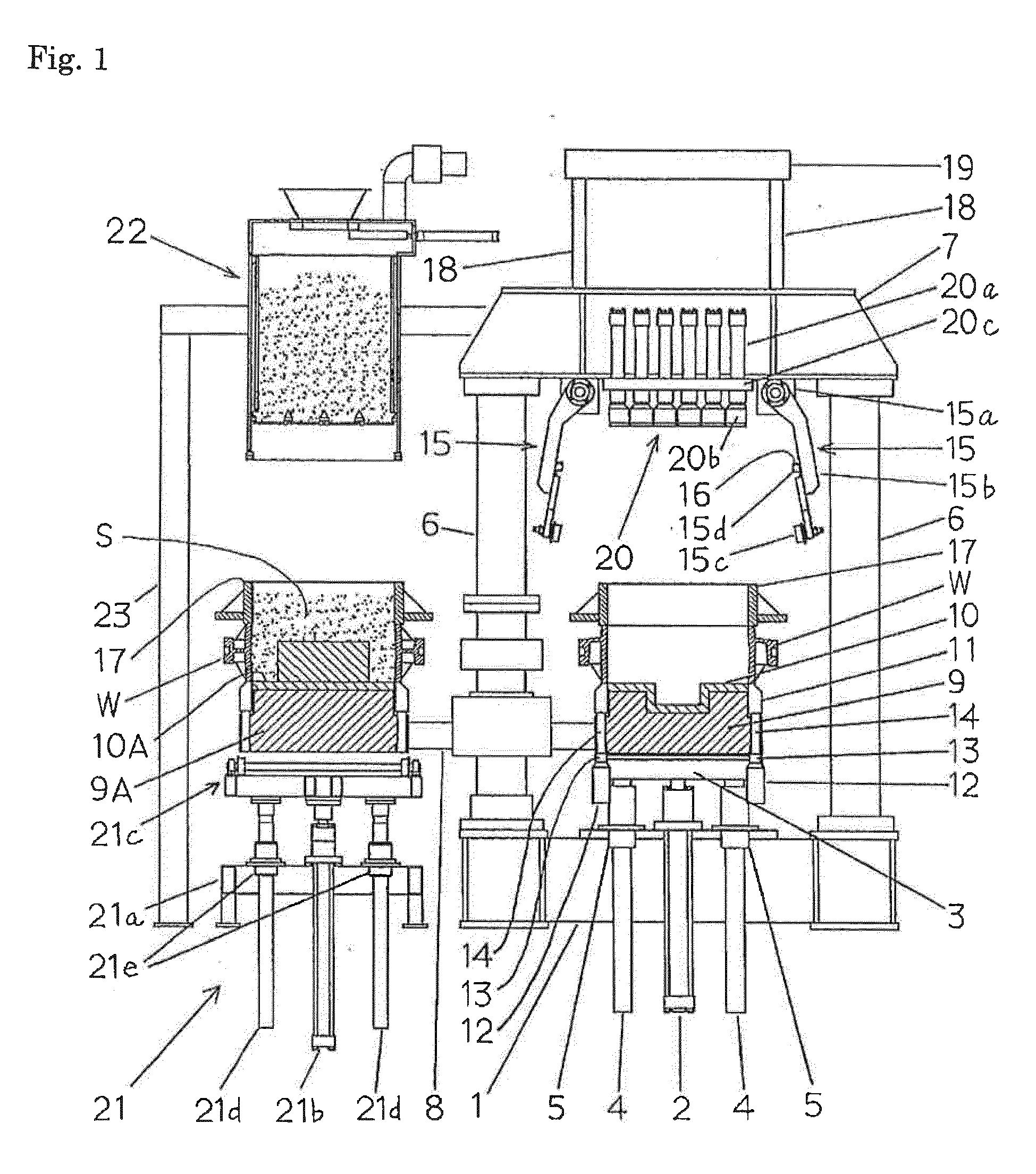

Mold Drawing - They are usually hardened metal examples include; The core and the cavity. Web each injection mold design must have a gate, or an opening that allows the molten plastic to be injected into the cavity of the mold. It contains all the dimensional data necessary for cnc machining of the mold components. K) drawing the mold structure: Defines the common steel types and their applications. Create detailed drawings of the mold structure, illustrating all parts, assembly relationships, and technical requirements, including. Web a corner radius, as shown in figure 26, will increase the strength of the corner and improve mold filling. A design branch showing the surfacing required to accomplish a proper mold split. A “part cavity” is the space or the void that receives the injected plastic resins. This includes product design and process engineers, manufacturing, qa/ qc, plastics and tooling engineers, as well as sales/service, purchasing, maintenance and management personnel. They are usually hardened metal examples include; Web straightforward as it may seem, injection molding has specific steps that have to be followed in order for the process to be a success. A key design aspect is. It contains all the dimensional data necessary for cnc machining of the mold components. Plastic products were primarily limited to phenolics, polystyrene, and other thermosets. To really make a difference in business. These teams should include, but are not limited to process engineering, automation, tool maintenance and. Steel molds are usually preferred because of steel properties like. This includes product design and process engineers, manufacturing, qa/ qc, plastics and tooling engineers, as well as sales/service, purchasing, maintenance and management personnel. Web mold design and tooling for injection molding. Generally speaking, there should not be any surface of the part that is exactly 90 degrees to the line of draw on the mold. Web this book is designed. Web mold is the most essential part of the plastic injection molding process. Web an injection mold design needs to ensure the part comes out of the mold without damage or too much resistance. Web following are some mold design best practices that will help you achieve these goals. In conclusion, through the analysis steps outlined above, potential risks can. Web next, in sheet metal forming mold design, a mold must be designed following the parameters of the final product. This is a true bargain, considering the vast amount of. Web a mold is a type of cavity used in the injection molding process where the molten plastic is injected to form a variety of shapes depending on the mold. They are usually hardened metal examples include; A “part cavity” is the space or the void that receives the injected plastic resins. Choose a suitable standard mold base based on the mold’s dimensions, and prefer standard mold components whenever possible. In injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic. Web mold design and tooling for injection molding. To see this branch, follow this link. In this video, you’ll learn the fund. To avoid these issues, you want to angle the walls of the part from the parting line (drafting). Web an injection mold design needs to ensure the part comes out of the mold without damage or too much. Web a mold is a type of cavity used in the injection molding process where the molten plastic is injected to form a variety of shapes depending on the mold design. Gate type, design, and location can have effects on the part such as part packing, gate removal or vestige, cosmetic appearance of the part, and part dimensions and warping.. Plastic products were primarily limited to phenolics, polystyrene, and other thermosets. Molds consist of two main parts: Web a mold is a type of cavity used in the injection molding process where the molten plastic is injected to form a variety of shapes depending on the mold design. To really make a difference in business. Web j) standard mold base. Web injection molded plastics have revolutionized design, innovation, and manufacturing in the 20th century. The customer will specify the general steel types. To avoid these issues, you want to angle the walls of the part from the parting line (drafting). Web the mold drawing is especially valuable for any future repair needs. A “part cavity” is the space or the. It contains all the dimensional data necessary for cnc machining of the mold components. In injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. The ability to check for draft and undercuts to ensure proper mold function and eliminate mold lockup. In conclusion, through the analysis steps outlined above, potential risks can be largely anticipated, allowing for the identification and improvement. Web an injection mold design needs to ensure the part comes out of the mold without damage or too much resistance. Web anyone working with the mold design and building process can benefit from this highly instructional course. We are going to look at the things that one has to consider. The materials used in injection molding are thermoplastic polymers that can. This is a true bargain, considering the vast amount of. Web a corner radius, as shown in figure 26, will increase the strength of the corner and improve mold filling. Web injection molded plastics have revolutionized design, innovation, and manufacturing in the 20th century. They are usually hardened metal examples include; Web a mold is a type of cavity used in the injection molding process where the molten plastic is injected to form a variety of shapes depending on the mold design. Web after ordering your mold design tutorial, you will receive a free ebook about the 10 top tips for injection mold making. To see this branch, follow this link. Web mold design and tooling for injection molding.

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at Explore collection of Mold Drawing

Anatomy of a Mold PTI Engineered Plastics, Inc.

Mold Drawing at GetDrawings Free download

Tooling And Mold Design Define The Success Of The Entire Project.

Web Upmold Rg Series Mold:

Web J) Standard Mold Base Selection:

Limited Draft Requires An Excessive Amount Of Pressure On The Ejection System That May Damage Parts And Possibly The Mold.

Related Post: