Minitab X Bar Chart

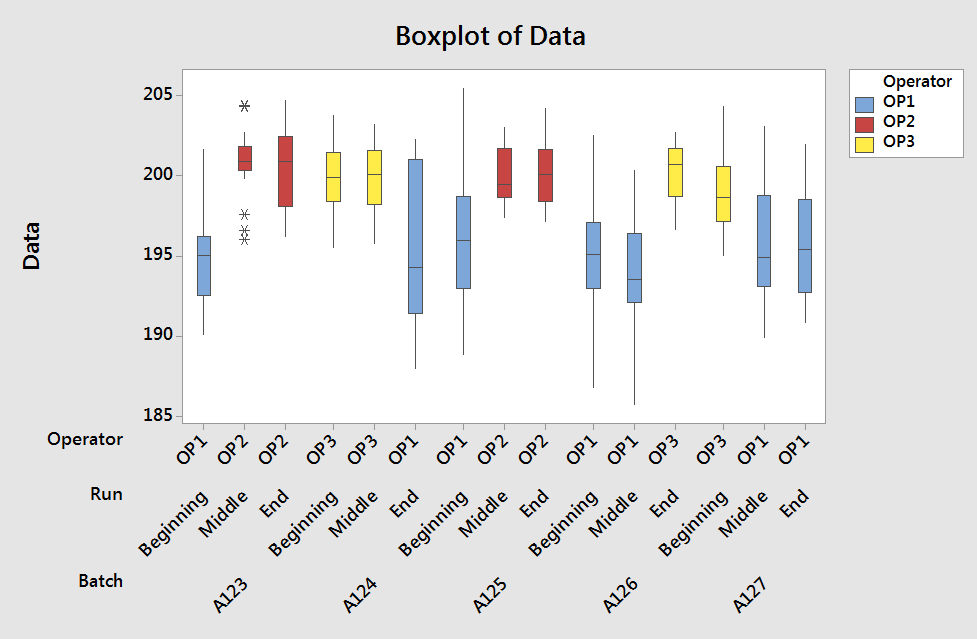

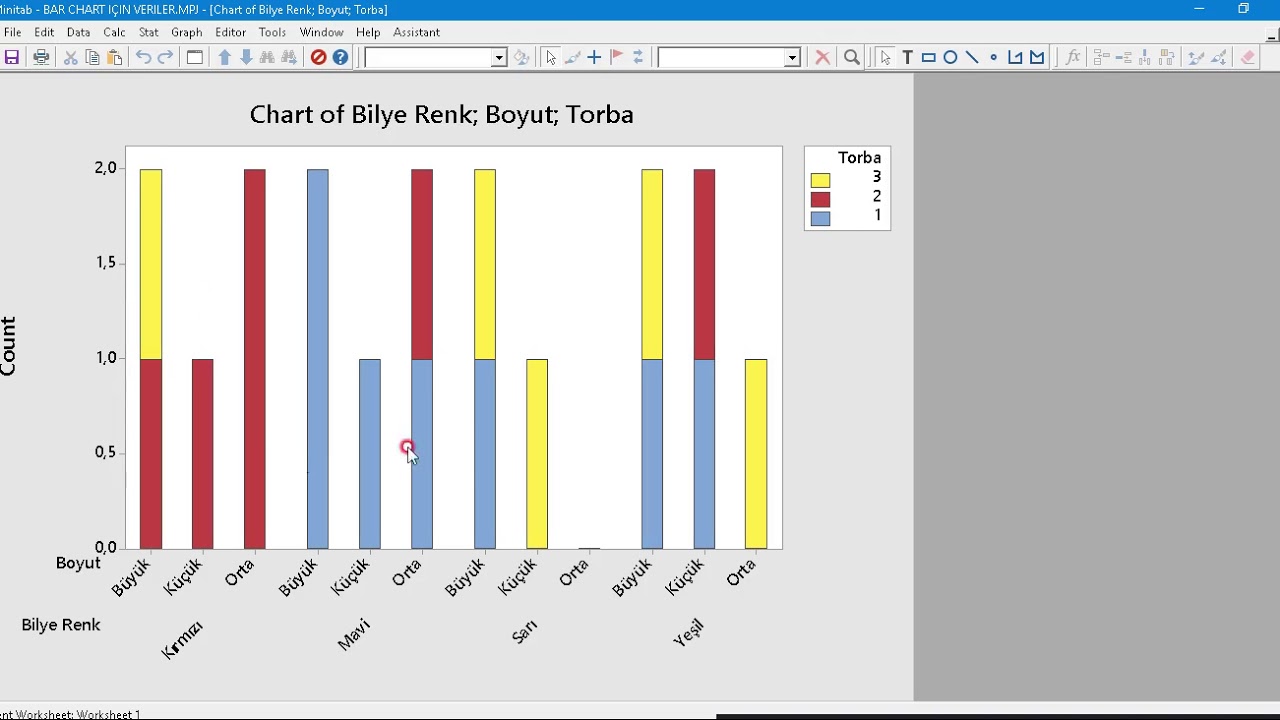

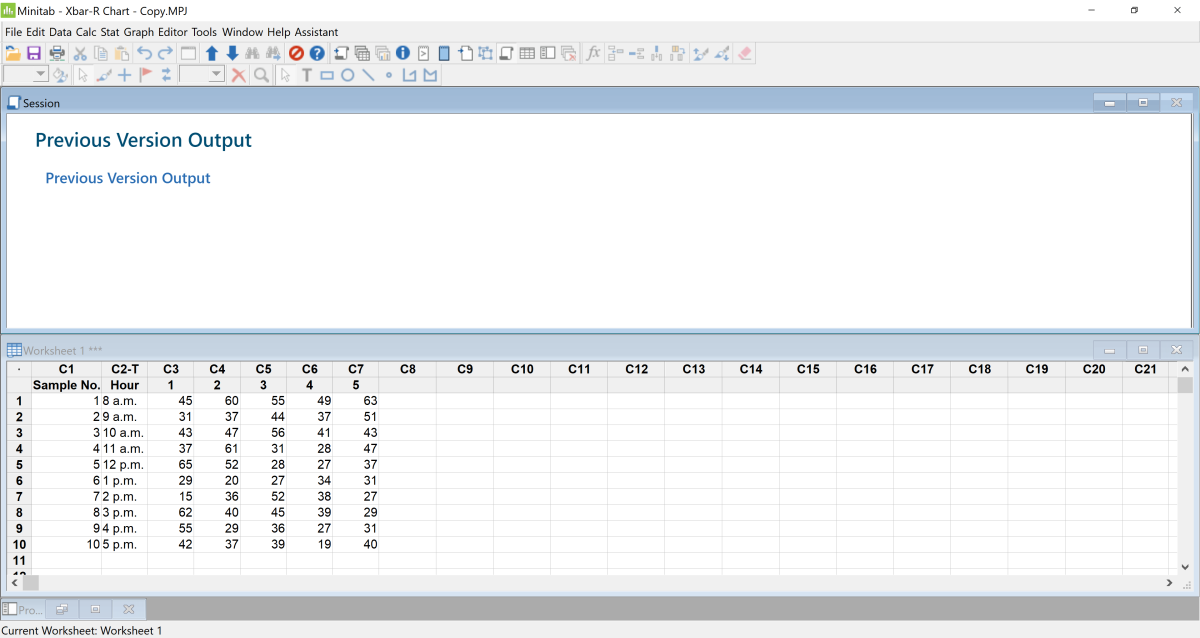

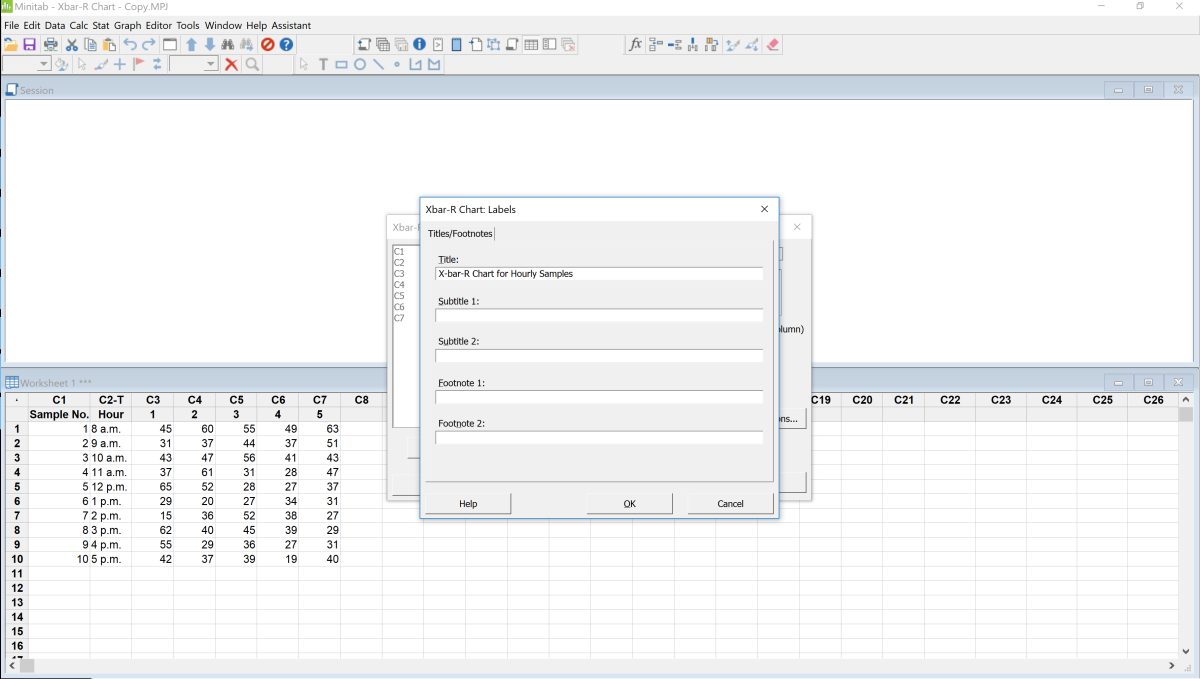

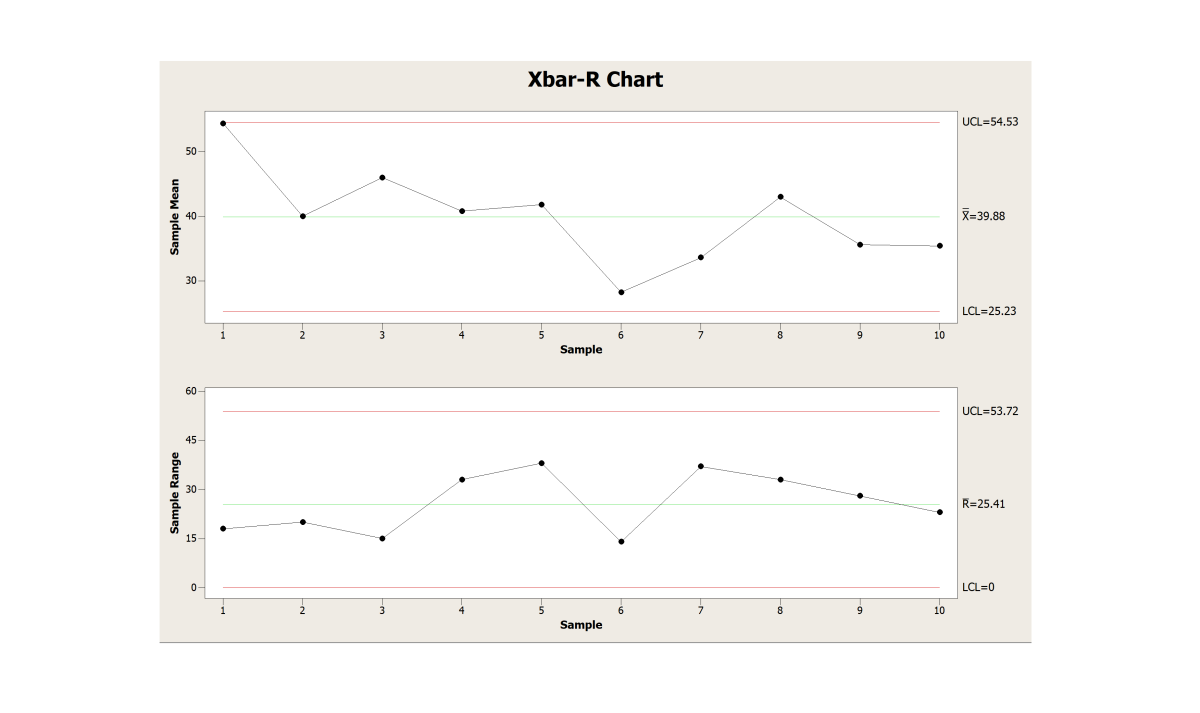

Minitab X Bar Chart - Click in the blank box right below “all observations for a chart are in one column” and the variables appear in the list box on the left. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Choose observations for a subgroup are in one row of columns, then click x1, x2, x3, x4, x5 in the box. Go to stat > control charts > variables for subgroups > xbar & s. Web use xbar chart to monitor the mean of your process when you have continuous data in subgroups. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. Each hour, the engineer collects a subgroup of 10 cans. Identify which points failed each test. Web select the method or formula of your choice. Choose stat > control charts > variables charts for subgroups > xbar. If you have attribute data, you need to determine if you're looking at proportions or counts. The first choice is ‘counts of unique values,’ which has three options (simple, cluster, and stack). Each hour, the engineer collects a subgroup of 10 cans. The height of the bar shows either the count or variable function for the group. Use this control. Select “observations for a subgroup are in one row of columns”: Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Choose observations for a subgroup are in. The height of the bar shows either the count or variable function for the group. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. Select “observations for a subgroup are in one row of columns”: Web if. If you have attribute data, you need to determine if you're looking at proportions or counts. Web if you go to graph > bar chart., the first option you’ll see is a drop down titled ‘bars represent,’ which is a detailed way of asking how you want minitab to calculate how tall your bars should be. Don't forget to subscribe. Select “observations for a subgroup are in one row of columns”: Don't forget to subscribe and share. Web use xbar chart to monitor the mean of your process when you have continuous data in subgroups. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control. Stages show how a process changes over specific time periods. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. Web if you go to graph > bar chart., the first option you’ll see is a drop down. Identify which points failed each test. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Web find definitions and interpretation guidance for every statistic and graph that is provided with the xbar chart. Select “observations for a subgroup are in one row of columns”: Web x bar r. The first choice is ‘counts of unique values,’ which has three options (simple, cluster, and stack). Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). They measure. Web about press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features nfl sunday ticket press copyright. Web use bar chart to compare the counts, means, or other summary statistics using bars to represent groups or categories. Choose stat > control charts > variables charts for subgroups > xbar. They measure performance. Click in the blank box right below “all observations for a chart are in one column” and the variables appear in the list box on the left. Stages show how a process changes over specific time periods. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Don't forget. Web about press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features nfl sunday ticket press copyright. Go to stat > control charts > variables for subgroups > xbar & s. Select “observations for a subgroup are in one row of columns” 4. Choose observations for a subgroup are in one row of columns, then click x1, x2, x3, x4, x5 in the box. Screenshots are provided for each step, making it easy for beginners to follow along. Web if you go to graph > bar chart., the first option you’ll see is a drop down titled ‘bars represent,’ which is a detailed way of asking how you want minitab to calculate how tall your bars should be. Select “observations for a subgroup are in one row of columns”: Click in the blank box right below “all observations for a chart are in one column” and the variables appear in the list box on the left. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. Select “tests” tab and “perform all tests for special causes” 6. Identify which points failed each test. Examine the xbar chart to determine whether the process mean is in control. Web select the method or formula of your choice. Don't forget to subscribe and share. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). They measure performance on any type of process, from all the steps in a manufacturing process to determining the time customers must wait in line at a pharmacy.

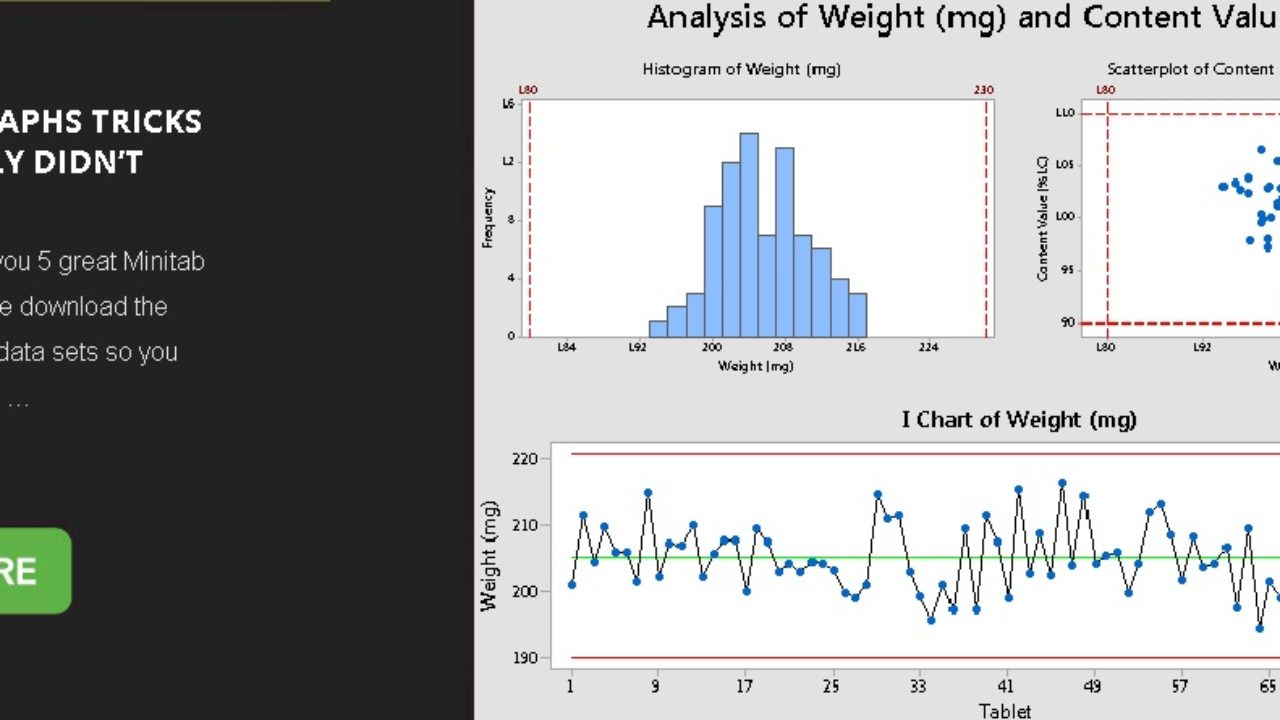

5 Minitab graphs tricks you probably didn’t know about Master Data

Çubuk GrafiğiMinitab (Bar Chart) minitab kalite kontrol 6 sigma

How to Create an XbarR Chart in Minitab 18 ToughNickel

How to Create an XbarR Chart in Minitab 18 ToughNickel

How To Make X Bar R Chart In Minitab Chart Examples

How to Create an XbarR Chart in Minitab 18 ToughNickel 德赢Vwin888

X Bar And R Chart Minitab Chart Examples

MinitabDataAnalysisXbarRChart CSense Management Solutions

Introduction to the X Bar R Control Chart using Minitab Version 20

Xbar S Chart with Minitab Lean Sigma Corporation

The Height Of The Bar Shows Either The Count Or Variable Function For The Group.

Web Use Xbar Chart To Monitor The Mean Of Your Process When You Have Continuous Data In Subgroups.

Go To Stat > Control Charts > Variables For Subgroups > Xbar & R:

Use This Control Chart To Monitor Process Stability Over Time So That You Can Identify And Correct Instabilities In A Process.

Related Post: