Minitab R Chart

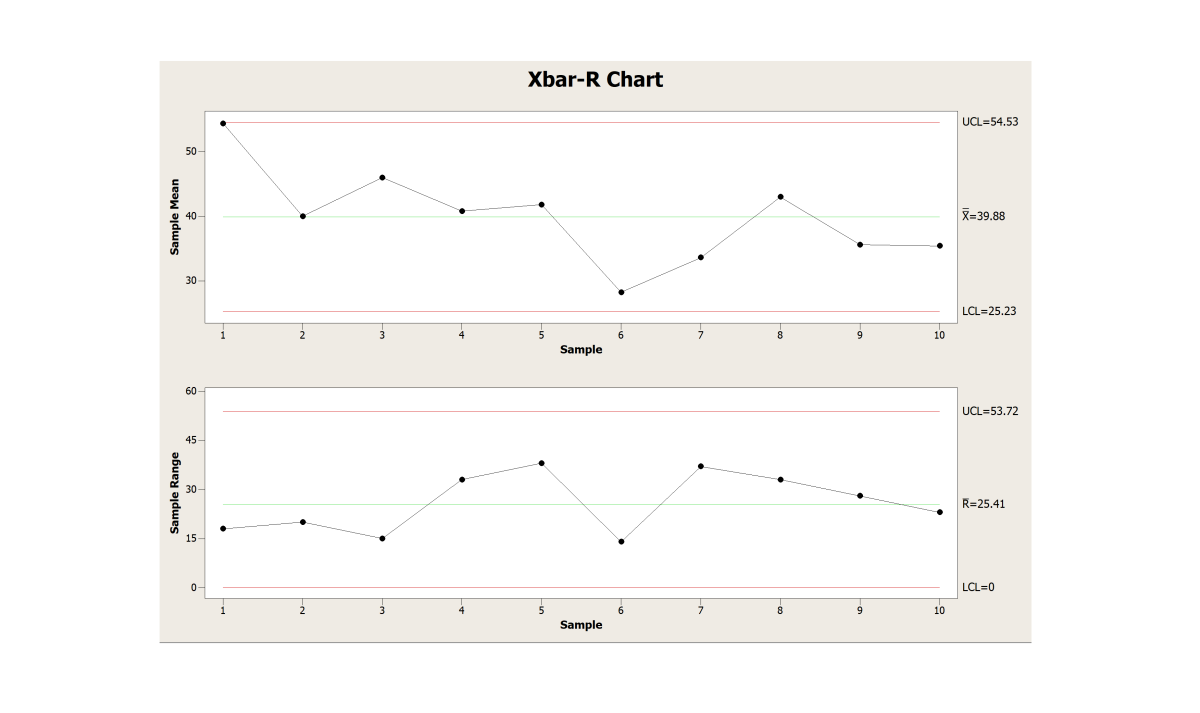

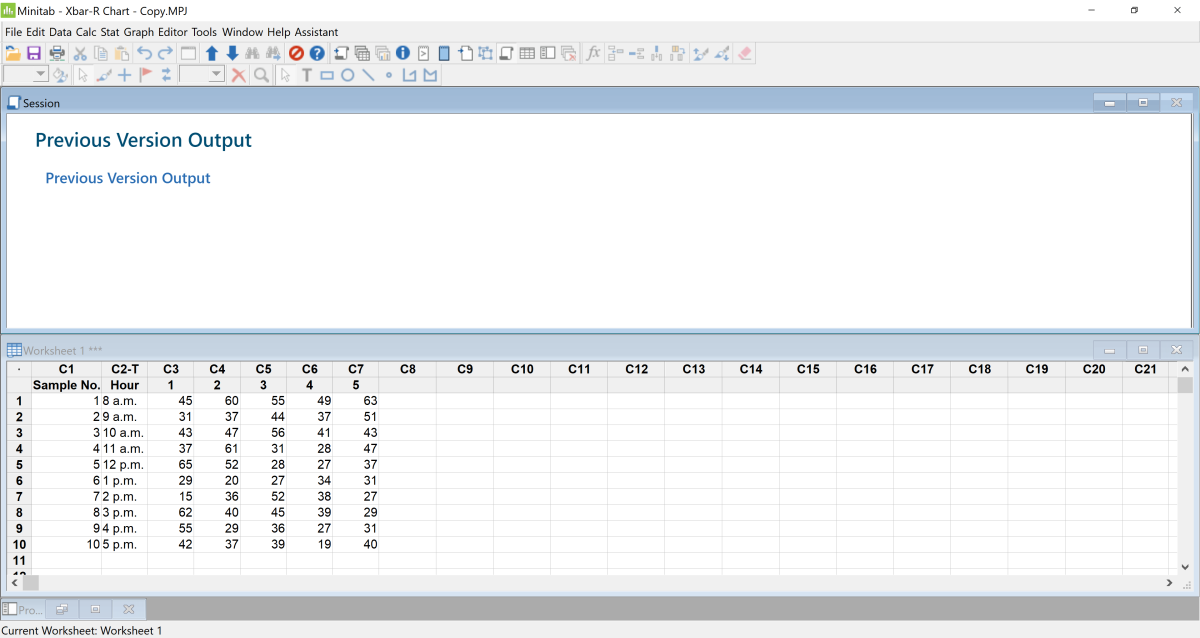

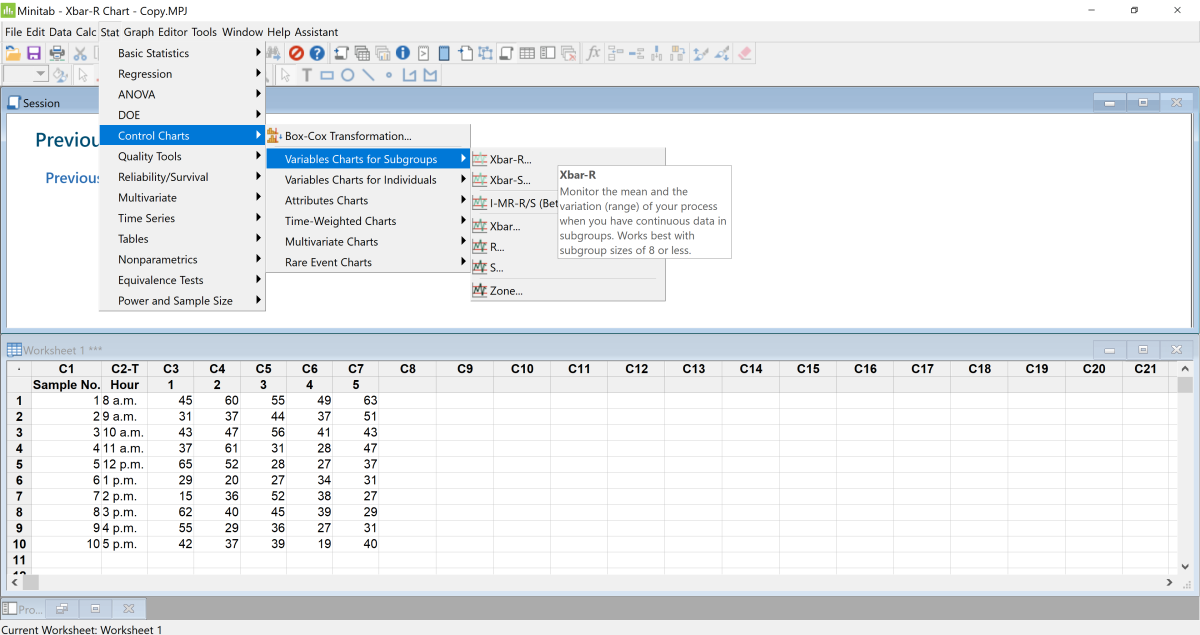

Minitab R Chart - Each plotted point, ri, represents the range for subgroup i. Here's the latest tuorial using minitab software. The value of the center line for each subgroup, , is calculated as follows: Web use r chart to monitor the variation (range) of your process when you have continuous data and subgroup sizes of 8 or less. Total gage r&r %study var. None of the points are outside the control limits and the points display a random pattern for all 3 machines. At each stage, minitab statistical software recalculates the center line and control limits on the chart by default. Stages show how a process changes over specific time periods. If we instead use the real subgroup size reflective of how we collected the data, here is what we see: Even very stable processes have some variation, and when you try to fix minor fluctuations in a process you can actually cause instability. Web use r chart to monitor the variation (range) of your process when you have continuous data and subgroup sizes of 8 or less. Monitoring the stability of a process. Here's the latest tuorial using minitab software. To create an r chart, minitab needs to know the range and the sample size for each subgroup. Key output includes variability estimates,. Go to stat > control charts > variables for subgroups > xbar & r: Stages show how a process changes over specific time periods. Web minitab creates three r charts, one chart for each machine. Total gage r&r % contribution. Choose stat > control charts > variables charts for subgroups > To build control limits for a range chart we need to estimate the standard deviation, σ. 187 views 10 months ago. Go to stat > control charts > variables for subgroups > xbar & r: However, you can also create an r chart from a column of subgroup ranges. Total gage r&r %study var. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Once mastered, it provides data to leaders on changes they should make as well as measuring the success of changes put into place. To build control limits for a range chart we need to estimate the standard deviation, σ.. Are you worried about scrap or rework? Thus, the process variation is in control, and the engineer can examine the process center on. Each subgroup is a collection of n samples made under like conditions. Web minitab for r chart. Web create an r chart with summary data. Here's the latest tuorial using minitab software. Web accounting for process changes in a control chart. Go to stat > control charts > variables for subgroups > xbar & r: Cp and cpk, working together (minitab.com) next generation of spc solutions. Are you worried about scrap or rework? Web minitab creates three r charts, one chart for each machine. Here are the main results for the minitab data analysis, shown as a summary table. Click in the blank box right below “all observations for a chart are in one column” and the variables appear in the list box on the left. Web accounting for process changes in a. At each stage, minitab statistical software recalculates the center line and control limits on the chart by default. Web use r chart to monitor the variation (range) of your process when you have continuous data and subgroup sizes of 8 or less. Cp and cpk, working together (minitab.com) next generation of spc solutions. Is your business missing shipment deadlines due. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Web about press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features nfl sunday ticket press copyright. Go to stat > control charts > variables for subgroups > xbar & r:. 187 views 10 months ago. Total gage r&r %study var. To build control limits for a range chart we need to estimate the standard deviation, σ. Web minitab creates three r charts, one chart for each machine. Web the range chart. Even very stable processes have some variation, and when you try to fix minor fluctuations in a process you can actually cause instability. 187 views 10 months ago. Here's the latest tuorial using minitab software. Monitoring the stability of a process. Stages show how a process changes over specific time periods. 3.8k views 2 years ago minitab tutorials. Once mastered, it provides data to leaders on changes they should make as well as measuring the success of changes put into place. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control, then the control limits on the xbar chart are inaccurate. Web about press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features nfl sunday ticket press copyright. The value of the center line for each subgroup, , is calculated as follows: Usually, you create an r chart from a column of individual measurements. If we instead use the real subgroup size reflective of how we collected the data, here is what we see: Web minitab creates three r charts, one chart for each machine. Choose stat > control charts > variables charts for subgroups > To create an r chart, minitab needs to know the range and the sample size for each subgroup. Here are the main results for the minitab data analysis, shown as a summary table.

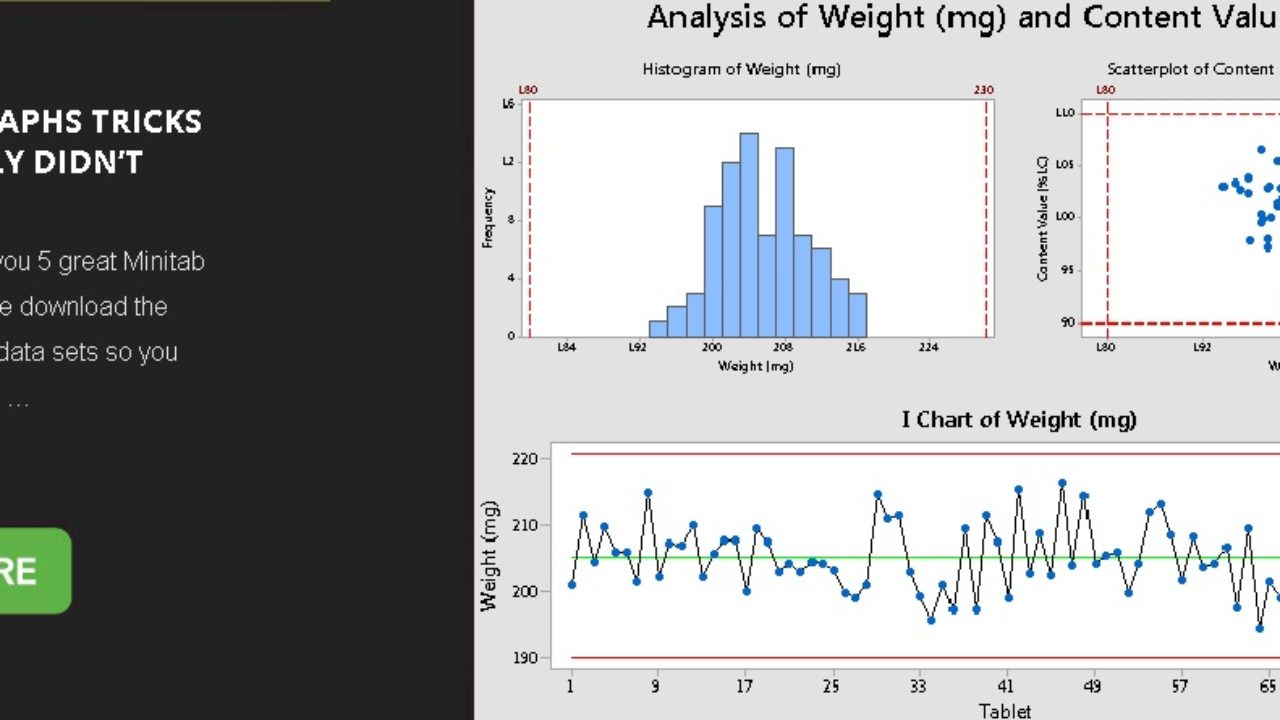

5 Minitab graphs tricks you probably didn’t know about Master Data

Minitab para Construir o Gráfico XBarra / R Aprendendo Gestão

How to Create an XbarR Chart in Minitab 18 ToughNickel 德赢Vwin888

MinitabDataAnalysisXbarRChart CSense Management Solutions

X Bar And R Chart Minitab Chart Examples

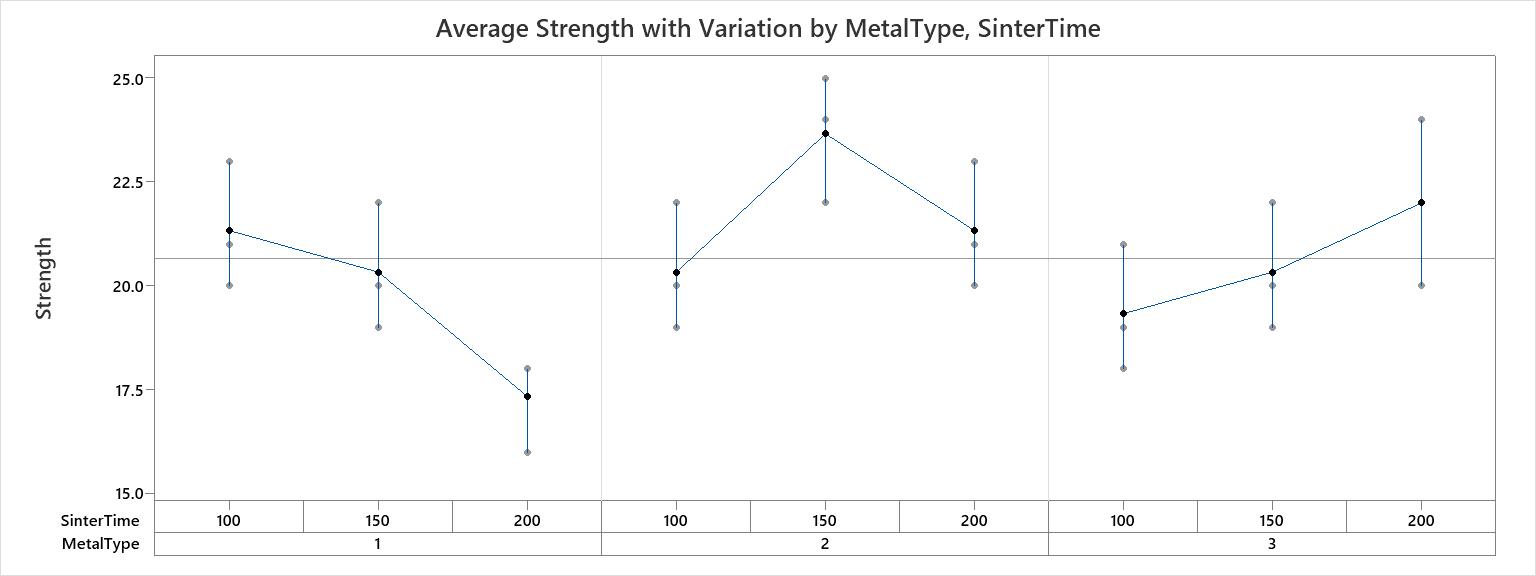

Interpret the key results for Variability Chart Minitab

How to Create an XbarR Chart in Minitab 18 ToughNickel

How To Make X Bar R Chart In Minitab Chart Examples

How to Create an XbarR Chart in Minitab 18 ToughNickel

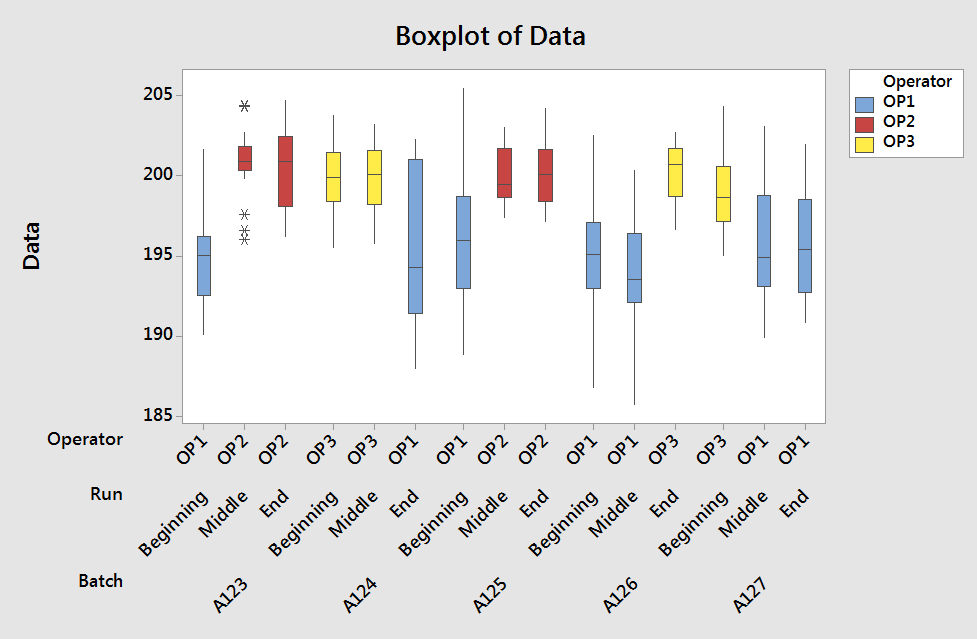

Interpreting Minitab’s Gage R&R Chart Business Performance

None Of The Points Are Outside The Control Limits And The Points Display A Random Pattern For All 3 Machines.

Web Use R Chart To Monitor The Variation (Range) Of Your Process When You Have Continuous Data And Subgroup Sizes Of 8 Or Less.

Use This Control Chart To Monitor Process Stability Over Time So That You Can Identify And Correct Instabilities In A Process.

Is Your Business Missing Shipment Deadlines Due To Quality Issues?

Related Post: