Mig Welding Amps To Metal Thickness Chart

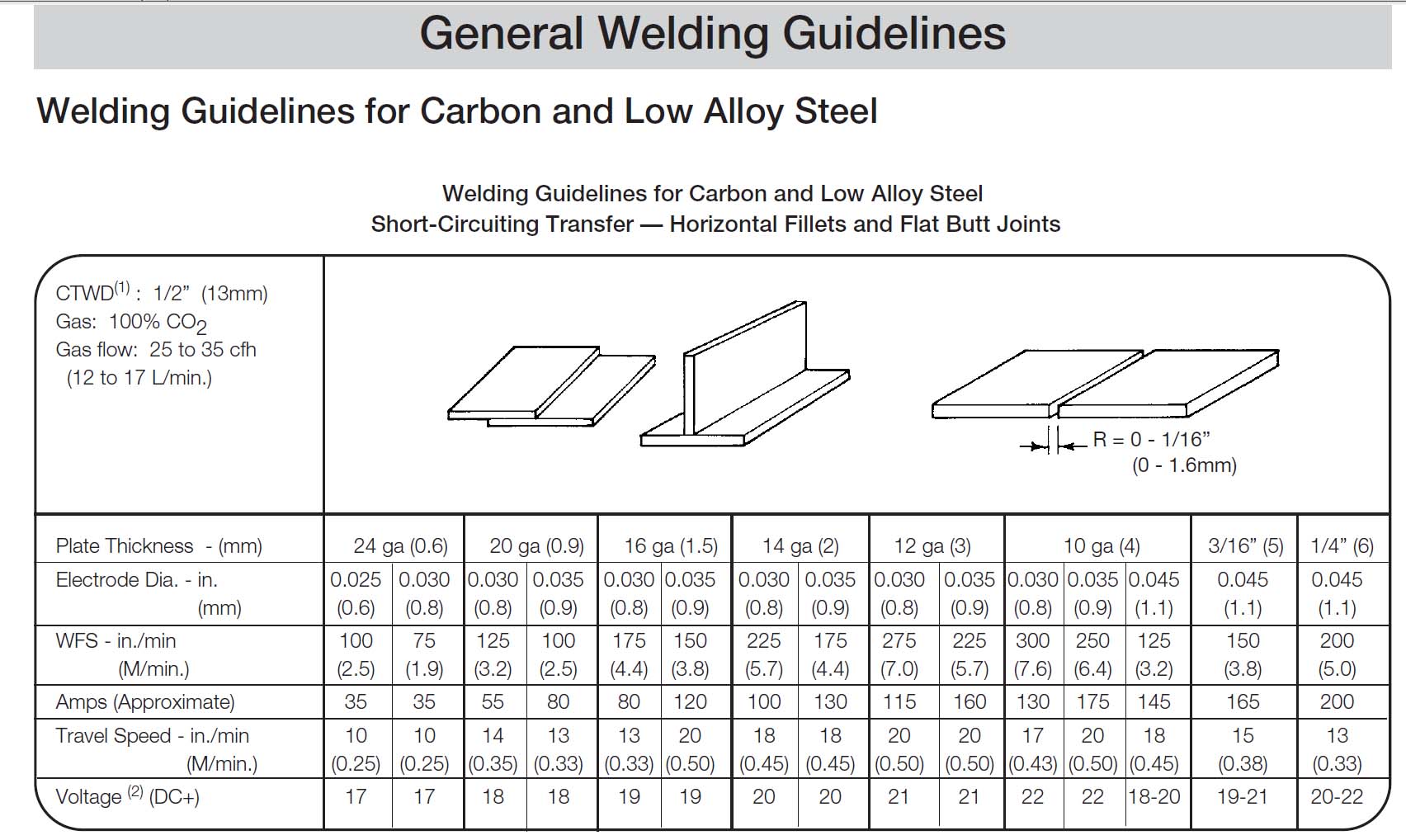

Mig Welding Amps To Metal Thickness Chart - Web mig (metal inert gas) welding, also known as gas metal arc welding (gmaw), is a welding process that uses a continuous wire electrode and a shielding gas to fuse two pieces of metal together. Web in general, you can expect your mig welder to be able to weld.001 thickness for every amp. Web download the app version of the weld setting calculator for easy reference! Web the mig welding amperage chart works by providing you with the maximum amperage, voltage and wire feed speed that should be used when welding a specific material and thickness. ( fronius) (1) mains connection. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Wire diameter and metal thickness: Once you get the hang of tig welding you might find you prefer to weld at higher or lower amps depending on technique and travel speed. The chart is divided into sections which indicate the type of material being welded and the thickness of the material. Are you welding indoors or outdoors? Stainless steel and aluminium amps chart. Web what material are you welding? Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Web download the app version of the weld setting calculator for easy reference! So, for example, if you are welding 1/8″ mild steel (0.125 inches. Web download the app version of the weld setting calculator for easy reference! For thicker metals, mig can struggle due to its lower penetration compared to other processes like stick or tig welding. However, you will need special wire if you plan to weld other metals, such as aluminum. Web as a guideline, each.001 inch of material thickness requires 1. Web mig (metal inert gas) welding, also known as gas metal arc welding (gmaw), is a welding process that uses a continuous wire electrode and a shielding gas to fuse two pieces of metal together. Stainless steel and aluminium amps chart. For thicker metals, mig can struggle due to its lower penetration compared to other processes like stick or tig. Web generally speaking, 3mm to 6mm thick metals are considered moderately thin, lightweight, flexible, and durable. There might be variations with the settings depending on the manufacturer. Since you don't want to change wire, select one for your most commonly used thicknesses. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding. Web tig welding amp charts. One of the things that can significantly help in dealing with thin metal is the pulsed mig. There might be variations with the settings depending on the manufacturer. Web these charts are just starting points/rough settings to get your machine set somewhere fairly close, and then you will most likey have to fine tune the. Once you determine these three main variables, you can set your welding machine and start. They’re easy to form and fabricate due to a flexible, ductile mechanical structure. Are you welding indoors or outdoors? So, for example, if you are welding 1/8″ mild steel (0.125 inches thick), you should provide 125 amps. Web generally speaking, 3mm to 6mm thick metals. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Are you welding indoors or outdoors? These are all things to consider when deciding which type of welder you’ll need. .125 inch = 125 amps. One of the things that can significantly help in dealing with thin metal is the pulsed mig. It's just a place to start, that's all. How thick is the metal you want to weld? Web as a guideline, each.001 inch of material thickness requires 1 amp of output: The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. This will be good for most jobs. It's just a place to start, that's all. There are a few factors that will influence the type of welding that will work best for you. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web see our chart and guide on how to select the. Web what material are you welding? Since you don't want to change wire, select one for your most commonly used thicknesses. Web generally speaking, 3mm to 6mm thick metals are considered moderately thin, lightweight, flexible, and durable. One of the things that can significantly help in dealing with thin metal is the pulsed mig. .125 inch = 125 amps. That would mean that 75 to 80 amps would be a good setting to start out on for mild steel that is 2mm in thickness. For thicker metals, mig can struggle due to its lower penetration compared to other processes like stick or tig welding. The ultimate mig welding guide. ( fronius) (1) mains connection. There are a few factors that will influence the type of welding that will work best for you. Web these charts are just starting points/rough settings to get your machine set somewhere fairly close, and then you will most likey have to fine tune the machine. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Web download the app version of the weld setting calculator for easy reference! They’re fully rigid and utilized in some construction applications and for heavier vehicle components, such as car crumple zones. The chart is divided into sections which indicate the type of material being welded and the thickness of the material. The filler metals most commonly used are er4043 and er5356, each with its own pros and cons. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: There might be variations with the settings depending on the manufacturer. Web generally speaking, 3mm to 6mm thick metals are considered moderately thin, lightweight, flexible, and durable. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode.

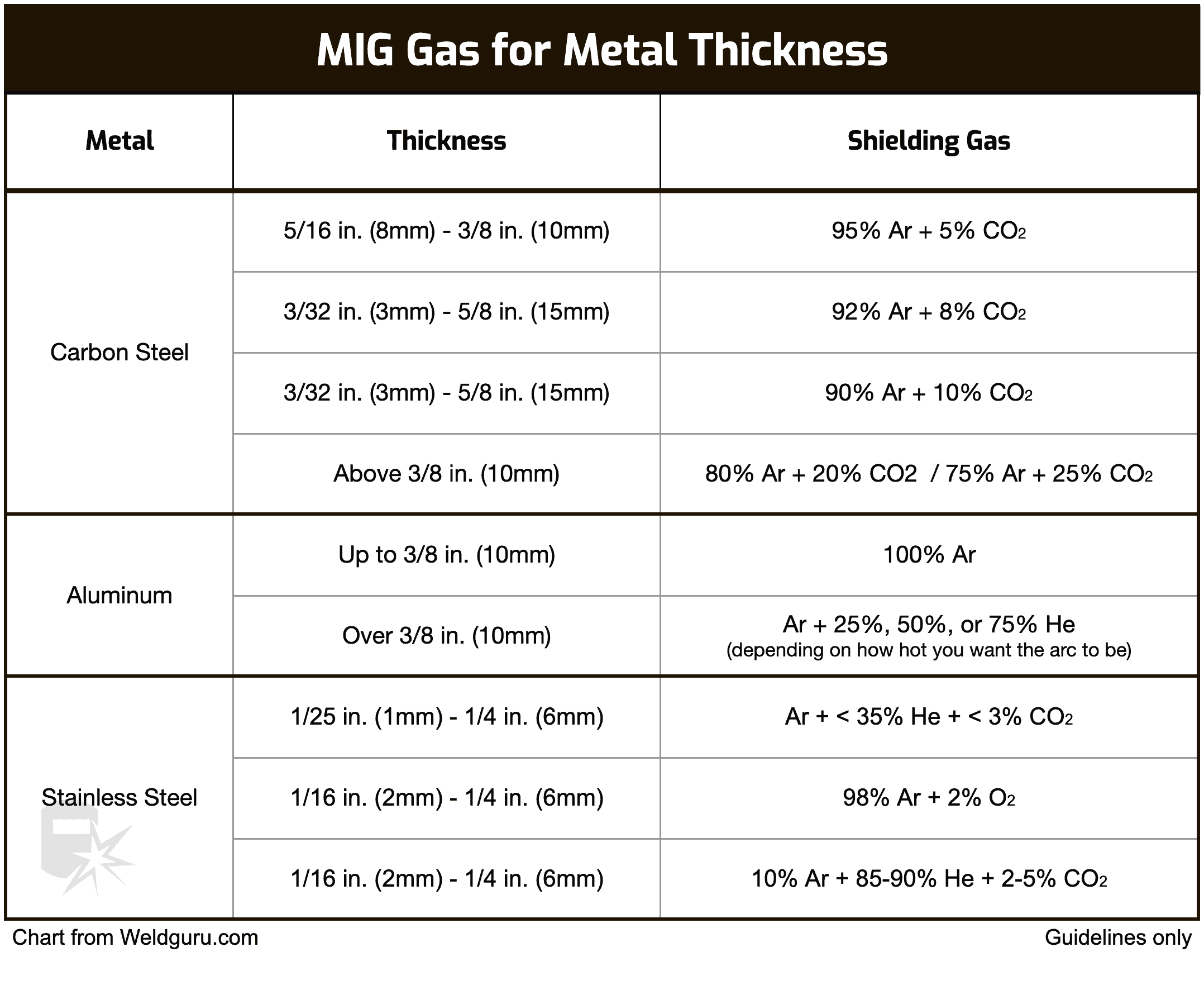

Best Gas for MIG Welding What to Use (with Chart)

Welding Amps Metal Thickness Chart

Mig Welding Settings Chart Metric Pdf

How To MIG Weld Aluminum Beginners Guide (with Chart)

Metal Thickness Stick Welding Amperage Chart

Mig Welding Amps To Metal Thickness Chart

Mig Welding Parameters Chart

MIG settings for welding different thickness mild steel

MIG welder settings explained Amperage & Wire Speed

Important MIG Welder Settings You Need to Know (with Chart)

Web Here Is A Chart That Summarizes The Mig Welding Amps According To The Three Most Common Types Of Metal And Their Thickness:

.125 Inch = 125 Amps.

Are You Welding Indoors Or Outdoors?

Web Tig Welding Amp Charts.

Related Post: