Mig Amperage Chart

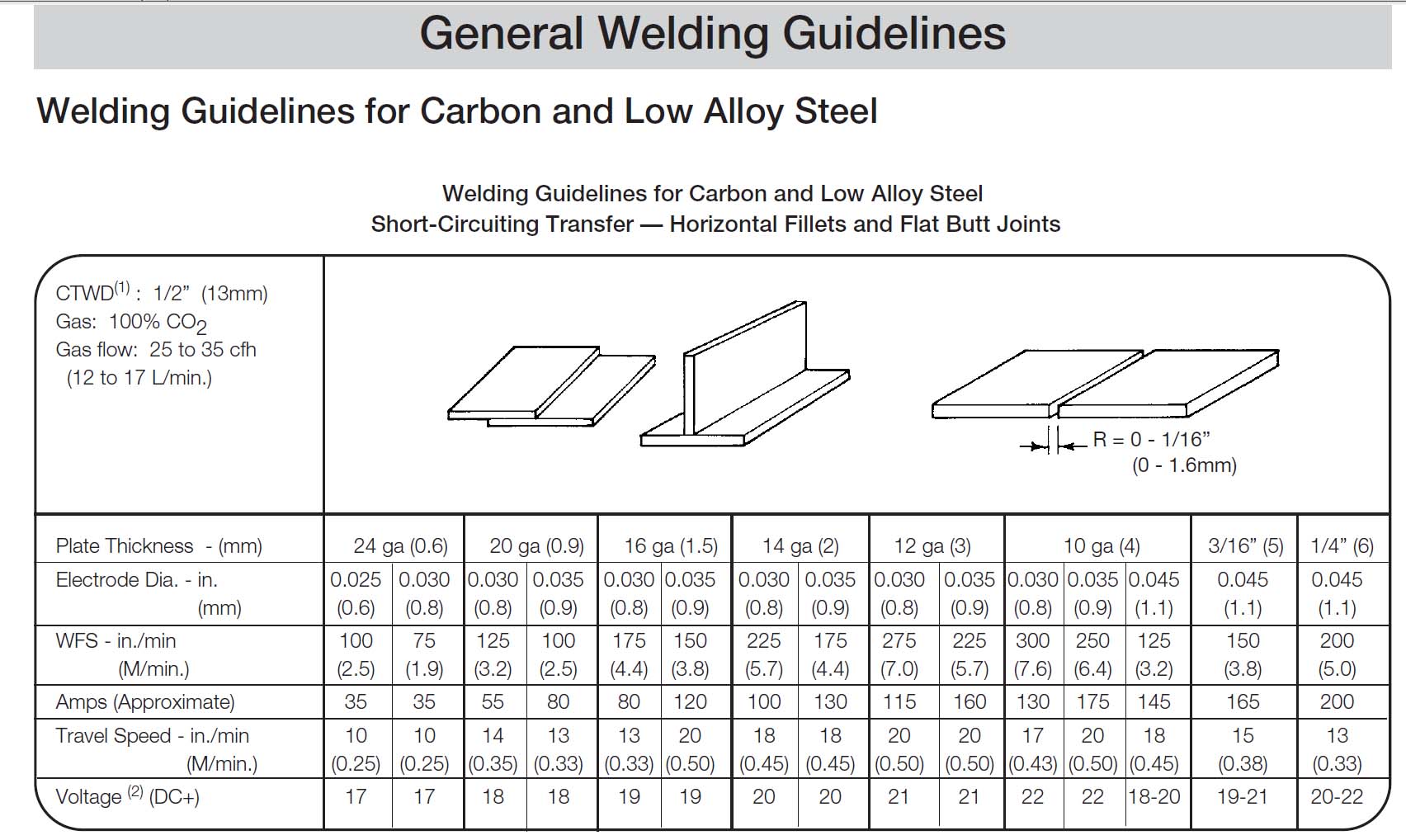

Mig Amperage Chart - But before using these values, we suggest that you have a decent understanding of your preferred metal. Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. How will i prepare the joint? It gives a detailed description of which wire speed and voltage you’ll need for a range of metal types, wire sizes and parent metal thicknesses. Wire speed controls amperage as well as the amount of weld penetration. Web a mig welding amperage chart is a guide that helps you determine the right amperage to set your welding machine to when welding a specific type of material. Web what material are you welding? Mig welding, also called metal inert gas, is widely used and practiced in various industrial zones to weld different metals, and multiple shielding gasses are used to complete its process. Higher amperage settings result in a larger, more robust weld, while lower amperage settings create smaller, more delicate welds. This will be good for most jobs up to about ½”. But before using these values, we suggest that you have a decent understanding of your preferred metal. So, for example, if you are welding 1/8″ mild steel (0.125 inches thick), you should provide 125 amps. Web consult your mig welder’s chart for a rough guide on wire feed speed and voltage settings according to material thickness. Working at 650 ft. However, you will need special wire if you plan to weld other metals, such as aluminum. As i printed this off and found it so useful in my workshop for quick reference as a beginner. This will be good for most jobs up to about ½”. So, for example, if you are welding 1/8″ mild steel (0.125 inches thick), you. So, for example, if you are welding 1/8″ mild steel (0.125 inches thick), you should provide 125 amps. How will i prepare the joint? It directly affects the size and strength of the weld bead. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. What is the metal thickness that i will. What type of metal will i be welding? Wire speed controls amperage as well as the amount of weld penetration. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Amperage, measured in amperes (a), refers to the amount of electrical current flowing through the welding circuit. How will i prepare the. Web what material are you welding? What is the metal thickness that i will be welding? So, for example, if you are welding 1/8″ mild steel (0.125 inches thick), you should provide 125 amps. Web before setting up you machine you need to get the answers to: Before tackling any mig welding application, look at the charts and tips below. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Web for mig welding mild steel, a good rule of thumb is to adjust the welder amperage level using. Mig welding, also called metal inert gas, is widely used and practiced in various industrial zones to weld different metals, and multiple shielding gasses are used to complete its process. There are many mig setting charts available from manufacturers that all vary. Before tackling any mig welding application, look at the charts and tips below. Web what material are you. Mig welding, also called metal inert gas, is widely used and practiced in various industrial zones to weld different metals, and multiple shielding gasses are used to complete its process. Working at 650 ft on open steel work. Web or you can use a detailed amperage chart that will help you calculate the required amperage. As i printed this off. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web or you can use a detailed amperage chart that will help you calculate the required amperage. Web a mig welding amperage chart is a guide that helps you determine the right amperage to set your welding machine to when welding a specific. There might be variations with the settings depending on the manufacturer. Higher amperage settings result in a larger, more robust weld, while lower amperage settings create smaller, more delicate welds. Before tackling any mig welding application, look at the charts and tips below. It directly affects the size and strength of the weld bead. A too slow wire speed might. Is there a mig amp chart, the same format as the tig amp chart ? Working at 650 ft on open steel work. That would mean that 75 to 80 amps would be a good setting to start out on for mild steel that is 2mm in thickness. There might be variations with the settings depending on the manufacturer. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Web a mig welding amperage chart is a guide that helps you determine the right amperage to set your welding machine to when welding a specific type of material. As i printed this off and found it so useful in my workshop for quick reference as a beginner. The chart lists the recommended welding parameters for different types. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: A too slow wire speed might result in a weak weld, while a too fast speed may cause the wire to burn back towards the contact tip. Web every unimig welding machine comes with a user manual and setup guide, which provides a good starting point for your machine settings. Web for mig welding mild steel, a good rule of thumb is to adjust the welder amperage level using one amp for every thousandth of an inch of thickness. What type of metal will i be welding? How will i prepare the joint? Web before setting up you machine you need to get the answers to: Web what material are you welding?

How To MIG Weld Aluminum Beginners Guide (with Chart)

Important MIG Welder Settings You Need to Know (with Chart)

The parameter values for MIG welding Download Scientific Diagram

MIG Wire Amperage Chart

Mig Welding Settings Chart Metric Pdf

Aluminum Mig Welding Amperage Chart

pear user Wink aluminum mig welding settings chart intentional Have

Mig Welding Amps To Metal Thickness Chart

MIG welder settings explained Amperage & Wire Speed

MIG settings for welding different thickness mild steel

Web There Are Various Criteria To Consider When Setting Your Mig Weld Controls, Including Materials, Metal Thickness, Shielding Gas, Electrode Wires, And Amperage.

Web Here Is A Chart Showing The Wire Speed And Voltage Speed Settings That Suit Lincoln Mig Welders.

Search And You Shall Find.

Stainless Steel And Aluminium Amps Chart.

Related Post: