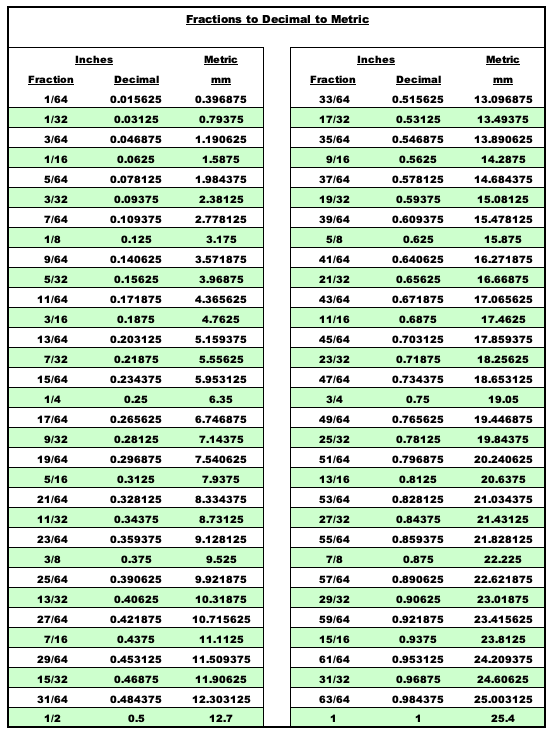

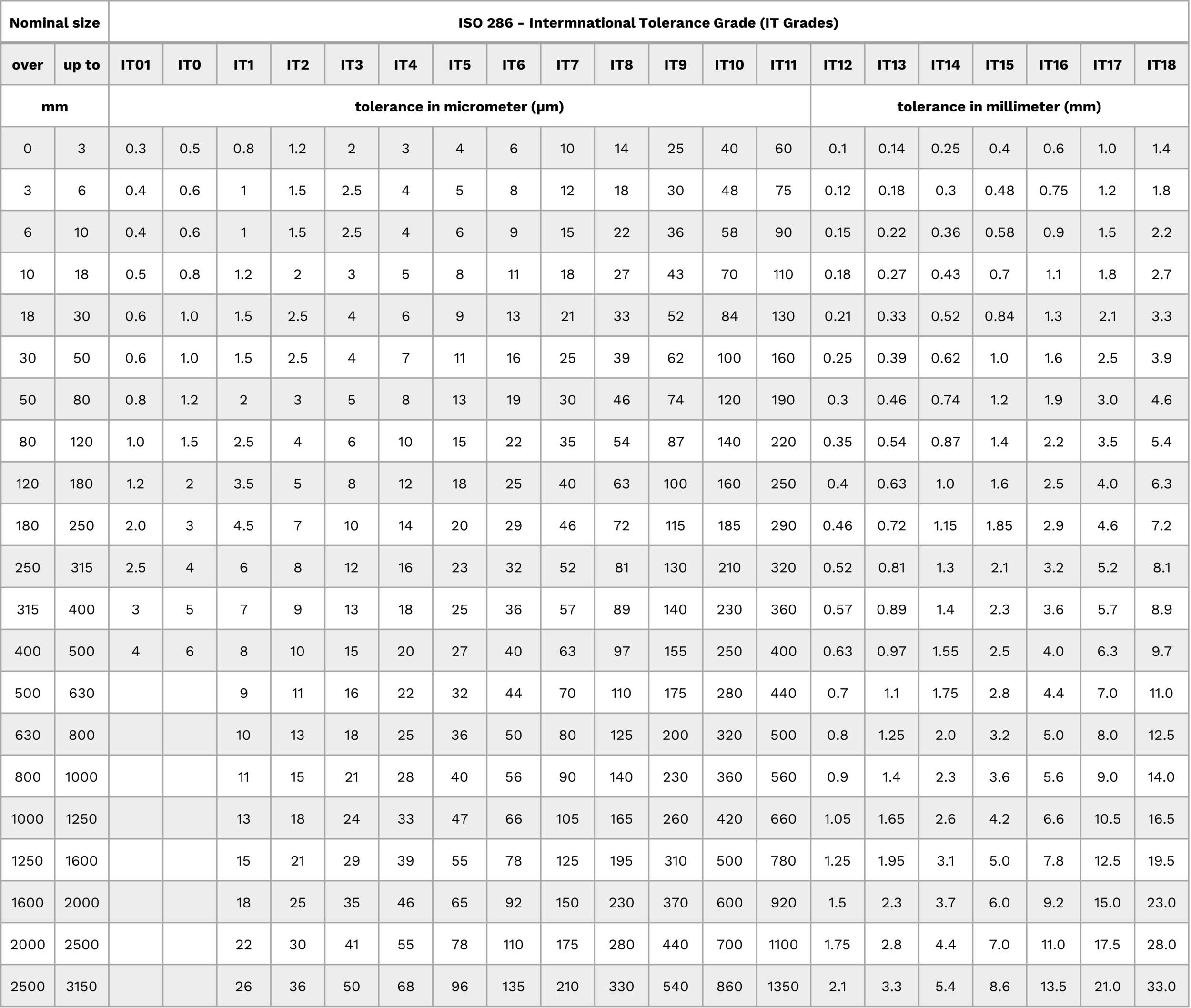

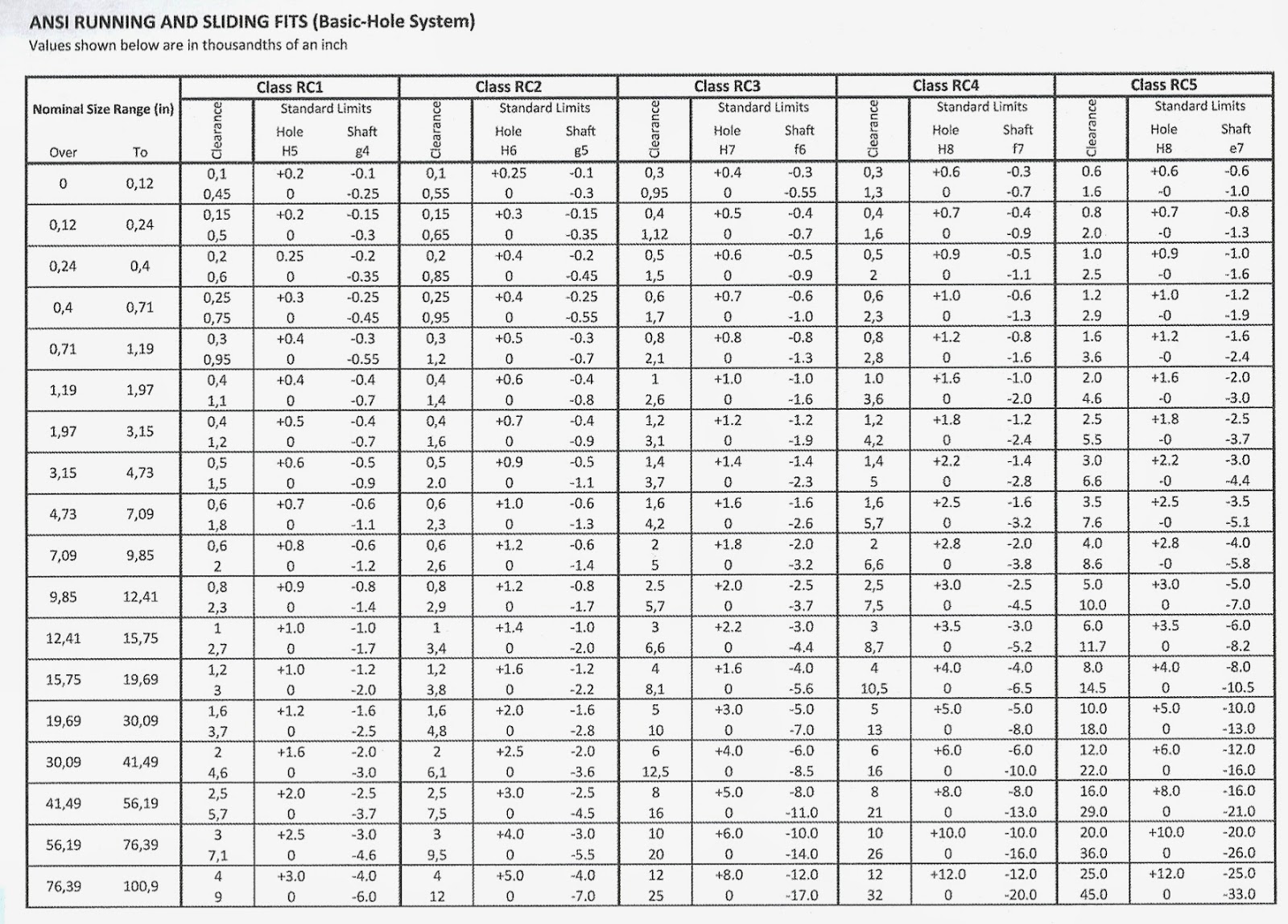

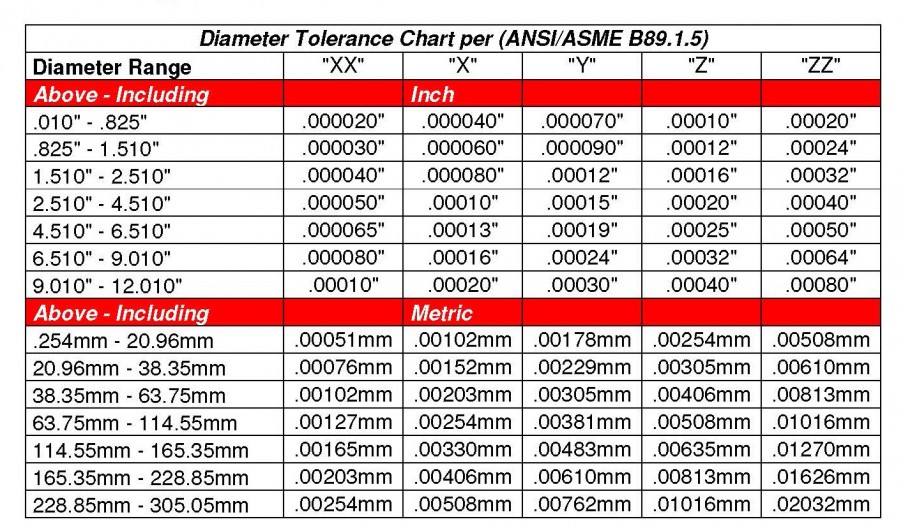

Metric Tolerance Chart

Metric Tolerance Chart - All internal calculations are done in metric millimeters to a. Web learn how to use the iso 286 system to specify and calculate tolerances for shafts and holes. These dimensions are standardized limits for assemblies of mechanical component. Find your data faster with our fits and tolerance calculator. Web the following are general geometrical tolerances per. Web metric tolerances and thread pitch. Web use this chart to determine what the round bar tolerance is in millimeters and inches based on the diameter. Web tables of standard tolerance grades and limit deviations for holes and shafts. See the symbols, descriptions, and tolerance classes for. Green = prefered tolerance classes per iso 286. Web use this chart to determine what the round bar tolerance is in millimeters and inches based on the diameter. Green = prefered tolerance classes per iso 286. These dimensions are standardized limits for assemblies of mechanical component. The tolerance of size is normally defined as the difference between the upper and lower. Tolerances can be applied to holes and. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. See schematic representation of the fit, basic terminology, and supplemental information on. Find your data faster with our fits and tolerance calculator. External radius and chamfer heights. The tolerance of size is normally defined as the difference between the upper and lower. The iso metric screw thread family is a. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Find your data faster with our fits and tolerance calculator. Tolerances can be applied to holes and shafts as well as other shapes. Web the following are general geometrical tolerances per. Web geometric dimensioning and tolerancing, or gd&t for short, is a language of symbols used to communicate information on technical drawings. Web tables of standard tolerance grades and limit deviations for holes and shafts. Tolerances can be applied to holes and shafts as well as other shapes. Iso 2768 for the following: Find your data faster with our fits and. Iso 2768 for the following: Find your data faster with our fits and tolerance calculator. Web metric tolerances and thread pitch. Green = prefered tolerance classes per iso 286. Find your data faster with our fits and tolerance calculator. Web find the plus and minus tolerance for any iso 286 hole tolerance grade and nominal size. Web geometric dimensioning and tolerancing, or gd&t for short, is a language of symbols used to communicate information on technical drawings. Green = prefered tolerance classes per iso 286. Use the engineering calculator to enter your preferred tolerance grade and nominal. Green =. Green = prefered tolerance classes per iso 286. Web use this chart to determine what the round bar tolerance is in millimeters and inches based on the diameter. Find your data faster with our fits and tolerance calculator. Use the engineering calculator to enter your preferred tolerance grade and nominal. Web geometric dimensioning and tolerancing, or gd&t for short, is. External radius and chamfer heights. Find your data faster with our fits and tolerance calculator. Tolerances can be applied to holes and shafts as well as other shapes. Green = prefered tolerance classes per iso 286. Iso 2768 for the following: The iso metric screw thread family is a. External radius and chamfer heights. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Green = prefered tolerance classes per iso 286. Web the following are general geometrical tolerances per. Web learn how to use the iso 286 system to specify and calculate tolerances for shafts and holes. Green = prefered tolerance classes per iso 286. See the symbols, descriptions, and tolerance classes for. External radius and chamfer heights. Find your data faster with our fits and tolerance calculator. All internal calculations are done in metric millimeters to a. Find your data faster with our fits and tolerance calculator. Find your data faster with our fits and tolerance calculator. Web metric tolerances and thread pitch. Find your data faster with our fits and tolerance calculator. External radius and chamfer heights. Find interactive charts, terminology explanations, and a calculator for metric and. Iso 2768 for the following: Find your data faster with our fits and tolerance calculator. Web learn how to use the iso 286 system to specify and calculate tolerances for shafts and holes. Green = prefered tolerance classes per iso 286. Web use this chart to determine what the round bar tolerance is in millimeters and inches based on the diameter. Green = prefered tolerance classes per iso 286. See the symbols, descriptions, and tolerance classes for. Web geometric dimensioning and tolerancing, or gd&t for short, is a language of symbols used to communicate information on technical drawings. Web tables of standard tolerance grades and limit deviations for holes and shafts.

Avoiding the Risks of Standard to Metric Tolerance Chart Conversion

iso hole tolerance chart pdf Focus

ISO Tolerances for Holes & Shafts International Economic

ISO Tolerances For Holes PDF Engineering Tolerance World Economy

Tolerances IT Grades, General Tolerances

ENGR1304 Chapter 7 Tolerances

Metric Tolerance Chart PDF PDF Engineering Tolerance Scientific

Metric Thread Gage Tolerance Chart My XXX Hot Girl

st_technica tolerances ISO tolerances

Metric Tolerance Chart Boston Centerless

Web Find The Plus And Minus Tolerance For Any Iso 286 Hole Tolerance Grade And Nominal Size.

Allowance/Deviations (Es/El) Tolerances (T D /T D) Normal Length Of Engagement.

Tolerances Can Be Applied To Holes And Shafts As Well As Other Shapes.

These Dimensions Are Standardized Limits For Assemblies Of Mechanical Component.

Related Post: