Metal Finish Chart

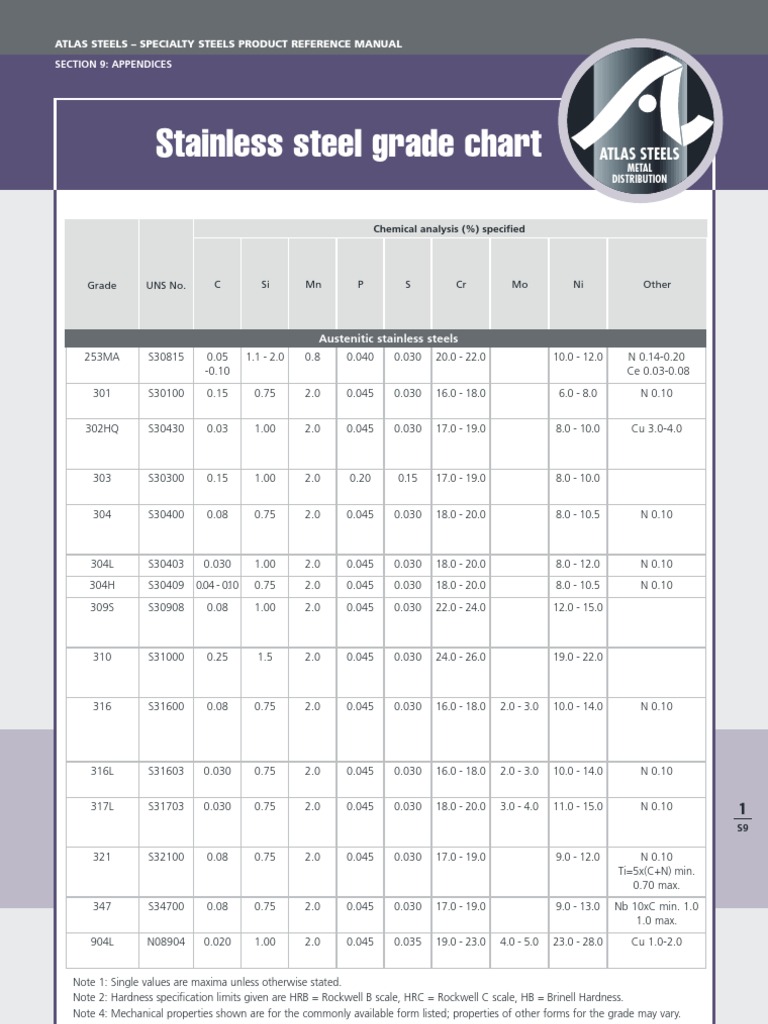

Metal Finish Chart - When we try to measure a surface finish, the methods fall into three categories: Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish symbols, charts, and measurements like ra and rz. Web surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Cutting commercial keys, i/c core keys, control keys, and master keys. Web metal finishing chart is an engineering tool designed to document and analyze finish options and specifications for different metal products. These finishing machines create a uniform, parallel grain surface texture to smooth out a product’s exterior. Web a metal surface finish chart is a handy guide to standard surface finishes and characteristics such as measurement units, conversions, and typical ra values. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Web surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts manufactured by various manufacturing processes. Keep reading as we provide you with answers and other important information about surface finishes and roughness. Our chart of surface finishes by manufacturing process (see above) gives both. These finishes range from dull to bright and include special textures that may be mechanically applied for highly specialized applications. Web here are some of the most common types of metal finishes: It is commonly used on stainless steel, aluminum, and brass. Unlike plating, metal finishing with brushes. In this guide, get it made shares everything you need to know about surface roughness in manufacturing. Cutting commercial keys, i/c core keys, control keys, and master keys. Unlike plating, metal finishing with brushes is an effective method for removing surface imperfections. What is surface finish in machining? This plating process involves immersing the component in a bath containing metal. Web in this guide, we will delve into the various types of metal surface finishes, their applications, and how they impact the overall aesthetics and performance of metal products. Web surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. This will help designers and manufacturers select surface finishing. When we try to measure a surface finish, the methods fall into three categories: Web there are two major types of plating: But we won’t stop there. Web here are some of the most common types of metal finishes: This will help designers and manufacturers select surface finishing techniques that are most effective for products. What is surface finish in machining? It is commonly used on stainless steel, aluminum, and brass. These finishes range from dull to bright and include special textures that may be mechanically applied for highly specialized applications. Web there are two major types of plating: This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions,. How can you measure the surface roughness? Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish symbols, charts, and measurements like ra and rz. These finishing machines create a uniform, parallel grain surface texture to smooth out a product’s exterior. Web surface finish refers to the. Web this unique chart compares different metal finishes by cost, corrosion resistance, applications and more. Web for your reference, this metal finish cross reference chart provides typical finishes and plating descriptions for aluminum and stainless steel surfaces. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. Web metal finishing chart is an. What is surface finish in machining? When we try to measure a surface finish, the methods fall into three categories: Web there are two major types of plating: Web here are some of the most common types of metal finishes: Keep reading as we provide you with answers and other important information about surface finishes and roughness. Web here are some of the most common types of metal finishes: Web surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. When we try to measure a surface finish, the methods fall into three categories: This plating process involves immersing the component in a bath containing metal. What is surface finish in machining? In this guide, get it made shares everything you need to know about surface roughness in manufacturing. When we try to measure a surface finish, the methods fall into three categories: Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Manufacturers leverage metal finishing solutions to. Web this unique chart compares different metal finishes by cost, corrosion resistance, applications and more. A direct current is then delivered to the metal, depositing ions on the metal and forming a new layer over the surfaces. How can you measure the surface roughness? Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish symbols, charts, and measurements like ra and rz. We’ll also explore why surface finish matters, offering practical insights into how it can impact your. Web metal finishing chart is an engineering tool designed to document and analyze finish options and specifications for different metal products. This plating process involves immersing the component in a bath containing metal ions for coating. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface finishes to. In this guide, get it made shares everything you need to know about surface roughness in manufacturing. When we try to measure a surface finish, the methods fall into three categories: Web surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts manufactured by various manufacturing processes. This will help designers and manufacturers select surface finishing techniques that are most effective for products. Keep reading as we provide you with answers and other important information about surface finishes and roughness. When we try to measure a surface finish, the methods fall into three categories: Our chart of surface finishes by manufacturing process (see above) gives both. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system.Stainless Steel Grade Chart PDF Stainless Steel Steel

Metal Finish reference guideNewport Brass In the home Pinterest

Door Hardware Finish Chart

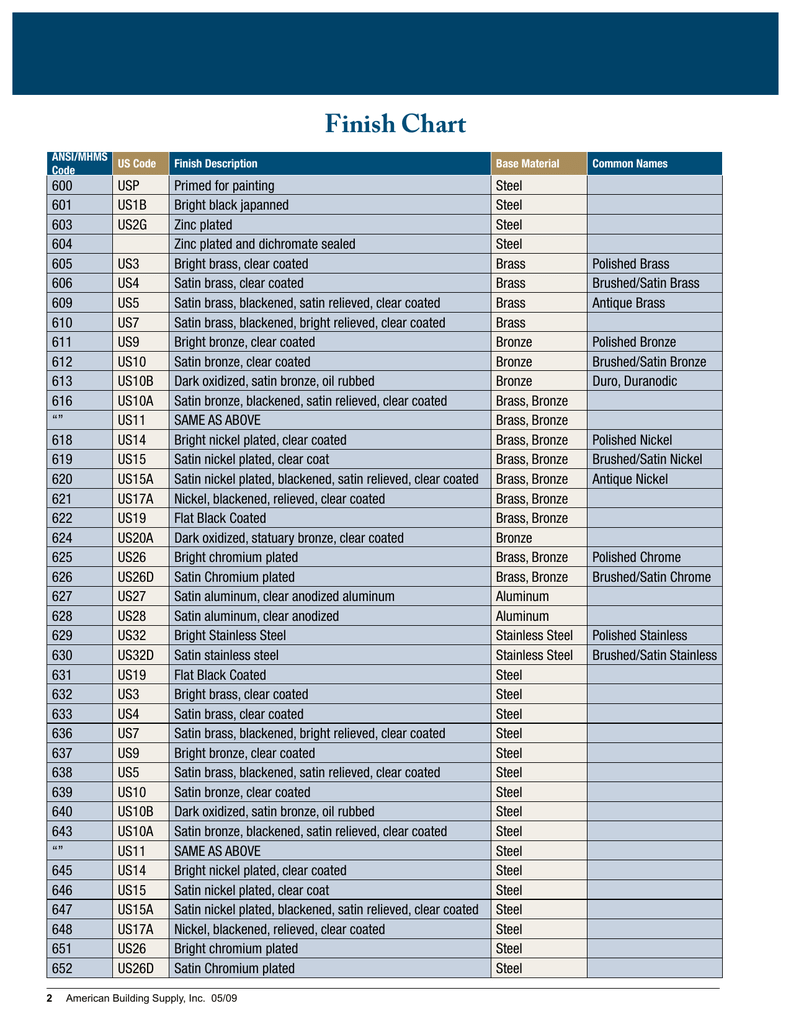

Finish Chart American Building Supply, Inc.

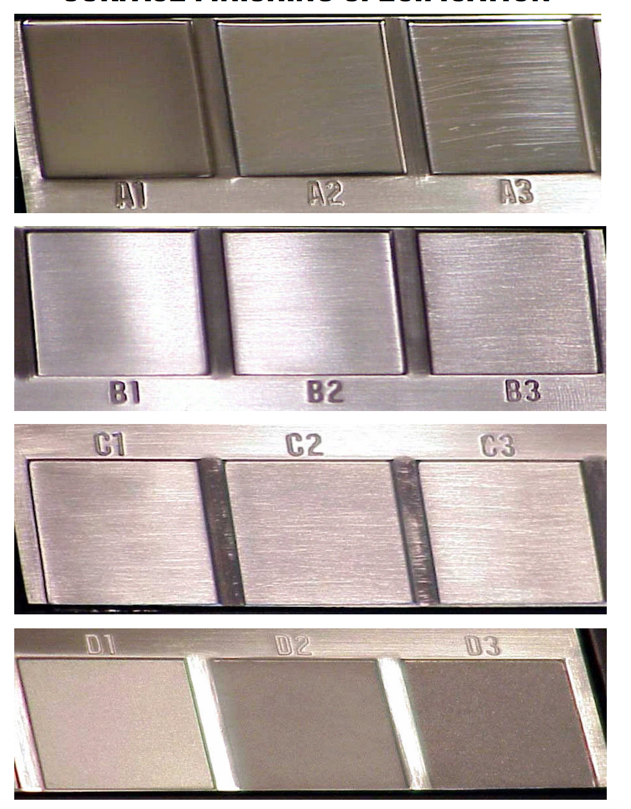

Metal Surface Finish Chart

Hardware Finish Color Chart

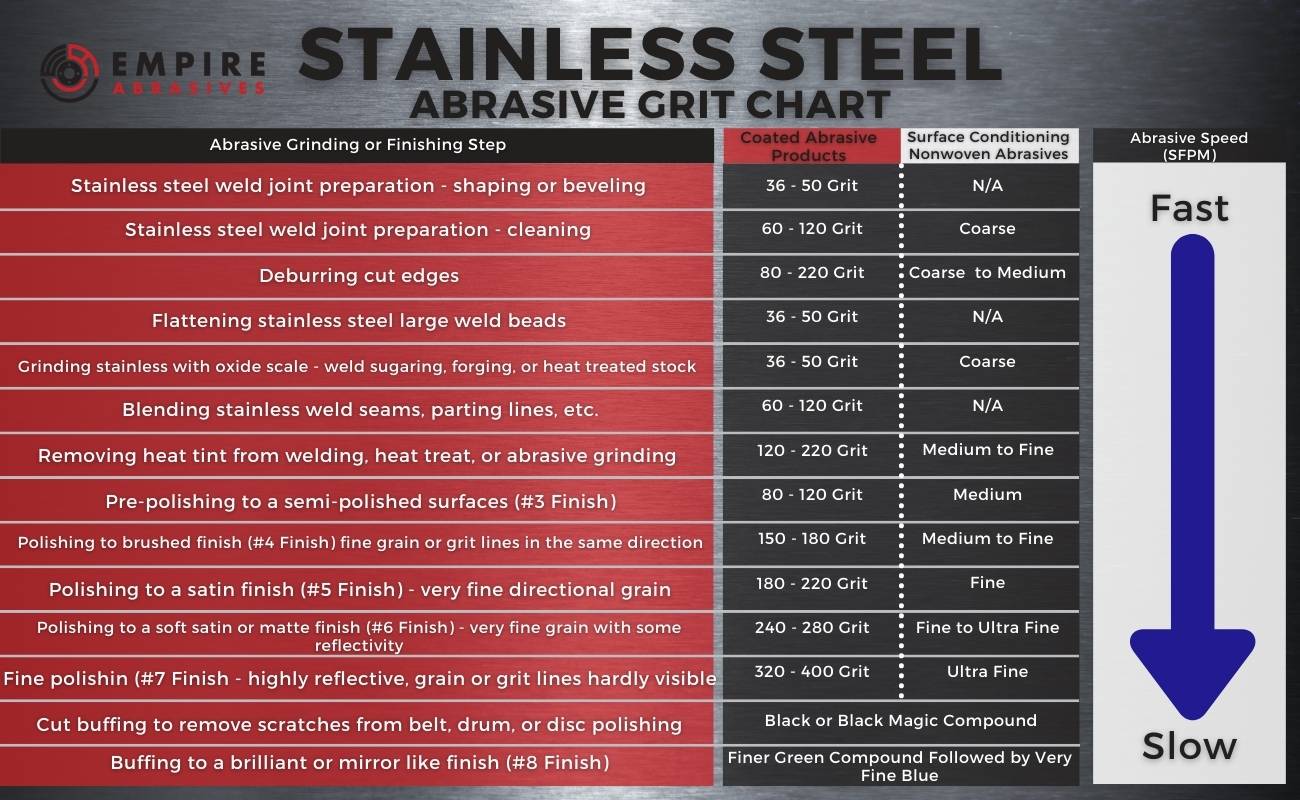

Ultimate Guide Stainless Steel Fabrication, Grinding, and Finishing

Wasatch Steel Metal Finishes and Coatings for Steel

Stainless Steel Sheet and Plate Finishes Euro Steel, SA

Ultimate Guide Stainless Steel Fabrication, Grinding, and Finishing

Cutting Commercial Keys, I/C Core Keys, Control Keys, And Master Keys.

3 Elements Make Up Surface Finish.

Our Chart Of Surface Finishes By Manufacturing Process (See Above) Gives Both.

Web A Metal Surface Finish Chart Is A Handy Guide To Standard Surface Finishes And Characteristics Such As Measurement Units, Conversions, And Typical Ra Values.

Related Post: