Metal Drawing

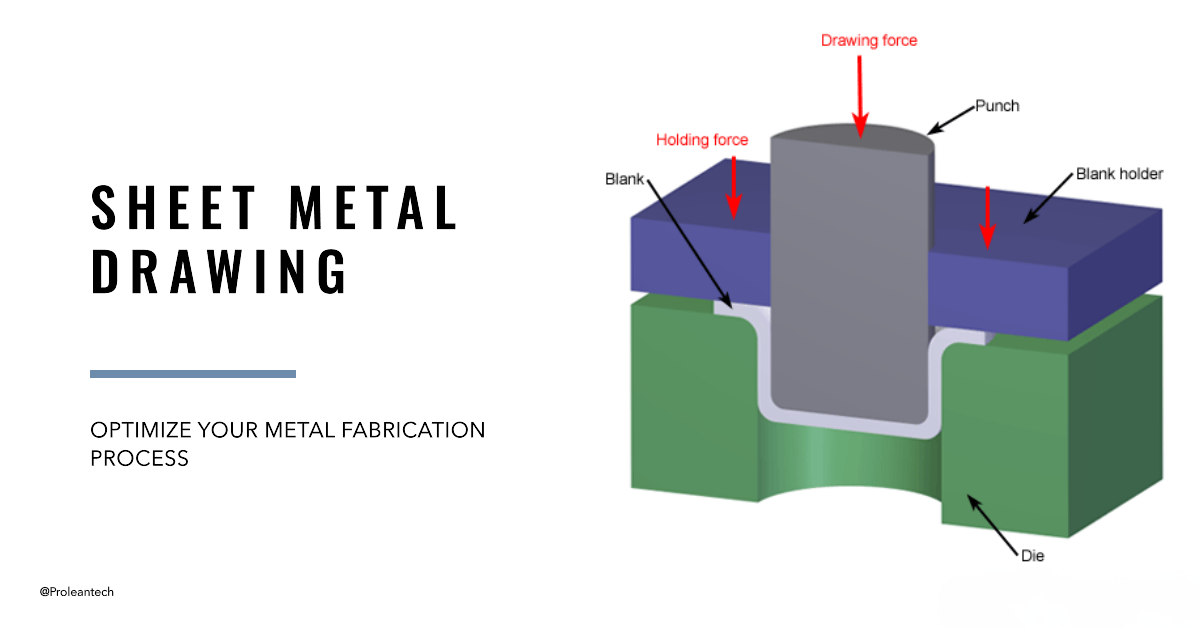

Metal Drawing - Web deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than the work. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. A comprehensive guide | machinemfg. The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through the application of force. This technique is commonly used to produce wires, tubes, and various metal components with precise. Choosing the right materials, especially graphite pencils and bristol board, is crucial to accurately capture the sheen and texture of metal in your drawings. Web drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Choosing the right materials, especially graphite pencils and bristol board, is crucial to accurately capture the sheen and texture of metal in your drawings. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. However, when broken down into simple components, such as boxes and cups, deep drawing becomes a much simpler operation. Drawing is classified into two types: Because of this added complexity sheet metal drawings can be particularly tricky to create. Web metal stamping and die design for deep drawing: This deformation process uses tensile forces to elongate the workpiece. This technique is commonly used to produce wires, tubes, and various metal components with precise. Web metal drawing, by definition, is the process of stretching metal material and forming it using tensile, or pliable, force. Drawing is a metalworking technique classified under forming, or the deformation of a material by the application of forces to the desired shape without the addition or removal of any of the material. Web a wide variety of metals can. Metal flow patterns in metal drawing operations. The ultimate guide to metal deep drawing. Web a wide variety of metals can be used in the metal drawing process, including alloys, aluminum, brass, bronze, cold rolled steel, copper, iron, kovar, molybdenum, nickel, silver, stainless steel, and titanium. Web metal drawing is a manufacturing process that forms metal work stock by reducing. How does quantity affect pricing? Metal & alloy selection for metal drawing and hydroforming. Metal flow patterns in metal drawing operations. Web now back for a second bite of the burgeoning nu metal cherry, korn and adidas return for spring/summer 2024 with a capsule even more impressive than its first. It is an essential aspect of manufacturing in various industries,. Get info on equipment, processes, parts and more. Web metal drawing is a machining process used to reduce the diameter of a metal material, such as wire or tubing, through the application of controlled tensile forces. Drawing is a metalworking technique classified under forming, or the deformation of a material by the application of forces to the desired shape without. It involves applying tensile forces to the material, causing it to elongate and take on a desired shape. Web metal stamping and die design for deep drawing: During drawing, the material is fed through a series of dies or dies with progressively smaller hole sizes. Drawing metal & metal forming. Choosing the right materials, especially graphite pencils and bristol board,. Metal flow patterns in metal drawing operations. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. Regardless of the application, metal drawing offers a number of advantages over other metalworking methods: The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from. Drawing metal & metal forming. This process is done in cold temperatures to help ensure precise tolerances. Web now back for a second bite of the burgeoning nu metal cherry, korn and adidas return for spring/summer 2024 with a capsule even more impressive than its first. Web metal stamping and die design for deep drawing: Regardless of the application, metal. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Drawing metal & metal forming. How does quantity affect pricing? Web metal drawing is a metalworking process where a workpiece is pulled through a die to reduce its diameter and increase its length. During drawing, the material is fed through a series of dies or dies. Widely used in various industries, such as automotive, aerospace, and construction, metal forming encompasses a diverse range of methods,. The definition of deep drawing. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Regardless of the application, metal drawing offers a number of advantages over other metalworking methods: Changing the color of the medallions. Deep draw depth & process. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. Web learn about metal drawing and specifically the deep drawing process, a popular form of metalwork. During drawing, the material is fed through a series of dies or dies with progressively smaller hole sizes. This process is very similar to metal extrusion, the difference being in the application of force. Sheet metal drawing and wire, bar, and tube drawing. Web metal drawing is a metalworking process where a workpiece is pulled through a die to reduce its diameter and increase its length. Web metal drawing is a machining process used to reduce the diameter of a metal material, such as wire or tubing, through the application of controlled tensile forces. A comprehensive guide | machinemfg. Drawing metal & metal forming.

Deep Draw Metal Stamping Getting Started

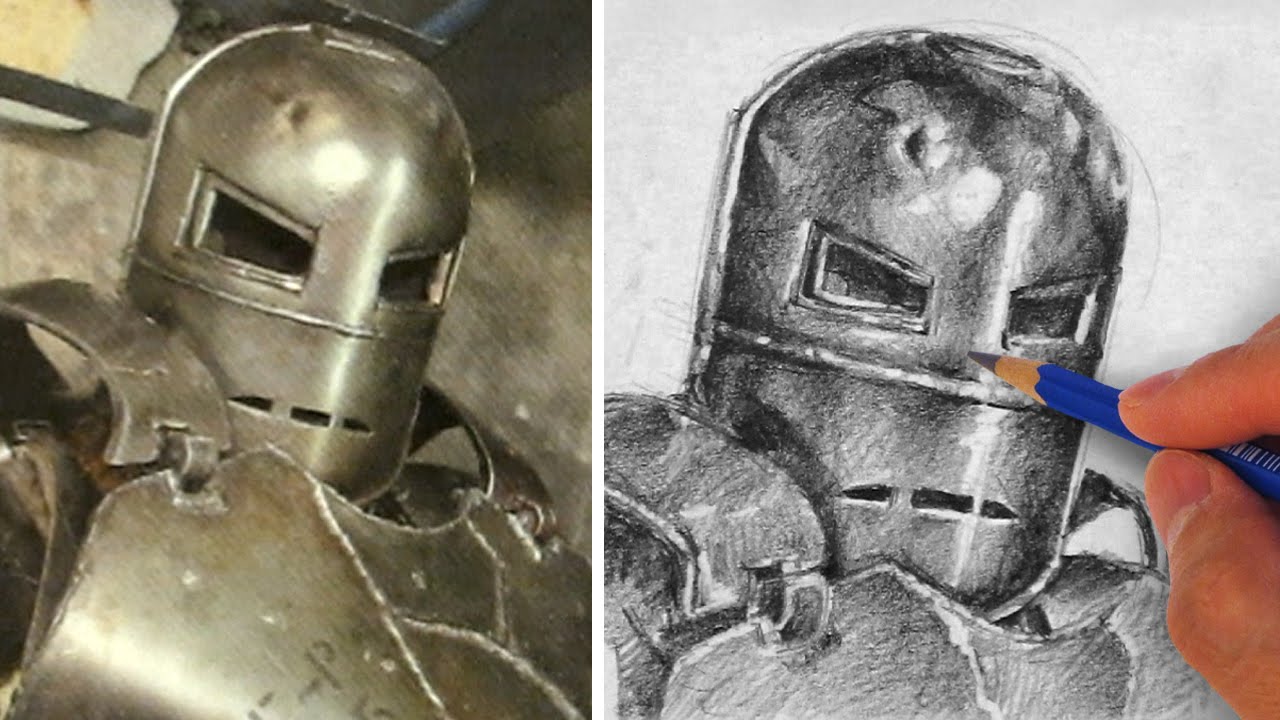

How to draw Steel YouTube

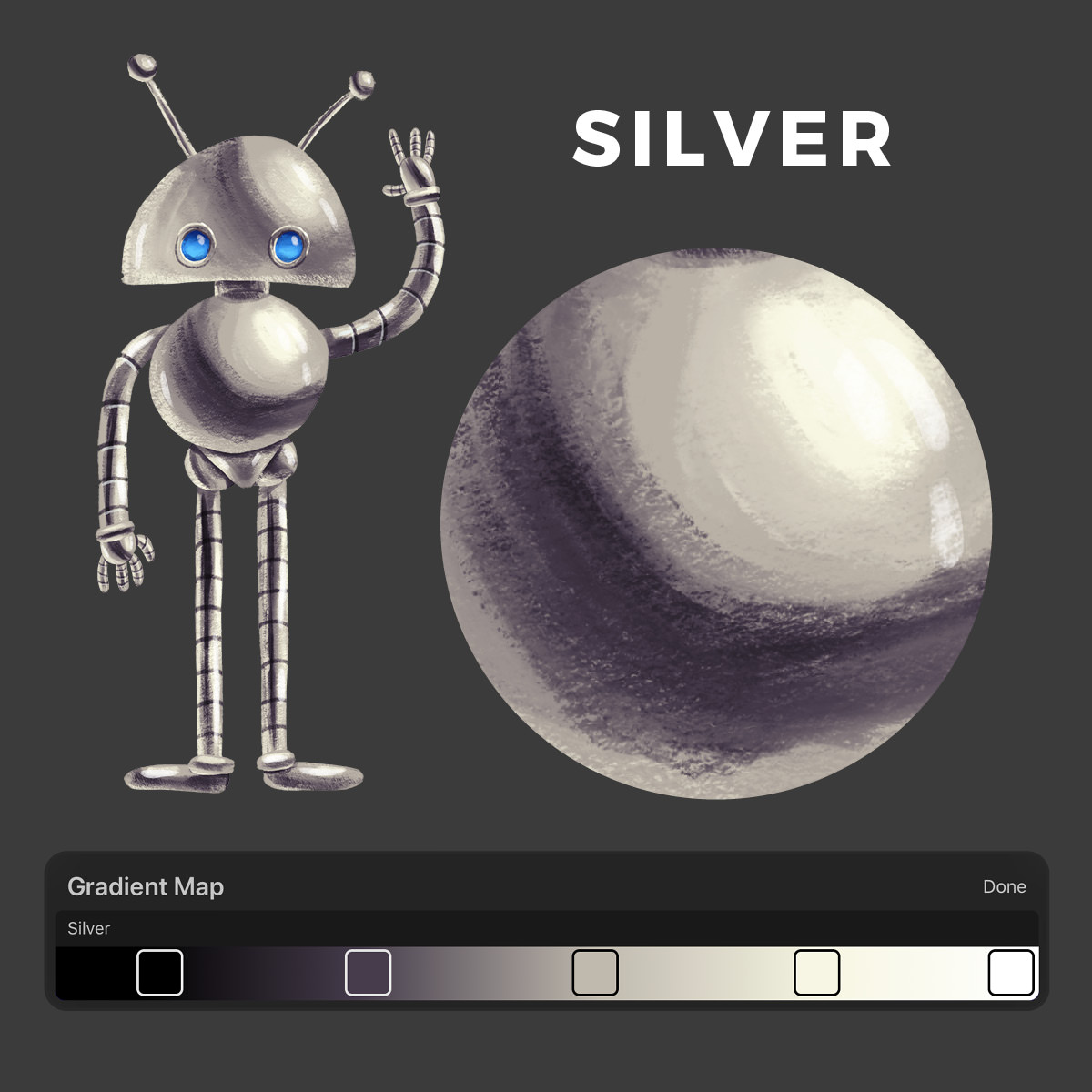

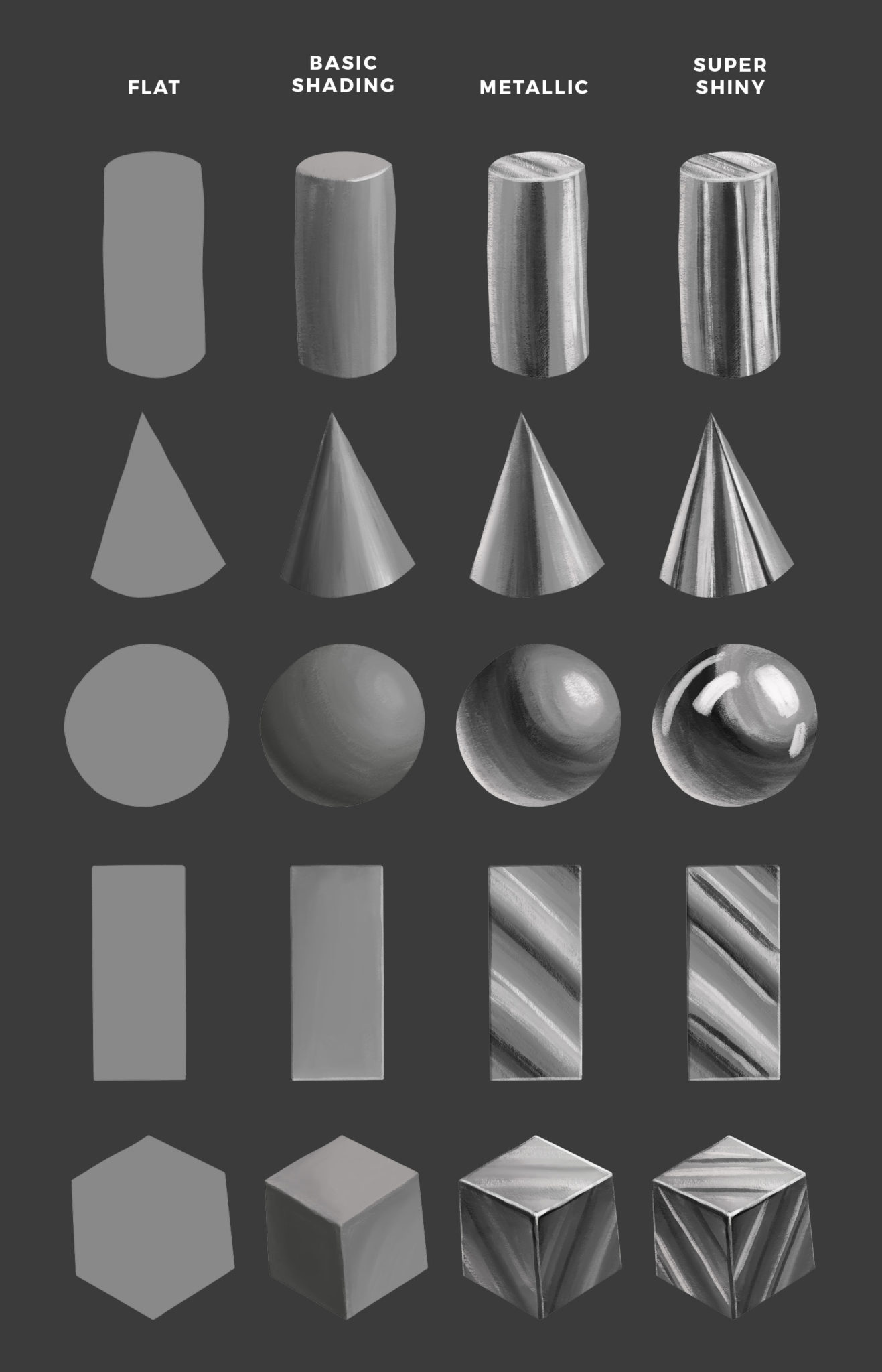

How to Draw Metallic Surfaces the Easy Way • Bardot Brush

How to Draw Metallic Surfaces the Easy Way • Bardot Brush

Metal Drawings at Explore collection of Metal Drawings

How to draw a metal ingot aluminium aluminum

Metal Drawing, Pencil, Sketch, Colorful, Realistic Art Images Drawing

33 Metallic Pencil Drawing Ideas Realistic drawings, Realistic pencil

Sheet Metal Drawing Optimize Your Metal Fabrication Process CNC

![How To Draw Metal [Drawing Tips] Metal drawing, Ink drawing](https://i.pinimg.com/originals/eb/17/39/eb1739b95291295ec4e039060265f1ff.jpg)

How To Draw Metal [Drawing Tips] Metal drawing, Ink drawing

The Metal Drawing Process Is A Fundamental Manufacturing Technique That Transforms Metal Materials Into Desired Shapes And Structures Through The Application Of Force.

The Experts At Stamping Journal Are Here To Help You Understand The Metal Flow Patterns That Can Occur During Metal Drawing Operations.

Because Of This Added Complexity Sheet Metal Drawings Can Be Particularly Tricky To Create.

This Is Accomplished By Forcing The Work Through A Mold, (Die), Of Smaller Cross Sectional Area Than The Work.

Related Post: