Machining Finish Chart

Machining Finish Chart - Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: This is a calculation of the average length between all the peaks and valleys (or the average height) from the mean line of the surface. Web welcome to our comprehensive guide on machine surface finish charts. Web the surface finishing has 6 impacts for a machined parts: How to measure surface roughness. It provides a visual guide to different surface finishes, with notations and surface roughness values. Tyson garvin, a resident of joplin, missouri, had his cybertruck polished to give it a chrome finish. This can be used to help determine the best machining process for a given surface. Tyson garvin waited nearly five years to get his. N = new iso (grade) scale numbers. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Web jun 3, 2024, 12:22 am pdt. Surface roughness parameters and standards. This can be used to help determine the best machining process for a given surface. If you are unsure of. Before embarking on any machining project, it is essential to comprehend the significance of machining finish charts. Tips for improving surface finish. Web jun 3, 2024, 12:22 am pdt. Web surface finish specification and comparison. This can be used to help determine the best machining process for a given surface. Surface roughness parameters and standards. Manufacturers consistently reference it to guarantee product quality during the manufacturing process. In this post, we will delve into everything you need to know about surface finish charts, their importance, interpretation, and practical applications in machining processes. N = new iso (grade) scale numbers. Web the following charts and tables convert surface finish or roughness. Improve corrosion and chemical resistance effectively. If you are unsure of the standard surface finishes for precision machined parts, or how to measure surface roughness, read on. Tips for improving surface finish. Web introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, ra, rz, rms for iron and steel castings by dandong foundry in china. There are. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. N = new iso (grade) scale numbers. Tyson garvin, a resident of joplin, missouri, had his cybertruck polished to give it a chrome finish. Web a surface finish chart such as this could include the following parameters: These charts serve as a comprehensive. Web this diagram shows how waviness, lay, and roughness are related to each other: Web there are a variety of surface finishes charts that can be used to help machining operations. Web a guide to surface finish and surface roughness chart. Improve mating properties, wear resistance, fatigue strength, contact stiffness, vibration and noise of mechanical parts. Before embarking on any. It depends on the structure of the metal before and after machining, depends on cutting conditions such as type and degree of sharpness of the cutting tool, depth of cut, amount of feed, coolant used, working conditions such as. By looking at these charts we can choose material and process wisely for. Specialize in cnc milling, cnc turning, 3d printing,. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Improve corrosion and chemical resistance effectively. Web prime minister narendra modi will serve a third term in office after india's election authority confirmed the national democratic alliance coalition headed by his ruling bharatiya janata party won. Web welcome to our comprehensive guide on. It is typically defined in terms of its roughness, waviness, and lay. Web a guide to surface finish and surface roughness chart. This is a calculation of the average length between all the peaks and valleys (or the average height) from the mean line of the surface. Web prime minister narendra modi will serve a third term in office after. Tyson garvin waited nearly five years to get his. Jack lie cnc machining expert. It is typically defined in terms of its roughness, waviness, and lay. By looking at these charts we can choose material and process wisely for. Several factors influence surface finish in cnc machining. It is typically defined in terms of its roughness, waviness, and lay. Web surface finish specification and comparison. Web there are a variety of surface finishes charts that can be used to help machining operations. Several factors influence surface finish in cnc machining. These charts serve as a comprehensive reference tool, outlining the different surface finish options achievable through various machining processes. This is a calculation of the average length between all the peaks and valleys (or the average height) from the mean line of the surface. Web introduction to machining finish charts. N = new iso (grade) scale numbers. Web jun 3, 2024, 12:22 am pdt. Surface finish is a term describing the texture of the surface of a printed object. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Web welcome to our comprehensive guide on machine surface finish charts. In this post, we will delve into everything you need to know about surface finish charts, their importance, interpretation, and practical applications in machining processes. How to measure surface roughness. The most commonly used parameter is roughness average (ra). It provides a visual guide to different surface finishes, with notations and surface roughness values.

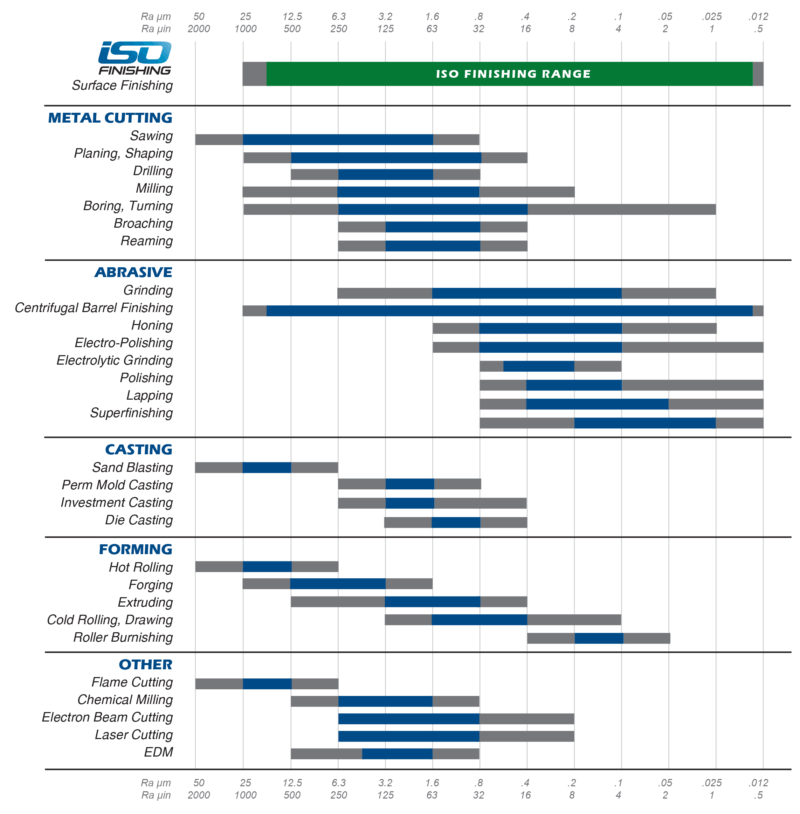

Surface Roughness Chart Comparison ISO Finishing

Machine Surface Finish Chart

Machine Surface Finish Chart

Surface Finish Machinng Chart Pdf Surface Roughness Machining IMAGESEE

Selecting right surface roughness for CNC machining Xometry Europe

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Surface Finish Destiny Tool

Machining Surface Finish Chart & Specifications Moseys Production

Surface Finish Chart A Guide to Understanding Surface Finishing Chart

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

Tips For Improving Surface Finish.

Web This Diagram Shows How Waviness, Lay, And Roughness Are Related To Each Other:

This Can Be Used To Help Determine The Best Machining Process For A Given Surface.

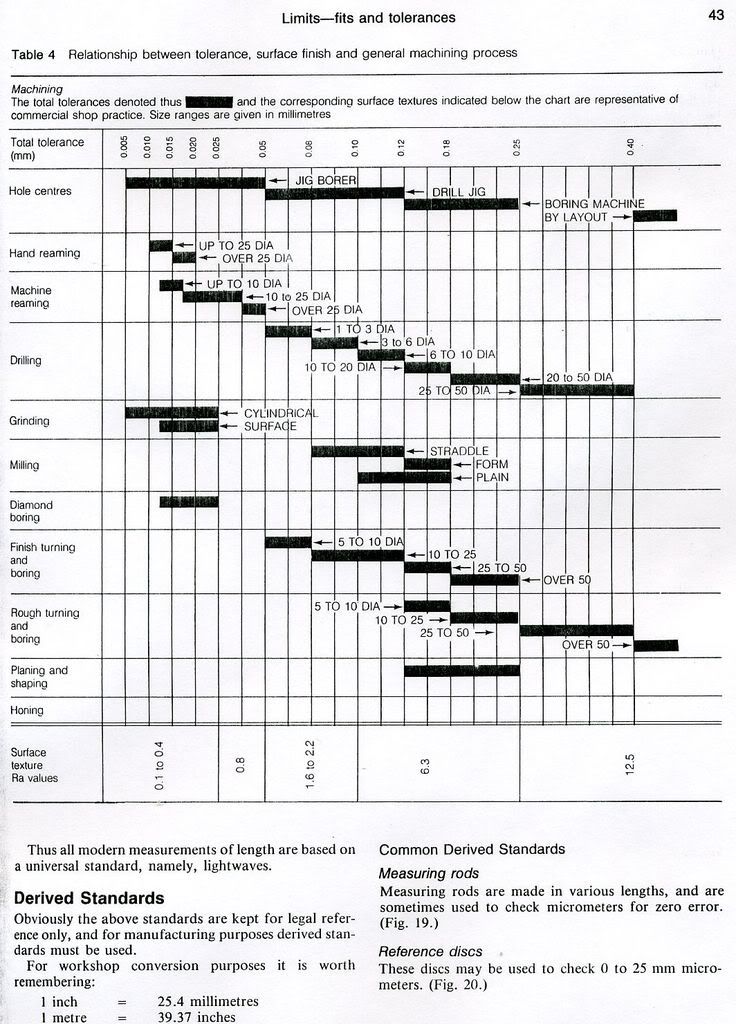

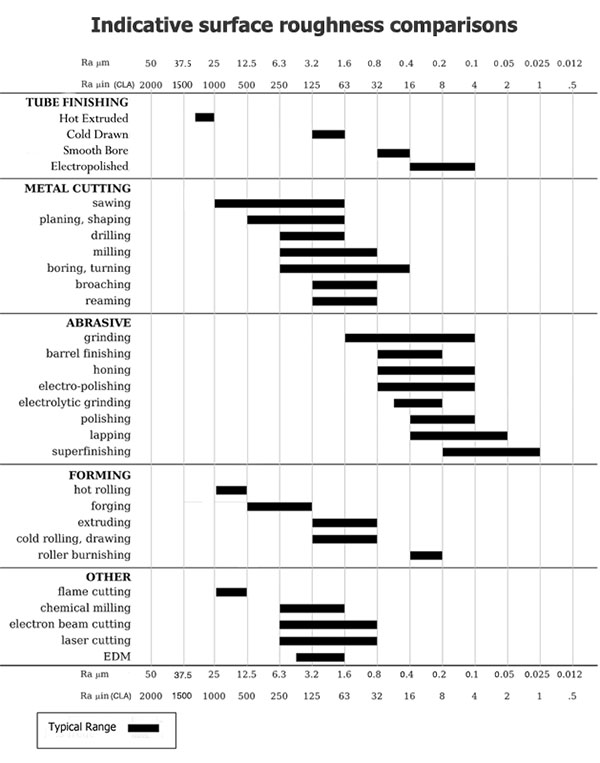

Web Here’s A Table With A Chart Demonstrating The Relative Surface Roughness Of Several Production Processes:

Related Post: