Machine Finish Chart

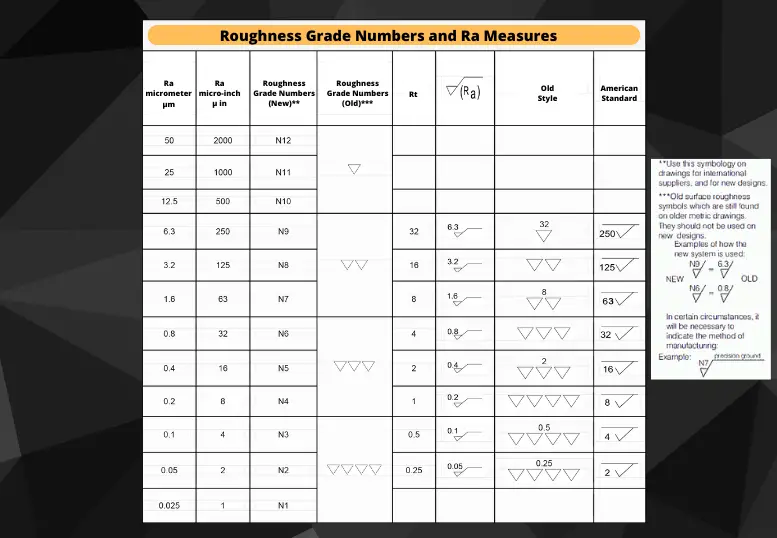

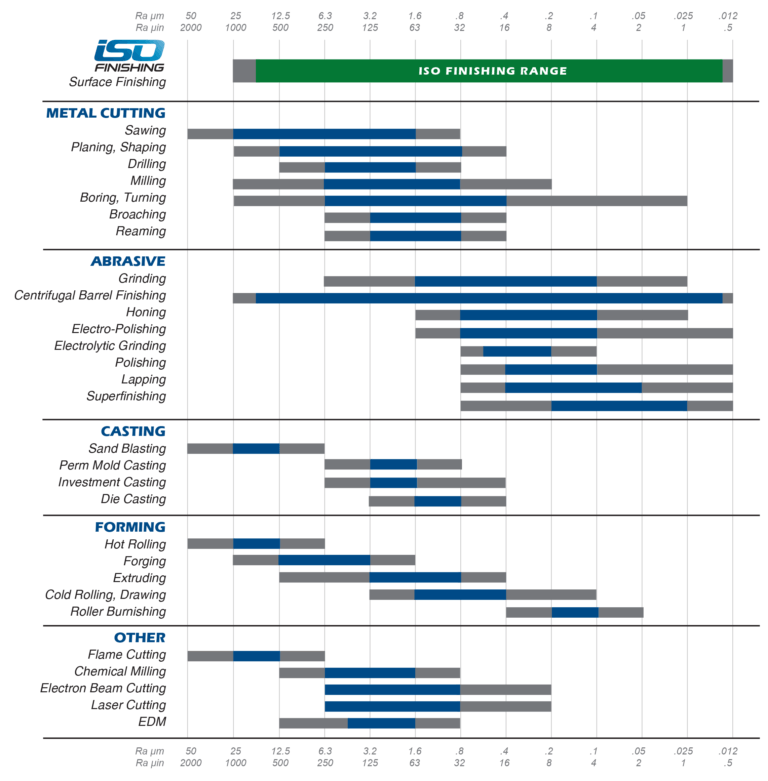

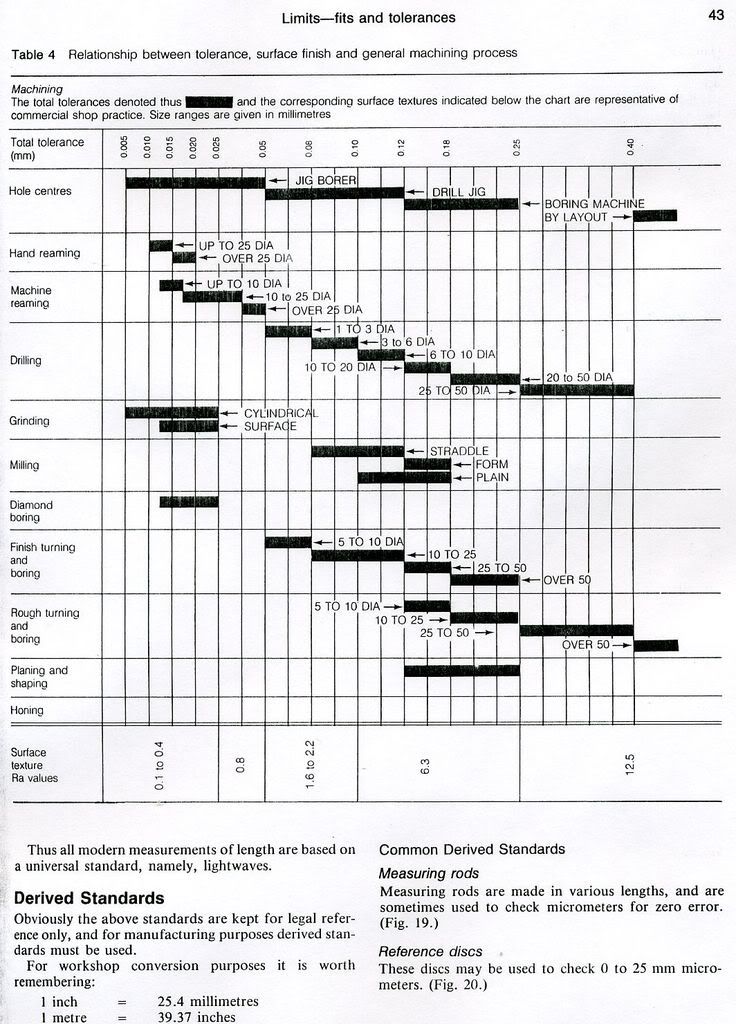

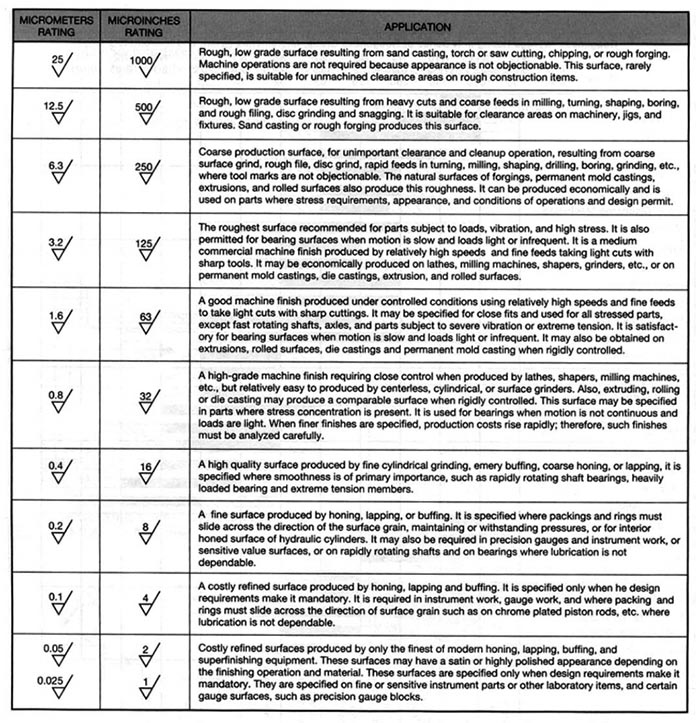

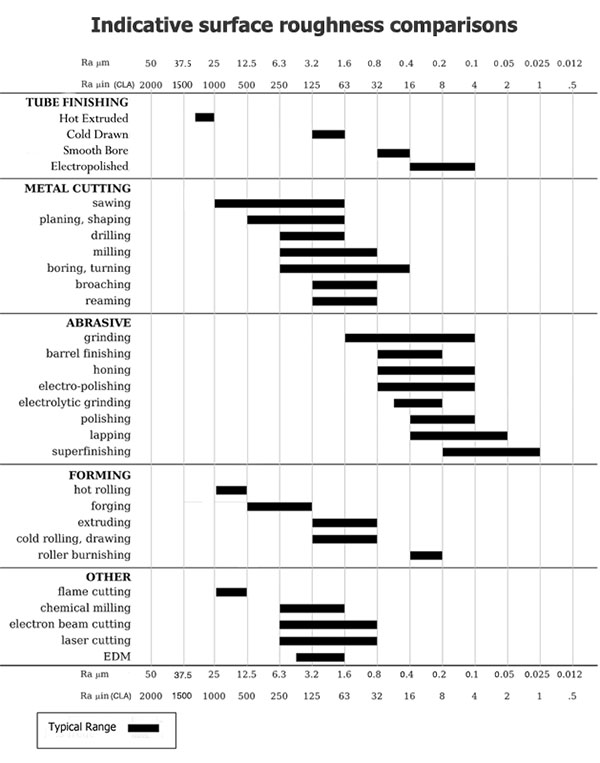

Machine Finish Chart - Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. It is often used to refer to the roughness of a surface, which is typically measured with a profilometer. Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish symbols, charts, and measurements like ra and rz. Let's explore some common machine finish charts and their significance: Surface roughness parameters and standards. It depends on the structure of the metal before and after machining, depends on cutting conditions such as type and degree of sharpness of the cutting tool, depth of cut, amount of feed, coolant used, working conditions such as. We will highlight how surface finish data impacts the performance and quality of machined components. After the finishing process is complete, it's vital to conduct thorough testing and quality control checks to ensure that the machined parts meet the required standards. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. This will help designers and manufacturers select surface finishing techniques that are most effective for products. Here a high resolution probe is used to measure the surface. We’ll also explore why surface finish matters, offering practical insights into how it can impact your. Web machine finish charts provide a visual representation of surface finish parameters, aiding machinists in achieving the desired finish quality. This step is essential for identifying any defects or deviations from the specified. Here a high resolution probe is used to measure the surface. There are a variety of considerations, and they may even vary for different stages in. Web surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. Web surface finish chart by machining technology in the. Web introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, ra, rz, rms for iron and steel castings by dandong foundry in china. Web a surface finish machining chart serves as a valuable tool for machinists, providing a visual representation of recommended cutting parameters based on material type, tooling, and desired surface finish. Web surface finish charts. The ra chart illustrates the average roughness of a machined surface. Web surface finish specification and comparison. Web testing and quality control. The surface finish graphical symbol usage is defined in iso 1302:2002. N = new iso (grade) scale numbers. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. There are a variety of considerations, and they may even vary for different stages in. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. Several factors influence surface finish in cnc machining. It can also refer to how the. Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish symbols, charts, and measurements like ra and rz. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. We’ll also explore. Web testing and quality control. Web from the coolant used to the width and depth of a cut, every process of machining needs to be calculated with pinpoint accuracy to ensure the optimal quality of manufactured goods. Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish. Here a high resolution probe is used to measure the surface. Manufacturers always use it as a reference material to ensure quality in the manufacturing process. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. By following these guidelines, manufacturers can enhance productivity. Web a surface finish machining chart serves as a valuable tool for machinists, providing a visual representation of recommended cutting parameters based on material type, tooling, and desired surface finish. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Web this. Web surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts manufactured by various manufacturing processes. Several factors influence surface finish in cnc machining. Web introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, ra, rz, rms for iron and steel castings by dandong foundry in china. Web the finish on. Here a high resolution probe is used to measure the surface. There are a variety of considerations, and they may even vary for different stages in. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Surface roughness parameters and standards. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? When we try to measure a surface finish, the methods fall into three categories: The ra chart illustrates the average roughness of a machined surface. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. A comprehensive understanding of these factors enables machinists to optimize surface finish and minimize defects. Manufacturers consistently reference it to guarantee product quality during the manufacturing process. Let's explore some common machine finish charts and their significance: Web introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, ra, rz, rms for iron and steel castings by dandong foundry in china. Several factors influence surface finish in cnc machining. Web in this comprehensive guide, we’ll navigate through the intricate world of surface finishes, providing you with a detailed understanding of surface finish symbols, charts, and measurements like ra and rz. But we won’t stop there.

Surface Finish Destiny Tool

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA

Surface Roughness Chart Comparison ISO Finishing

Surface Finish Chart A Guide to Understanding Surface Finishing Chart

Machine Surface Finish Chart

Surface Finish Chart A Guide to Understanding Surface Finishing Chart

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

Machining Surface Finish Chart Comparator Method Degr vrogue.co

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

After The Finishing Process Is Complete, It's Vital To Conduct Thorough Testing And Quality Control Checks To Ensure That The Machined Parts Meet The Required Standards.

The Most Common Type Is The Roughness Chart Which Shows A Graphical Representation Of The Roughness Of A Surface.

By Following These Guidelines, Manufacturers Can Enhance Productivity And Precision In Their Machining Processes.

By Looking At These Charts We Can Choose Material And Process Wisely For.

Related Post: