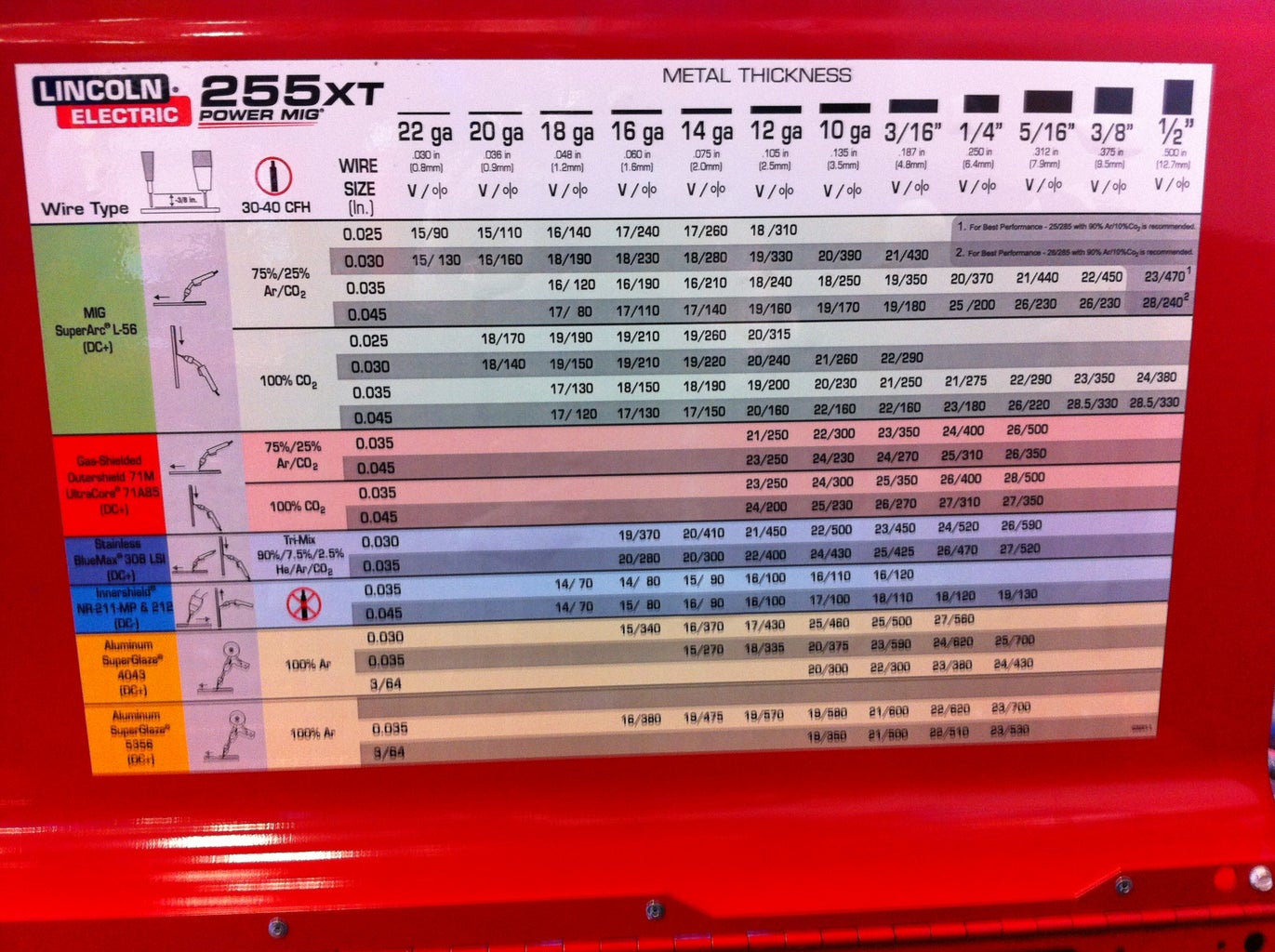

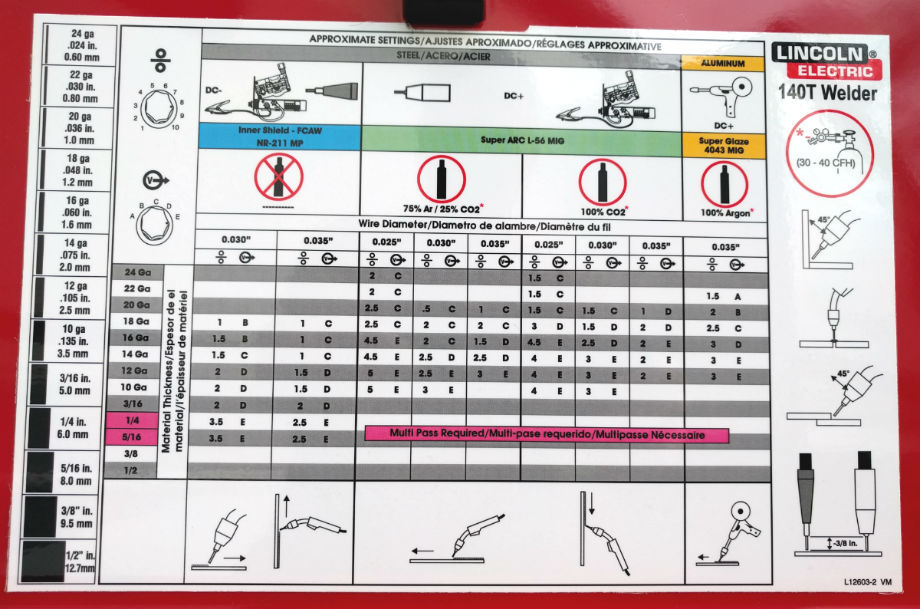

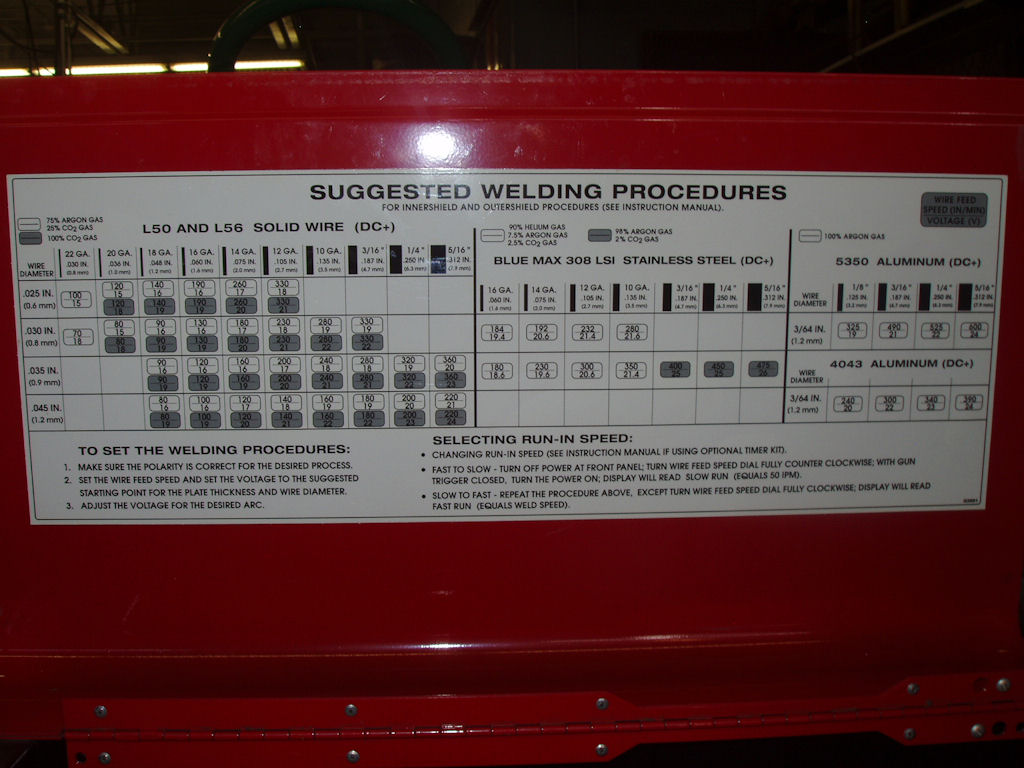

Lincoln Welder Settings Chart

Lincoln Welder Settings Chart - Web just a video for diy guys or girls thinking about getting into mig welding and how to set the machine up for sheet metal weldingas far as sheet metal welding. We also recommend that you seek additional advice from a professional. But, again, all the retail lincoln 140 mig welders are identical. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: 180 welding system pdf manual download. Controls and operational features 1. Select proper wire size according to amperage. Web as the wire feed speed is adjusted, the power source adjusts the waveform parameters to maintain good welding characteristics. Download the app version of the weld setting calculator for easy reference! Vertical up techniques provide deeper penetration and lower overall welding costs on plate over 3/16” thick. But before using these values, we suggest that you have a decent understanding of your preferred metal. Vertical up techniques provide deeper penetration and lower overall welding costs on plate over 3/16” thick. Since you don't want to change wire, select one for your most commonly used thicknesses. Web lincoln mig welding electrode and gas selection chart settings to start. Most lincoln 140 mig welder reviews treat each brand name as a unique model. Web view and download lincoln electric 140 operator's manual online. Your lincoln electric 140 has a welding output of 30 to 140 amp in four voltage. Web view and download operator's manuals for lincoln electric welding, cutting, and automation products. Web as a guideline, each.001 inch. Your lincoln electric 140 has a welding output of 30 to 140 amp in four voltage. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. Web as the wire feed speed is adjusted, the power source adjusts the waveform parameters to maintain good welding characteristics. Web explains. There are many mig setting charts available from manufacturers that all vary. Output connections refer to points [1], [2] and [3] of the figures below. Web explains the settings of wire speed and voltage for better understanding controls of lincoln 180hd welder. 180 welding system pdf manual download. Web lincoln stick welder settings chart. Web to determine the correct electrode diameter and current settings to use please consult the lincoln weldirectory (bulletin #c2.10) • fleetweld® 35 •. 180 welding system pdf manual download. See for yourself and compare model specs and. Each pulse sends a small droplet of molten metal from the wire to the weld puddle. Output connections refer to points [1], [2]. Download the app version of the weld setting calculator for easy reference! 180 welding system pdf manual download. Here is a chart showing the ideal settings for working with a lincoln stick welder. 140 welding system pdf manual download. Web view and download operator's manuals for lincoln electric welding, cutting, and automation products. Controls and operational features 1. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web just a video for diy guys or girls thinking about getting into mig welding and how to set the machine up for sheet metal weldingas far as sheet metal welding. The most common metals welded with the. Web view and download operator's manuals for lincoln electric welding, cutting, and automation products. Also, consider the amperage settings and the task at hand. See for yourself and compare model specs and. There are many mig setting charts available from manufacturers that all vary. Most lincoln 140 mig welder reviews treat each brand name as a unique model. Lincoln electric welder user manual. Web view and download lincoln electric 180 user manual online. Select proper wire size according to amperage. The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. You set your welding output voltage on your lincoln 140 using one of the dials on the front of your welder. Web to determine the correct electrode diameter and current settings to use please consult the lincoln weldirectory (bulletin #c2.10) • fleetweld® 35 •. Web lincoln 140 mig welder settings. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. Web stainless alloys products to meet the process requirements. .125 inch = 125 amps. Web lincoln stick welder settings chart. Lincoln electric welder user manual. 180 welding system pdf manual download. See for yourself and compare model specs and. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. Web as the wire feed speed is adjusted, the power source adjusts the waveform parameters to maintain good welding characteristics. You set your welding output voltage on your lincoln 140 using one of the dials on the front of your welder. Most lincoln 140 mig welder reviews treat each brand name as a unique model. Also, consider the amperage settings and the task at hand. There are many mig setting charts available from manufacturers that all vary. Vertical up techniques provide deeper penetration and lower overall welding costs on plate over 3/16” thick. Web view and download lincoln electric 140 operator's manual online. Web to determine the correct electrode diameter and current settings to use please consult the lincoln weldirectory (bulletin #c2.10) • fleetweld® 35 •. But before using these values, we suggest that you have a decent understanding of your preferred metal. Download the app version of the weld setting calculator for easy reference!

Basics of MIG Welding 17 Steps (with Pictures) Instructables

8 Tips for MIG Welding Beginners Beginner Welding Guide

Lincoln 140 MIG Welder Reviews The Models Explained WelditU

Lincoln Mig Welding Settings Chart

Lincoln Mig Welding Settings Chart

MIG welder settings explained Amperage & Wire Speed

Lincoln Mig Welder Settings Chart

MIG Welding Aluminum Electrodes, Gasses, Welder Setting & Equipment

Lincoln Stick Welder Settings Chart

Tell us your fave volts/wirespeed settings. MIG Welding Forum

Controls And Operational Features 1.

Since You Don't Want To Change Wire, Select One For Your Most Commonly Used Thicknesses.

Web Stainless Alloys Products To Meet The Process Requirements Of Many Stainless Steel And High Alloy Welding Applications.

The Most Common Metals Welded With The Mig Process Include Mild Steel, Stainless Steel, And Aluminum.

Related Post: