Laser Engraver Wattage Chart

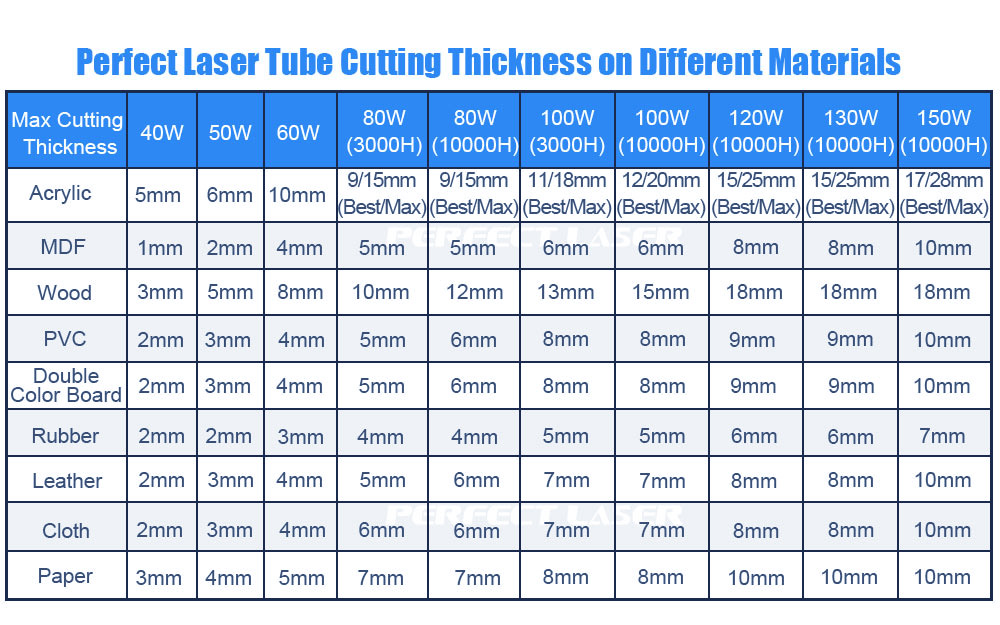

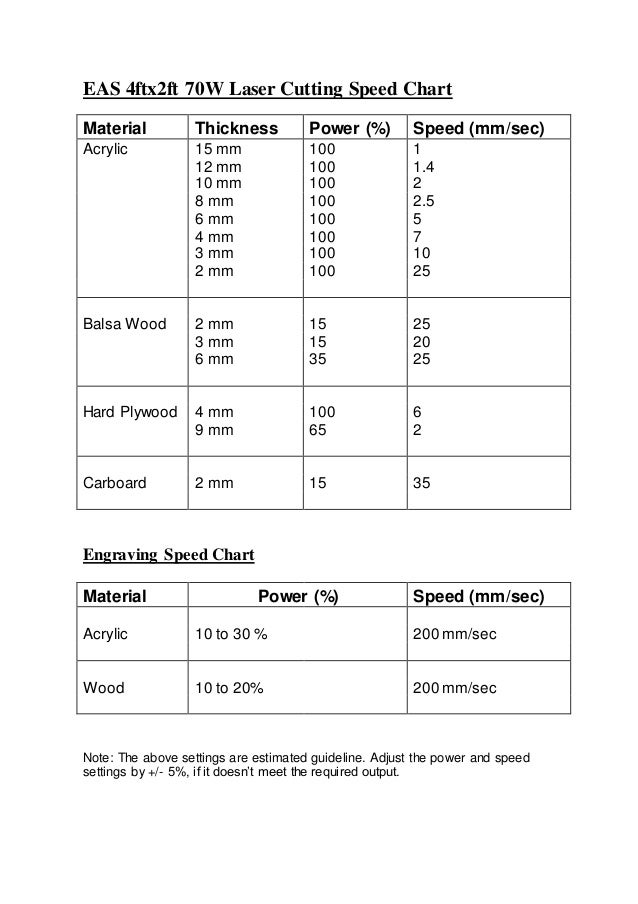

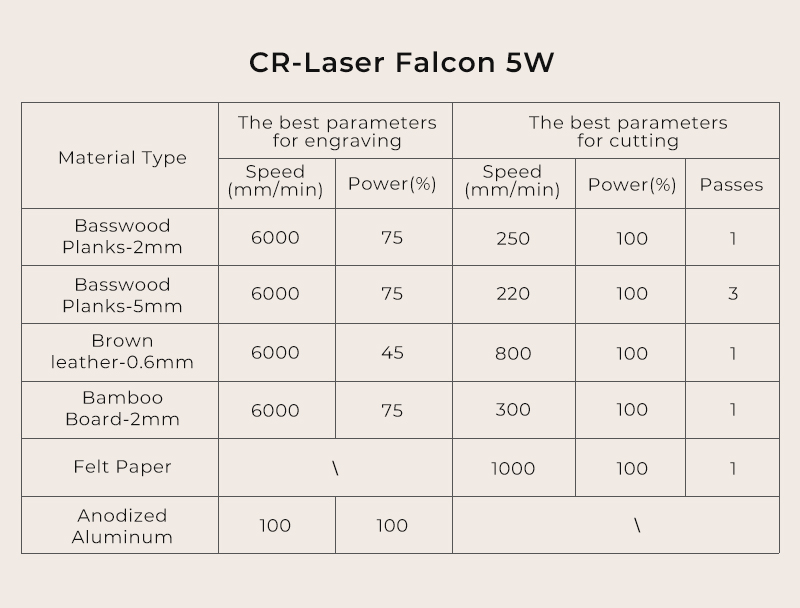

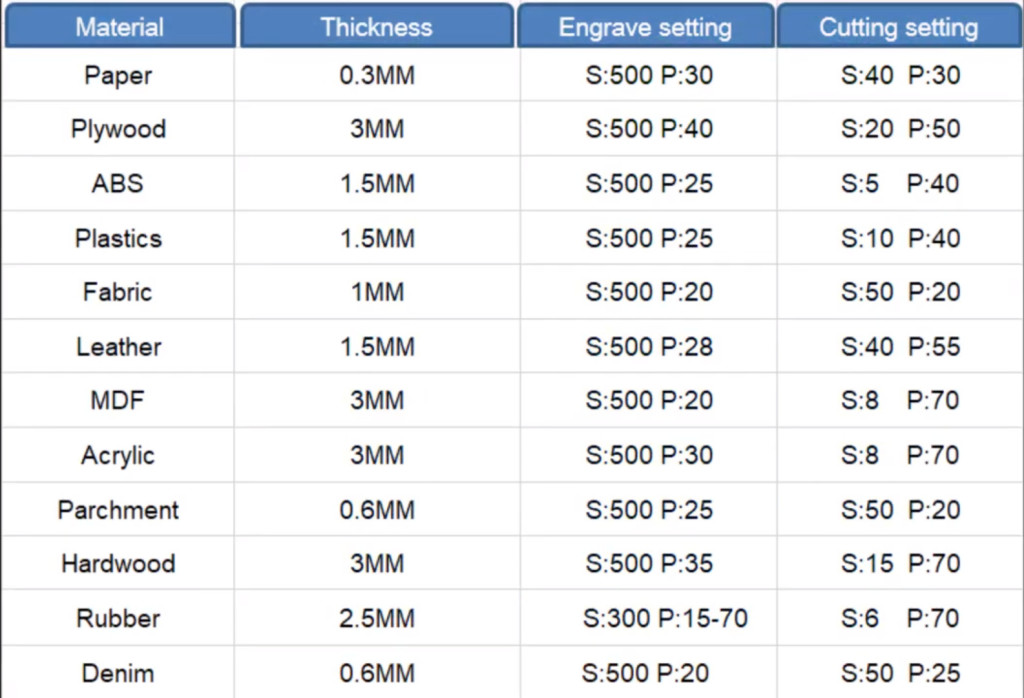

Laser Engraver Wattage Chart - Web this article lists the thickness, speed, and gas pressure charts for laser processing of different materials like wood, acrylic, leather, rubber, plastic, glass, paper, foam, aluminum, stainless steel, and more. However, if you wish to test engraving effects, you should choose fill under mode. afterward, click. Create 11 squares to be cut and set the power to increase for each cut—where the middle square is the recommended cutting power. Our comprehensive chart helps you determine the optimal speed and thickness for your material. Web chart interpretation guidelines. Web metals can be engraved at just about any settings. Web laser cutting machine power refers to the power output of the laser equipment, generally in watts (w). Best premium laser cutter for home business 6. Web if the laser will be primarily used for engraving, you can achieve good results with a laser having a power level of between 25 and 80 watts (w). Even with a fiber laser, the main application is crucial when it comes to choosing the right laser power. Laser wood engraver engraving capacity: Laser power determines the energy of the laser, influencing the depth and width of the cut, as well as the amount of smoke and charring produced. The lasers wattage, hardness of metal, desired mark (etch, polish, anneal) and the required time/contrast/depth will have to be considered when deciding on the final settings. Depending on the. Web list in brief 1. Co2 laser cutting thickness & speed chart for acrylic. Choosing the right power is therefore particularly important. Web laser cutting machine power refers to the power output of the laser equipment, generally in watts (w). For annealing and marking, good results are achieved with laser powers of 20 or 30 watts. The importance of wattage in laser engraving. Power and its effect on laser cutting. Web to start, a laser cutting power chart should be used to find the recommended power required for the given thickness, material type, and cutting speed. Even with a fiber laser, the main application is crucial when it comes to choosing the right laser power. Choosing. Web the power of a laser engraver is typically measured in watts (w) and represents the energy output of the laser beam. Different materials require adjustments to the laser power setting and the wattage of the laser to achieve the best results. Web most hobby laser engravers are available in a range of wattages, typically starting from 5 watts and. High laser powers are required when engraving metals. Best budget laser cutter 5. Meanwhile, the operator and bystanders should wear the laser safety goggles provided by snapmaker during the whole process. For annealing and marking, good results are achieved with laser powers of 20 or 30 watts. When engraving, there are 3 main parameters that affect the quality: Web posted on 08.10.2021 (18.08.2022) by george fomitchev. Unlike the tons of other videos out there who skip steps and explanations, this video will walk you through the entire process, start to finish. Of course, there are many variables to consider for metal engraving. The power has a great impact on the energy density of the laser beam, cutting speed,. Power choose, power setting and speed. In simple terms, higher wattage means a more powerful laser, enabling faster cutting and deeper engraving capabilities. Of course, there are many variables to consider for metal engraving. Even with a fiber laser, the main application is crucial when it comes to choosing the right laser power. Different materials require adjustments to the laser. The greater precision and details required, the higher the recommended power within this range. In simple terms, higher wattage means a more powerful laser, enabling faster cutting and deeper engraving capabilities. Co2 laser cutting thickness & speed chart for die cutting & creasing plate. Co2 laser cutting thickness & speed chart for acrylic. The lasers wattage, hardness of metal, desired. Laser cutting chart for plastic. Web if the laser will be primarily used for engraving, you can achieve good results with a laser having a power level of between 25 and 80 watts (w). Web laser cutting machine power refers to the power output of the laser equipment, generally in watts (w). For annealing and marking, good results are achieved. In simple terms, higher wattage means a more powerful laser, enabling faster cutting and deeper engraving capabilities. High laser powers are required when engraving metals. Unlike the tons of other videos out there who skip steps and explanations, this video will walk you through the entire process, start to finish. Depending on the density and type of wood, a power. Web to start, a laser cutting power chart should be used to find the recommended power required for the given thickness, material type, and cutting speed. You should always operate it with the enclosure developed by snapmaker and wear the laser safety goggles provided by snapmaker. Our comprehensive chart helps you determine the optimal speed and thickness for your material. Of course, there are many variables to consider for metal engraving. Web this article lists the thickness, speed, and gas pressure charts for laser processing of different materials like wood, acrylic, leather, rubber, plastic, glass, paper, foam, aluminum, stainless steel, and more. Web understanding the basics of laser speed settings is key to getting the best results. Create 11 squares to be cut and set the power to increase for each cut—where the middle square is the recommended cutting power. Laser wood engraver engraving capacity: Power choose, power setting and speed. Web chart interpretation guidelines. Laser power determines the energy of the laser, influencing the depth and width of the cut, as well as the amount of smoke and charring produced. Different materials require adjustments to the laser power setting and the wattage of the laser to achieve the best results. Web in this chapter, we’ve included a laser engraving wattage comparison chart, along with some helpful information about laser beam power settings and processing speed. Web need to find the perfect laser cutting settings? Depending on the density and type of wood, a power wattage of around 100w is recommended for monport's 100w co2 laser engraver & cutting machine. Web if the laser will be primarily used for engraving, you can achieve good results with a laser having a power level of between 25 and 80 watts (w).

Diode Laser Cutting Speed And Power Chart

Laser Cutter/Engraver SU FASTEnER LAB

Laser Cutting Speed And Power Chart

YoraHome All You Need To Know About The Burn Settings of The Yora Diode

RAY5 5W VS RAY5 10W LONGER RAY5 Laser Engraver Comparison And Review

ATOMSTACK Graveur laser A5 Pro, machine de gravure laser 40 W avec

How to Find Best Settings for Laser Engraving and Marking Advanced

Creality CRLaser(CV30) Falcon Engraving and Cutting Settings

Laser Cut Engraved Samples Parameters Thunderlaser Indian

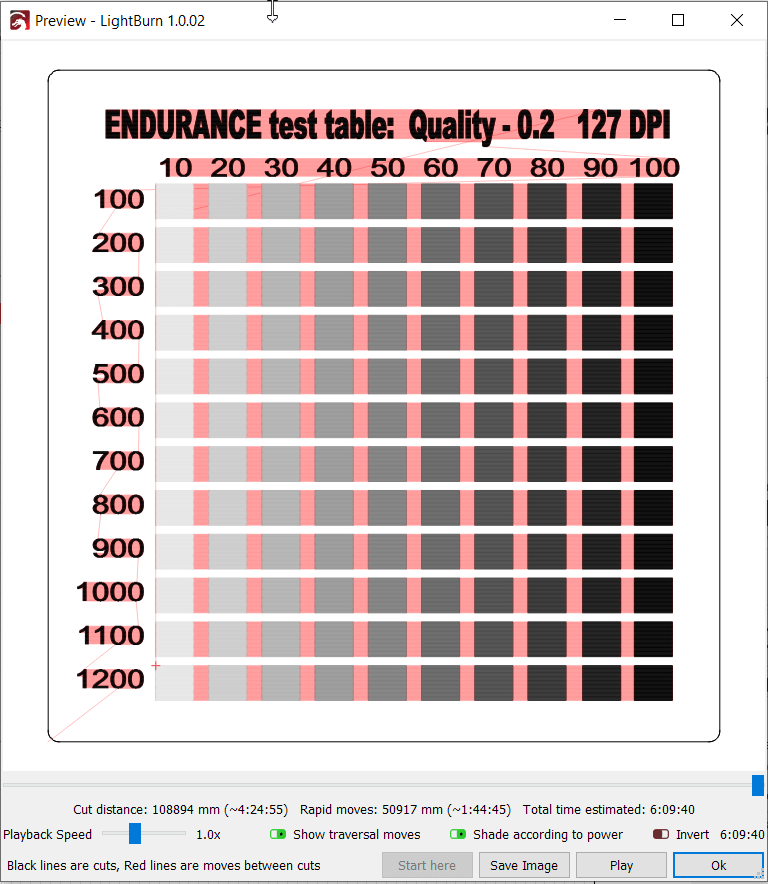

Table for determining the parameters of laser engraving. EnduranceLasers

The Power Has A Great Impact On The Energy Density Of The Laser Beam, Cutting Speed, Depth, And The Cutting Material, Etc.

In Simple Terms, Higher Wattage Means A More Powerful Laser, Enabling Faster Cutting And Deeper Engraving Capabilities.

Co2 Laser Cutting Thickness & Speed Chart For Die Cutting & Creasing Plate.

Web Metals Can Be Engraved At Just About Any Settings.

Related Post: