Laser Cutting Thickness Chart

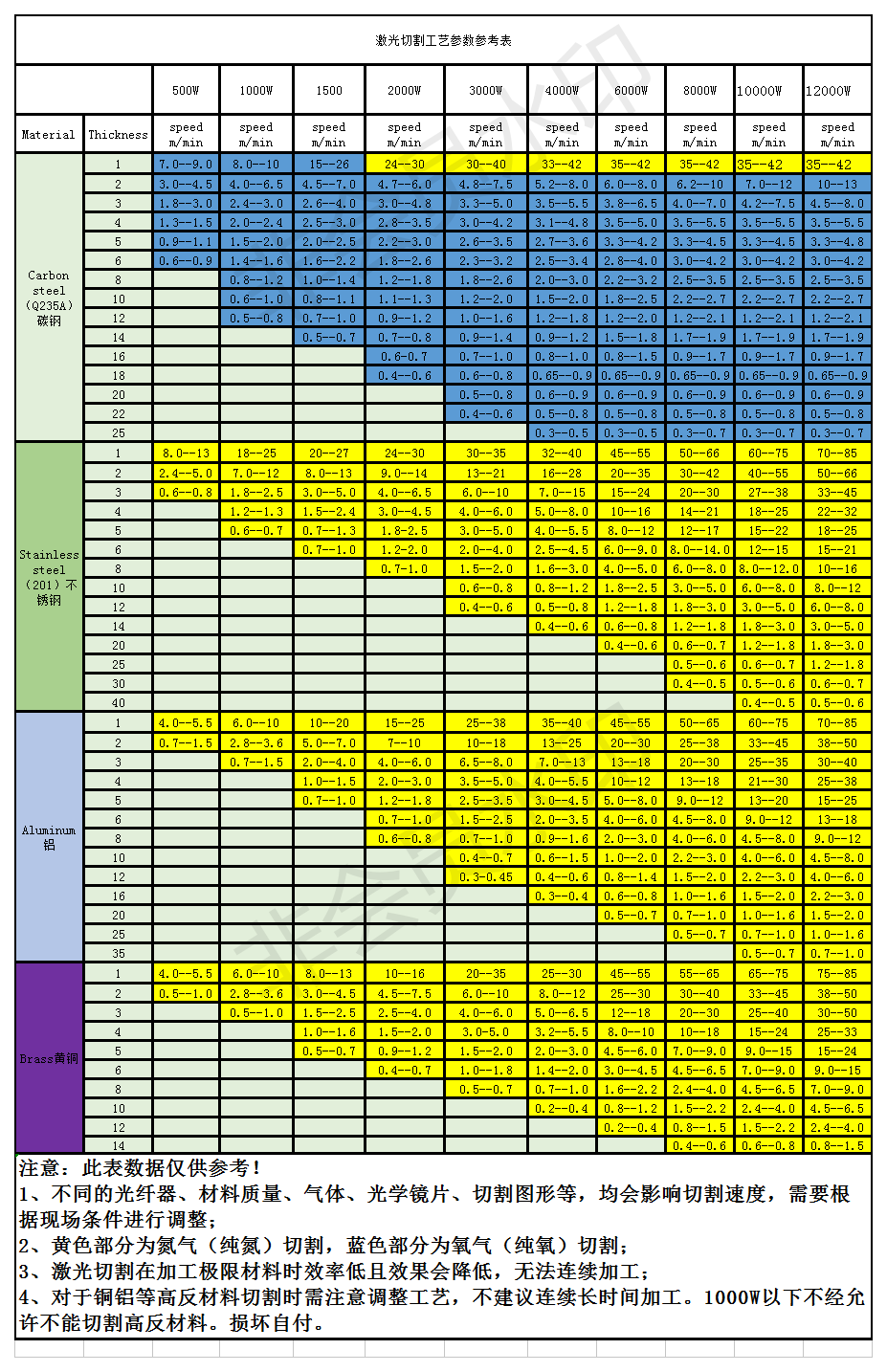

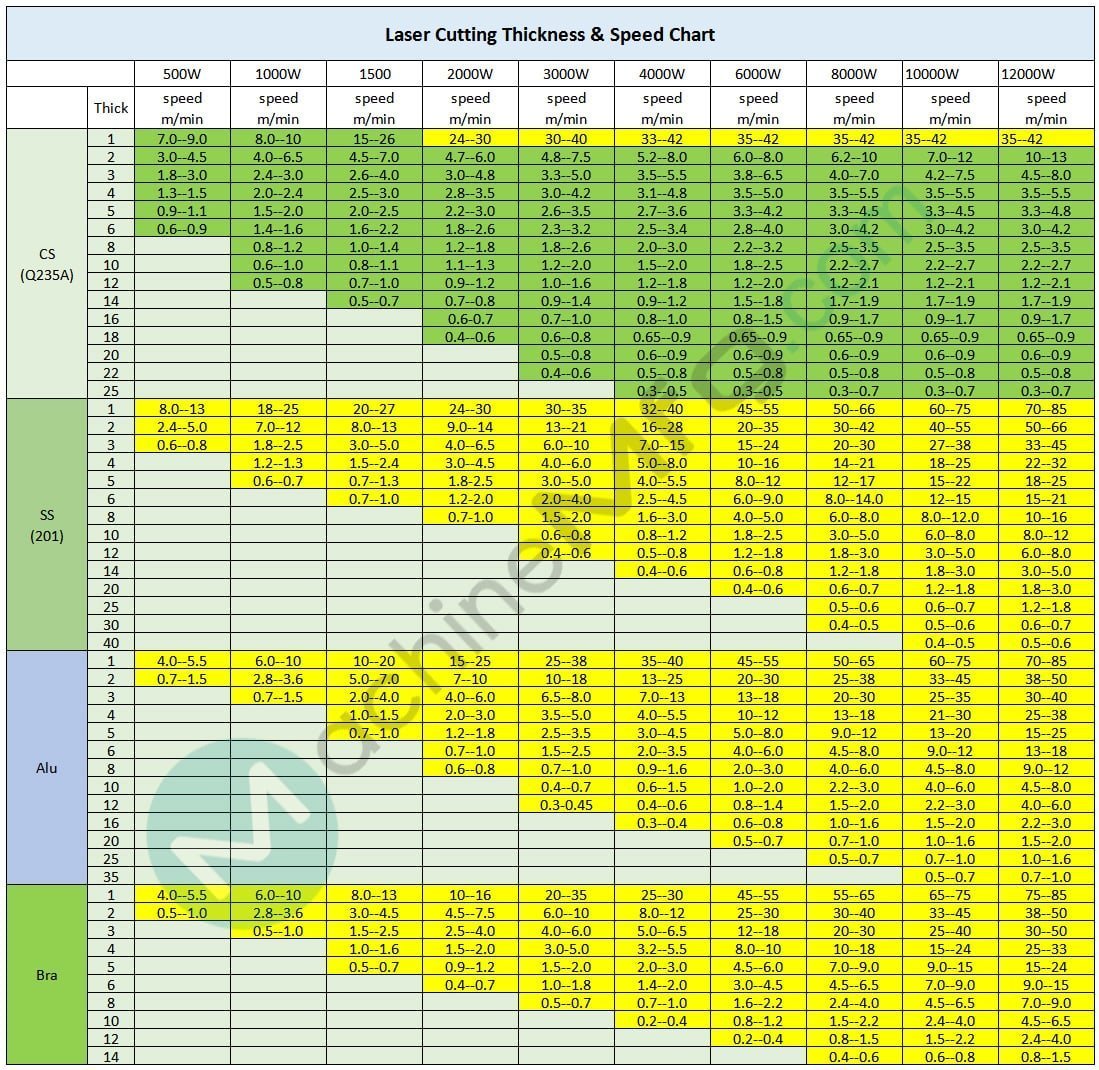

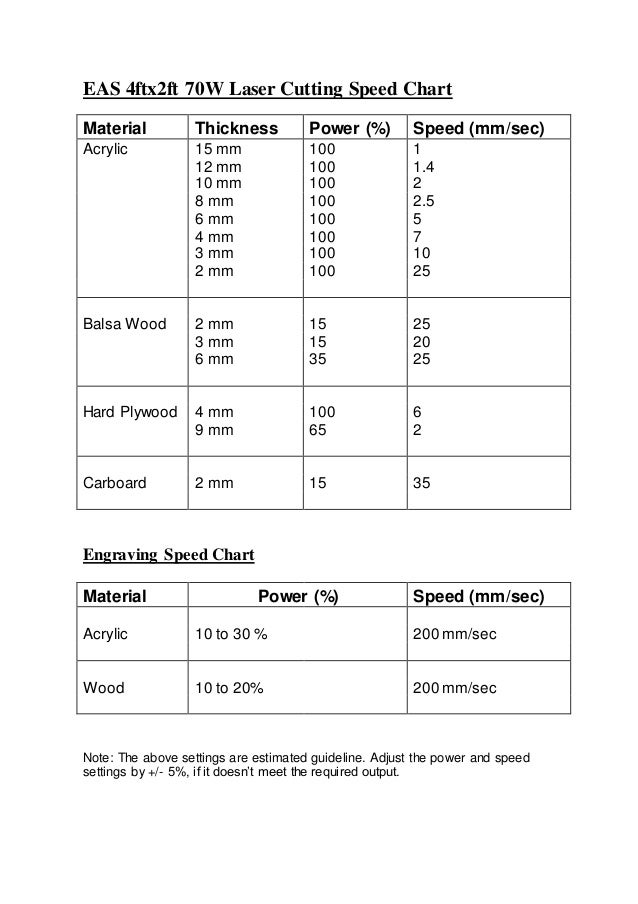

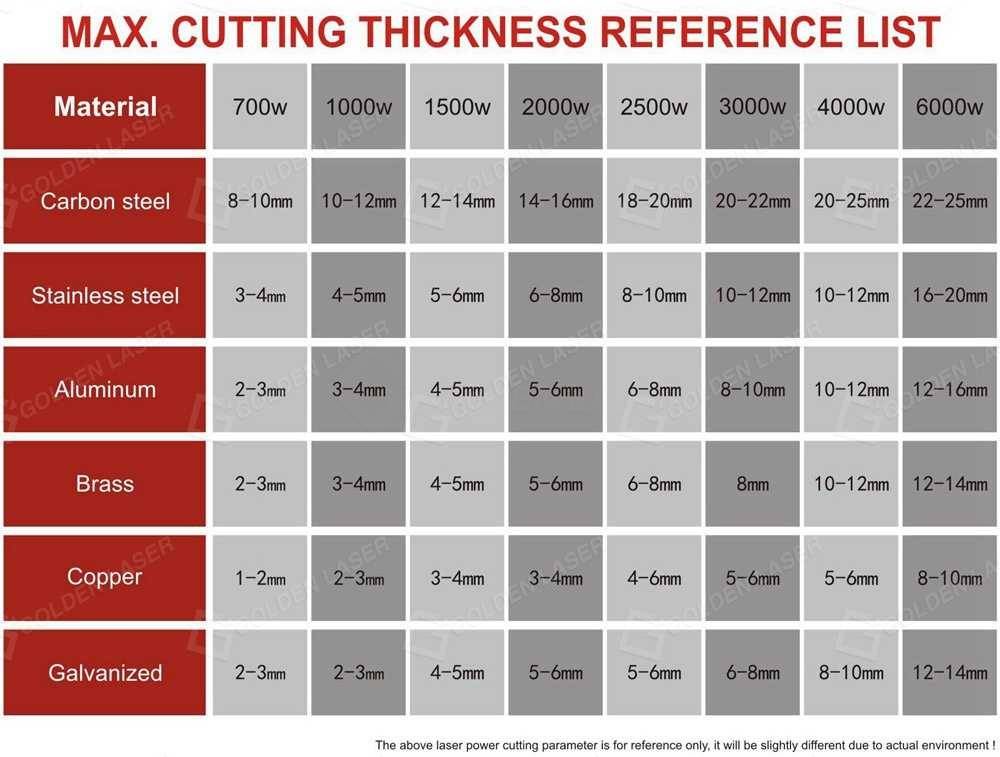

Laser Cutting Thickness Chart - No matter what type or model of cutting machine you buy, it is crucial to know the cutting speed, thickness and power of the machine. These hole size recommendations are crucial for achieving precision and quality in laser cutting processes. It maps the correlation between the laser cutter’s power settings, the speed at which it operates, and the material thickness it is capable of cutting. The manufacturing industry’s laser cutting machine is a breath of fresh air. A complete guide is provided for better understanding. Web learn about the various factors that affect laser cutting performance, including table thickness, cutting speed, gas selection, focus, pressure, and nozzle selection, in our comprehensive guide. By understanding the importance of speed and power in laser cutting, as well as the factors influencing them, you can achieve remarkable results in your projects. Web from smooth cutting edges on mild steel as thick as a finger to tubes: Web here this thickness chart will help you getting familiar with the laser cutting power for different materials and the relation with its thickness. Considerations when using thickness charts. Web the laser cutting thickness chart serves as your guide in navigating through various materials and their corresponding optimal thicknesses for laser cutting. Considerations when using thickness charts. By understanding the importance of speed and power in laser cutting, as well as the factors influencing them, you can achieve remarkable results in your projects. The detail chart for each thickness. It is vital for one to understand the laser source’s characteristics and how different materials interact with this technology. It provides valuable information about which materials can be cut using a specific type of laser cutter and at what power settings. Thickness chart of co2 laser cutter for acrylic. Web wenn schneidstoff mit einer dicke ≥4mm, sollten die parameter für. Web learn how to utilize a laser cutting thickness chart to select the right settings for the job. It is vital for one to understand the laser source’s characteristics and how different materials interact with this technology. These hole size recommendations are crucial for achieving precision and quality in laser cutting processes. Safety considerations when using a thickness chart. Web. It maps the correlation between the laser cutter’s power settings, the speed at which it operates, and the material thickness it is capable of cutting. By gaining a thorough understanding of these fundamentals, you’ll be well on your way to knowing you have the right laser cutter for your projects so you can achieve maximum efficiency and quality. Since a. As shown in the above list, the thickest boards of various materials that can be cut by fiber laser cutting machines of different powers in mass production are different. Considerations when using thickness charts. When purchasing a laser cutting machine, it is very important to know the detailed parameters of the machine. Web from smooth cutting edges on mild steel. The speed range also falls between 0.5mm/min to 50mm/min depending upon the range of power too. Web the following table provides invaluable insights into the recommended minimum hole size for laser cutting, specifically for round holes, depending on the material type and sheet thickness. This is because a low power machine do not offers high speed cutting. For a 1000w. The importance of thickness charts. As shown in the above list, the thickest boards of various materials that can be cut by fiber laser cutting machines of different powers in mass production are different. Our comprehensive chart helps you determine the optimal speed and thickness for your material. Different types of cuts and their thickness requirements. Web fiber laser cutting. Calculating material thickness when using a laser cutter. It maps the correlation between the laser cutter’s power settings, the speed at which it operates, and the material thickness it is capable of cutting. By understanding the importance of speed and power in laser cutting, as well as the factors influencing them, you can achieve remarkable results in your projects. As. No matter what type or model of cutting machine you buy, it is crucial to know the cutting speed, thickness and power of the machine. Thickness chart of co2 laser cutter for acrylic. These tolerances serve as a general guide and can vary depending on the specific material, machine. Web wenn schneidstoff mit einer dicke ≥4mm, sollten die parameter für. Different types of cuts and their thickness requirements. The speed range also falls between 0.5mm/min to 50mm/min depending upon the range of power too. For a ms material the maximum speed achieved can be 9 m/min whereas for an aluminum and ss this is 25 m/min. Web fiber laser cutting machine gives a thickness range of 1mm to 24mm for. How to read and interpret thickness charts. By gaining a thorough understanding of these fundamentals, you’ll be well on your way to knowing you have the right laser cutter for your projects so you can achieve maximum efficiency and quality. It maps the correlation between the laser cutter’s power settings, the speed at which it operates, and the material thickness it is capable of cutting. For a 1000w laser cutting machine the thickness of material only ranges between 1mm to 12mm. The manufacturing industry’s laser cutting machine is a breath of fresh air. Safety considerations when using a thickness chart. There is no simple answer on the thickness a laser system can cut. For a ms material the maximum speed achieved can be 9 m/min whereas for an aluminum and ss this is 25 m/min. Considerations when using thickness charts. Thanks to intelligent functions, your 2d laser cutting machine masters an almost infinite variety of contours and materials. Web here this thickness chart will help you getting familiar with the laser cutting power for different materials and the relation with its thickness. It provides valuable information about which materials can be cut using a specific type of laser cutter and at what power settings. No matter what type or model of cutting machine you buy, it is crucial to know the cutting speed, thickness and power of the machine. It is vital for one to understand the laser source’s characteristics and how different materials interact with this technology. Then, run a test on a scrap piece of material of. Web from smooth cutting edges on mild steel as thick as a finger to tubes:

The Primary Products of XT (IV Laser Cutting)Tony XTLASER

Таблица толщины и скорости лазерной резки CNC Maniac

Laser Cutting Isle Of Wight And Hampshire

Fiber Laser Cutting Thickness Chart

1000W 1500W 2000W 3000W 4000W Fiber Laser Cutting Machine for Metal

Laser Cutting Thickness Chart

Laser Cutting Speed & Thickness Chart (500W30kW) MachineMFG

Eas 4ftx2ft 70 w laser cutting speed chart

Laser cutting thickness selection

Dual CNC Fiber Laser Sheet Metal and Tube / Pipe Cutting Machine

Web Need To Find The Perfect Laser Cutting Settings?

When Purchasing A Laser Cutting Machine, It Is Very Important To Know The Detailed Parameters Of The Machine.

Different Types Of Cuts And Their Thickness Requirements.

It Cuts Through Thick And Hardcore Metals With Ease And Neatly.

Related Post: