Keyway Tolerance Chart

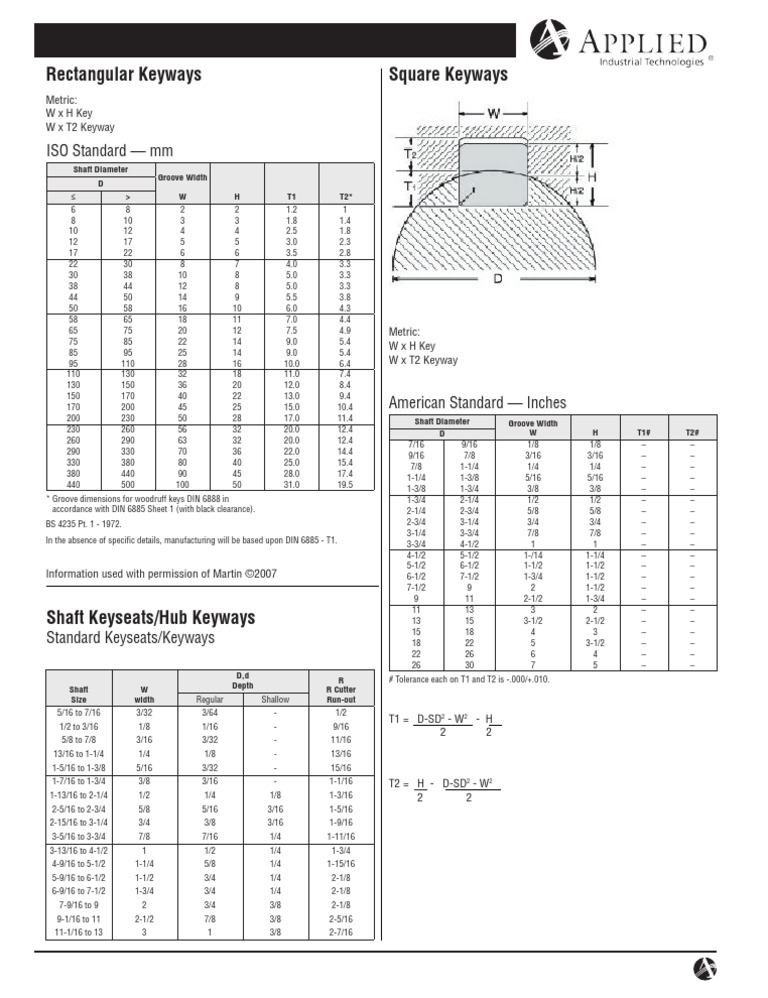

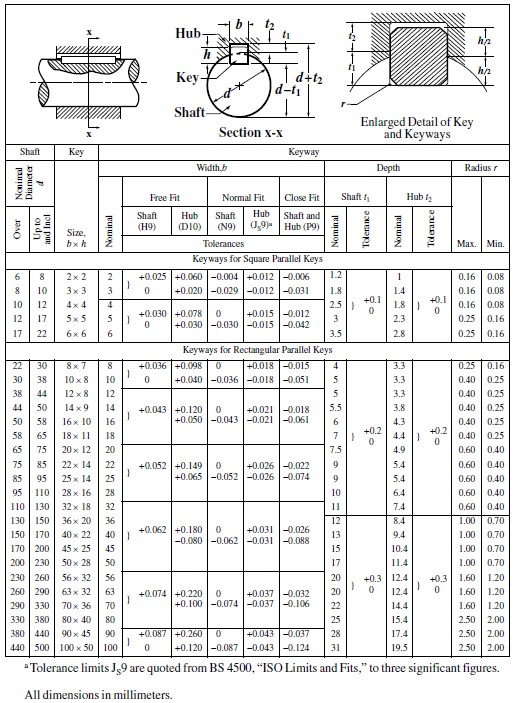

Keyway Tolerance Chart - Web class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9 h8 h9 b9 c9 d9 sliding fit driving fit press fit strong press fit shrinkage fit loose fit light roll fit roll fit (code t) − s 1. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Parallel key and taper keys dimensions; Shaft keyway shear and yield strength formulae and calculator; Web nominal nominal shaft bore dia. Which specification was applicable to machine tools. Metric keyways are dimensioned by width and depth as measured from the radius of the shaft to the center of the keyway. Find your data faster with our fits and tolerance calculator. B x h width x thck: Web the keyway dimensions are also different from the english system. Web class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9. (code t) − s 1. B x h width x thck: The advantage of the js9 tolerance is that the key can be inserted and the gear manipulated without much difficulty. Web shaft with keyway torque applied deformation and stress equations and calculator; Slope key, gib head key and key groove. (code t) − s 1. Parallel keys and key grooves. Web the dimensions and tolerances of keys of sizes 4 x 4 to40 x 22 covered in is: (dimensions comply with din 6885/1) † requires use of chamfered keys. Slope key, gib head key and key groove. Green = prefered tolerance classes per iso 286. Which specification was applicable to machine tools. Whereas the p9 tolerance is a press fit tolerance. Table 1 details the appropriate key slot and key sizes for various. Parallel keys and key grooves. (dimensions comply with din 6885/1) † requires use of chamfered keys. Web it is vital to have the correct fit between the shaft keyway, key and hub keyway. Web the dimensions and tolerances of keys of sizes 4 x 4 to40 x 22 covered in is: Shaft keyway shear and yield strength formulae and calculator; Which specification was applicable to. Web nominal nominal shaft bore dia. See dimensions w and h in figure 1. Metric keyways are dimensioned by width and depth as measured from the radius of the shaft to the center of the keyway. Also, t1 and t2 are not necessarily equal. B x h width x thck: Web the keyway dimensions are also different from the english system. Bottom of shaft to bottom of keyway. B x h width x thck: The advantage of the js9 tolerance is that the key can be inserted and the gear manipulated without much difficulty. (code t) − s 1. Web shaft with keyway torque applied deformation and stress equations and calculator; Web it is vital to have the correct fit between the shaft keyway, key and hub keyway. Generally, there are two classes of stock available for sunk keys, mainly parallel keys. The system of limits and fits is useful for determining tolerances of components that need to have. The system of limits and fits is useful for determining tolerances of components that need to have a relationship or function with one another. See dimensions w and h in figure 1. Web class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7. Surface finish — sides and bottom of keyways shall not exceed 250 micro inches. Web class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8. The following tables show standard dimensions for keys and their grooves. Bottom of shaft to bottom of keyway. Which specification was applicable to machine tools. Parallel keys and key grooves. Green = prefered tolerance classes per iso 286. Only the range of key lengths and dimensions of keyways differed for machine tool. Metric keyways are dimensioned by width and depth as measured from the radius of the shaft to the center of the keyway. Web it is vital to have the correct fit between the shaft keyway, key and hub keyway. Generally, there are two classes of stock available for sunk keys, mainly parallel keys. Unless otherwise specified, the shaft keyway is assumed to be standard. Find your data faster with our fits and tolerance calculator. Web nominal nominal shaft bore dia. (dimensions comply with din 6885/1) † requires use of chamfered keys. Web the dimensions and tolerances of keys of sizes 4 x 4 to40 x 22 covered in is: Also, t1 and t2 are not necessarily equal. The system of limits and fits is useful for determining tolerances of components that need to have a relationship or function with one another.Hole And Shaft Tolerance Chart

Aakkosellinen hakemisto K Samaa tarkoittava suhdelaskenta

Iso Hole Tolerance Chart unlimitedmertq

Pin on Machine design

Iso Fits And Tolerances Chart worksapje

Bore and Keyway Tolerance Table PDF Engineering Tolerance

Keyway Sizing Chart Mechanical Engineering Hardlines

AGMA 9002A86 Inch Bore and ANSI B17.1 Square Keyway Tolerances [PDF

Metric Key Keyway Dimensions Per ISO/R773.Js9 Widt...

keyway tolerance chart Conomo.helpapp.co

The Advantage Of The Js9 Tolerance Is That The Key Can Be Inserted And The Gear Manipulated Without Much Difficulty.

Shaft Keyway Shear And Yield Strength Formulae And Calculator;

B X H Width X Thck:

(Code T) − S 1.

Related Post: