Kennametal Inserts Grades Chart

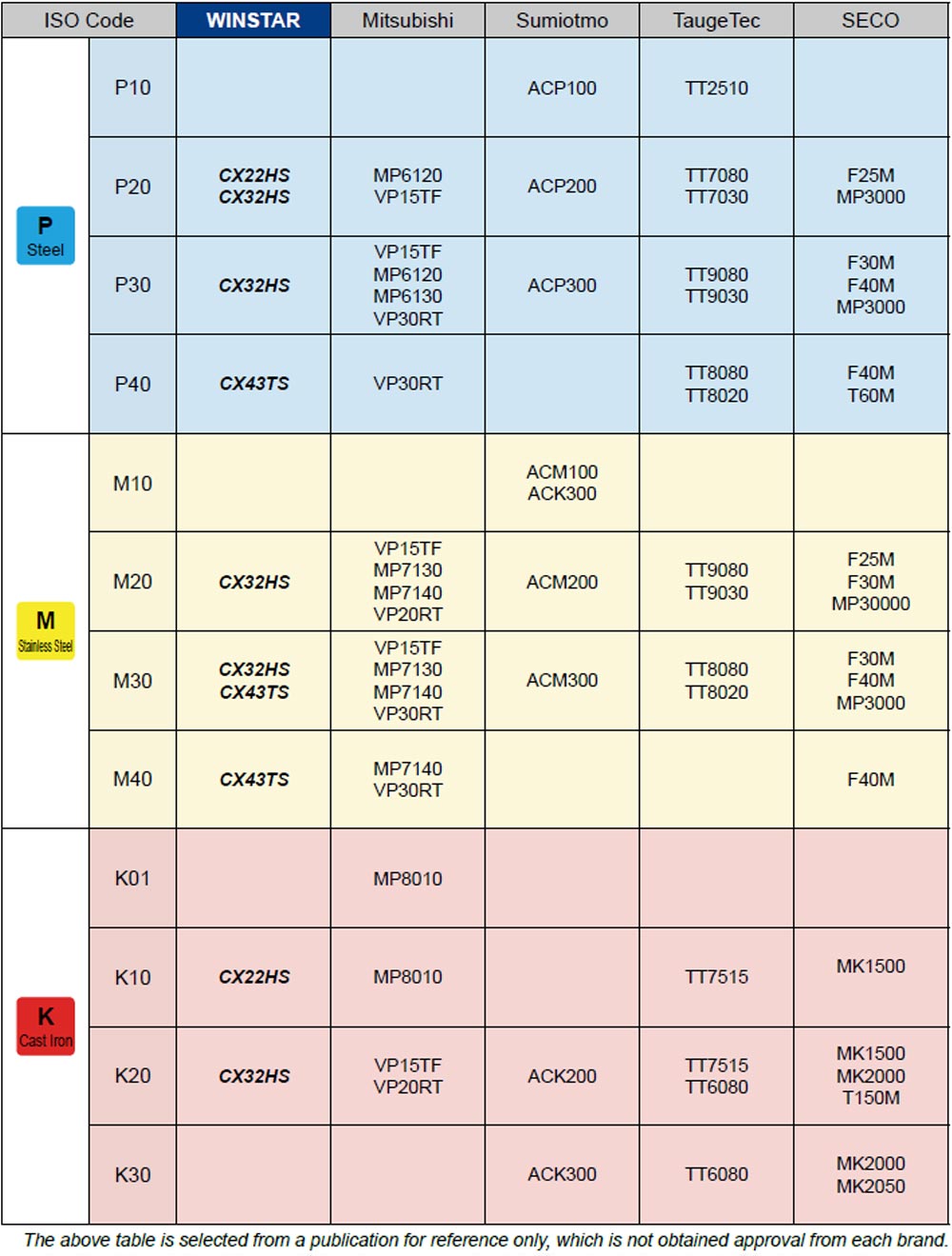

Kennametal Inserts Grades Chart - Coatings for solid carbide end mills. Choose from inserts, holders, boring bars, and more. Web impact strength of kennametal grades is about the same, while kentanium grades are about 20% lower in impact strength at cryogenic temperatures. How to understand and make the most out of our grade tables. Cemented tungsten carbide grades for tools, dies, and wear components. Web kennametal has released kcp25c with kengold in the most common insert shapes and styles: Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. I have some older kennametal inserts with grades my catalogs do not show what they are good for, i am wanting to sell these inserts but need to know what. We use the pmk convention that is used in most of the cutting tool. Kennametal’s milling insert identification system is provided as a general reference.the dimensional tables associated with each insert should be used for. Web as indicated on the properties chart, kennametal has a wide variety of carbide grades including fine, medium, and coarse grained tungsten carbides with cobalt binders,. Longer term, the company plans to expand on kcp25c with. Coatings for solid carbide end mills. Web kennametal inserts grade naming system a system of grades, geometries, and application guidelines to provide optimal solutions. Choose from inserts, holders, boring bars, and more. Web impact strength of kennametal grades is about the same, while kentanium grades are about 20% lower in impact strength at cryogenic temperatures. Web 15 10 05 20 25 30 35 40 45 c3, c4 Web kennametal grooving grades chart. Web kennametal grade name alternate or legacy name grain family industry classification. How to understand and make the most out of our grade tables. We use the pmk convention that is used in most of the cutting tool. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. Kennametal’s milling insert identification system is provided as a general reference.the dimensional tables associated with each insert should be. Web kennametal grooving grades chart. Coatings for solid carbide end mills. C, d, s, t, v and w. We use the pmk convention that is used in most of the cutting tool. Web impact strength of kennametal grades is about the same, while kentanium grades are about 20% lower in impact strength at cryogenic temperatures. Kennametal’s milling insert identification system is provided as a general reference.the dimensional tables associated with each insert should be used for. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. Web common applications kennametal grade name legacy name grain family industry classification binder (wt %) other carbides tic (ta, nb) c hardness density (g/cm3).. Web as indicated on the properties chart, kennametal has a wide variety of carbide grades including fine, medium, and coarse grained tungsten carbides with cobalt binders,. How to understand and make the most out of our grade tables. Web kennametal has released kcp25c with kengold in the most common insert shapes and styles: Longer term, the company plans to expand. Kff05 k96 k6 hca ha a ca443. Web as indicated on the properties chart, kennametal has a wide variety of carbide grades including fine, medium, and coarse grained tungsten carbides with cobalt binders,. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. Web check out our cutting tool blank grade chart. Kennametal’s milling insert. Web as indicated on the properties chart, kennametal has a wide variety of carbide grades including fine, medium, and coarse grained tungsten carbides with cobalt binders,. Coatings for solid carbide end mills. Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. Bold type = standard horizon grades and.. Our inserts give you the cutting edges you need to control downtime and reduce wear and. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. Longer term, the company plans to expand on kcp25c with. Web impact strength of kennametal grades is about the same, while kentanium grades are about 20% lower in impact. Cemented tungsten carbide grades for tools, dies, and wear components. Web for success with a turning application, precision and accuracy are key. Kennametal’s milling insert identification system is provided as a general reference.the dimensional tables associated with each insert should be used for. How to understand and make the most out of our grade tables. Kff05 k96 k6 hca ha. Web common applications kennametal grade name legacy name grain family industry classification binder (wt %) other carbides tic (ta, nb) c hardness density (g/cm3). Bold type = standard horizon grades and. %) hardness (hv30 estimated) density (g/cm3) trs c code iso. Our inserts give you the cutting edges you need to control downtime and reduce wear and. Web 15 10 05 20 25 30 35 40 45 c3, c4 We use the pmk convention that is used in most of the cutting tool. Web as indicated on the properties chart, kennametal has a wide variety of carbide grades including fine, medium, and coarse grained tungsten carbides with cobalt binders,. Longer term, the company plans to expand on kcp25c with. These are approximate grade conversions. I have some older kennametal inserts with grades my catalogs do not show what they are good for, i am wanting to sell these inserts but need to know what. Web check out our cutting tool blank grade chart. Kennametal’s milling insert identification system is provided as a general reference.the dimensional tables associated with each insert should be used for. How to understand and make the most out of our grade tables. Web 150 rows kennametal carbide insert grade chart wiith descriptions Cutting tool blanks grade chart. Web for success with a turning application, precision and accuracy are key.Selecting Carbide Inserts for Metalworking Kennametal

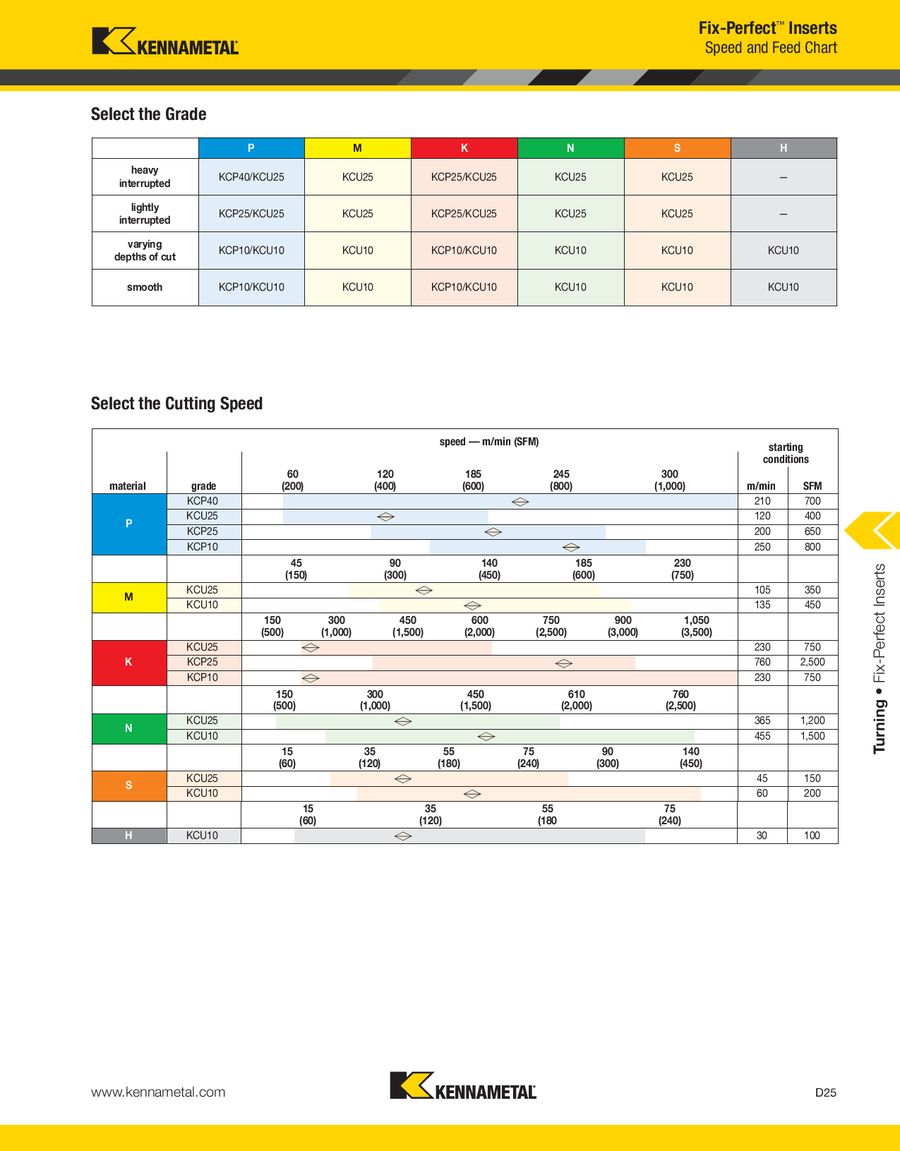

Kennametal Speeds And Feeds Chart A Visual Reference of Charts Chart

Kennametal Insert Grade Chart

Kennametal Grade Chart Transborder Media

kennametal insert chart Focus

Kennametal Inserts Grades Chart

Kennametal Grade Chart Transborder Media

Kennametal Insert Chart

Kennametal A4 Groove & Turn Insert Designation Chart

Kennametal Solid Carbide Drill Selection Guide and Dimensions

Choose From Inserts, Holders, Boring Bars, And More.

Web Kennametal Has Released Kcp25C With Kengold In The Most Common Insert Shapes And Styles:

C, D, S, T, V And W.

Web Impact Strength Of Kennametal Grades Is About The Same, While Kentanium Grades Are About 20% Lower In Impact Strength At Cryogenic Temperatures.

Related Post: