Kennametal Grades Chart

Kennametal Grades Chart - Medium and high carbon steels c <.25%; I have some older kennametal inserts with grades my catalogs do not show what they are good for, i am wanting to sell these inserts but need to know what. Web grade specifications and application chart. / solid end milling grades. For additional options please refer to our european brochure. Web kennametal grade name legacy name grain family industry classification. You can count on the new kcsm15a. Web kennametal plants can manufacture tungsten carbide parts up to 14 in length and up to 7 in diameter. Web this new kennametal grade is excellent when used for either straight or lightly interrupted cut applications. Coatings for solid carbide end mills. Web we divide the grades into several grade statuses: Medium and high carbon steels c <.25%; Web this new kennametal grade is excellent when used for either straight or lightly interrupted cut applications. Cemented tungsten carbide grades for metal forming and wear components. Web / solid carbide end milling. Web we have a complete line of metal cutting tool blanks in a wide selection of tungsten carbide grades with binders ranging from 5.5% to 25%, and grain sizes to suit your application. / solid end milling grades. It provides outstanding protection for solid carbide tools. I have some older kennametal inserts with grades my catalogs do not show what. Web grade specifications and application chart. Web grade specifications and application chart. Coatings for solid carbide end mills. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. Web kennametal plants can manufacture tungsten carbide parts up to 14 in length and up to 7 in diameter. Web grades featured on this chart are primarily supplied to the north american market. Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. Cemented tungsten carbide grades for metal forming and wear components.. %) hardness (hv30 estimated) density (g/cm3) trs c code iso. Moreover, if you’re looking for high productivity performance, the. Web grade specifications and application chart. As indicated on the properties chart, kennametal has a wide variety of. Web / solid carbide end milling. Web we have a complete line of metal cutting tool blanks in a wide selection of tungsten carbide grades with binders ranging from 5.5% to 25%, and grain sizes to suit your application. Common applications kennametal grade name legacy name grain family industry classification binder (wt. As indicated on the properties chart, kennametal has a wide variety of. Web kennametal. It provides outstanding protection for solid carbide tools. Coatings for solid carbide end mills. You can count on the new kcsm15a. Web grade specifications and application chart. Web we divide the grades into several grade statuses: Cd750 only available as standard edm block. Web kennametal grade name alternate or legacy name grain family industry classification cobalt binder (wt. I have some older kennametal inserts with grades my catalogs do not show what they are good for, i am wanting to sell these inserts but need to know what. Coatings for solid carbide end mills. Medium and. Common applications kennametal grade name legacy name grain family industry classification binder (wt. Medium and high carbon steels c <.25%; Web performance grade for milling all types of material.this grade is characterized by good hardness and wear resistance. I have some older kennametal inserts with grades my catalogs do not show what they are good for, i am wanting to. Web 150 rows the new kc8050 turning grade from kennametal inc. Web we divide the grades into several grade statuses: You can count on the new kcsm15a. %) hardness (hv30 estimated) density (g/cm3) trs c code iso. Web / solid carbide end milling. Web kennametal plants can manufacture tungsten carbide parts up to 14 in length and up to 7 in diameter. I have some older kennametal inserts with grades my catalogs do not show what they are good for, i am wanting to sell these inserts but need to know what. Cd750 only available as standard edm block. Web we divide the grades into several grade statuses: Moreover, if you’re looking for high productivity performance, the. Web / solid carbide end milling. It provides outstanding protection for solid carbide tools. %) hardness (hv30 estimated) density (g/cm3) trs c code iso. Kc850 exsists, but it is not recomended by kennametal for any application in their catalogs. Medium and high carbon steels c <.25%; Web kennametal grade name legacy name grain family industry classification. Web grades featured on this chart are primarily supplied to the north american market. Web we have a complete line of metal cutting tool blanks in a wide selection of tungsten carbide grades with binders ranging from 5.5% to 25%, and grain sizes to suit your application. Web grade specifications and application chart. Medium and high carbon steels c <.25%; Grade specifications and application chart | pdf | steel | corrosion.

Kennametal Solid Carbide Drill Selection Guide and Dimensions

Kennametal Indexable Milling Grade Charts

Kennametal KSSR Milling Application Guide

Kennametal Grade Chart Transborder Media

Kennametal A4 Groove & Turn Insert Designation Chart

Machining Resources US Alloy Die Corporation

Selecting Carbide Inserts for Metalworking Kennametal

Kennametal Drill Fix DFS Indexable Drilling Application Guide

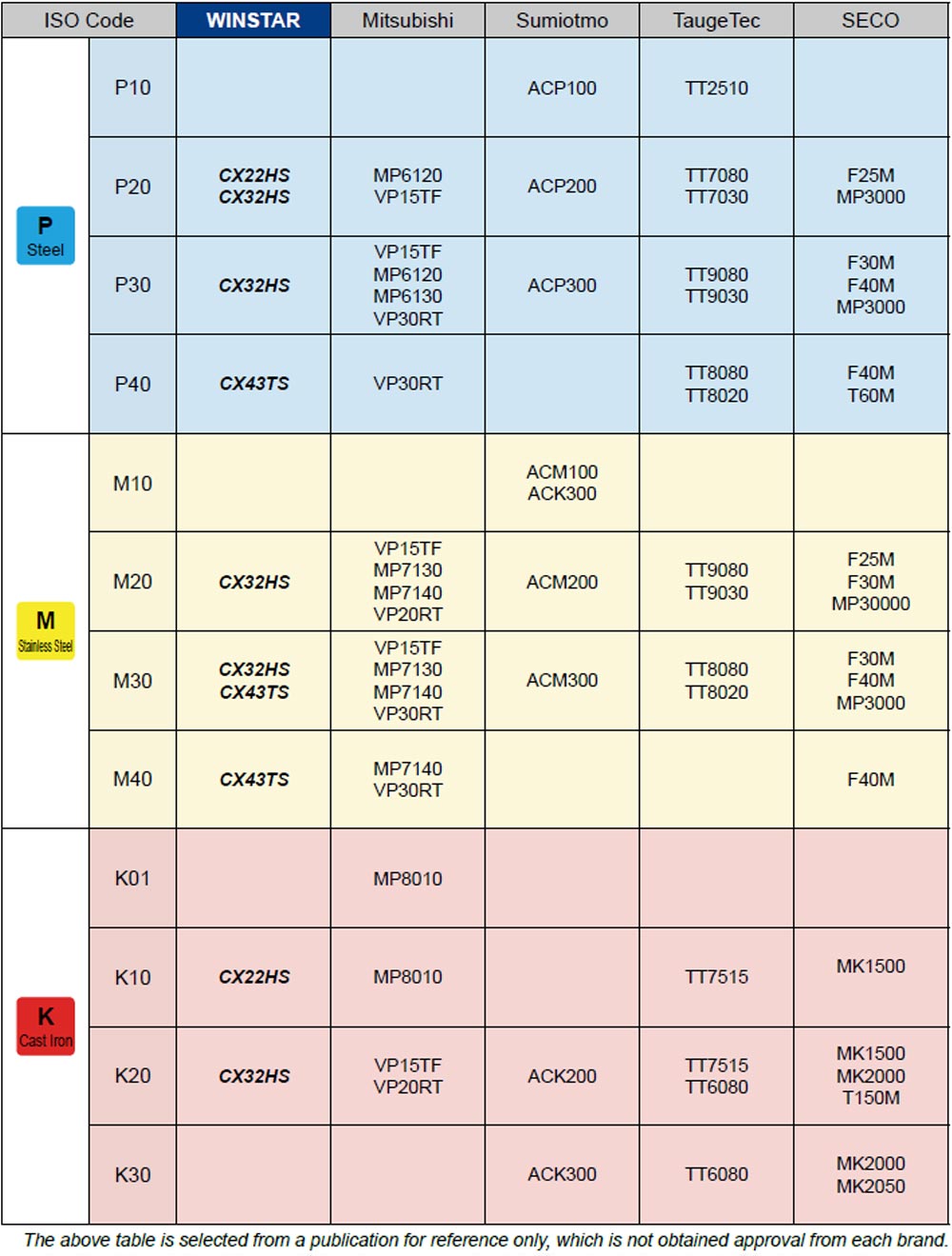

Carbide Insert Grade Comparison Chart Images

(30) KENNAMETAL MISC. KCPK30 GRADE CARBIDE INSERT

Web Performance Grade For Milling All Types Of Material.this Grade Is Characterized By Good Hardness And Wear Resistance.

Introducing Kennametal's Newest Solid End Milling Grade.

Web This Numbering System Chart From The Kennametal Innovations Catalog Provides A Guide To The Company’s Extensive Assortment Of Turning Inserts.

Cemented Tungsten Carbide Grades For Metal Forming And Wear Components.

Related Post: