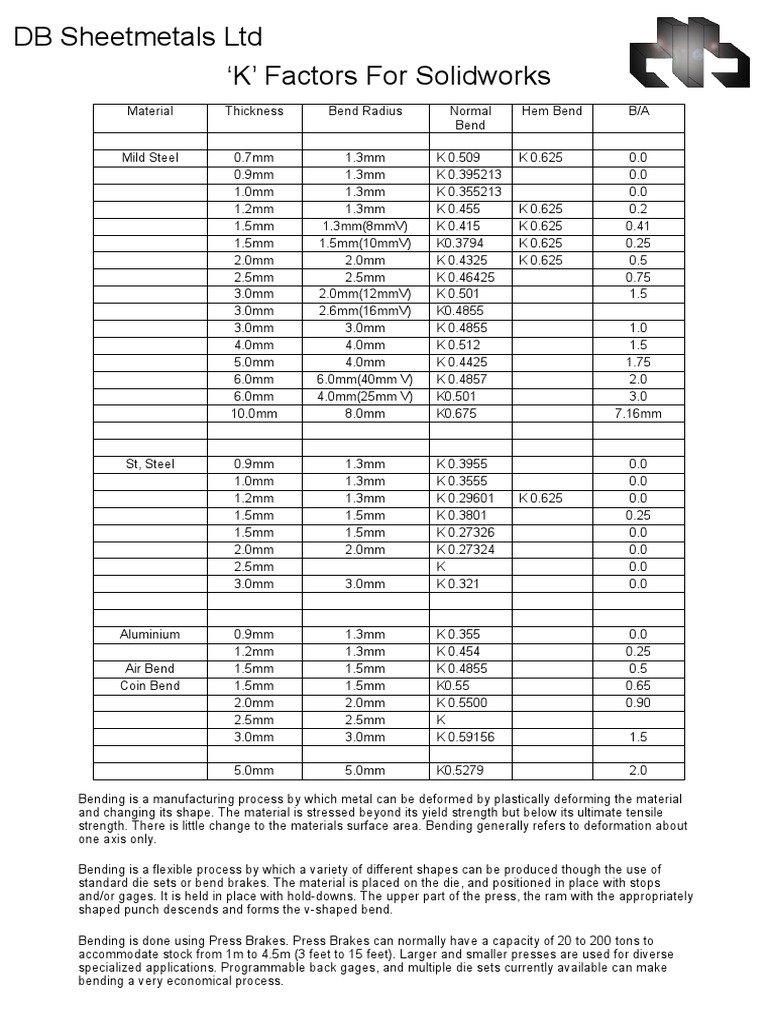

K Factor Chart

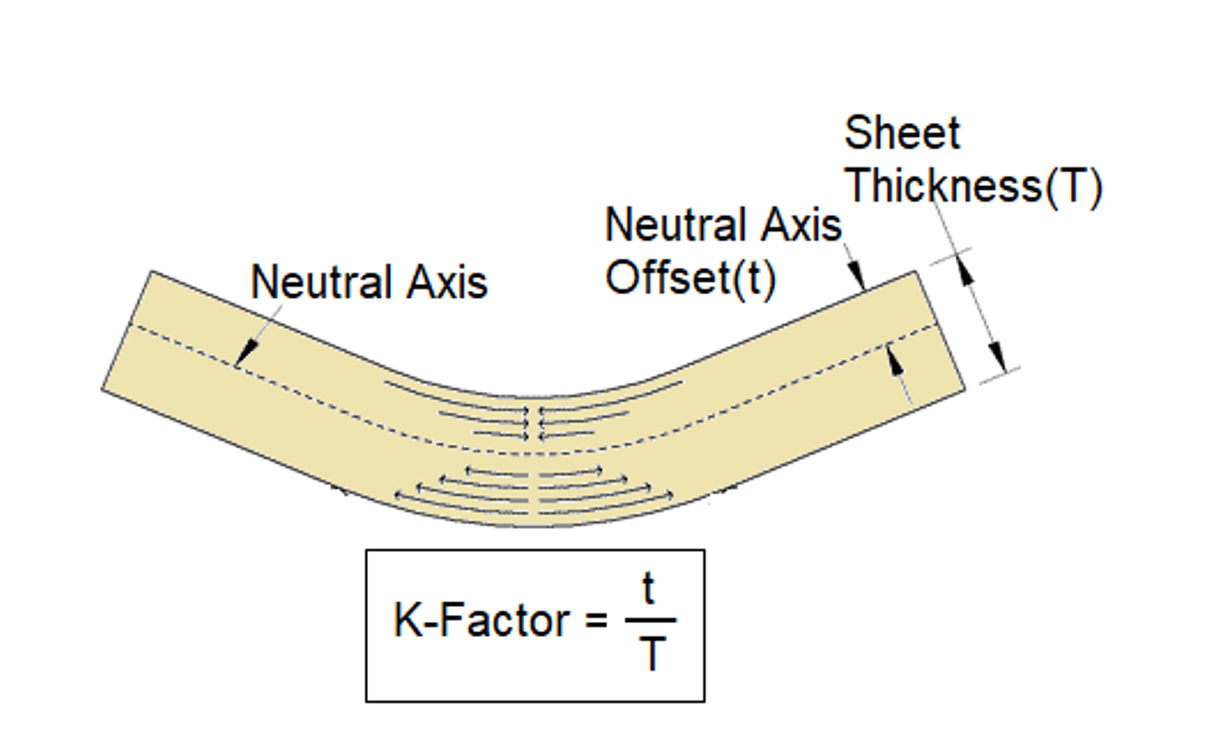

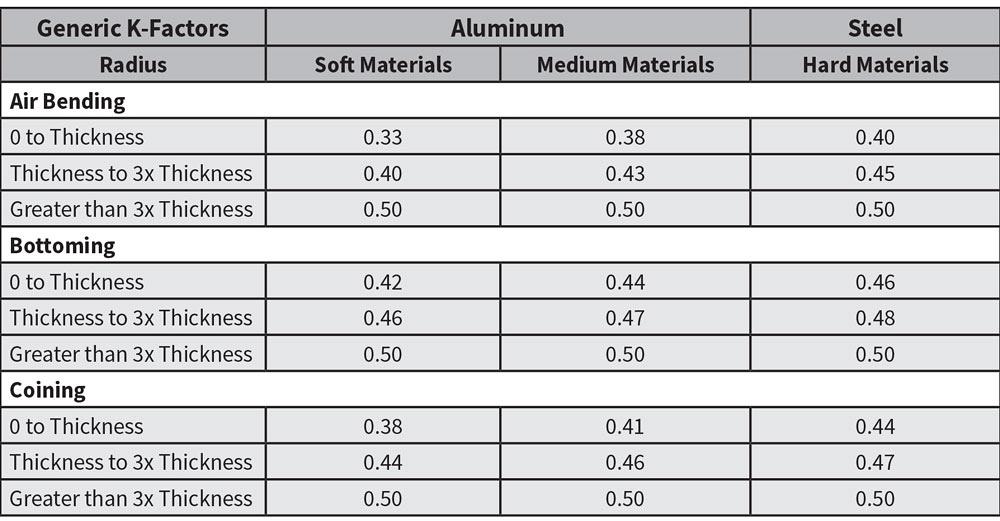

K Factor Chart - How to calculate bend allowance? All those questions are discussed in this post along with some bending tips. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. There’s a lot that goes into this value and various factors that affect it, many of which we covered last month. Sheet metal is the building block of structures, from forming the body of automobiles to the skin of aircraft wings. Because of the specific properties of any given metal, there is no easy way to calculate that value perfectly, hence the chart in figure 2. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. In essence, it's nothing more than the ratio of the sheet metal thickness to the neutral axis, i.e. Die dicke des zu biegenden blechs. It is also an independent value used to calculate the bending allowance (ba) under various situations, such as material thickness, bending radius/angle. This has been illustrated in the image given below for. Die dicke des zu biegenden blechs. The only truly effective way of working out the correct bend allowance is to reverse engineer it by taking a measured strip of material, bending it, and then measuring it to calculate the bend allowance. Input material thickness and and inner radius to get. Between t (distance between the inside of the bend and the neutral plane) and t (the workpiece thickness). The only truly effective way of working out the correct bend allowance is to reverse engineer it by taking a measured strip of material, bending it, and then measuring it to calculate the bend allowance. Input material thickness and and inner radius. Web what is the k factor in sheet metal? Web to calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. After bending the sheet, insert the inner radius, and flanges a and b. Web mathematically k factor value is. Web what is the k factor? Input material thickness and and inner radius to get the k factor. It is also an independent value used to calculate the bending allowance (ba) under various situations, such as material thickness, bending radius/angle. Between t (distance between the inside of the bend and the neutral plane) and t (the workpiece thickness). All those. Between t (distance between the inside of the bend and the neutral plane) and t (the workpiece thickness). Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend.. Between t (distance between the inside of the bend and the neutral plane) and t (the workpiece thickness). In essence, it's nothing more than the ratio of the sheet metal thickness to the neutral axis, i.e. How to calculate bend allowance? Web what is the k factor in sheet metal? Web mathematically k factor value is equal to the ratio. 63k views 5 years ago #sheetmetal #engineering #kfactor. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. How to calculate bend allowance? In essence, it's nothing more than the ratio of the sheet metal thickness to the neutral axis, i.e. After bending the sheet, insert the inner radius, and. Web what is the k factor in sheet metal? Between t (distance between the inside of the bend and the neutral plane) and t (the workpiece thickness). It is also an independent value used to calculate the bending allowance (ba) under various situations, such as material thickness, bending radius/angle. Knowing the tools helps you to engineer products that can be. This has been illustrated in the image given below for. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances. Web to calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the. This has been illustrated in the image given below for. Web what is the k factor? Web the experts at fma provide q deep dive into the k factor, what it is, and why it matters. Because of the specific properties of any given metal, there is no easy way to calculate that value perfectly, hence the chart in figure. Web the experts at fma provide q deep dive into the k factor, what it is, and why it matters. There’s a lot that goes into this value and various factors that affect it, many of which we covered last month. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Knowing the tools helps you to engineer products that can be manufactured. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances. 63k views 5 years ago #sheetmetal #engineering #kfactor. Web what is the k factor? Web what is the k factor in sheet metal? It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Between t (distance between the inside of the bend and the neutral plane) and t (the workpiece thickness). The only truly effective way of working out the correct bend allowance is to reverse engineer it by taking a measured strip of material, bending it, and then measuring it to calculate the bend allowance. We have also written another important post about press brake tooling. Web mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Input material thickness and and inner radius to get the k factor. Web to calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. After bending the sheet, insert the inner radius, and flanges a and b.

What is KFactor? Reference Chart from AGF Manufacturing

Sheet Metal K Factor (with Calculator and Formula)

K Factors + Bending Info Sheet Metal Industries

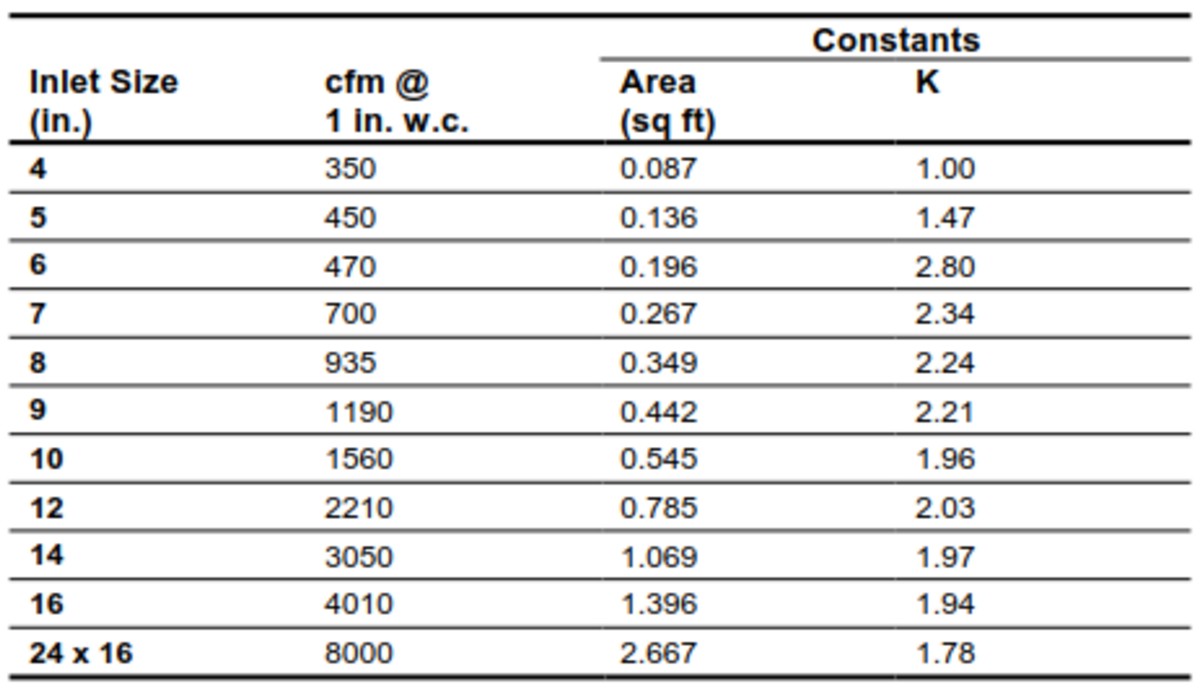

35 HYDRAULIC K FACTOR TABLE

Kfactor & Transformers Power Quality Blog

Analyzing the kfactor in sheet metal bending Part II

K Factor Table Statistics Elcho Table

Gc Column Equivalent Chart

Kfactors, Yfactors, and press brake bending precision

What is the K factor and how do we use it in HVAC applications? Hvac

Die Dicke Des Zu Biegenden Blechs.

It Is Also An Independent Value Used To Calculate The Bending Allowance (Ba) Under Various Situations, Such As Material Thickness, Bending Radius/Angle.

How To Calculate Bend Allowance?

Also, Find Our K Factor Calculator For The Bend Radius Formula Here.

Related Post: