Jic Fittings Chart

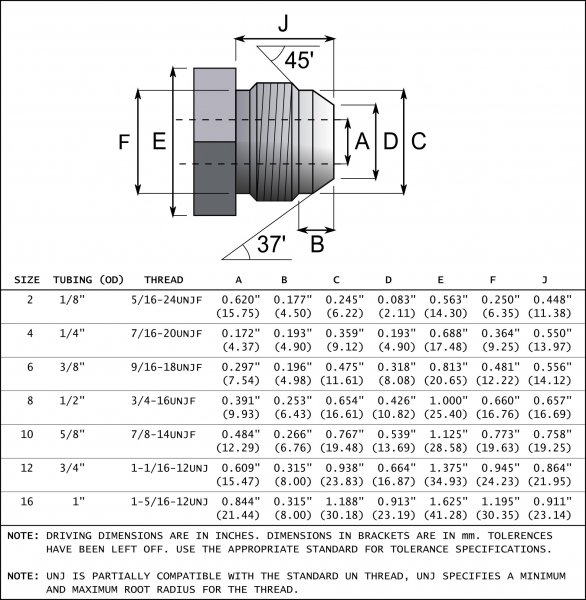

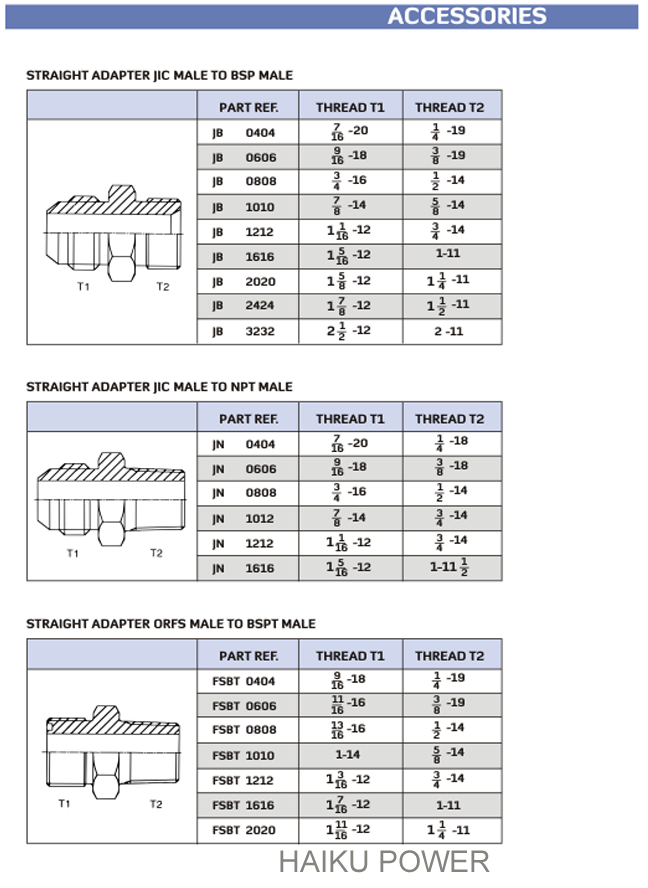

Jic Fittings Chart - Component function, material compatibility, component pressure and temperature rating, proper installation, operation and maintenance remain the sole responsibility of the system designer and the user. Web refer to this thread size chart, and ensure accurate measurement of jic fittings by comparing the thread o.d., thread i.d., and jic flare measurements for each fitting type. Annular tool marks of 100uin concentric with thread are permissible. Several flaring methods, ranging from simple hand flaring to hydraulic/electric power flaring, are available. Therefore, it is a preferred method of flaring. Choose from our selection of jic fittings, including over 1,200 products in a wide range of styles and sizes. Please contact us today at. Web the selection of component for any application or system design must be considered to ensure safe performance. Fittings according to sae j514 can also be used to connect flexible hose assemblies. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Web assembly procedure (drawing as follow) get ready tube with applicable length. Inspect for possible contamination or damage from shipping or handling. Slip in the nut and sleeve onto the tube end. Record the values and compare your measurements with the figures provided in this guide. Web hydraulic hose fittings & connector sizes charts. Web hydraulic hose fittings & connector sizes charts. Web jic fitting dimensions standard. Inspect for possible contamination or damage from shipping or handling. Below we’ve compiled hydraulic hose fittings charts that detail some of the more common fitting sizes and types currently in use by pipefitters and other professionals. Web in this article we cover jic pipe fittings, commonly known. Tighten the nut by using spanner & finger until the nut is tight. Web the selection of component for any application or system design must be considered to ensure safe performance. Web jic fitting dimensions standard. Web to get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. The names an fittings, jic fittings,. Below we’ve compiled hydraulic hose fittings charts that detail some of the more common fitting sizes and types currently in use by pipefitters and other professionals. Sealing surface should be smooth. Web to get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. Also known as check valves, these open to allow flow in. Slip in the nut and sleeve onto the tube end. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Form the end of the tube to 37 degrees by using flaring tool. When a male fitting and female fitting are mated, a mechanical seal is formed on the cone seat. Web hydraulic hose fittings & connector sizes. Jic fittings (aka sae 37° tube fittings, flared fittings, or sae j514 fittings ) are the most popular hydraulic fluid connector in north america. Web on an 37° flare fittings, both male and female fittings are made according to class 3a/3b unj/unjf radiused root threads. Therefore, it is a preferred method of flaring. Form the end of the tube to. Web assembly procedure (drawing as follow) get ready tube with applicable length. Below we’ve compiled hydraulic hose fittings charts that detail some of the more common fitting sizes and types currently in use by pipefitters and other professionals. Jic (joint industry council) fittings are widely used in fuel delivery and fluid power applications Web to get an accurate value, ensure. The names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types. Tighten the nut by using spanner & finger until the nut is tight. Below we’ve compiled hydraulic hose fittings charts that detail some of the more common fitting sizes and types currently in use by pipefitters and other professionals.. They are typically made from nickel alloys, brass, carbon steel, and stainless steel and are widely used in fluid power systems. Web refer to this thread size chart, and ensure accurate measurement of jic fittings by comparing the thread o.d., thread i.d., and jic flare measurements for each fitting type. Web hydraulic hose fittings & connector sizes charts. Jic fittings. Form the end of the tube to 37 degrees by using flaring tool. Jic (joint industry council) fittings are widely used in fuel delivery and fluid power applications Sealing surface should be smooth. Tighten the nut by using spanner & finger until the nut is tight. 45°, 90°, straight, cross, and tee Therefore, it is a preferred method of flaring. Begin by using a caliper to measure the port hole diameter the bolt. Also known as check valves, these open to allow flow in one direction and close when flow stops or reverses. Jic fittings (aka sae 37° tube fittings, flared fittings, or sae j514 fittings ) are the most popular hydraulic fluid connector in north america. Web assembly procedure (drawing as follow) get ready tube with applicable length. The names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types. Web jic fitting dimensions standard. Web the acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. When a male fitting and female fitting are mated, a mechanical seal is formed on the cone seat. Jic (joint industry council) fittings are widely used in fuel delivery and fluid power applications Inspect for possible contamination or damage from shipping or handling. J screw threads have a root radius that improves the tensile stress area of the fastener while reducing the stress concentration in. Please contact us today at. Power flaring is quicker and produces more accurate and consistent flares compared to hand flaring. Below we’ve compiled hydraulic hose fittings charts that detail some of the more common fitting sizes and types currently in use by pipefitters and other professionals. Web in this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings.Jic Hydraulic Fittings Size Chart Images and Photos finder

Jic Fitting Size Chart Pdf

Fitting Thread Size Chart Printable Michigan

Caterpillar Hydraulic Fitting Catalog Catalog Library

AN and JIC Fittings

jic fittings dimensions chart Medi Business News

Tabla de tallas de accesorios JIC de rosca SAE Conocimiento Fábrica

Hydraulic Hose Fittings Chart ubicaciondepersonas.cdmx.gob.mx

JIC Fittings Chart Hydraxio China SS Hydraulic Fittings Manufacturer

Jic Fittings Chart A Visual Reference of Charts Chart Master

Choose From Our Selection Of Jic Fittings, Including Over 1,200 Products In A Wide Range Of Styles And Sizes.

Form The End Of The Tube To 37 Degrees By Using Flaring Tool.

Web Refer To This Thread Size Chart, And Ensure Accurate Measurement Of Jic Fittings By Comparing The Thread O.d., Thread I.d., And Jic Flare Measurements For Each Fitting Type.

They Are Typically Made From Nickel Alloys, Brass, Carbon Steel, And Stainless Steel And Are Widely Used In Fluid Power Systems.

Related Post: