Ideal Air Fuel Ratio Chart

Ideal Air Fuel Ratio Chart - This ratio is crucial for several reasons: For a gasoline (petrol) engine, the stoichiometric air fuel ratio is around 14.7:1. Camshafts with very little overlap, short durations, and gentle ramp rates allow very high vacuum (suction) forces to be attained at low engine speeds. Web the ideal ratio is generally around 14.7:1. When burned all fuel and air is consumed without any excess left over. Web the stoichiometric mixture for a gasoline engine is the ideal ratio of air to fuel that burns all fuel with no excess air. This is referred to as the “ stoichiometric ” mixture. This occurs when we have 14.7 parts of air to one part of fuel, or an air/fuel ratio of 14.7:1. A modern engine will take information from various different sensors (such as throttle position, mass air flow, and lambda/o2 sensors to name a few) and alter the amount of fuel being delivered to adjust the air/fuel ratio accordingly. Many choose to go even richer, even 11.5:1. This the amount of air required for the complete combustion of the fuel, known as the stoichiometric mixture or lambda 1.0. A modern engine will take information from various different sensors (such as throttle position, mass air flow, and lambda/o2 sensors to name a few) and alter the amount of fuel being delivered to adjust the air/fuel ratio accordingly. Web. The combustion is possible even is the afr is different than. Web the safest air/fuel ratios are continuously being debated, but it is widely accepted that 13:1 is a good ratio for normally aspirated engines and 12:1 is good for forced induction engines. The ratios do not tell the full picture though. For a gasoline (petrol) engine, the stoichiometric air. This the amount of air required for the complete combustion of the fuel, known as the stoichiometric mixture or lambda 1.0. Web first, you need to select other as the fuel type. A modern engine will take information from various different sensors (such as throttle position, mass air flow, and lambda/o2 sensors to name a few) and alter the amount. In this case you have 14.7 parts of air for every 1 part of fuel. Web the ideal ratio is generally around 14.7:1. Camshafts with very little overlap, short durations, and gentle ramp rates allow very high vacuum (suction) forces to be attained at low engine speeds. The afr calculator gives you the rate between the mass of air and. Process heating equipment are rarely run that way. A modern engine will take information from various different sensors (such as throttle position, mass air flow, and lambda/o2 sensors to name a few) and alter the amount of fuel being delivered to adjust the air/fuel ratio accordingly. In this case you have 14.7 parts of air for every 1 part of. This occurs when we have 14.7 parts of air to one part of fuel, or an air/fuel ratio of 14.7:1. This means that for every kilogram of fuel, 12.5 to 15 kilograms of air are required for complete combustion. Those are the air to fuel ratios for the most common fuels, by mass, known as the stoichiometric ratio. Web the. That’s 14.7 parts air for every 1 part of fuel. This means that, in order to burn completely 1 kg of fuel, we need 14.7 kg of air. The combustion is possible even is the afr is different than. This means that for every kilogram of fuel, 12.5 to 15 kilograms of air are required for complete combustion. Camshafts with. In this case you have 14.7 parts of air for every 1 part of fuel. That’s 14.7 parts air for every 1 part of fuel. Different fuels have different weights and work best at different air/fuel ratios. When burned all fuel and air is consumed without any excess left over. Web what is the normal afr at idle? Camshafts with very little overlap, short durations, and gentle ramp rates allow very high vacuum (suction) forces to be attained at low engine speeds. Those are the air to fuel ratios for the most common fuels, by mass, known as the stoichiometric ratio. For a gasoline (petrol) engine, the stoichiometric air fuel ratio is around 14.7:1. Web the ideal ratio. Process heating equipment are rarely run that way. Those are the air to fuel ratios for the most common fuels, by mass, known as the stoichiometric ratio. Web the stoichiometric mixture for a gasoline engine is the ideal ratio of air to fuel that burns all fuel with no excess air. That’s 14.7 parts air for every 1 part of. For most gasoline engines, the afr at idle typically ranges from 14.7:1 to 15:1, as this is the stoichiometric ratio where complete combustion occurs. Web first, you need to select other as the fuel type. Web typically, maximum engine power is achieved using an air/fuel ratio of around 12:1. The afr calculator gives you the rate between the mass of air and the mass of fuel of a complete combustion process. The stoichiometric point is the afr where all of the oxygen in the air burns with all of the fuel. For a gasoline (petrol) engine, the stoichiometric air fuel ratio is around 14.7:1. Web the safest air/fuel ratios are continuously being debated, but it is widely accepted that 13:1 is a good ratio for normally aspirated engines and 12:1 is good for forced induction engines. They are the perfect ratios for a. The combustion is possible even is the afr is different than. How much air is required for the combustion of 1 kg of fuel? For every one gram of fuel, 14.7 grams of air are required. For pure octane fuel, the oxidation reaction is: The ratios do not tell the full picture though. Web the ideal ratio is generally around 14.7:1. Many choose to go even richer, even 11.5:1. This is handy to use when looking at a wideband display/gauge that displays a gas scale afr or just for curiosity’s sake.

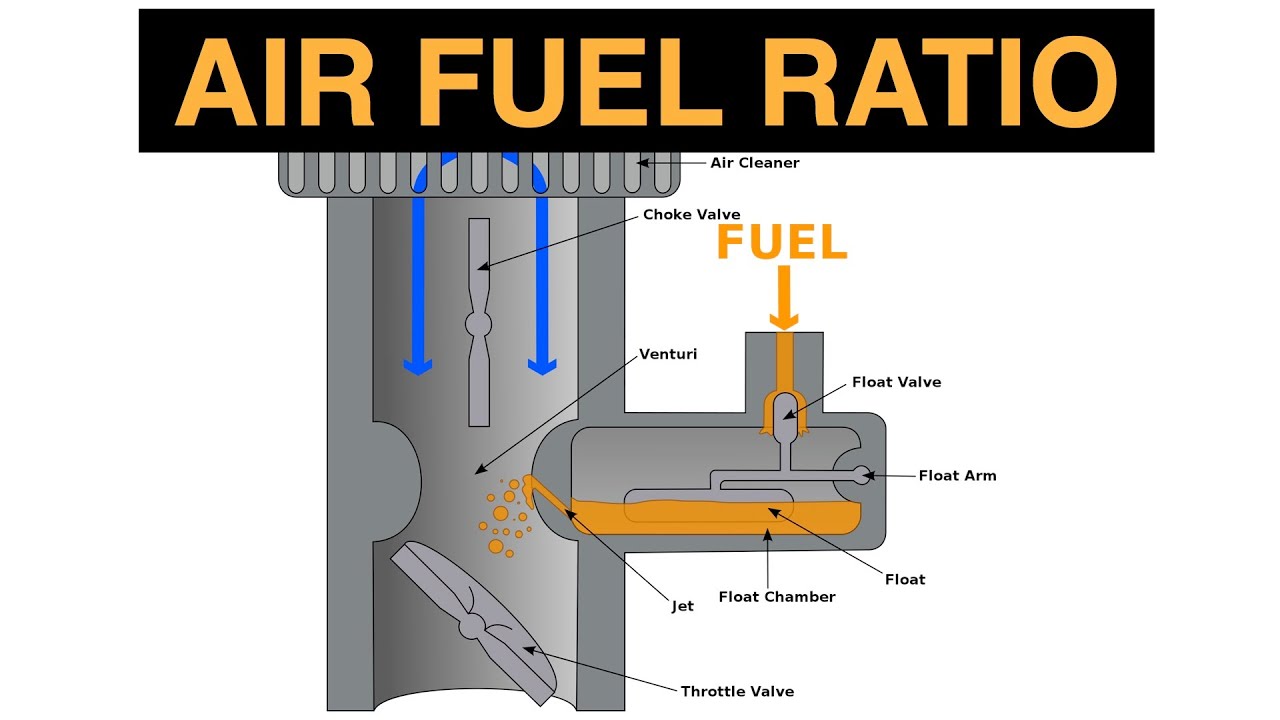

Air Fuel Ratio Explained YouTube

Air/Fuel Ratio Cycledoctor

Air Fuel Ratio chart Pelican Parts Forums

What is a Good AirFuel Ratio? (Chart Included) In The Garage with

April 2015 Learn How To Tune EFI Engine

426 Hemi Build Size Does Matter, Part 1 Hot Rod Network

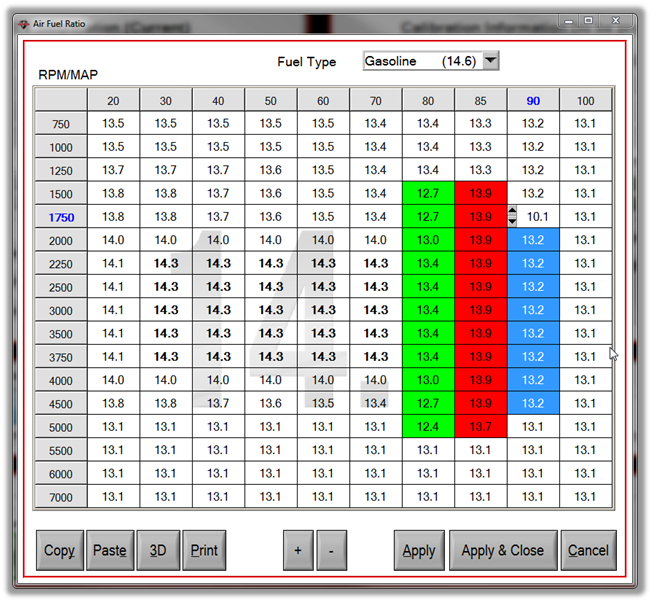

4.3 AFR Ratio Table TechnoResearch Manuals

Air Fuel Ratios for NA Engines Engine & fuel engineering EngTips

What Is Air Fuel Ratio And Why Is It Important

and isooctane )*** .

Process Heating Equipment Are Rarely Run That Way.

In This Case You Have 14.7 Parts Of Air For Every 1 Part Of Fuel.

This Ratio Is Crucial For Several Reasons:

This Occurs When We Have 14.7 Parts Of Air To One Part Of Fuel, Or An Air/Fuel Ratio Of 14.7:1.

Related Post: