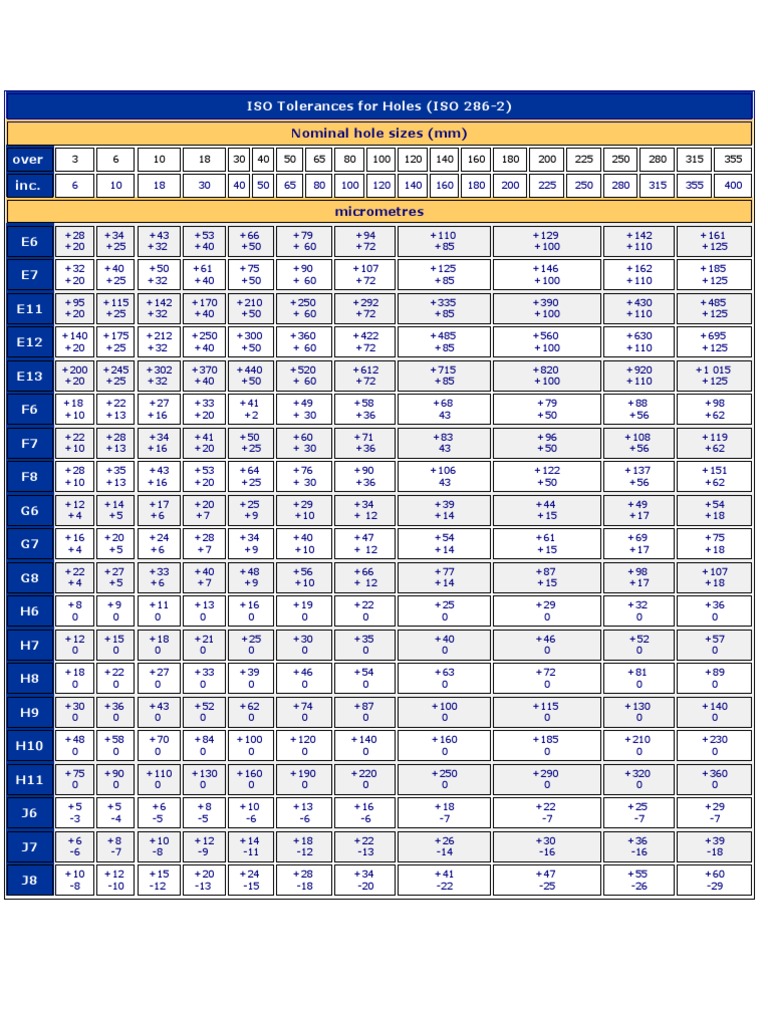

H8 Tolerance Chart

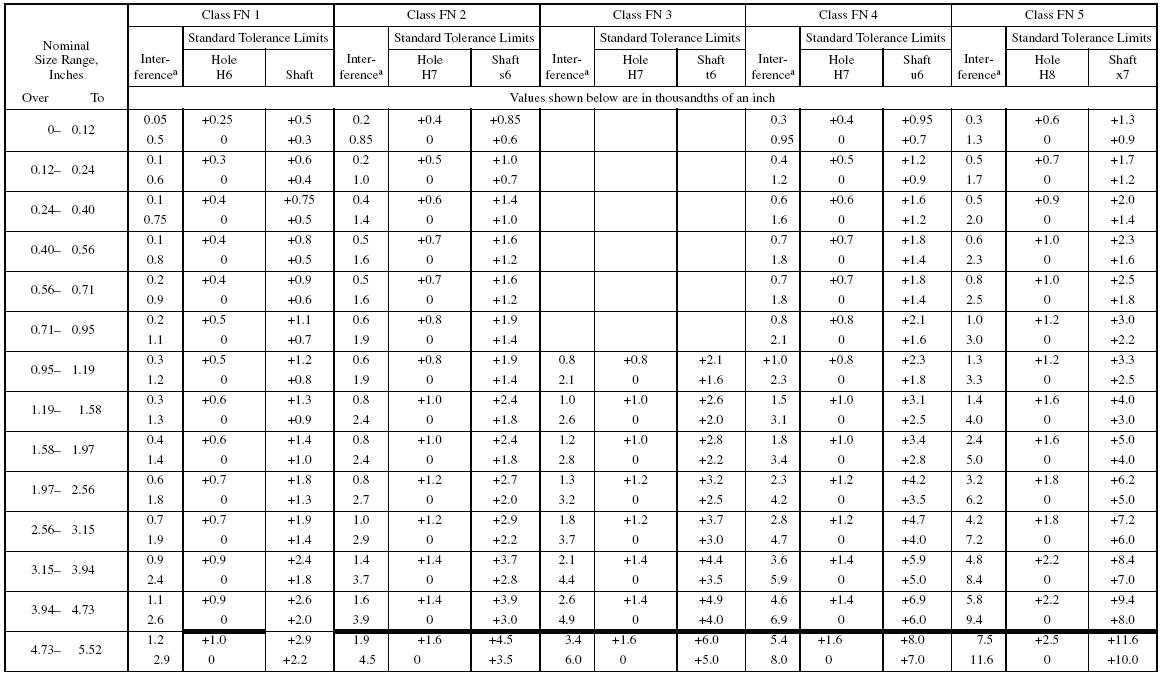

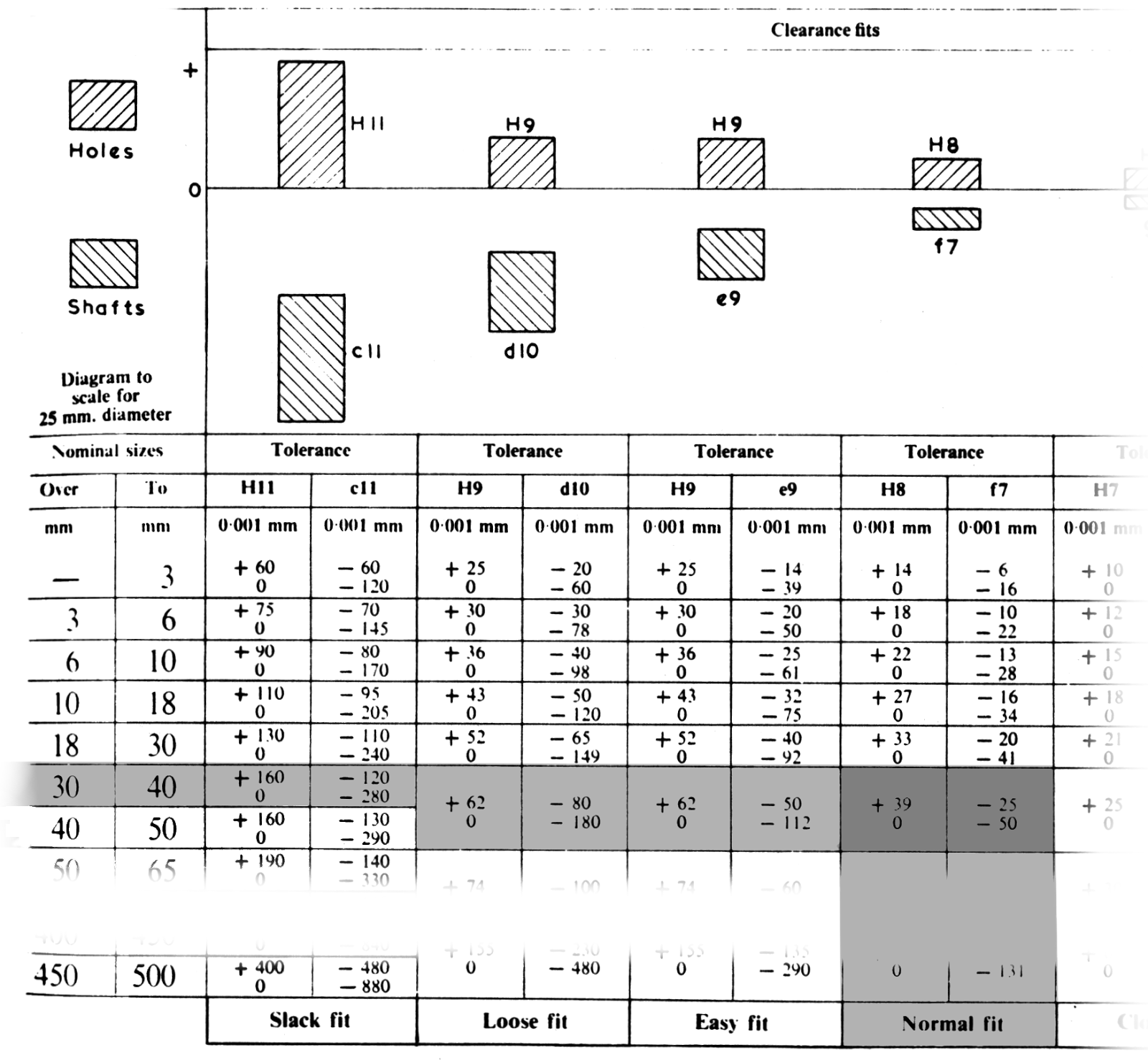

H8 Tolerance Chart - H8 +18 0 +22 0 +27 0 +33 0 +39 0 +46 0 +54 0 +63 0 +72 0 +81 0 +89 0. Enter your desired preferred tolerance grade and the nomial size, or see the table of hole tolerances per. Find your data faster with our fits and tolerance calculator. Web nominal shaft sizes (mm) over 3 B10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6. Also see table of hole tolerances per. This mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. Web learn how to use the iso 286 system to specify and calculate tolerances for shafts and holes. Iso metric tolerance zone limits and fits. General iso geometrical tolerances per. Tolerances can be applied to holes and shafts as well as other shapes. The following defines the preferred tolerance basis for hole and shaft per. International tolerance (it) grades table reference iso 286. This mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. Note some tolerance classes are only provided for a restricted number of nominal. This mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. Compare the grades h8, h9, h11, h13 and h14 for shaft and hole features. Iso metric tolerance zone limits and fits. Web hole tolerance range class. Also see table of hole tolerances per. Web determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator. Enter your desired preferred tolerance grade and the nomial size. Web given in tables 2 to 16, are not intended to give detailed directives on the selection of tolerance classes for any purpose. Iso metric tolerance zone limits and fits. International tolerance (it) grades table. Iso metric tolerance zone limits and fits. See the charts for millimeters and inches units and use the fits calculator for explanations. H8 +18 0 +22 0 +27 0 +33 0 +39 0 +46 0 +54 0 +63 0 +72 0 +81 0 +89 0. Green = prefered tolerance classes per iso 286. Compare the grades h8, h9, h11, h13. General iso geometrical tolerances per. Web complete charts for h8/e7 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. H8 +18 0 +22 0 +27 0 +33 0 +39 0 +46 0 +54 0 +63 0 +72 0 +81 0 +89 0. H8 is a close running fit for accurate machines and location. Web complete charts for h8/e7 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. Web given in tables 2 to 16, are not intended to give detailed directives on the selection of tolerance classes for any purpose. The following defines the preferred tolerance basis for hole and shaft per. Iso metric tolerance zone. International tolerance (it) grades table reference iso 286. Web complete charts for h8/e8 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Web complete charts for h8/e7 clearance fit per iso 286, including size. Web given in tables 2 to 16, are not intended to give detailed directives on the selection of tolerance classes for any purpose. Find interactive charts, terminology explanations, and a calculator for different units and fit types. Web find the size and tolerance zones for bolts and holes per iso 286 standard. These dimensions are standardized limits for assemblies of. The following defines the preferred tolerance basis for hole and shaft per. See the schematic representation of the fit, the tolerance designation, and the basic terminology for tolerances and deviations. Enter your desired preferred tolerance grade and the nomial size, or see the table of hole tolerances per. H9 +30 0 +36 0 +43 0 +52 0 +62 0 +74. H9 +30 0 +36 0 +43 0 +52 0 +62 0 +74 0 +87. Web mechanical tolerance chart data. Web table of metric shaft tolerances per. Web nominal shaft sizes (mm) over 3 Tolerances can be applied to holes and shafts as well as other shapes. Note some tolerance classes are only provided for a restricted number of nominal size ranges. General iso geometrical tolerances per. Web hole tolerance range class. Iso metric tolerance zone limits and fits. Web nominal shaft sizes (mm) over 3 This mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Also see table of hole tolerances per. Find your data faster with our fits and tolerance calculator. Web determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator. Web find the size and tolerance zones for bolts and holes per iso 286 standard. Compare the grades h8, h9, h11, h13 and h14 for shaft and hole features. Tolerances can be applied to holes and shafts as well as other shapes. Web find the plus and minus tolerance for any iso 286 hole tolerance grade and nominal size. Open iso 286 table of hole & bore tolerances calculator. These dimensions are standardized limits for assemblies of mechanical component.

Tolerances H8

ISO Hole Tolerance Chart

Download Iso 2768 Hole Tolerance Software pixlinoa’s blog

Iso 2768 hole tolerance table soswebsites

Iso fits and tolerances chart pasays

Iso 2768 Hole Tolerance Calculator metricsload

Iso 2768 Hole Tolerance Table

ISO Tolerances for Holes & Shafts

iso hole tolerance chart pdf Focus

Iso 2768 Hole Tolerance Table downafile

Enter Your Desired Preferred Tolerance Grade And The Nomial Size.

See The Charts For Millimeters And Inches Units And Use The Fits Calculator For Explanations.

Web Given In Tables 2 To 16, Are Not Intended To Give Detailed Directives On The Selection Of Tolerance Classes For Any Purpose.

Open Iso 286 Table Of Shaft Tolerances Calculator.

Related Post: