Grinding Wheel Grit Chart

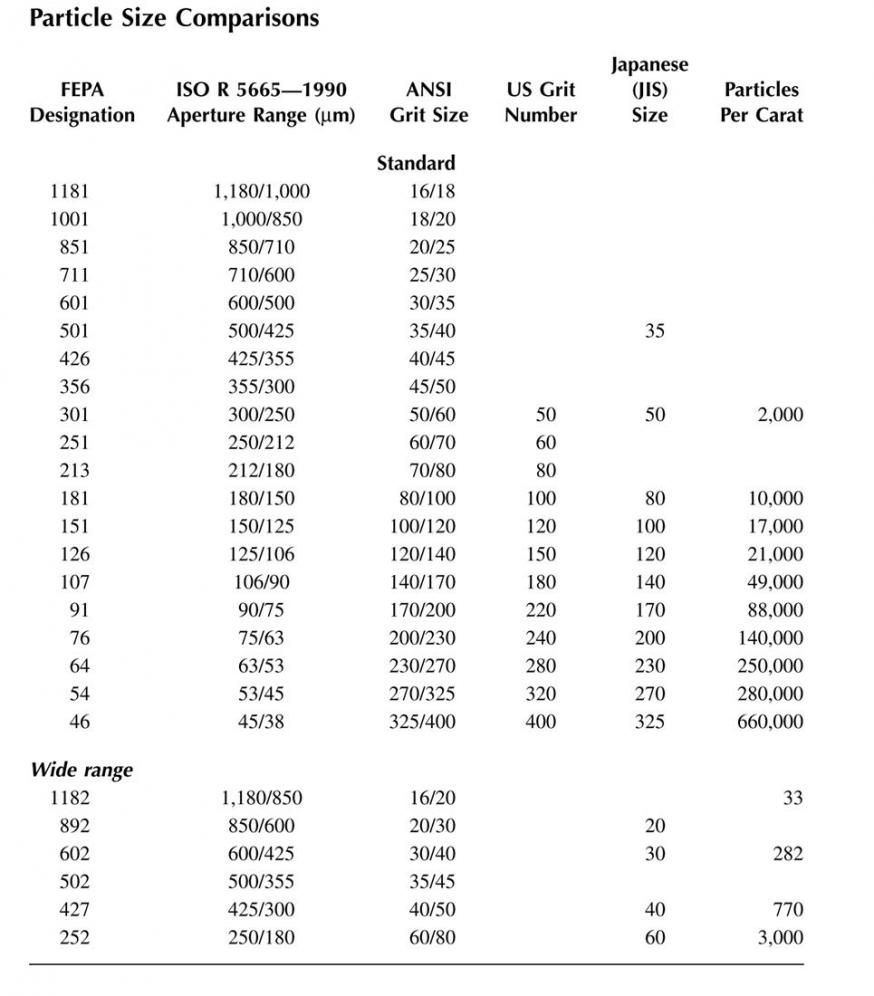

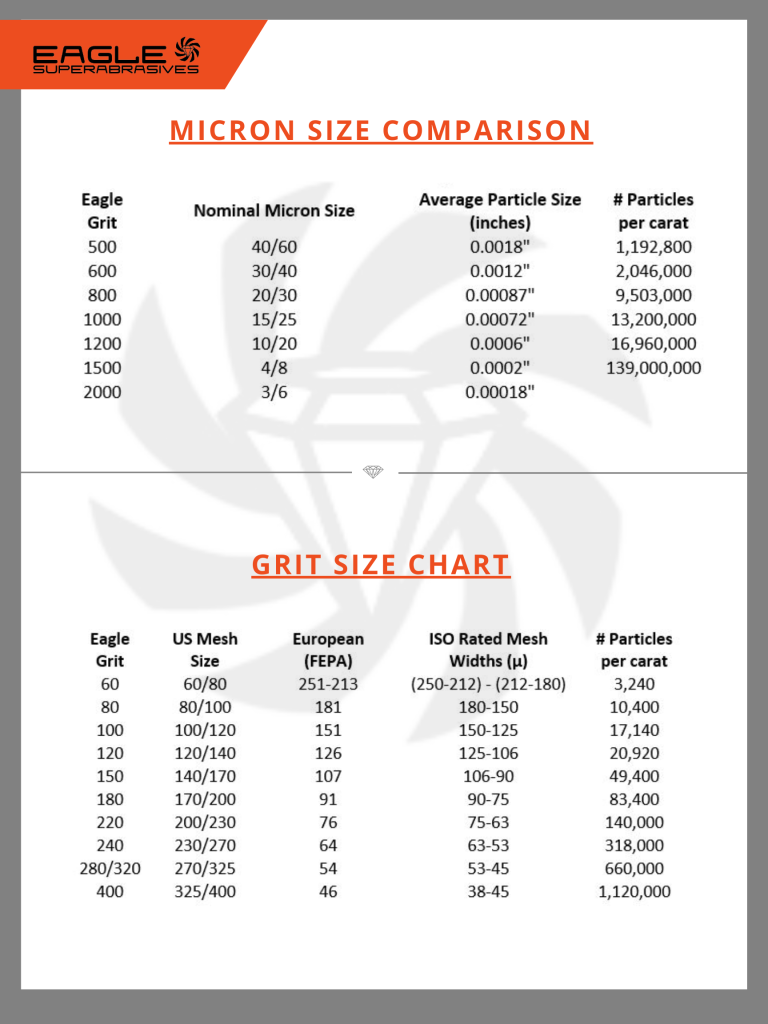

Grinding Wheel Grit Chart - Web lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. 8, 10, 12, 14, 18, 20, 24. There are nine main factors to be considered when selecting a grinding wheel for any application: Our friendly and knowledgeable staff will provide you with unparalleled customer service, offering advice and support along the way. What is a grinding wheel? These abrasive grains perform the same function just like the teeth like a saw. Web cbn (cubic boron nitride) is a type of superhard material, second only to diamond in its hardness. Harder or stronger bonds in grinding. Web in general terms, the abrasive grit size range for grinding wheels runs between 12 grit for rough grinding operations, such as those found in steel mills, and 220 grit for very fine/precision grinding operations. Review our selection include id and bearing wheels, cylinder wheels, and other shapes. Hardness is dependent on the grit type, the material being ground, the amount of stock removed, and a number of other factors. A/o also means aluminum oxide; When you’re ready to try the best, trust the experts at eagle superabrasives. Grit measurements generally range from coarse to fine. Work out the shape of the material and the surface finish (or. It is a crucial factor that influences the wheel's cutting ability, stock removal rate, and the surface finish of the workpiece. On weiler abrasives' grinding wheels, the coarsest grit has a rating of about 24 and the finest grit — the grit on snagging wheels —. Web cbn (cubic boron nitride) is a type of superhard material, second only to. Review our selection include id and bearing wheels, cylinder wheels, and other shapes. You need to create a form using contact form 7 plugin to be able to display it using this element. The dimension of the abrasive particle is referred to as grain size or grit size. Web grit size refers to the size of the abrasive particles embedded. This is a good starting point. On the other hand, fine grit wheels are preferred when finish is a fundamental aspect of the project. Web a grinding wheel, also known as an abrasive wheel, is a wheel made of abrasive particles bound together by various substances, such as rubber, shellac or silicate. When to select a coarse grit size: Web. A cbn wheel is essentially a grinding wheel made of cbn particles bonded together with other materials, such as resin or metal. The tool, the grinding wheel and application must be in agreement to ensure safe operation. Web below we have included a chart that displays the standard of grit size and the effect it has on the finishing surfaces.. True the wheel face and sides to eliminate any wheel runout for. When you’re ready to try the best, trust the experts at eagle superabrasives. For satisfactory results when grinding tool steels, the grinding wheel must be selected carefully. When to select a coarse grit size: Web selecting the right grinding wheel. You need to create a form using contact form 7 plugin to be able to display it using this element. Web lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. True the wheel face and sides to eliminate any wheel runout for. Web grinding wheels with a low grit size are commonly used in applications. Where the neatness of the surface finish is not essential to the. Review our selection include id and bearing wheels, cylinder wheels, and other shapes. A cbn wheel is essentially a grinding wheel made of cbn particles bonded together with other materials, such as resin or metal. When to select a coarse grit size: A/o also means aluminum oxide; Harder or stronger bonds in grinding. What stock needs to be removed from the material? The essential descriptions of abrasive types range from coarse to medium to fine. For satisfactory results when grinding tool steels, the grinding wheel must be selected carefully. Grit measurements generally range from coarse to fine. See the full toolroom grinding wheels range. Web available to fit many sizes and specification of machines with speed, quality and finish in mind. Web there are 4 main types of abrasive grains available for grinding wheels, these are: It is a crucial factor that influences the wheel's cutting ability, stock removal rate, and the surface finish of the workpiece.. Web grit size and surface finish. Web the grit of a wheel is critical for supplying the right abrasion. Web cbn (cubic boron nitride) is a type of superhard material, second only to diamond in its hardness. You need to create a form using contact form 7 plugin to be able to display it using this element. Web the amount of abrasive bond in the grinding wheel determines its grade or hardness. Web the chart below shows both the us mesh and european (fepa) grit size s compared to the eagle superabrasives standard designation. Grit sizes are categorized into coarse, medium, and fine ranges. The more the grit size, the finer the abrasive is. Web a grinding wheel, also known as an abrasive wheel, is a wheel made of abrasive particles bound together by various substances, such as rubber, shellac or silicate. Web see the grain size chart below. This is a good starting point. Review our selection include id and bearing wheels, cylinder wheels, and other shapes. Web there are 4 main types of abrasive grains available for grinding wheels, these are: When to select a coarse grit size: True the wheel face and sides to eliminate any wheel runout for. Web below we have included a chart that displays the standard of grit size and the effect it has on the finishing surfaces.

Grinding wheel grit size

Norton Grinding Wheels Chart

Grinding Wheel Grit Chart

Grit Surface Finish Chart

Grinding Wheel Mesh FEPA Grit Sizes

Cutting and Grinding Wheels Application Guide Archives Extreme

Grinding and Polishing Guide Buehler United Kingdom Metallography

Grit chart of grinding wheels Forture Tools

Bibielle UK Grinding Wheels

Grit chart of grinding wheels Forture Tools

The Coarser The Grain, The Larger The Size Of The Material Removed.

Hardness Is Dependent On The Grit Type, The Material Being Ground, The Amount Of Stock Removed, And A Number Of Other Factors.

Work Out The Shape Of The Material And The Surface Finish (Or Finishes) That Are.

A Grinding Wheel Is An Abrasive Tool With Thousands Of Cutting Points On Its Surface With Different Abrasive Grains Held In Place Through A Bond Matrix And Separated By Pores.

Related Post: