Gasket Material Compatibility Chart

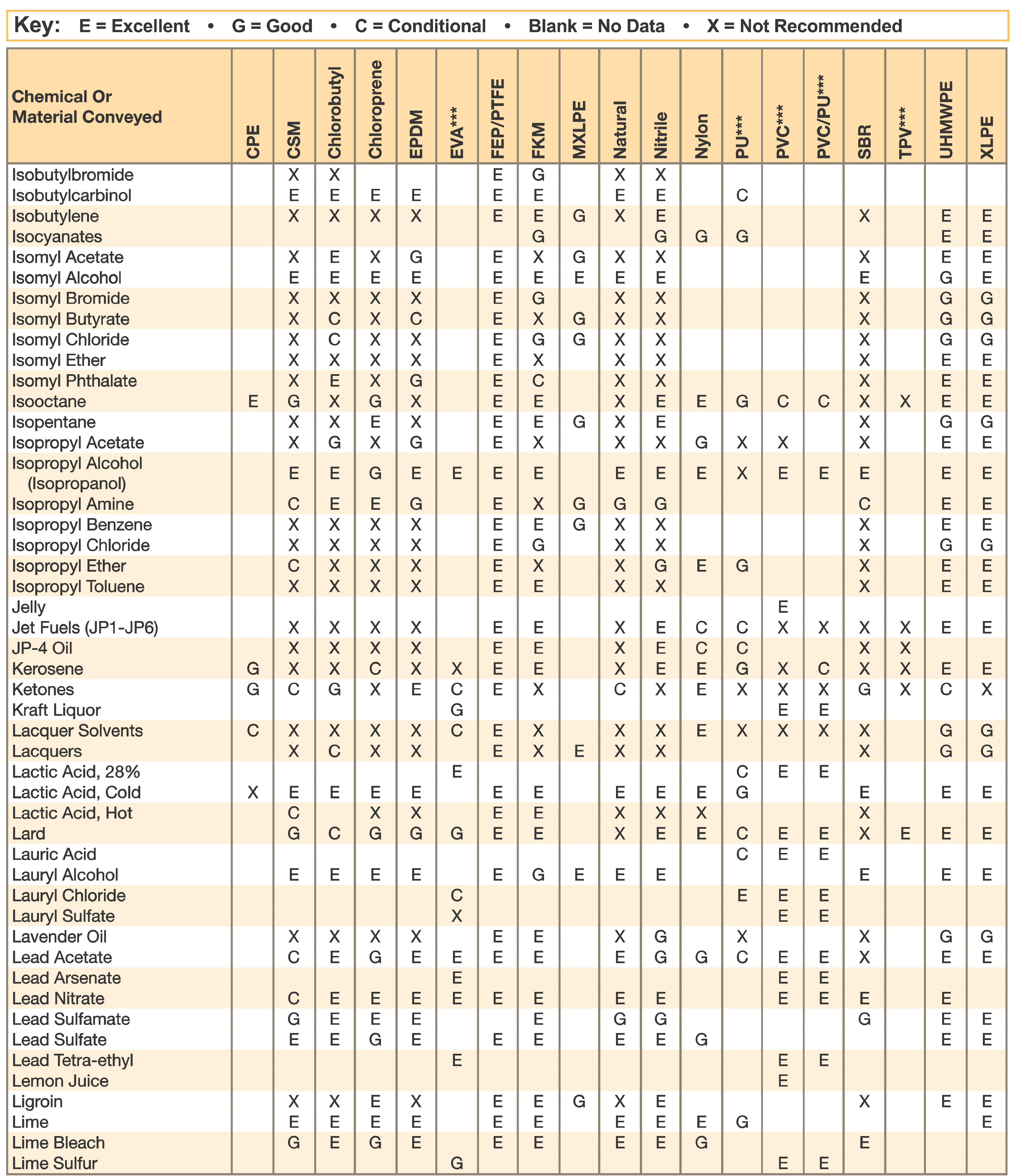

Gasket Material Compatibility Chart - Various chemicals impact the both the structural integrity and functional properties of the material. Web materials used in the pump and pumping systems must be chemically compatible. Do not expose to free immersion* c: Bal seal engineering europe b.v. For more information on compatibility with specific chemicals please see our chemical compatibility charts. Ssi incorporates design engineering, material science, and mechanical and physical property testing in its total engineering methodology. Web fluid resistance data for common gasket and seal elastomers rating legend: Use dropdowns below to select a chemical, and then a combination chemical. Web both the gasket division of the fsa and the flange gasket division of the esa are one of several divisions with a specific product technology focus. Web gasket material chemical resistance and compatibility charts. Web klingersil® compressed fiber gasket materials. Web fluid resistance data for common gasket and seal elastomers rating legend: Do not expose to free immersion* c: Ssi incorporates design engineering, material science, and mechanical and physical property testing in its total engineering methodology. Chemical resistance of the gasket material is important because without it, the other Generally suitable with sufficient surface stress. Web once a material with an acceptable pressure/temperature range has been identified it is important to determine if it is compatible with media being sealed. If your temperature differs from this, it may affect the compatibility of the fluid with the given pump materials by accelerating the reaction. The information in this chart should. Various chemicals impact the both the structural integrity and functional properties of the material. Web view our material compatiblity chart for chemicals ordering any gasket material. All information is provided in accordance with the current state of knowledge and subject to alteration. Web when designing a gasket or seal, chemical resistance is one of the most important steps to consider.. Web the following seal compound and body material compatibility chart is provided as an aid in selecting a specific synthetic rubber compound or body material for a particular application. The information in this chart should only be used as a general rule to the selection of a suitable material. Operating and environmental conditions must be considered when making the selection. Web fluid resistance data for common gasket and seal elastomers rating legend: Web find fkm & epdm chemical compatibility charts for describing the suitability of miniature fluidic and pneumatic component materials. Web once a material with an acceptable pressure/temperature range has been identified it is important to determine if it is compatible with media being sealed. Web view our material. Web once a material with an acceptable pressure/temperature range has been identified it is important to determine if it is compatible with media being sealed. Web fluid resistance data for common gasket and seal elastomers rating legend: Web the following seal compound and body material compatibility chart is provided as an aid in selecting a specific synthetic rubber compound or. Use this tool to help you select the rubber materials with the best chemical resistance score for your application. It is given as background information only. All information is provided in accordance with the current state of knowledge and subject to alteration. Web materials used in the pump and pumping systems must be chemically compatible. Web gasket material chemical resistance. This data has been compiled from literature published by various material suppliers. Use dropdowns below to select a chemical, and compare against all materials or any specific material. Or view all chemical combinations. Bal seal engineering europe b.v. Various chemicals impact the both the structural integrity and functional properties of the material. Do not expose to free immersion* c: Contact us for expert technical help on +44 (0)1209 314700 or email: The data provided for the chemicals is at 70ºf (21ºc), unless otherwise noted. Use dropdowns below to select a chemical, and then a combination chemical. Web both the gasket division of the fsa and the flange gasket division of the esa. The information in this chart should only be used as a general rule to the selection of a suitable material. Web once a material with an acceptable pressure/temperature range has been identified it is important to determine if it is compatible with media being sealed. B = possible minor to moderate adverse effect. Web find fkm & epdm chemical compatibility. We offer 3,000+ materials that deliver performance and price advantages for your application. Ssi incorporates design engineering, material science, and mechanical and physical property testing in its total engineering methodology. The information in this chart should only be used as a general rule to the selection of a suitable material. Web galvanic compatibility (conductive applications) seal science is structured as an engineer support organization, providing application and manufacturing solutions to a diverse industry group. Use dropdowns below to select a chemical, and compare against all materials or any specific material. If your temperature differs from this, it may affect the compatibility of the fluid with the given pump materials by accelerating the reaction. Use dropdowns below to select a chemical, and compare against all materials or a specific material. Web materials used in the pump and pumping systems must be chemically compatible. Use this tool to help you select the rubber materials with the best chemical resistance score for your application. Bal seal engineering europe b.v. This data has been compiled from literature published by various material suppliers. Web find fkm & epdm chemical compatibility charts for describing the suitability of miniature fluidic and pneumatic component materials. Generally suitable with sufficient surface stress. Chemical resistance of the gasket material is important because without it, the other Use dropdowns below to select a chemical, and then a combination chemical. The data provided for the chemicals is at 70ºf (21ºc), unless otherwise noted.

All Seals Inc. The Sealing Specialists

Gasket Selection Chart A Visual Reference of Charts Chart Master

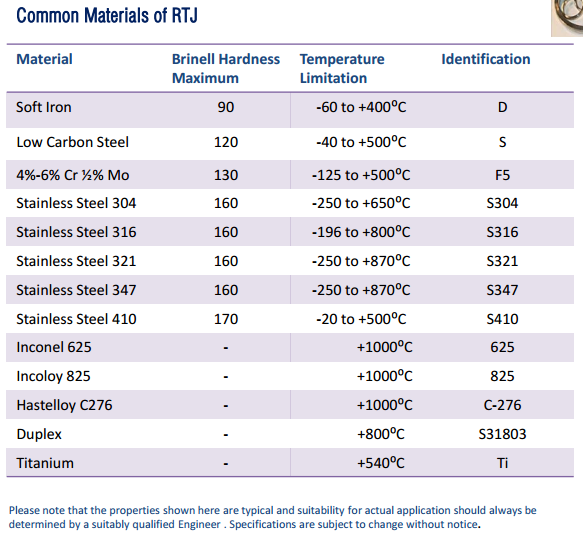

Metallic Ring Joint Gaskets for Pipe Flanges The Piping Engineering World

Gasket Chart

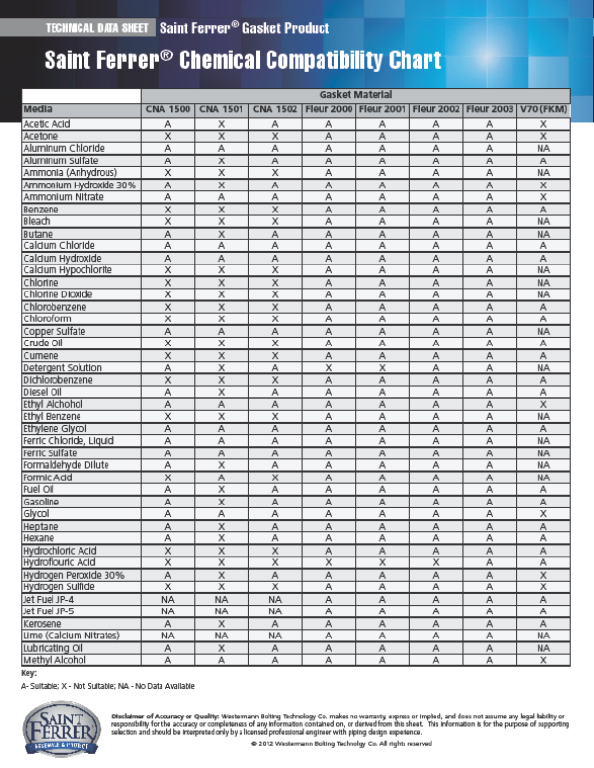

Gasket Chemical Compatibility Chart

Gasket Chemical Compatibility Chart

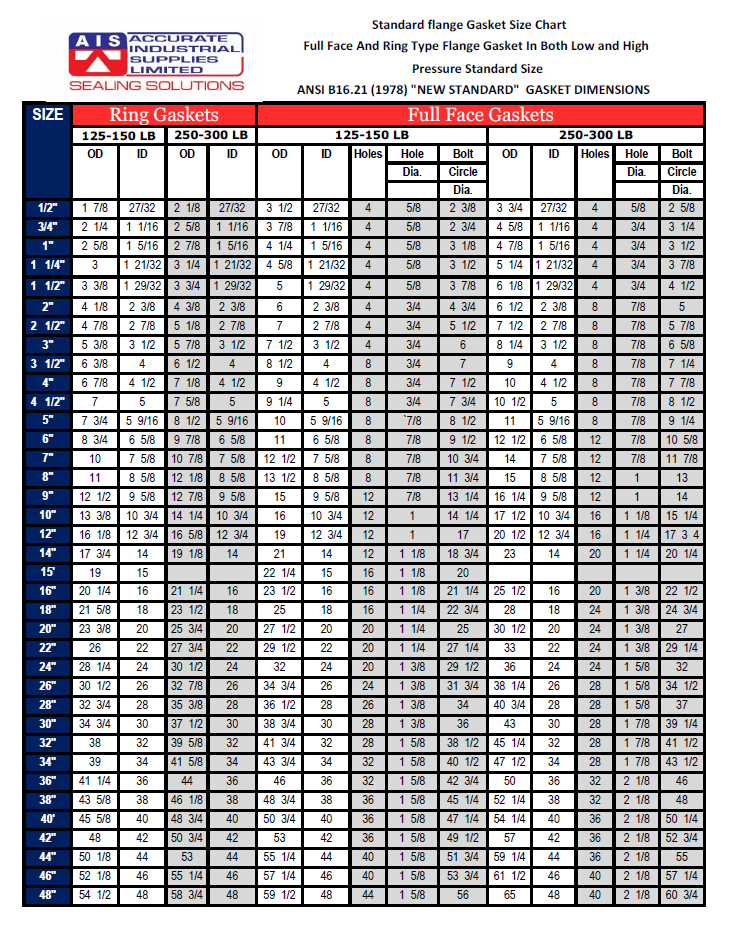

GASKET SIZING CHART Accurate Industrial Supplies

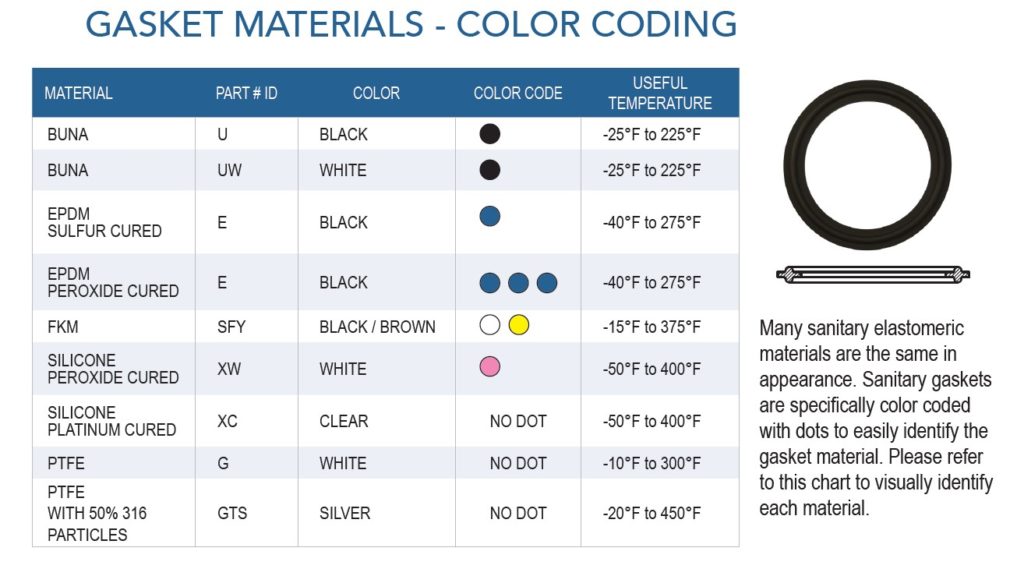

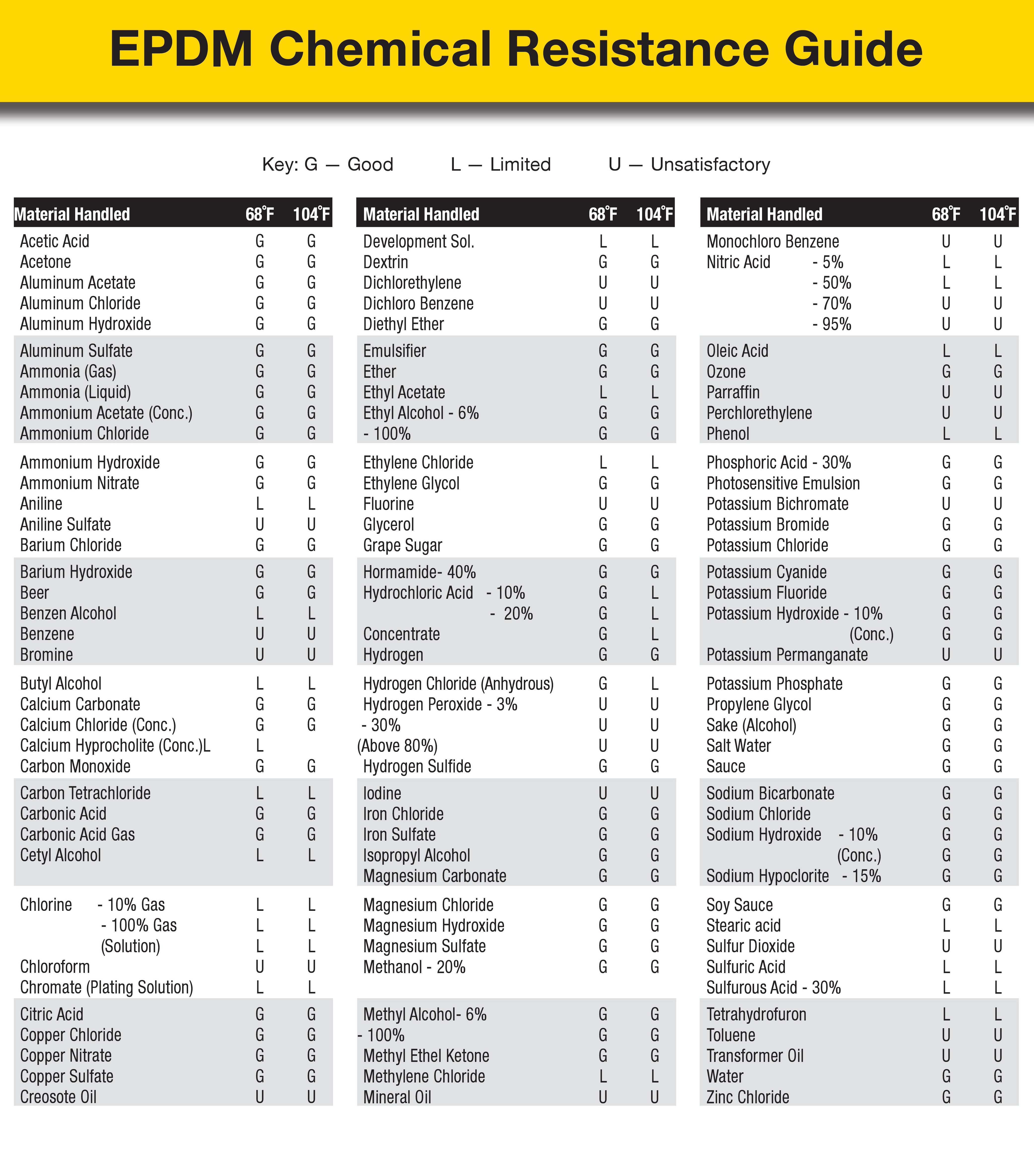

Epdm Gasket Compatibility Chart

Gasket Material Compatibility Chart

Chemical Compatibility Chart Plastics

Web Both The Gasket Division Of The Fsa And The Flange Gasket Division Of The Esa Are One Of Several Divisions With A Specific Product Technology Focus.

Or View All Chemical Combinations.

B = Possible Minor To Moderate Adverse Effect.

For More Information On Compatibility With Specific Chemicals Please See Our Chemical Compatibility Charts.

Related Post: