Flux Core Welding Chart

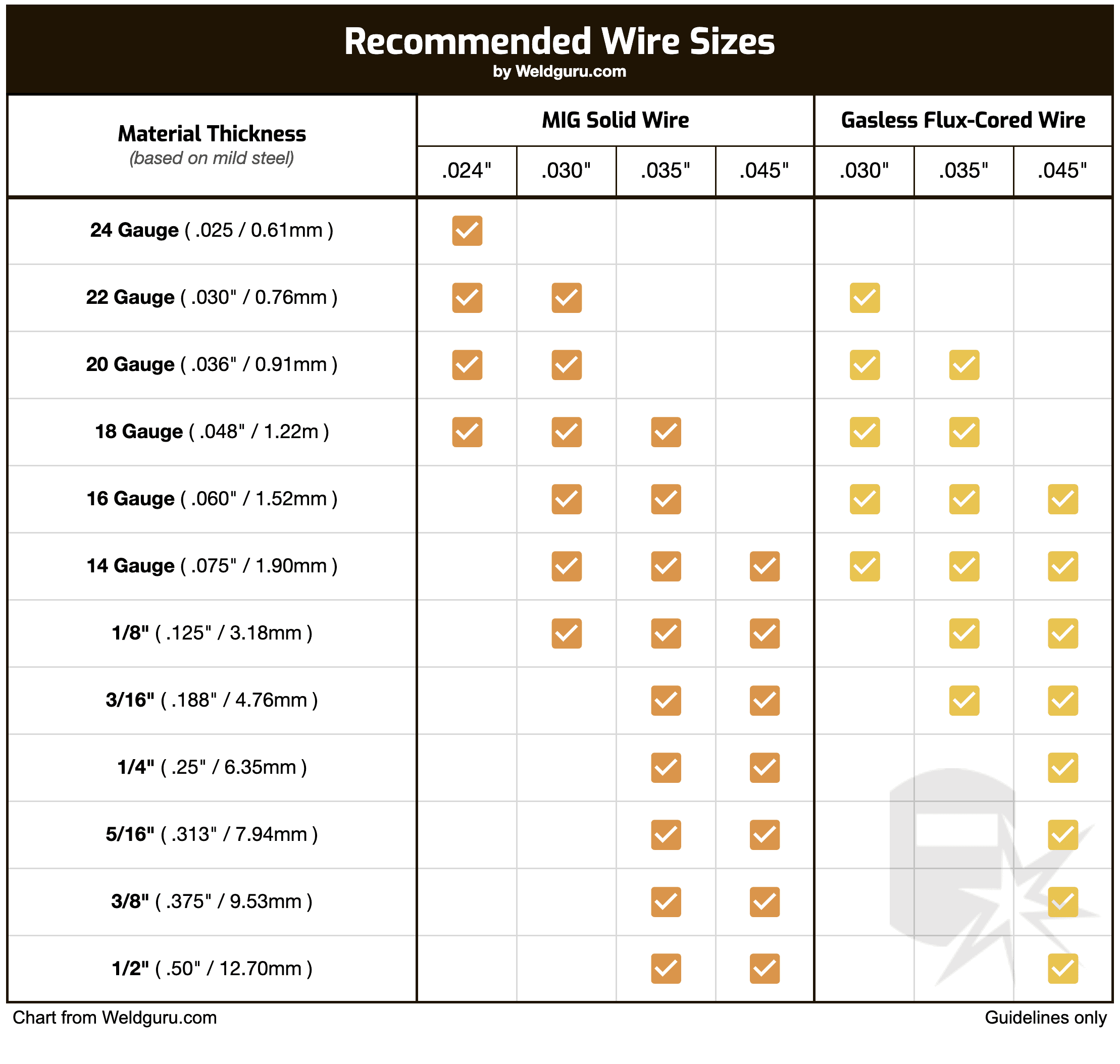

Flux Core Welding Chart - Even though it is considered a strong process suitable for thick stock, achieving the required strength will depend on various factors such as welding. Learn some techniques when using this process for welding mild steel. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. Here's a guide to setting it up. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Since you don't want to change wire, select one for your most commonly used thicknesses. Web what material are you welding? What electrode are you welding? Longevity is recognized worldwide for providing reliable welding, cutting, and power generating equipment. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: What electrode are you welding? Web flux core welding settings chart. Web comprehending flux core mig welding entails employing the correct wire speed and voltage settings for optimal outcomes. As the filler metal melts, it fuses the two. Web there is some nuance to it. At a beginning level its important to focus on setting up your welder , choosing the correct recommended settings based. Web mig (flux cored) welding calculator. Refer to the flux core mig welding wire speed and voltage chart to verify your accurate settings to attain the desired weld bead width, penetration, and overall. .125 inch = 125 amps. Web a flux core welding amperage chart specifies the required amperage based on the wire diameter and material thickness. This instructable is intended to teach you how to use the lincoln weld pak hd flux cored arc welder. Web flux core is an arc welding process that uses heat generated by welding arc to fuse. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Web there is some nuance to it. Web flux core is an arc welding process that uses heat generated by welding arc to fuse metals. Refer to the flux core mig welding wire. Learn some techniques when using this process for welding mild steel. Web what material are you welding? Flux core welding, or fcaw, is a versatile welding method that’s both portable and effective for various metal thicknesses and outdoor conditions. 1/16 flux core wire settings. Web we offer a variety of helpful welding charts and guides that you can reference online,. Here's a guide to setting it up. Web flux core wire classification. Since you don't want to change wire, select one for your most commonly used thicknesses. This instructable is intended to teach you how to use the lincoln weld pak hd flux cored arc welder. What electrode are you welding? Flux core welding, or fcaw, is a versatile welding method that’s both portable and effective for various metal thicknesses and outdoor conditions. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Web mig (flux cored) welding calculator. At a beginning level its important to focus. What metal are you welding? 1/16 flux core wire settings. Web flux core welding is a versatile and strong metal joining process that combines ease of use from mig welding and the ability to weld without shielding gas, like stick/arc welding. Basic guide to flux cored arc (mig) welding. 1/16 flux core wire settings. This instructable is intended to teach you how to use the lincoln weld pak hd flux cored arc welder. As the filler metal melts, it fuses the two. Web this is flux core welding made easy. Since you don't want to change wire, select one for your most commonly used thicknesses. Web a flux core welding amperage chart specifies the. Refer to the flux core mig welding wire speed and voltage chart to verify your accurate settings to attain the desired weld bead width, penetration, and overall quality. Web flux core wire classification. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. At a beginning level its important to focus. Also, consider the amperage settings and the task at hand. Web mig (flux cored) welding calculator. Hello and welcome to the slo makerspace guide to flux cored arc welding! Select proper wire size according to amperage. This chart is essential for achieving proper weld quality and avoiding common welding defects. Learn some techniques when using this process for welding mild steel. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web this is flux core welding made easy. Web a flux core welding amperage chart specifies the required amperage based on the wire diameter and material thickness. Web flux core welding 101: Longevity is recognized worldwide for providing reliable welding, cutting, and power generating equipment. 1/16 flux core wire settings. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. At a beginning level its important to focus on setting up your welder , choosing the correct recommended settings based. Flux core welding, or fcaw, is a versatile welding method that’s both portable and effective for various metal thicknesses and outdoor conditions.

Flux Core Wire Size Chart

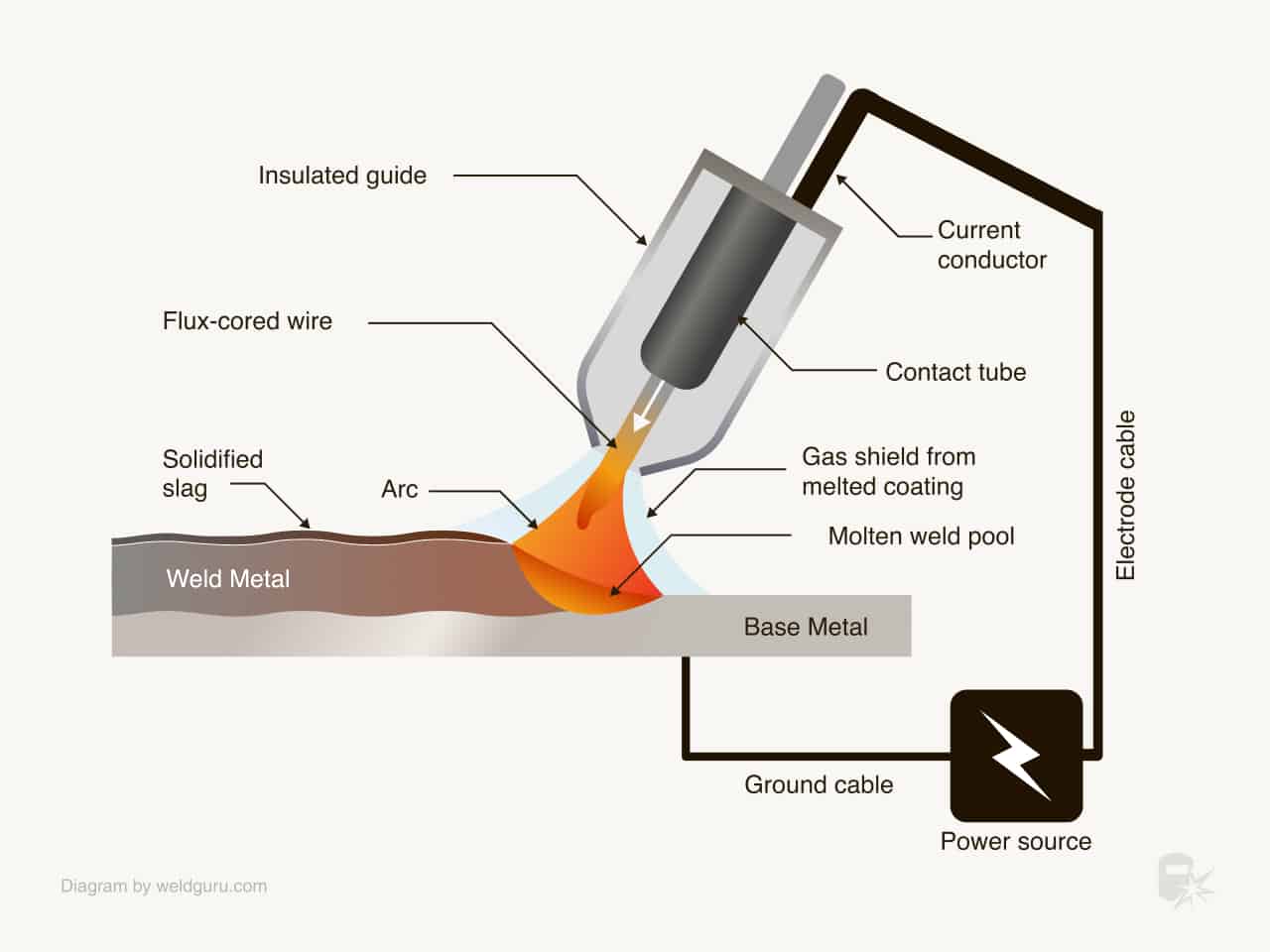

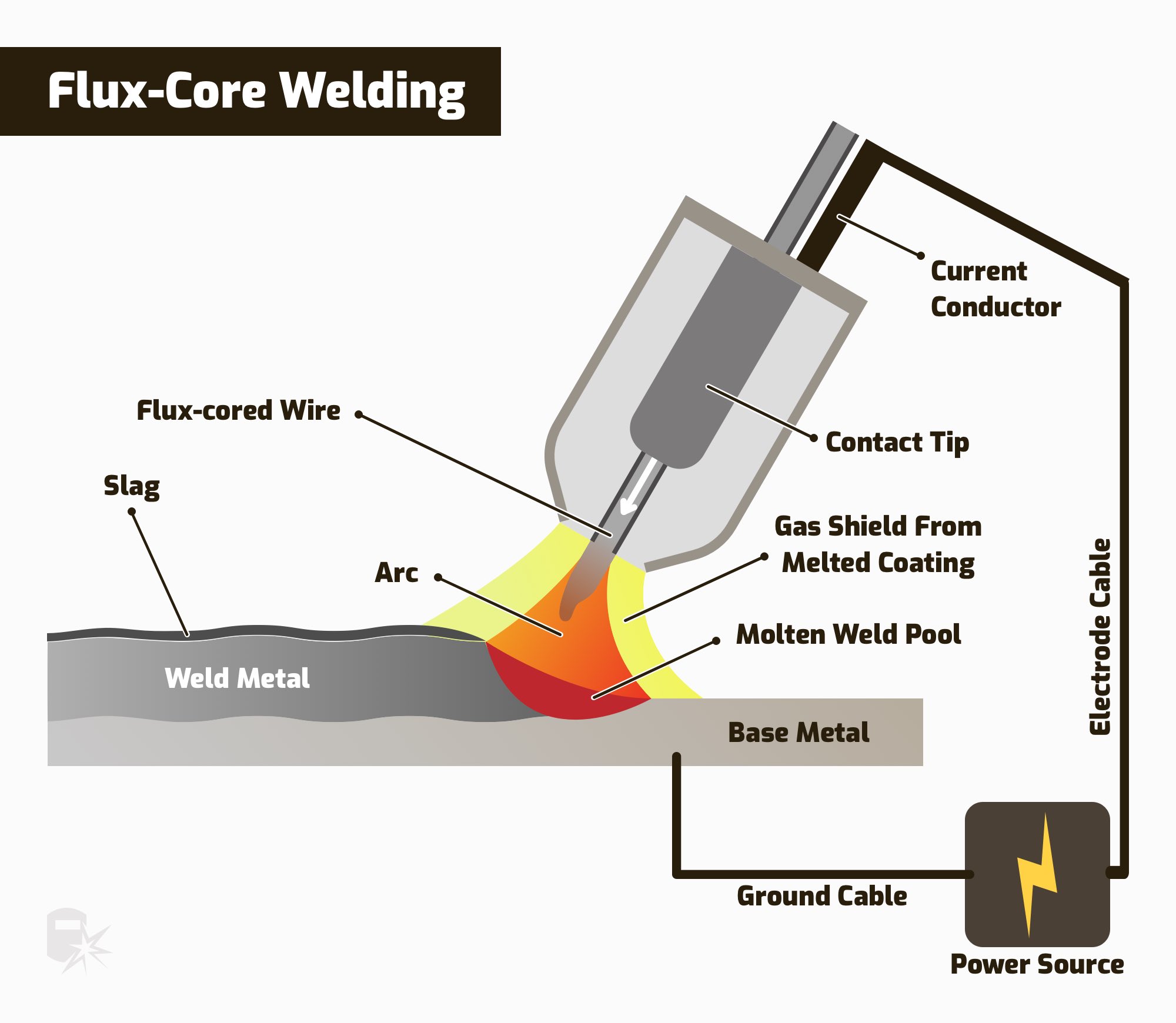

What is FluxCore Arc Welding (FCAW) & How Does it Work?

Arc Welding Explained What Is It & How Does It Work? Weld Guru

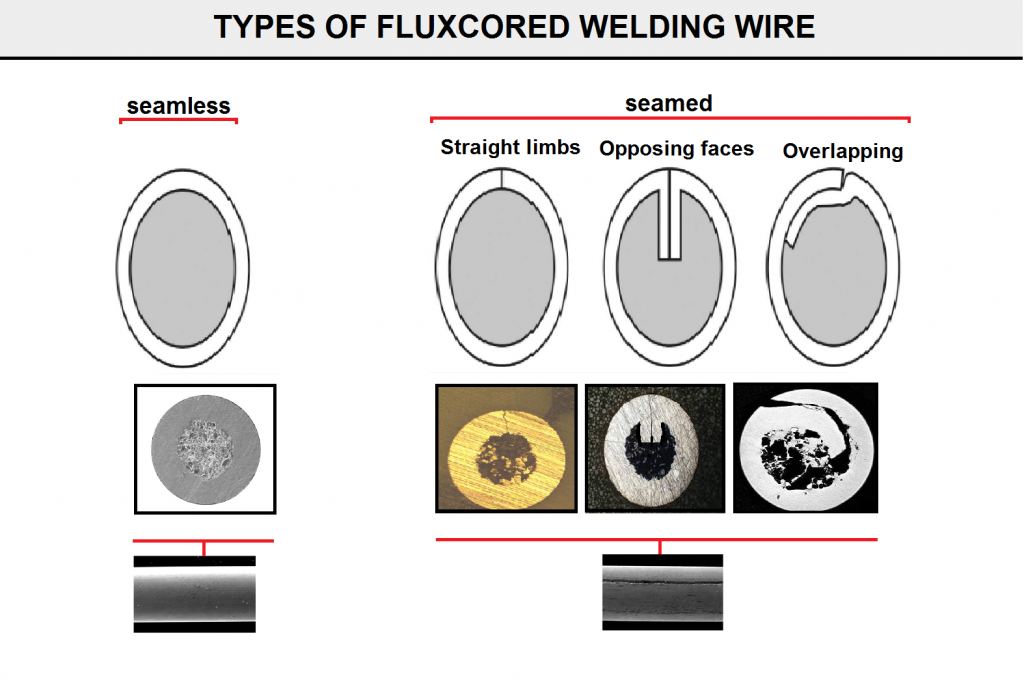

Flux Cored Welding Wire Manufacturing from A to Z by WESPEC

Getting to Know Fluxcore Wire

Gasless Flux Core Welding Basics for Beginners YouTube

What flux core wires to keep on hand? Welding Site

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Understanding the Basics of FluxCored Wires Fabricating and Metalworking

Insider's Guide to FluxCored Arc Welding (FCAW) Insider

Web Flux Core Welding Is A Versatile And Strong Metal Joining Process That Combines Ease Of Use From Mig Welding And The Ability To Weld Without Shielding Gas, Like Stick/Arc Welding.

Web The Welding Wire Size Chart Is A Crucial Guide For Selecting The Right Welding Wire Size, Which Varies According To Material Thickness And Type Of Welding.

Web Flux Core Welding Settings Chart.

Web As A Guideline, Each.001 Inch Of Material Thickness Requires 1 Amp Of Output:

Related Post: