Firing Cone Chart

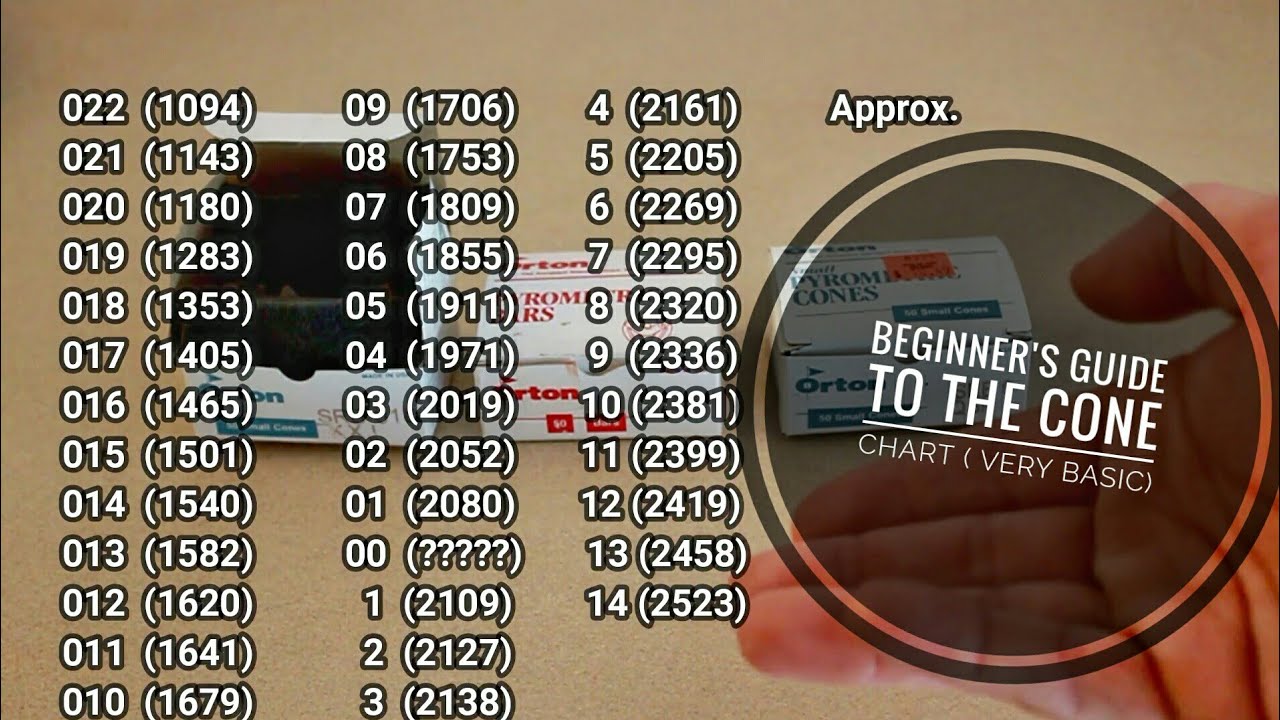

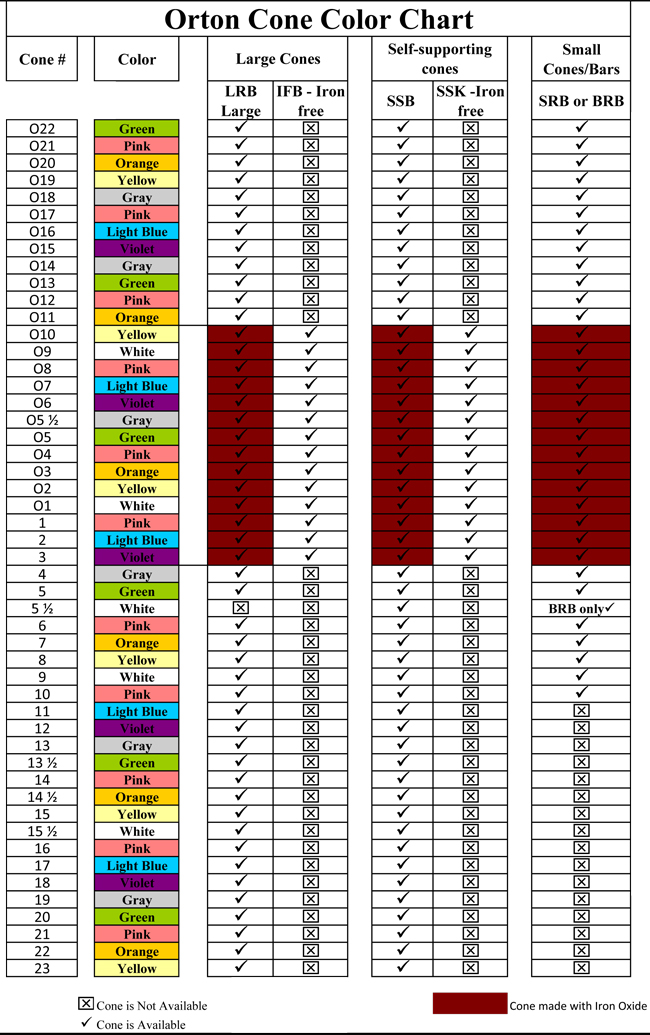

Firing Cone Chart - Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Web firing at cone 06 causes the clay to shrink and become porous and therefore will easily accept glaze. Web pyrometric kiln cones measure heat absorption as kiln temperatures reach heating ranges. Web a kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining. Pyrometric cones are used worldwide to monitor ceramic firings in industrial kilns, pottery kilns, and small hobby kilns where the consistent temperature is important to the. During the last 200 °f of the firing. Trapped water can cause the clay to explode so begin firing below this temperature until all water has evaporated 200. Web from cone 022 (approx. Web below is a chart of temperature equivalents for cones. Standard cones for common firings: If you are learning about firing pottery, you may have heard the term ‘pottery cone’ or ‘ceramic cone’. During the last 200 °f of the firing. Web firing converts ceramic work from weak greenware into a strong, durable permanent form. Slip, engobe, and terra sigillata; Refer to this cone temperature chart before firing. Web reference cone charts to select appropriate cones for your clay type, glazes, and desired firing methods. What are the different cones used in pottery? 71k views 5 years ago beginners pottery. But what are cones in pottery and how do they work? Slip, engobe, and terra sigillata; To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln. Temperatures are shown for specific heating rates. Web cone temperature conversion chart: Trapped water can cause the clay to explode so begin firing below this temperature until all water has. Web below is a chart of temperature equivalents for cones. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and. This guide provides useful information on cones and how firings can affect your pottery. Trapped water can cause the clay to explode so begin firing below this temperature until all water has. 71k views 5 years ago beginners pottery. To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln. Web reference cone charts to select appropriate cones for your clay type, glazes, and desired firing methods. But what are cones in pottery. But what are cones in pottery and how do they work? Web firing at cone 06 causes the clay to shrink and become porous and therefore will easily accept glaze. Standard cones for common firings: To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a. But what are cones in pottery and how do they work? To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln. Trapped water can cause the clay to explode so begin firing below this temperature until all water has evaporated. This guide provides useful information on cones and how firings can affect your pottery. Web cone temperature conversion chart: Web from cone 022 (approx. Standard cones for common firings: Firing to cone 04 increases the pottery’s strength and durability. To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln. Web download and print the orton cone wall chart at sheffield pottery. This ensures that time is taken into account when. During the last 200 °f of the firing. 71k. Ware must be fired at. Refer to this cone temperature chart before firing. 71k views 5 years ago beginners pottery. Trapped water can cause the clay to explode so begin firing below this temperature until all water has evaporated 200. Web firing at cone 06 causes the clay to shrink and become porous and therefore will easily accept glaze. The kiln cone is placed inside the kiln alongside. But what are cones in pottery and how do they work? Temperatures are shown for specific heating rates. Standard cones for common firings: Firing to cone 04 increases the pottery’s strength and durability. Web from cone 022 (approx. Web the cone values listed in the chart are only valid if the kiln is firing at exactly 108 °f/hr. Web cone temperature conversion chart: This chart is for large cones, and the temperature rate measures the last 90 to 120 minutes of firing. To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln. During the last 200 °f of the firing. Web download and print the orton cone wall chart at sheffield pottery. Pyrometric cones are used worldwide to monitor ceramic firings in industrial kilns, pottery kilns, and small hobby kilns where the consistent temperature is important to the. Web reference cone charts to select appropriate cones for your clay type, glazes, and desired firing methods. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Web pyrometric kiln cones measure heat absorption as kiln temperatures reach heating ranges.

What is a Cone? A Guide to Pyrometric Cones and Kilns Soul Ceramics

Pyrometric Cone Chart for Kiln Firing

Pyrometric Cone

Kiln Firing Charts Orton Cone Charts and 2 Kiln Firing Schedules (for

Ceramic Firing Cone Chart

Orton Cone Chart Cone Temperature Chart

Pyrometric Cone Temperature Conversion Chart Pottery

cone and temp color orton pyrometric temperature chart Ceramics

NEW CONE CHART FOR FIRING Cone

Firing Temperatures and cone equivalents Pottery techniques, Pottery

Have You Ever Glanced At Those Perplexing Columns Detailing Different Firing Temperatures For The Same Cone Number And.

What Are The Different Cones Used In Pottery?

This Ensures That Time Is Taken Into Account When.

Web Firing Converts Ceramic Work From Weak Greenware Into A Strong, Durable Permanent Form.

Related Post: