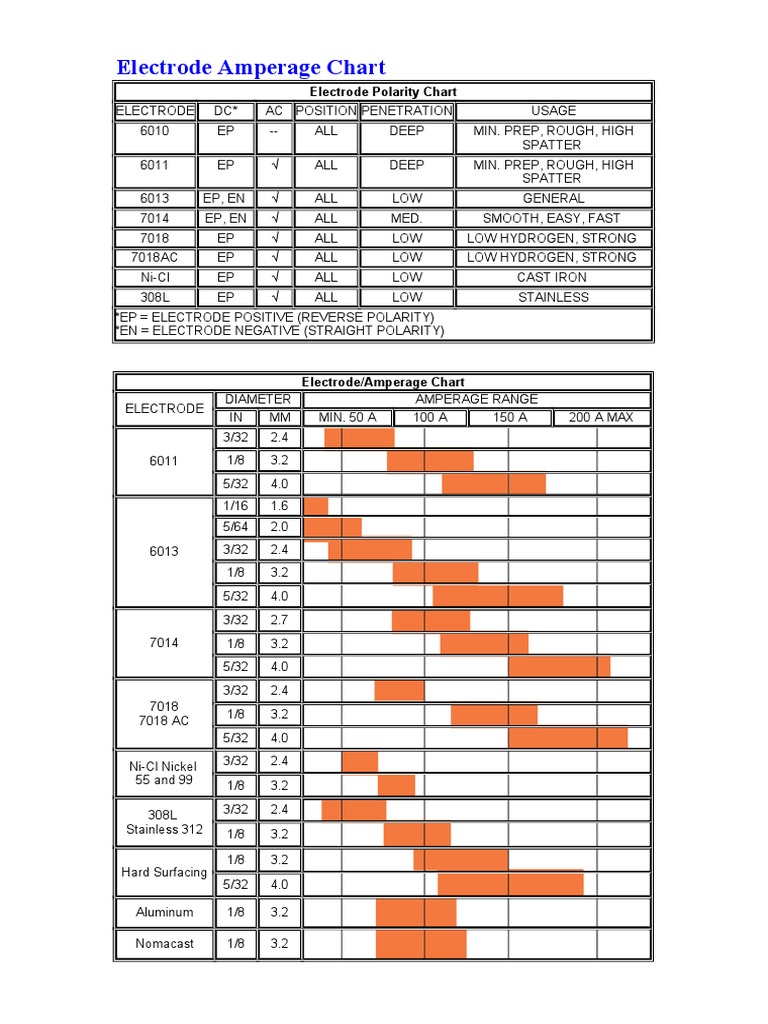

Electrode Amperage Chart

Electrode Amperage Chart - 50a 100a 150a 200a max. Electrodes for low alloy steel. Importance of proper electrode storage. Web the recommended amperages for electrodes vary depending on the type and diameter of the electrode. Web the chart provides a visual representation of the required settings, making it easy for welders to select the right amperage, depending on the material, joint type, electrode size, and welding position being used. Web the type of electrode used depends on the specific properties required in the weld deposited. 2.4 32 4.0 32 32. It serves as a guide for selecting the appropriate electrode for different welding applications. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Additionally, you might have your own preference that fits your unique situation. 50a 100a 150a 200a max. 2.4 32 4.0 32 32. Additionally, you might have your own preference that fits your unique situation. Before delving into amperage settings, it's essential to understand the characteristics of the stick electrodes you're using. Electrodes for copper and copper alloys. Web the following chart provides a general guideline for amperage recommendations based on electrode size for different welding positions and base metal thicknesses. Diameter (inches) diameter (mm) 6010/6011. We’ve put together a reference based on recommendations from the american welding society. Welding rod sizes with amperage chart. Web the recommended amperages for electrodes vary depending on the type and diameter. Electrodes for low alloy steel. The document is an electrode amperage chart listing welding electrode types, diameters in both inches and millimeters, and recommended amperage ranges. Web check out our welding electrode size chart, welding rod size chart, welding electrode chart, welding electrode amperage chart in mm and kg. Web a welding electrode chart categorizes electrodes based on factors such. Electrode amperage chart aws class dia. Here are some general guidelines: 50a 100a 150a 200a max. Web the type of electrode used depends on the specific properties required in the weld deposited. Web the recommended amperages for electrodes vary depending on the type and diameter of the electrode. With experience, you can use thicker rods with a higher amperage for faster results. It serves as a guide for selecting the appropriate electrode for different welding applications. 1/8 24 32 4.0 48 2.0 2.4 32 4.0 48 2.4 32. Web a welding electrode chart categorizes electrodes based on factors such as material, coating, current, and position. Influence of gasses. Web the type of electrode used depends on the specific properties required in the weld deposited. Types of shielding gases used in arc welding. Here are some general guidelines: 2.4 32 4.0 32 32. Welding rod sizes with amperage chart. Electrode polarity chart all all all all all horiz fillet all all deep. 50a 100a 150a 200a max. Web printable electrode amperage chart. How to choose gases based on the electrode chart. Welding rod sizes with amperage chart. Before delving into amperage settings, it's essential to understand the characteristics of the stick electrodes you're using. Storing electrodes according to chart recommendations. The different types of coating on the electrodes produce different types of welds. Web weldi ng electrode chart. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes. Types of shielding gases used in arc welding. Web below are the standard welding electrode sizes and lengths as specified in aws a5.1 specification. The document is an electrode amperage chart listing welding electrode types, diameters in both inches and millimeters, and recommended amperage ranges. Web printable electrode amperage chart. Web look at the tig welding amperage charts below for. Diameter (inches) diameter (mm) 6010/6011. Electrode polarity chart all all all all all horiz fillet all all deep. It serves as a guide for selecting the appropriate electrode for different welding applications. Importance of proper electrode storage. Influence of gasses on arc welding. It is important to note that these are just recommendations, and you should always refer to the manufacturer’s recommended amperage range for the specific. Diameter (inches) diameter (mm) 6010/6011. Types of shielding gases used in arc welding. The pdf has 8 sections: 50a 100a 150a 200a max. 1/8 24 32 4.0 48 2.0 2.4 32 4.0 48 2.4 32. Web the recommended amperages for electrodes vary depending on the type and diameter of the electrode. Web look at the tig welding amperage charts below for information to help you with any weld, no matter the material, size, or anticipated outcome. Electrodes listed include 6010/6011, 6013, 7014, and 7018, with diameters ranging from. Web a chart with stick rod amperage per metal thickness in gauge, inches, and mm. Web check out our welding electrode size chart, welding rod size chart, welding electrode chart, welding electrode amperage chart in mm and kg. Web although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16. The table is published in aws a5.1. Electrodes come in various sizes and types, each designed for specific applications. The weight of welding electrodes is typically expressed in pounds per thousand (lb/1000) and is subject. You can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding.Electrode Amperage Chart PDF

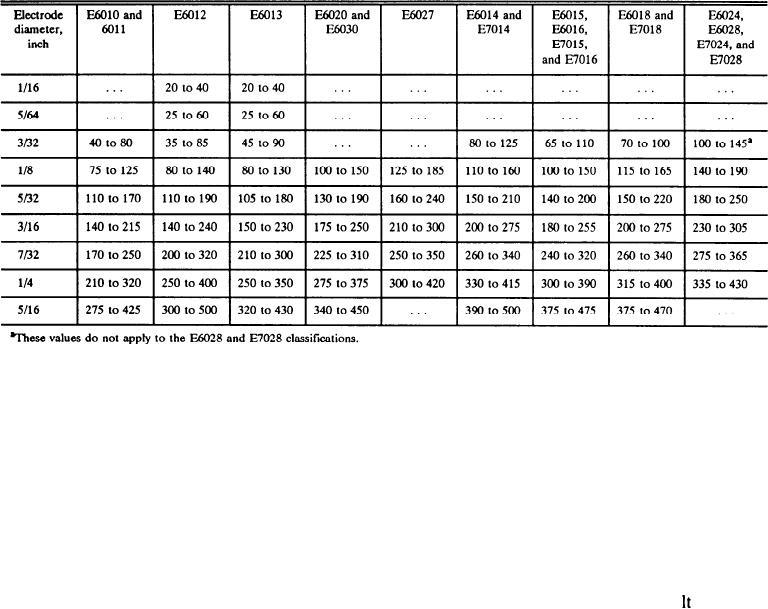

Table 103.Typical Current Ranges in Amperes for Electrodes

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Electrode Amperage Chart PDF

Electrodes and Amps

Electrode Amperage Chart Baker's Gas & Welding Supplies, Inc.

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Welding

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc

Electrode Amperage Chart

Electrode Amperage Chart Aws Class Dia.

It Serves As A Guide For Selecting The Appropriate Electrode For Different Welding Applications.

Storing Electrodes According To Chart Recommendations.

Importance Of Proper Electrode Storage.

Related Post: