Electric Motor Efficiency Chart

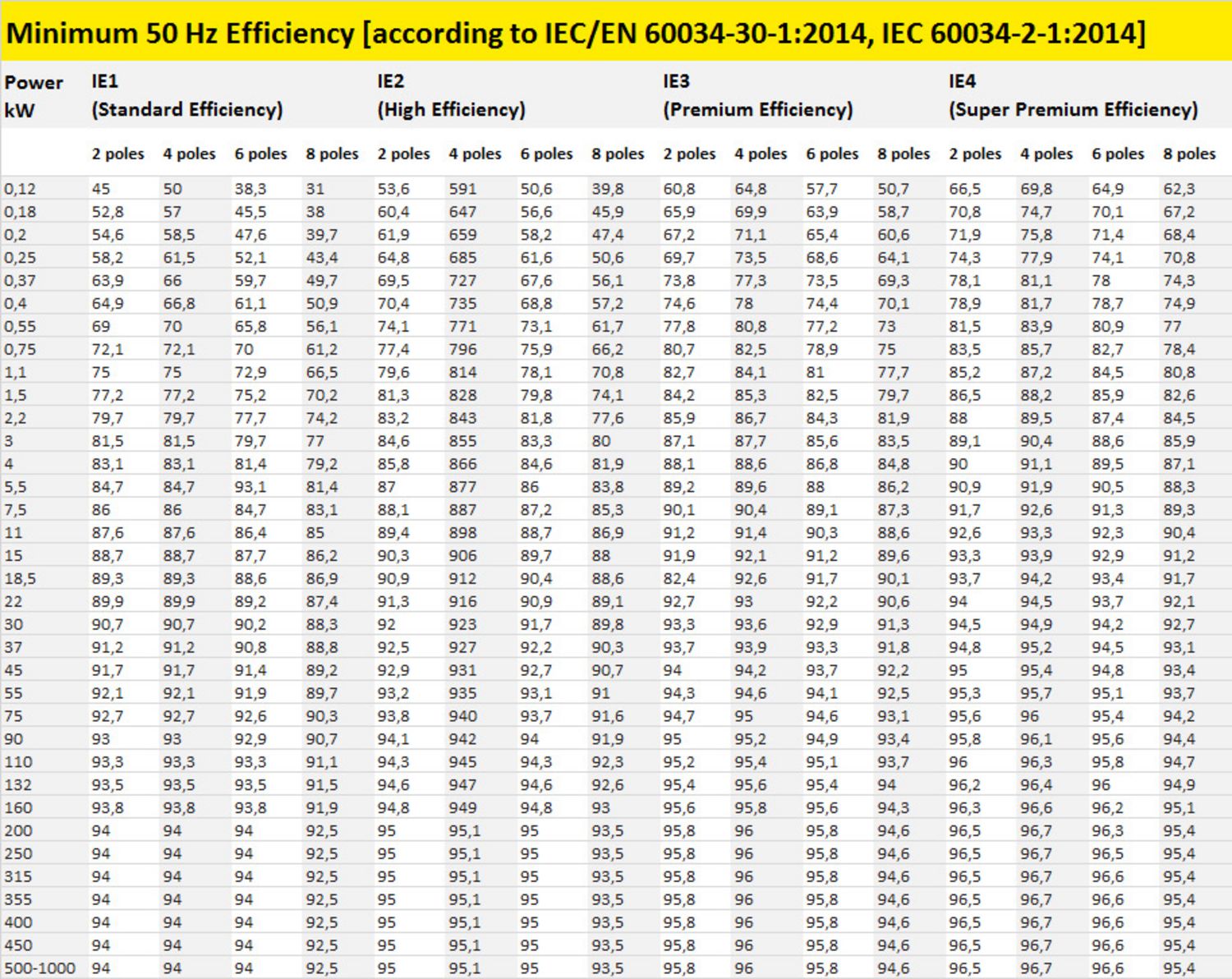

Electric Motor Efficiency Chart - What is eff2 motor efficiency class? The engineering toolbox privacy policy. Web the efficiency of an electrical motor is the ratio mechanical power output to the electric power input. Web electric motor efficiency is dependent on (but not limited to) design, materials, construction, rating, load, power quality, and operating conditions. Web efficient motors help cut energy costs and limit carbon dioxide emissions. Popular internal searches in the engineering toolbox. Moment of inertia is the measure of any given object’s resistance to its rotation rate changes. When we observe the standard tables of three efficiency classes, it is found that eff1 motors have an efficiency of 40% higher than that of the eff3 motors and 20% higher than the eff2. Considering that 45% of electrical energy is converted today into motion by electrical motors, research estimates that the world’s electricity consumption could be reduced by 10% with high efficiency motion solutions. The efficiency computed from this ratio is known as the direct efficiency. From 1 july 2023, motors between 75 kw and 200 kw will be required to meet the even higher efficiency class of ie4. The speed range for available motors, however, exceeds 40 to 60 rpm. Abb’s energy efficient motors are designed and labeled to comply with international iec standards and local meps requirements. The documentation must clearly indicate the efficiency. An electric motor of the eff1 class will have an efficiency higher than that of the eff2 and eff3 class motors. The map displays the motor’s efficiency as a function of load and speed, allowing users to identify the operating conditions where the motor achieves the highest efficiency. When we observe the standard tables of three efficiency classes, it is. The energy efficiency requirements have also been reinforced, reflecting technological progress and market evolution in the past decade. Web electric motor efficiency is dependent on (but not limited to) design, materials, construction, rating, load, power quality, and operating conditions. Power factor basics pf, often discussed as an energy cost reduction. The documentation must clearly indicate the efficiency testing method used. The map displays the motor’s efficiency as a function of load and speed, allowing users to identify the operating conditions where the motor achieves the highest efficiency. Work is the result of a force acting over some distance. Motor efficiency can be directly expressed as the ratio of power output to power input (see equation 6.1). Web most electric motors. Web the revision was published on october 1, 2019. Web how it works. All the details are available here. Maximum efficiency is usually near 75% of rated load. The engineering toolbox privacy policy. Maximum efficiency is usually near 75% of rated load. An object at rest has a zero moment of inertia. Web the revision was published on october 1, 2019. Web typically, it would be eff3 < eff2 < eff1. Web motor efficiency is a measure of the effectiveness with which electrical energy is converted to mechanical energy. Motor minimum efficiency performance standards. Web electric motor output power and torque vs. Web most electric motors are designed to run at 50% to 100% of rated load. Iec stands for the international electrical commission, a global standardization organization. The map displays the motor’s efficiency as a function of load and speed, allowing users to identify the operating conditions where. Web how it works. All the details are available here. Nema has established the efficiency index: Web efficient motors help cut energy costs and limit carbon dioxide emissions. Motors are defined by levels of efficiency per kw rating and the number of poles. From 1 july 2023, motors between 75 kw and 200 kw will be required to meet the even higher efficiency class of ie4. Web the efficiency of an electrical motor is the ratio mechanical power output to the electric power input. When we observe the standard tables of three efficiency classes, it is found that eff1 motors have an efficiency. Torque is a rotating force produced by a motor’s crankshaft. The engineering toolbox privacy policy. Determining the moment of inertia. Popular internal searches in the engineering toolbox. What is eff2 motor efficiency class? Web efficient motors help cut energy costs and limit carbon dioxide emissions. Web how it works. Motor efficiency can be directly expressed as the ratio of power output to power input (see equation 6.1). Web motor efficiency is a measure of the effectiveness with which electrical energy is converted to mechanical energy. A motor’s efficiency tends to decrease dramatically below about 50% load. Popular internal searches in the engineering toolbox. Web minimum efficiency performance standards for electric motors. Motors are defined by levels of efficiency per kw rating and the number of poles. An object at rest has a zero moment of inertia. Web the revision was published on october 1, 2019. Web the efficiency of an electrical motor is the ratio mechanical power output to the electric power input. Web 6 specification of electric motors 1.1 electric motors the electric motor is a machine capable of converting electrical energy into mechanical energy. Eff2 is nothing but an energy efficiency class 2 or standard efficiency class or improved efficiency class. Peak efficiency is at 7.5 hp. Energy consumption is dependent on the kw rating of the motor, What is eff2 motor efficiency class?![]()

Increasing the range of EV with the same battery size Part I The

![Motor efficiency classes (according to IEC60034301) [8], [9](https://www.researchgate.net/profile/Fernando_Ferreira7/publication/299401653/figure/download/fig1/AS:545408414949376@1507046907663/Motor-efficiency-classes-according-to-IEC60034-30-1-8-9.png)

Motor efficiency classes (according to IEC60034301) [8], [9

DC motor y potencia Electronica

motorefficiencytable Precision Motor Repair

Typical efficiency map of an electric motor. The figure shows equal

The Efficiency of an Electric Motor. GCSE Science Marked by

Motor Efficiency & Ratings Explained Republic Manufacturing Blog

The Efficiency of an Electric Motor. GCSE Science Marked by

Power and efficiency of a 10 kW electric motor as a function of motor

Energy efficiency classes for IEC motors

The Efficiency Is Expressed At Both Full Load And 3/4 Load And Labels Must Appear On The Motor.

Web From 1 July 2021 Motors Between 0.75 Kw And 1000 Kw Will Be Required To Meet A Minimum Efficiency Class Of Ie3, The Group Of Smaller Motors From 0.12 Kw To 0.75 Kw Minimum Ie2.

Work Is The Result Of A Force Acting Over Some Distance.

Determining The Moment Of Inertia.

Related Post: