Drill Sfm Chart

Drill Sfm Chart - Suitable for deep drilling and operations where low power consumption is required. Start conservatively and increase speed and feed until drilling cycle is optimized. With high speed steel drills. Web hss drills reduce sfm 50% with coating, add 10% to the sfpm Web use these charts for carbide tipped drills. Cobalt & hss drills speeds & feeds. First choice for stainless steel. Web suitable for severe cutting conditions. Enter the series number of the guhring tool you which to find speeds and feeds for. = 0.2618 x drill diameter x r.p.m. Start conservatively and increase speed and feed until drilling cycle is optimized. Web hss twist drill recommended speeds and point angles (scroll down for recommended feed rates by diameter) steels. Start conservatively and increase speed and feed until drilling cycle is optimized. The common unit and term for this velocity is surface feet per minute, abbreviated sfm. = surface feet. Ideal for long chipping materials. = surface feet per minute feed stroke = drill depth + 1/3. Web here is the chart with the recommended cutting speed for different materials. Indexable drill bodies require both periphery and center inserts. Web use these charts for carbide tipped drills. Cobalt & hss drills speeds & feeds. Feed rate (inches per revolution) hole diameter in inches cutting speed (sfm) 1/8 1/4 3/8 1/2 5/8 3/4 1 1/4 1/2 starting range* chip gen. Web hss twist drill recommended speeds and point angles (scroll down for recommended feed rates by diameter) steels. Web r p m = 12 × s f m. Web the speed of a drill is measured in terms of the rate at which the outside or periphery of the tool moves in relation to the work being drilled. Web use these charts for carbide tipped drills. Web r p m = 12 × s f m π × d. Indexable drill bodies require both periphery and center inserts.. = surface feet per minute feed stroke = drill depth + 1/3. Web drilling speed and feed calculator. Determine the spindle speed (rpm) and feed rate (ipm) for a drilling operation, as well as the cut time for a given cut length. With high speed steel drills. Web use these charts for carbide tipped drills. Indexable drill bodies require both periphery and center inserts. Always use the speeds and feeds recommended from your tool manufacturer. Suitable for deep drilling and operations where low power consumption is required. Web drill diameter = diameter of the drill top chart is for general purpose drilling. Web r p m = 12 × s f m π × d. Web drill diameter = diameter of the drill top chart is for general purpose drilling. Rpm (spindle speed) * learn more about the fundamentals behind this equation. Feeds & speeds — drilling or reaming general purpose or coolant fed. With high speed steel drills. Enter the series number of the guhring tool you which to find speeds and feeds for. Sfm to rpm chart (metric) Web high speed steel & cobalt drills speed and feed recommendations. Web the best online speeds and feeds calculator. Recommended feeds of various diameter drills. Web suitable for severe cutting conditions. Cobalt & hss drills speeds & feeds. First choice for stainless steel. Web hss twist drill recommended speeds and point angles (scroll down for recommended feed rates by diameter) steels. Start conservatively and increase speed and feed until drilling cycle is optimized. Web drill diameter = diameter of the drill top chart is for general purpose drilling. Speed and feed calculator for drilling and milling,easyspeedsandfeeds.com is the easiest speeds and feed cacuator to use. The common unit and term for this velocity is surface feet per minute, abbreviated sfm. Web speed and feed charts. Web use these charts for carbide tipped drills. Enter the series number of the guhring tool you which to find speeds and feeds. Web r p m = 12 × s f m π × d. Enter the series number of the guhring tool you which to find speeds and feeds for. Web drill diameter = diameter of the drill top chart is for general purpose drilling. Web drilling speed and feed calculator. For milling, turning, drilling, grooving, and parting off. The speeds and feeds shown are suggested starting points only and may be increased or decreased depending on actual material and machining conditions. Determine the spindle speed (rpm) and feed rate (ipm) for a drilling operation, as well as the cut time for a given cut length. Start conservatively and increase speed and feed until drilling cycle is optimized. Feed rate (inches per revolution) hole diameter in inches cutting speed (sfm) 1/8 1/4 3/8 1/2 5/8 3/4 1 1/4 1/2 starting range* chip gen. Sfm to rpm chart (metric) Recommended feeds of various diameter drills. Find speeds and feeds chart by: Cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. = surface feet per minute. With high speed steel drills. Easy speeds and feeds only serves as a starting point and educational site.

Drilling through metal easily Best drill bits to drill hard metal

Drill Speed Chart For Steel

Sfm Chart For Milling

Cutting Speed (Vc) SFM Stainless Steel Steel

eeeeeeeeeee Get 38 Printable Drill Press Speed Chart Metal

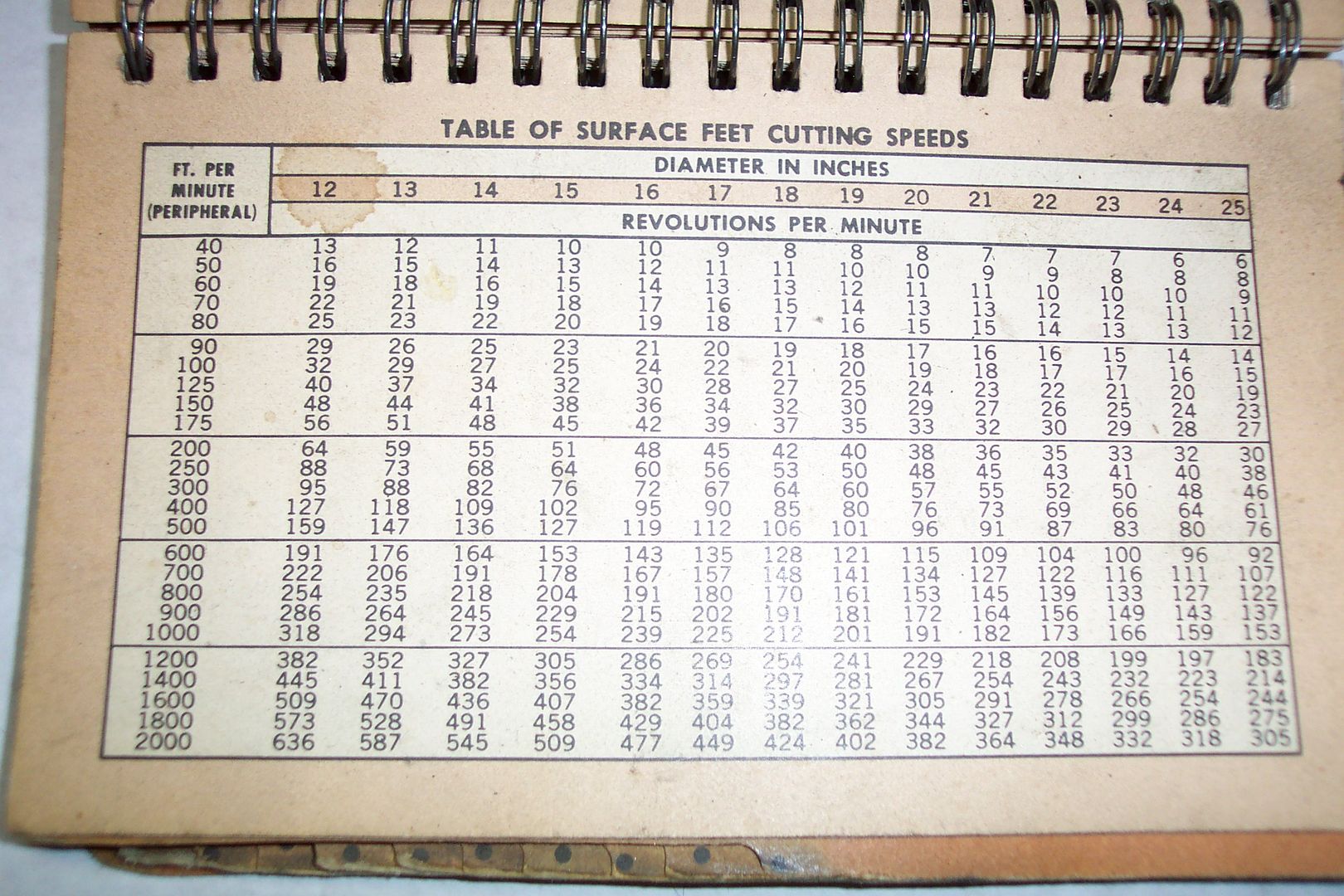

Surface footage charts ( for long tool life) The HobbyMachinist

simplefootage Speed And Feed Chart For Drilling

Center Drill Dimension Chart Drill Guide Sheet for CNC Shop

SFM Chart Surface, Drill, It cast

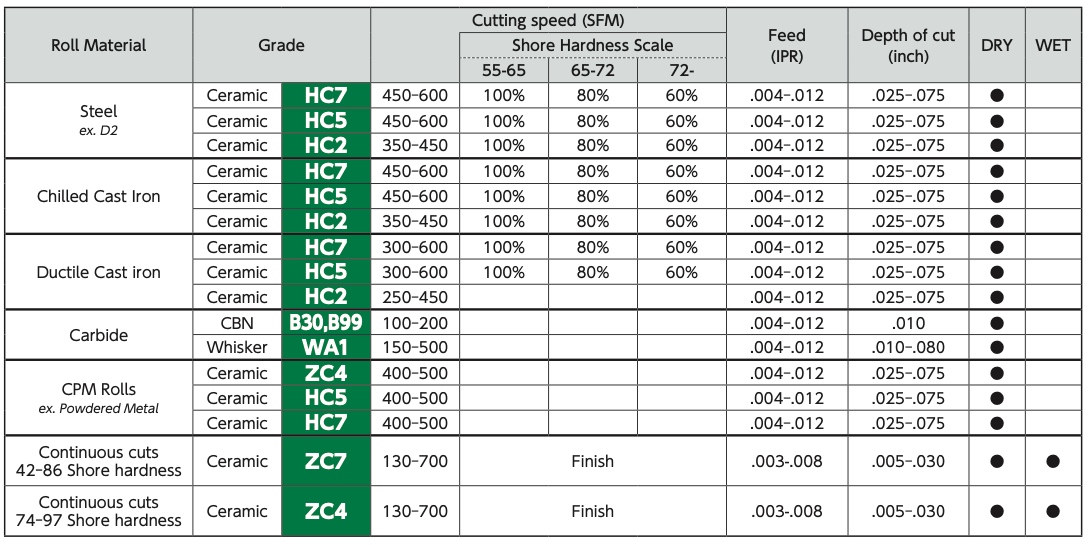

Category Hard Turning NEXT GENERATION TOOLING

Web Speeds And Feeds Are Suggested Starting Points Only And May Be Increased Or Decreased Depending On Actual Material And Machining Conditions.

Cutting Speed For Turning, Drilling, Reaming, And End Milling.

Web High Speed Steel & Cobalt Drills Speed And Feed Recommendations.

Web Speed And Feed Charts.

Related Post: