Drill Bit Angle Chart

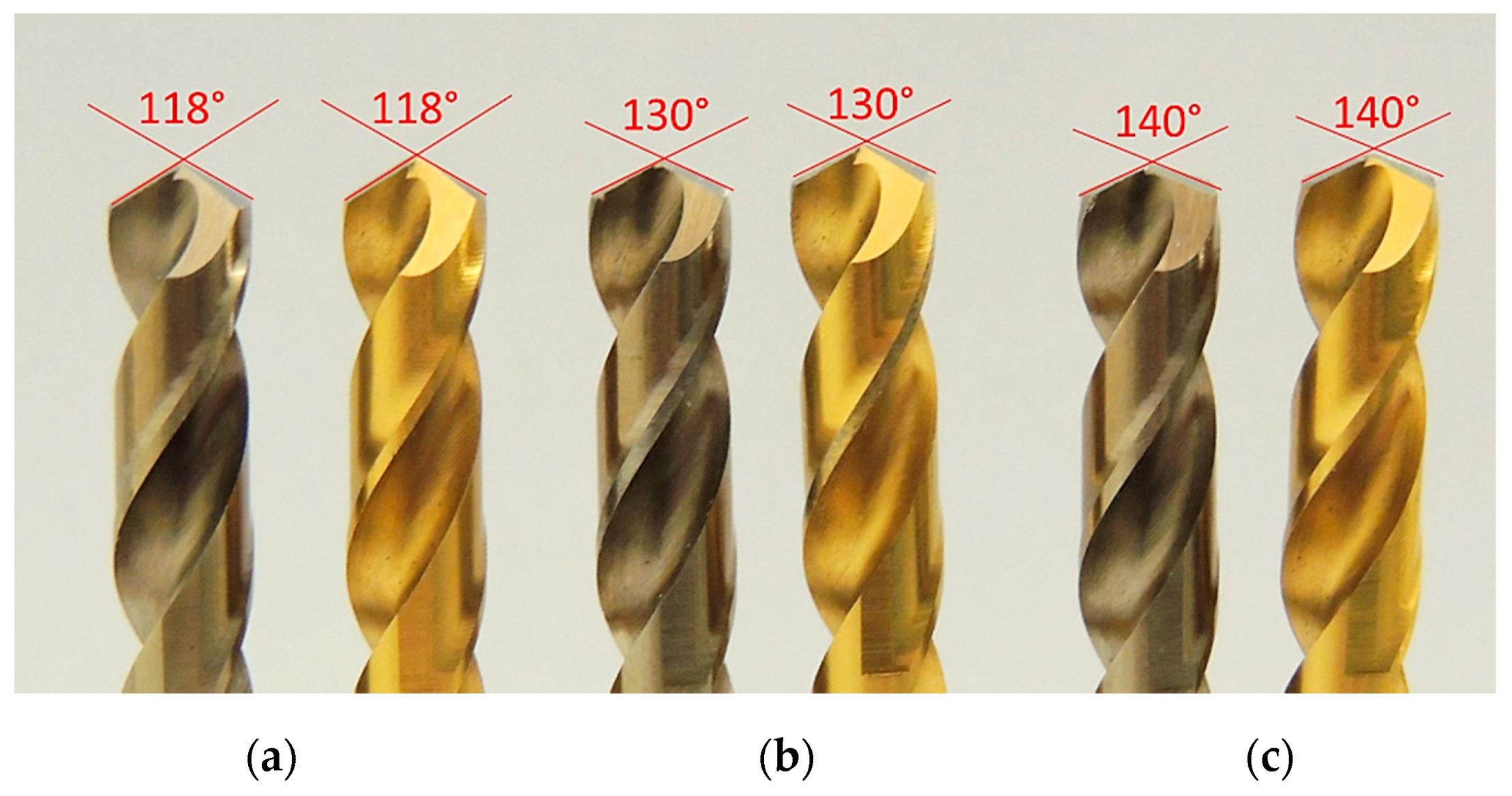

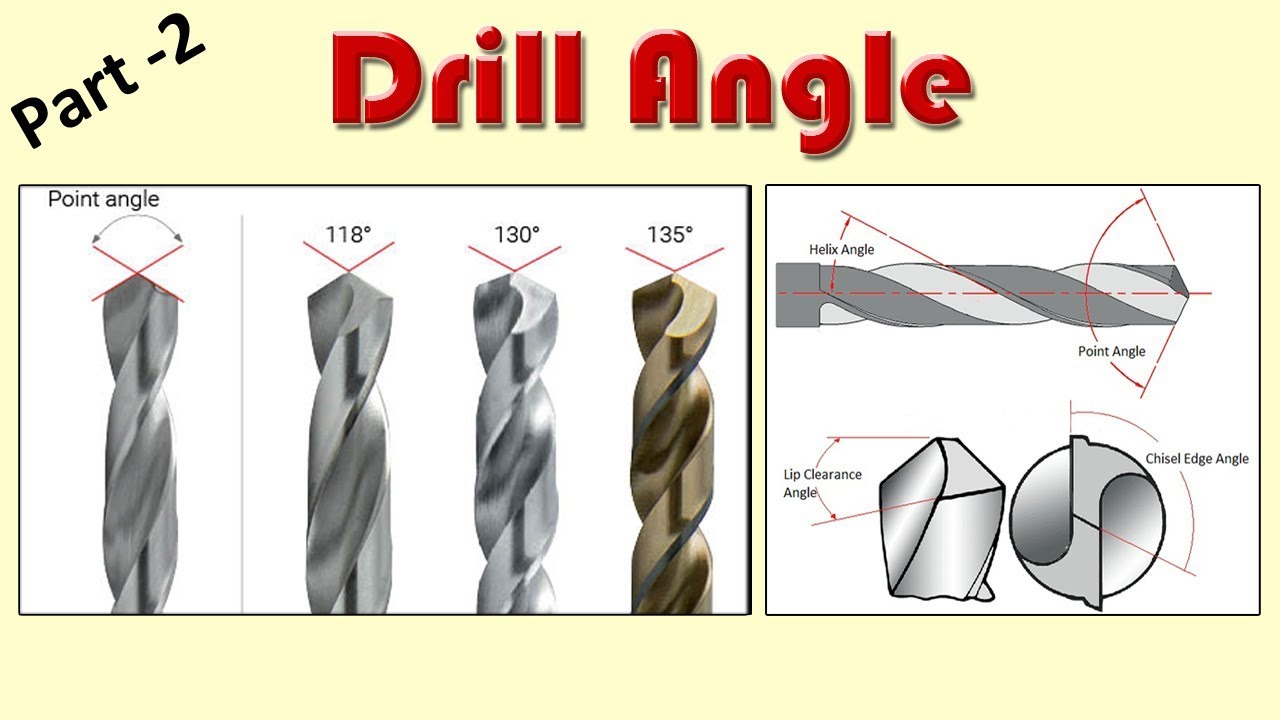

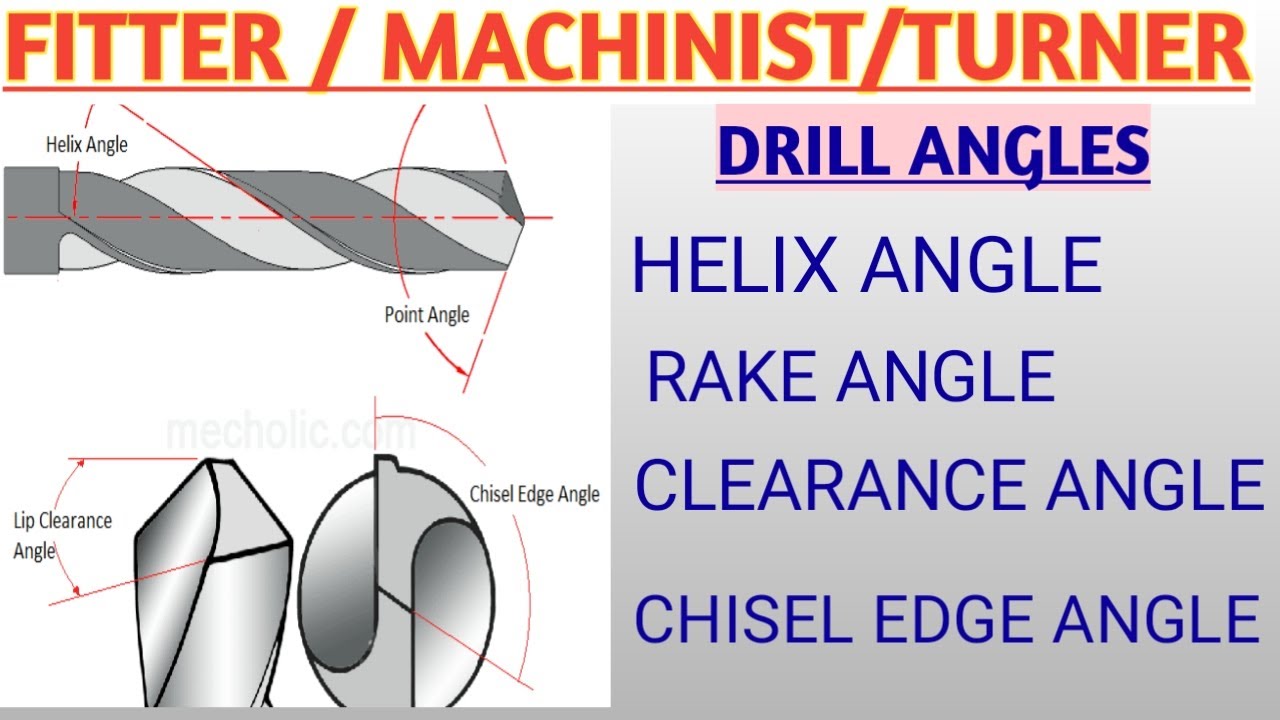

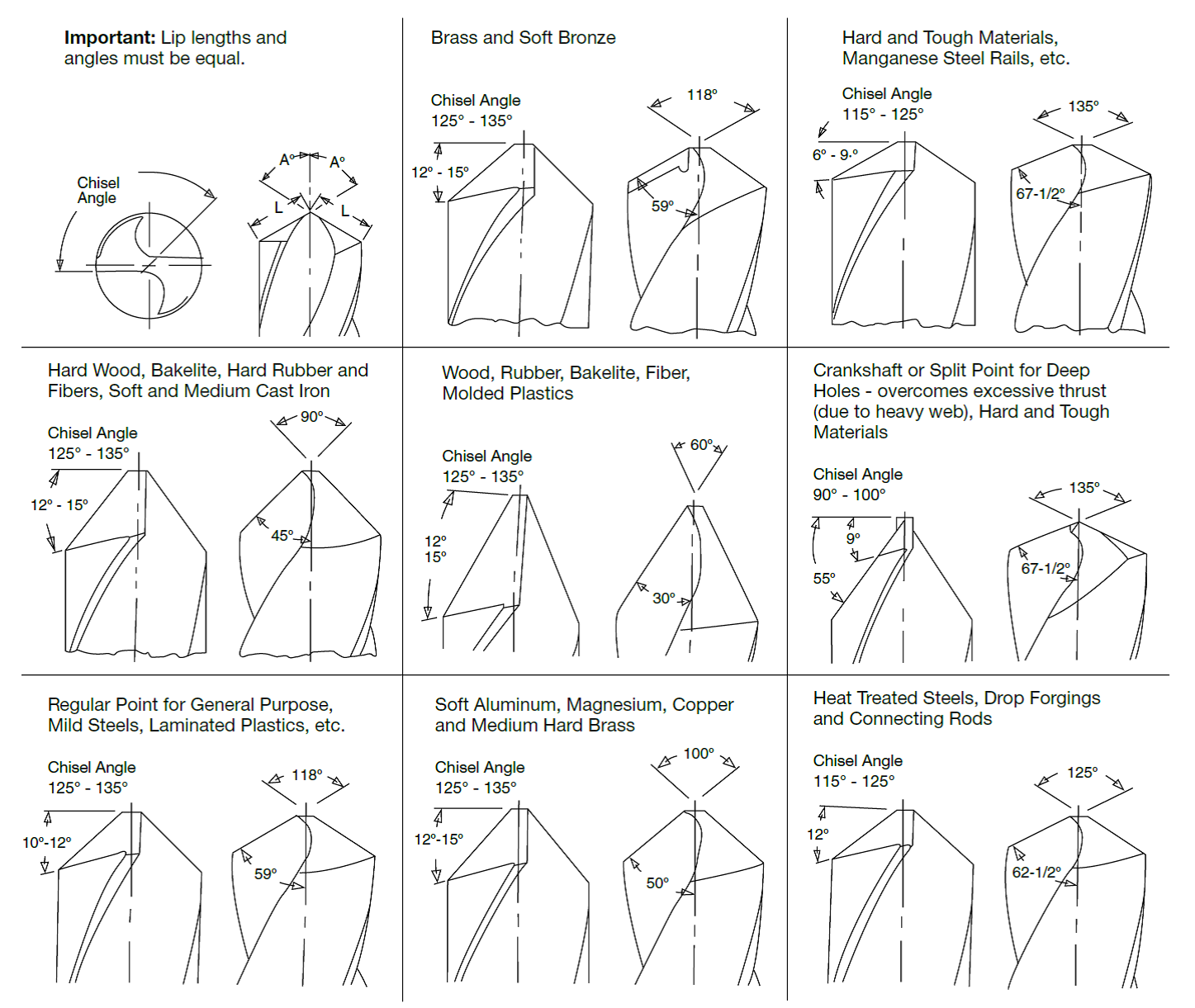

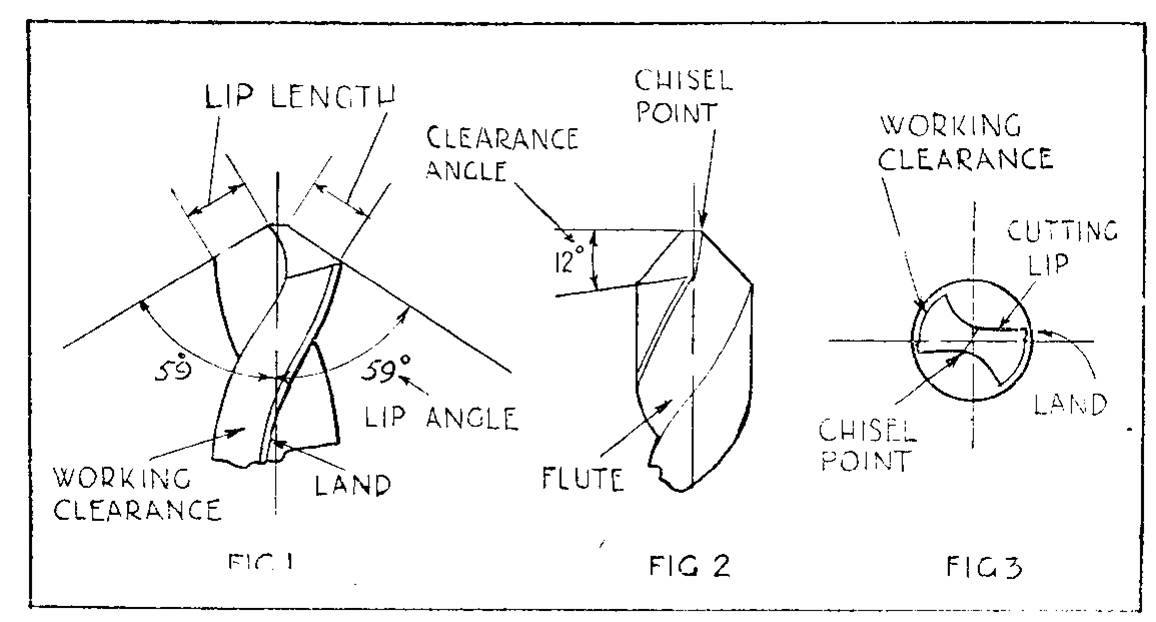

Drill Bit Angle Chart - Web the drill size chart below contains all commonly used centre drill bit sizes. Mathematically, 1mm = 0.0393701 inches. For typical mechanical tolerances that are achievable see: Mazoff requires 165% less thrust than the rp point to drill the same size hole. Read hundreds of great mechanical engineering articles at engineeringclicks.com: Web a drill bit’s angle refers to the angle between the spur and the cutting lip on its point. Web the most common angle for wood drill bits is 118 degrees, while larger bits may have a point angle of 135 degrees. Web clearance angles based on drill bit size should be used. How to convert drill bit mm to inch? Web the 118 and 135 degrees drill bit angles are two of the most common cutting angles in drills. Web the angle at which a drill bit should be sharpened depends on the material being drilled. These specialist drill bits are used for drilling centre. Web specifically, the lip length of a 1 diameter drill with 140° included angles will measure 9/16 per lip and the same drill with 118° included angles will measure 39/64 length. The difference between. For typical mechanical tolerances that are achievable see: Web the point angle is located on the head of the twist drill. Web the drill size chart below gives fractional sizes and their metric conversions up to 1 inch. Web the drill size chart below contains all commonly used centre drill bit sizes. Web the drill size chart provides a list. Mazoff requires 165% less thrust than the rp point to drill the same size hole. This is the most common angle for general purpose drilling in materials such as wood, plastic, and soft metals. Web specifically, the lip length of a 1 diameter drill with 140° included angles will measure 9/16 per lip and the same drill with 118° included. The angle is measured between both cutting edges on the point. Web the two most common drill bit point angles are 118 degrees and 135 degrees. Web the drill size chart contains twist drill data for up to 1.0 inches in diameter. Web the drill size chart below contains all commonly used centre drill bit sizes. When would you use. • various other drill point angles • flat bottom 180°(not. This is the most common angle for general purpose drilling in materials such as wood, plastic, and soft metals. Web the 118 and 135 degrees drill bit angles are two of the most common cutting angles in drills. Web drill bit rpm chart. Web the drill size chart below contains. Compare the common drill angles (118° and 135°) and the specialize… A drill bit with a 118° angle cuts more. Web the angle at which a drill bit should be sharpened depends on the material being drilled. The angle is measured between both cutting edges on the point. When the drill bit diameter is available in mm, it can be. This is the most common angle for general purpose drilling in materials such as wood, plastic, and soft metals. Web the two most common drill bit point angles are 118 degrees and 135 degrees. For typical mechanical tolerances that are achievable see: Compare the common drill angles (118° and 135°) and the specialize… Learn how to choose the right drill. The angle is measured between both cutting edges on the point. Learn how to choose the right drill point angle and configuration for your drilling application. The difference between the two is the shape; Web the point angle is located on the head of the twist drill. Web the most common angle for wood drill bits is 118 degrees, while. Mathematically, 1mm = 0.0393701 inches. Compare the common drill angles (118° and 135°) and the specialize… The difference between the two is the shape; Learn how to choose the right drill point angle and configuration for your drilling application. Web the 118 and 135 degrees drill bit angles are two of the most common cutting angles in drills. Web the drill size chart contains twist drill data for up to 1.0 inches in diameter. A drill bit with a 118° angle cuts more. Mazoff requires 165% less thrust than the rp point to drill the same size hole. When the drill bit diameter is available in mm, it can be converted into inches easily. Web the drill size. Knowing the different drill bit angles and considering factors such as. Working in metal and plastic a a b b c c d split point. Compare the common drill angles (118° and 135°) and the specialize… There are two main drill bit point angles: Web the two most common drill bit point angles are 118 degrees and 135 degrees. • various other drill point angles • flat bottom 180°(not. These specialist drill bits are used for drilling centre. Web the drill size chart provides a list of standard size drill bits in several measurement systems, including fractional, metric, wire gauge number, and letter. Web specifically, the lip length of a 1 diameter drill with 140° included angles will measure 9/16 per lip and the same drill with 118° included angles will measure 39/64 length. Web clearance angles based on drill bit size should be used. Learn how to choose the right drill point angle and configuration for your drilling application. Drill bit sharpening angle chart for wood. A drill bit with a 118° angle cuts more. Mathematically, 1mm = 0.0393701 inches. Web a drill bit’s angle refers to the angle between the spur and the cutting lip on its point. Web understanding the drill bit angles is a crucial factor in achieving successful drilling operations.

Drill bit angles 'Easily Explained', angles for materials

118 vs 135 Drill Bit Point Angles Explained. (with Pics)

Drill Bit Sharpening Angle Chart

Drill Bit Sharpening Angle Chart

Drill angle YouTube

Drill Bit Guide Best Types Chart Hand Tool Essentials

Drill Bit Sharpening Angle Chart Metal, Wood, and Masonry Bits

DRILL BIT ANGLES (हिन्दी)l ड्रिल के कोण Drill Angles Types Of Drill

Drill Bit Sharpening Angle Chart

DRILLING ROUND HOLES

The Difference Between The Two Is The Shape;

Web The Drill Size Chart Contains Twist Drill Data For Up To 1.0 Inches In Diameter.

Mazoff Requires 165% Less Thrust Than The Rp Point To Drill The Same Size Hole.

Read Hundreds Of Great Mechanical Engineering Articles At Engineeringclicks.com:

Related Post: