Dc Motor Capacitor Sizing Chart

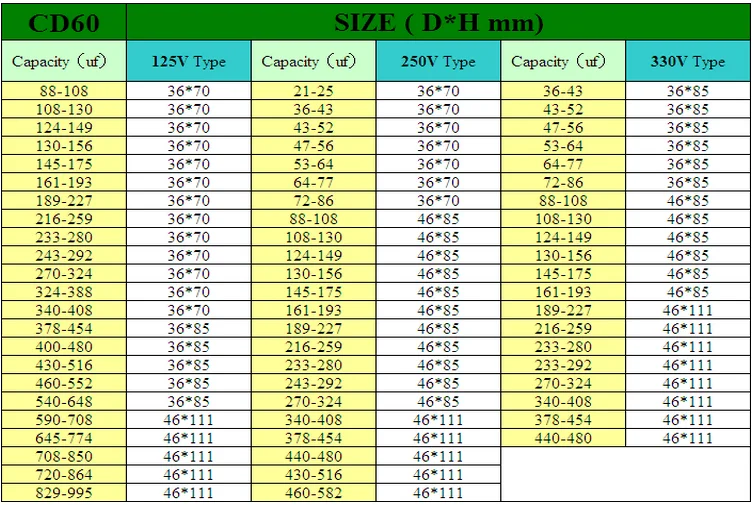

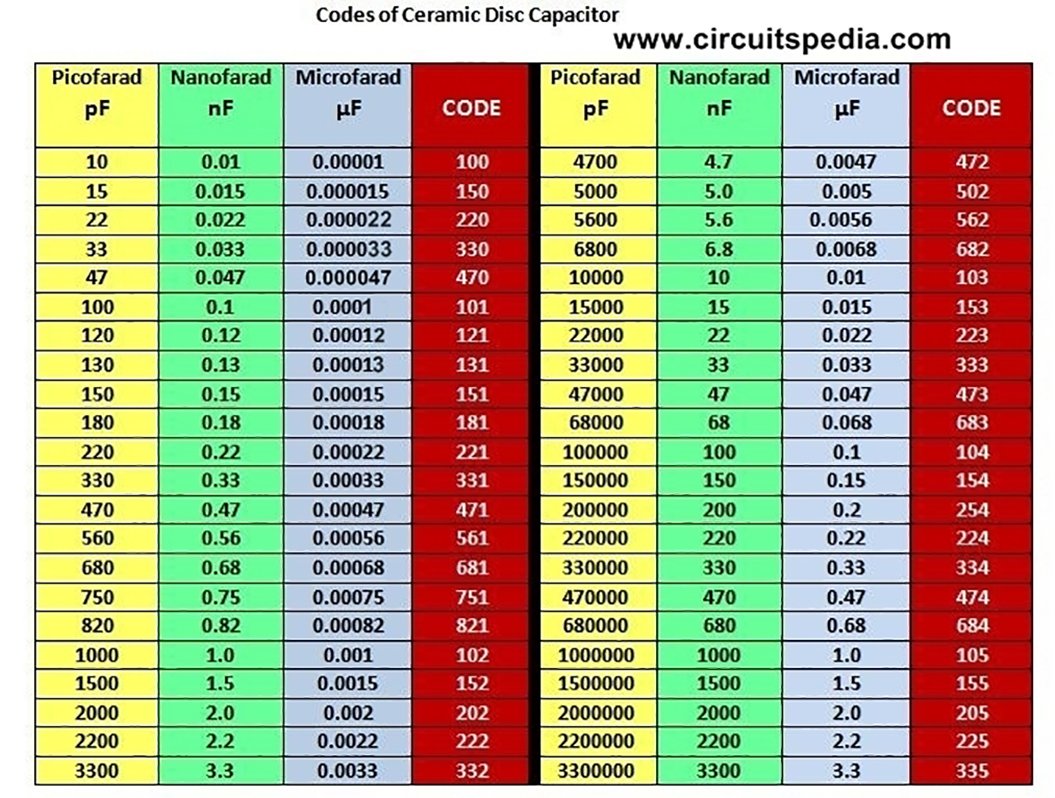

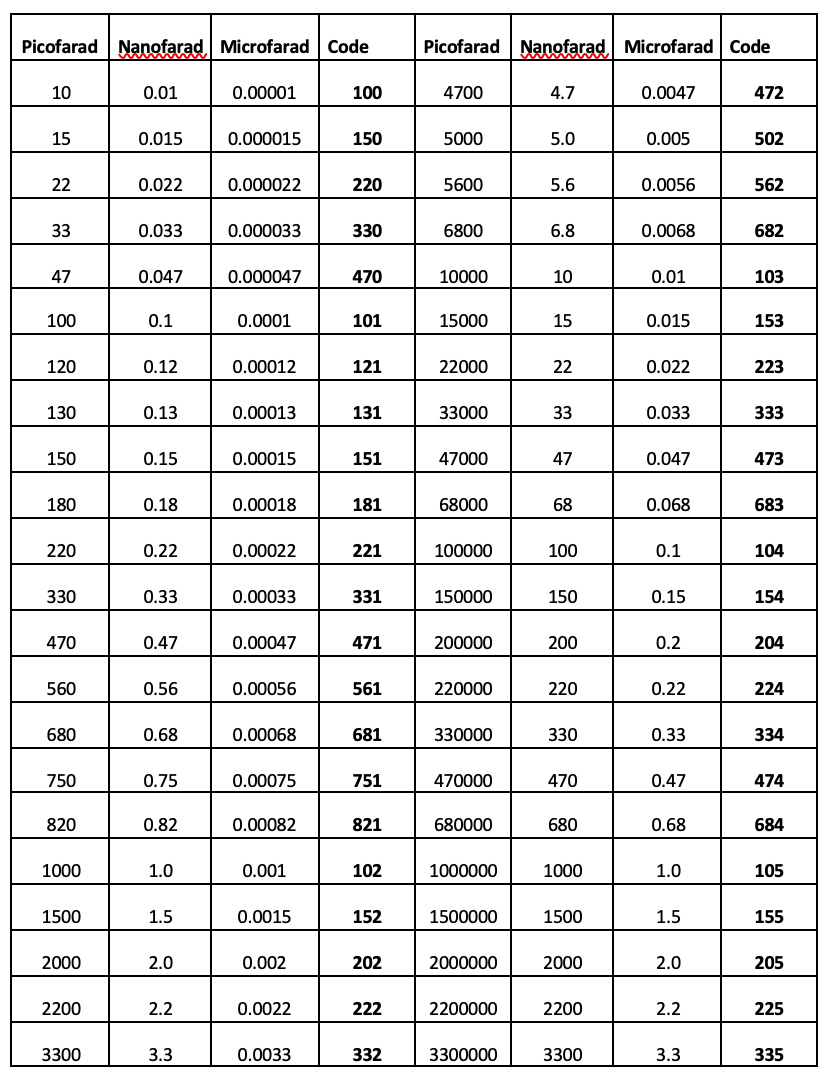

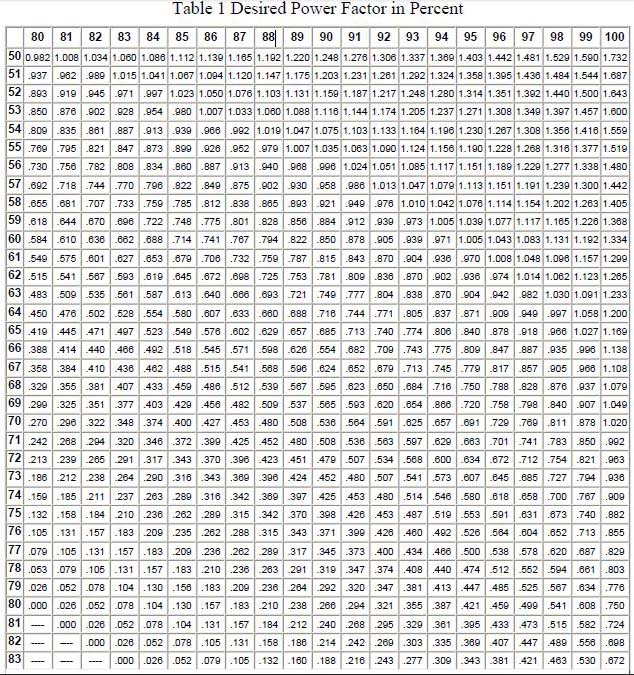

Dc Motor Capacitor Sizing Chart - Start capacitors possess a very large capacitance value for their size and voltage rating. For example, if you need to improve the existing power factor from 0.6 to 0.98, just look at the multiplier for both figures in the table which is 1.030. Guide to electric motor sizing. Usually with very large motors with normal load torque during acceleration. The capacitance value for which the capacitor has been designed, measured at 20°c at frequency of 1khz. Web this paper will present a practical mathematical approach on how to properly size a bus link capacitor for a high performance hard switched dc to ac inverter using film capacitors and will show how film capacitors are advantageous over electrolytic capacitors in terms of size, weight, lifetime, inverter efficiency and cost. Web this application note provides information how to calculate and dimension the input capacitor (dclink capacitor) for single phase motor bridge to drive brushed dc motors. To select the correct capacitance value, start with 30 to 50μf/kw and adjust the value as required, while measuring motor performance. Ideally place those caps on the motor terminals, right at the motor's case. Web inputting these values into the calculator using the formula, we find the appropriate capacitor size to be approximately 481.3μf. Web november 15, 2022 by simon mugo. Energy flowing back to power supply. The article guides electrical engineers on electric motor sizing and selection to satisfy their power system requirements. Web how to size and select a dc motor: Web this article series explains how to choose & buy an electric motor start capacitor, hard start capacitor, or run capacitor. Ideally place those caps on the motor terminals, right at the motor's case. The specs i have available for the motor are 2.25hp, 130v, 12.9a. 1) a rule of thumb has been developed over the years to help simplify this process. We also can use this basic formula to calculate capacitor sizing : 2 p = i xr. The primary source of heat in a dc motor is the power dissipated in the coil through copper losses. Web this article series explains how to choose & buy an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or. Energy flowing back to power supply. Rated capacitance of the capacitor c (μf): The specs i have available for the motor are 2.25hp, 130v, 12.9a. Guide to electric motor sizing. However, the exact sizing may vary based on the motor’s characteristics and manufacturer recommendations. The amount of current drawn from the line depends on the capacitor sizing. Enter the input voltage, motor power in watts, efficiency in percentage, frequency, then press the calculate button, you get the required capacitance value. 2 p = i xr. This 'grounds' the case to rf to prevent it from radiating interference, but doesn't put a. To select the. The article guides electrical engineers on electric motor sizing and selection to satisfy their power system requirements. We also can use this basic formula to calculate capacitor sizing : Usually with very large motors with normal load torque during acceleration. Web 369 1 3 6. By miles budimir 1 comment. Web do i need a capacitor and how would i calculate what size i need? A popular configuration is two 100nf capacitors in series, one from each motor terminal to the metal case. The amount of current drawn from the line depends on the capacitor sizing. Web inputting these values into the calculator using the formula, we find the appropriate. Web the basic formula for sizing a run capacitor is approximately 0.1 to 0.2 μf per horsepower, and for a start capacitor, it’s around 100 to 200 μf per horsepower. Web a start capacitor is used to briefly shift phase on a start winding in a single phase electric motor to create an increase in torque. Web how to sizing. Start capacitors possess a very large capacitance value for their size and voltage rating. Motor start capacitors are used during the motor startup phase and are disconnected from the circuit once the rotor reaches a predetermined speed, which is usually about 75% of the maximum speed for that motor type. The amount of current drawn from the line depends on. A capacitor can be checked and replaced in 20 minutes if the producer has the replacement on hand, a few tools, and the knowledge to safely troubleshoot. 1) a rule of thumb has been developed over the years to help simplify this process. Enter the input voltage, motor power in watts, efficiency in percentage, frequency, then press the calculate button,. The primary source of heat in a dc motor is the power dissipated in the coil through copper losses. Guide to electric motor sizing. The amount of current drawn from the line depends on the capacitor sizing. Motor start capacitors are used during the motor startup phase and are disconnected from the circuit once the rotor reaches a predetermined speed, which is usually about 75% of the maximum speed for that motor type. To select the correct capacitance value, start with 30 to 50μf/kw and adjust the value as required, while measuring motor performance. The specs i have available for the motor are 2.25hp, 130v, 12.9a. That includes pwm and motor on/off signals. Web this article series explains how to choose & buy an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or fan motor where the capacitor is to be installed. Usually with very large motors with normal load torque during acceleration. For example, if you need to improve the existing power factor from 0.6 to 0.98, just look at the multiplier for both figures in the table which is 1.030. The article guides electrical engineers on electric motor sizing and selection to satisfy their power system requirements. Web do i need a capacitor and how would i calculate what size i need? The max i ever need to use it is maybe 80%, after that it's almost too fast to be useable. This 'grounds' the case to rf to prevent it from radiating interference, but doesn't put a. Starting torque is the same as for across the line starting. Web the following power factor correction chart can be used to easily find the right size of capacitor bank for desired power factor improvement.

Motor Capacitor Sizing Chart Transborder Media

Single Phase Motor Capacitor Sizing Chart

Run Capacitor Size Chart

Basic Electronics Selecting a Capacitor, Capacitor Values

Capacitor sizing for power factor correction Electrical Engineering

Motor Capacitor Sizing Chart Transborder Media

Common capacitor code chart atworkvol

Power Factor Correction Capacitors Sizing Calculations Part Eleven

Capacitor Sizes Chart Pdf diazgard

Capacitor Equivalent Chart A Visual Reference of Charts Chart Master

Enter The Input Voltage, Motor Power In Watts, Efficiency In Percentage, Frequency, Then Press The Calculate Button, You Get The Required Capacitance Value.

Web November 15, 2022 By Simon Mugo.

I've Attached A Rudimentary Schematic Of What I Did Below.

Web Inputting These Values Into The Calculator Using The Formula, We Find The Appropriate Capacitor Size To Be Approximately 481.3Μf.

Related Post: