Cutting Crown Flat Chart

Cutting Crown Flat Chart - For this first piece, both ends will be squared off and cut at 90° (or a 0° angle on your saw) while the molding rests flat on your saw (on flat). Web to be honest, once you steer away from 90 degree corners, cutting crown molding flat in the miter saw gets a little complicated. Cutting crown molding flat on your miter saw is one of the most challenging cuts you can make in woodworking. Web here is an easier, more precise method you can use to cut crown molding while it's flat on a miter saw. Web joe fusco taught me how to understand crown molding, especially how to install it on a cathedral ceiling. And i’ll always remember the crown chart he prepared and allowed me to publish in my finish carpentry book. I’ll always remember him for that. Web place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). Our crown moldings cut in most positions in most miter saws. I generally only use small crown moulding for furniture but the cuts are the same as for wall/ceilings. Web set your miter saw to bevel (tilt) left at 33.9 degrees. There are no more spring angles to figure. Web joe fusco’s crown molding miter & bevel angle chart. Once that's locked in, you're all set. Flip the material around to cut both ends of the inside and outside corners. (your saw might say 33.8 — the.1 degree is not enough of a difference to matter.) your crown molding always lays flat on the saw. Start with cutting a regular inside 90 degree corner. Web installing crown molding in your home or on a project? The standard angle of a wall to ceiling is 90 degrees. New trim carpenters often. Miter will change between right and left (but at the same setting of 31.6 degrees). Set saw miter and bevel angles from table and diagrams below. Web place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). The standard angle of a wall to ceiling is 90 degrees. Master the process. You must flip the material around to cut both ends of the inside and outside corners. Web joe fusco taught me how to understand crown molding, especially how to install it on a cathedral ceiling. Installing traditional crown moulding requires patience and effort. Web here's a convenient reference for looking up the miter angle and face bevel for cutting and. Installing traditional crown moulding requires patience and effort. Miter will change between right and left (but at the same setting of 31.6 degrees). Web master diy crown molding installation with our expert tips on how to cut crown molding flat, measuring, and precise fitting. This should be easy to visualize. 85k views 10 years ago. This should be easy to visualize. Cutting creative crown flat back foam crown moldings. Cutting molding on a miter saw can be tricky business. Web set your miter saw to bevel (tilt) left at 33.9 degrees. Our crown moldings cut in most positions in most miter saws. Web here is an easier, more precise method you can use to cut crown molding while it's flat on a miter saw. You can find a chart here with some numbers that may help, and another here, or, you can figure out the angles yourself using a little trigonometry. A compound miter cut = making a cut that is both. There are no more spring angles to figure. Miter will change between right and left (but at the same setting of 31.6 degrees). Cutting creative crown flat back foam crown moldings. Once that's locked in, you're all set. For this first piece, both ends will be squared off and cut at 90° (or a 0° angle on your saw) while. Miter saw measure and mark the length of the molding. Web joe fusco’s crown molding miter & bevel angle chart. Web cutting crown molding on the flat. Web master diy crown molding installation with our expert tips on how to cut crown molding flat, measuring, and precise fitting. Web set your miter saw to bevel (tilt) left at 33.9 degrees. We subtract 90 from 120, which gives us a 30 degree. For this first piece, both ends will be squared off and cut at 90° (or a 0° angle on your saw) while the molding rests flat on your saw (on flat). Web how to cut crown molding. No more complex compound miter cuts to make. Compound method (flat) molding. Take an angle finder and measure the degree from the wall to the ceiling. The standard angle of a wall to ceiling is 90 degrees. Most techniques for cutting crown molding involve awkwardly holding the crown against the fence of the saw while making the cut. Web installing crown molding in your home or on a project? Start with cutting a regular inside 90 degree corner. Let us assume that you measure and angle of 120 degrees. For this first piece, both ends will be squared off and cut at 90° (or a 0° angle on your saw) while the molding rests flat on your saw (on flat). Set saw miter and bevel angles from table and diagrams below. Then set the bevel of your saw matching the direction of your miter to 33.9 degrees. 85k views 10 years ago. You can find a chart here with some numbers that may help, and another here, or, you can figure out the angles yourself using a little trigonometry. Web to be honest, once you steer away from 90 degree corners, cutting crown molding flat in the miter saw gets a little complicated. Web how to cut crown molding. Cutting crown molding flat on your miter saw is one of the most challenging cuts you can make in woodworking. *these two things will change depending on the cut you are making. Web joe fusco taught me how to understand crown molding, especially how to install it on a cathedral ceiling.

The 'Secret' Numbers For Cutting Crown Flat Family Handyman

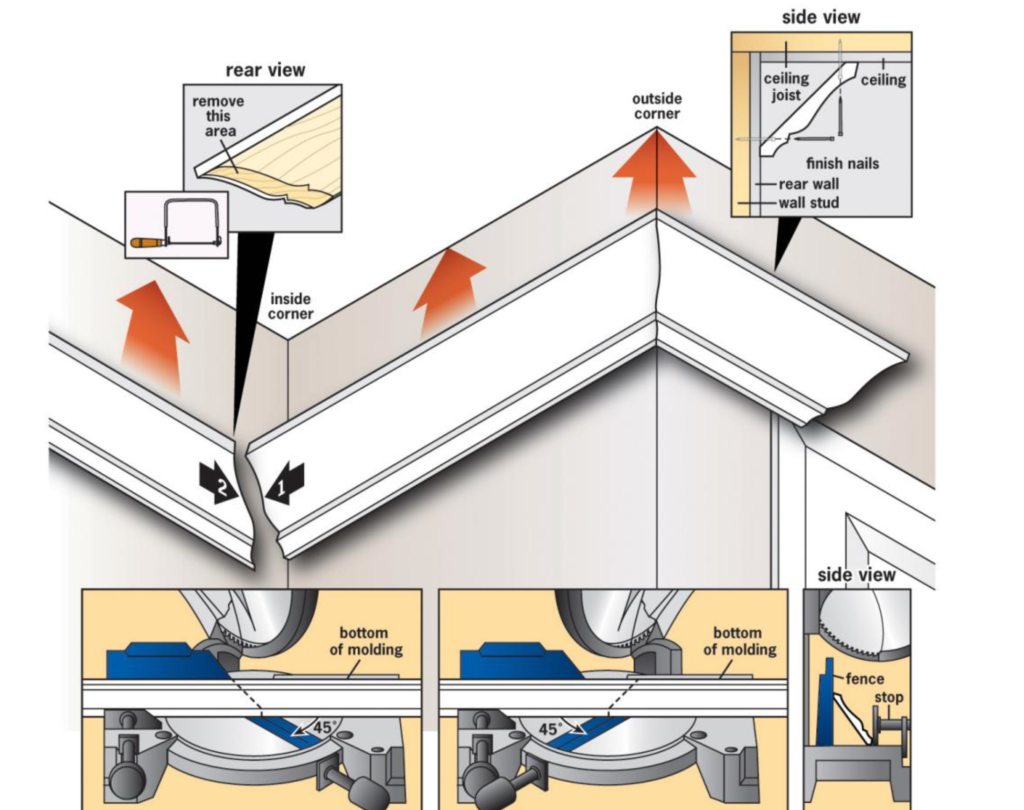

How To Cut Crown Molding Inside Corners With A Miter Saw Next Saw

How to Cut Crown Molding Laying Flat

Joe Fusco’s Crown Chart THISisCarpentry

How To Install Interior Crown Molding The Complete Guide To Inside

Angles For Cutting Crown Molding Flat

The 'Secret' Numbers For Cutting Crown Flat Family Handyman

How to cut crown moulding angles flat (& adding rope lighting) YouTube

crown on a 45 angle Fine Homebuilding

How to Cut Crown Moulding The Home Depot

Precise Measurements And Quality Cuts Ensure A Smooth Joint Between Segments.

There Are No More Spring Angles To Figure.

And I’ll Always Remember The Crown Chart He Prepared And Allowed Me To Publish In My Finish Carpentry Book.

This Should Be Easy To Visualize.

Related Post: