Cutting Angles For Crown Molding Chart

Cutting Angles For Crown Molding Chart - This discussion of cutting crown molding includes a set of tables for determining angle and bevel cuts when cutting flat on the saw table. No more complex compound miter cuts to make. Armed with this information, you can confidently cut your crown molding at the precise angle required for a flawless installation. Web by gary katz on september 12, 2008. Finding compound angles for crown moulding. Web to cut weird angles for crown molding, one needs to measure the angle for their corners and the angle for the peak of the molding (where the wall meets the ceiling) and then adjust their miter saw accordingly. Web in woodworking, a miter is a joint made by crosscutting two pieces of boards at an angle (or two different angles) to form a corner at a specific joint angle. So print this chart and carry it in your truck. *these two things are constant: Web there are three common angles for crown molding and about 100 different ways to cut it. Web in woodworking, a miter is a joint made by crosscutting two pieces of boards at an angle (or two different angles) to form a corner at a specific joint angle. Web if you’re cutting templates for crown molding with 45 degree spring angles, substitute these angles on your miter saw. Web crown molding table is for cutting 52°/38° (38°. Here's a convenient reference for looking up the miter angle and face bevel for cutting and fitting crown moulding. Asked 11 years, 1 month ago. This method of cutting crown molding can be done with any miter saw. Swing the table to cut the miter, tilt the blade to cut the bevel. Web there is no more need for crown. Flip the material around to cut both ends of the inside and outside corners. Modified 5 years, 2 months ago. Crown typically comes in 45°/45° or 52°/38°. Web execute flawless crown molding installations effortlessly. Cutting approach if often determined for you by the type of saw you have: Set saw miter and bevel angles from table and diagrams below. Set miter angle to 35.3. We see miter joints at the corners of a picture frame, crown moldings, and. Swing the table to cut the miter, tilt the blade to cut the bevel. Standard crown molding with 52° and 38° angles, and assume that the angle between the wall. *these two things are constant: I have a 10 sliding comp. In fact, you can cut the compound. Web in this video i show how i find inside and outside angles and cut them on my miter saw. In this example we will show you how to cut a 120 degree vaulted up and down crown molding corner for vaulted,. *these two things are constant: And i’ll always remember the crown chart he prepared and allowed me to publish in my finish carpentry book. I’ll always remember him for that. Web place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). Web there is no more need for crown molding spring. Web when using an angle chart, it is important to know the spring angle of the crown, which is the measured angle between the back of the crown to the wall when the molding is installed. In some cases, one may need a block or jig to adjust their saw properly. Visit his roof framing site at www.josephfusco.org. Dual bevel. See what tools and measurements i use to get the p. So print this chart and carry it in your truck. I have a 10 sliding comp. Set the miter angle to 31.6 degrees. How to cut crown molding in 9 steps. On most saws, “31.6” is specially marked. In fact, you can cut the compound. I do 4 examples in this video. I have a 10 sliding comp. Lay the crown flat and cut. In fact, you can cut the compound. August 7, 2008 reprinted with permission from joseph fusco. So print this chart and carry it in your truck. Armed with this information, you can confidently cut your crown molding at the precise angle required for a flawless installation. Standard crown molding with 52° and 38° angles, and assume that the angle between. On most saws, “31.6” is specially marked. Web 56k views 3 years ago. Web simply enter the wall angle and spring angle into the designated input fields. Asked 11 years, 1 month ago. August 7, 2008 reprinted with permission from joseph fusco. For an inside corner cut, you’ll need to measure the exact angles. I’ll always remember him for that. Web if you’re cutting templates for crown molding with 45 degree spring angles, substitute these angles on your miter saw. Set the bevel to 33.9 degrees. Not many crown charts calculate miter/bevel angles for corners less than 60 degrees (even the bosch angle finder will not currently calculate miter/bevel angles for corners sharper than 60 degrees). We see miter joints at the corners of a picture frame, crown moldings, and. Web execute flawless crown molding installations effortlessly. To find the correct bevel and miter angles, use a chart, such as this one, which was laminated for jobsite use by a carpenter named bruce abernathy: I have a 10 sliding comp. Web what miter and bevel angle do i need for coping 38/52 crown molding? So print this chart and carry it in your truck.

Compound miter saw angles crown molding kits, cordless drill and

Crown Moulding Angles

Crown Molding Cutting Angles Chart

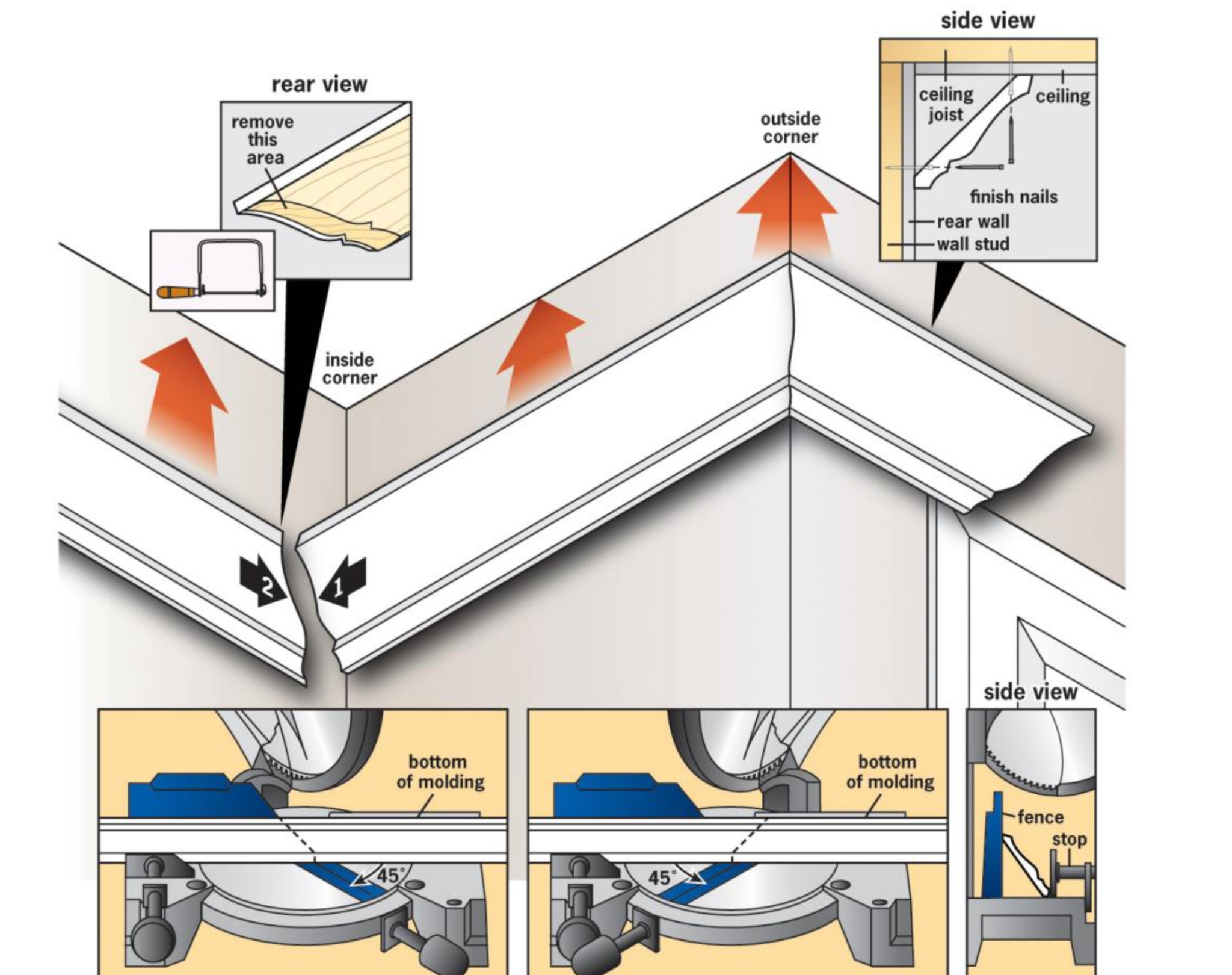

How to Cut Crown Molding Laying Flat

How To Cut Crown Molding Inside Corners With A Miter Saw Next Saw

How To Measure Crown Molding The Woodworking Post

How to Cut Crown Moulding The Home Depot

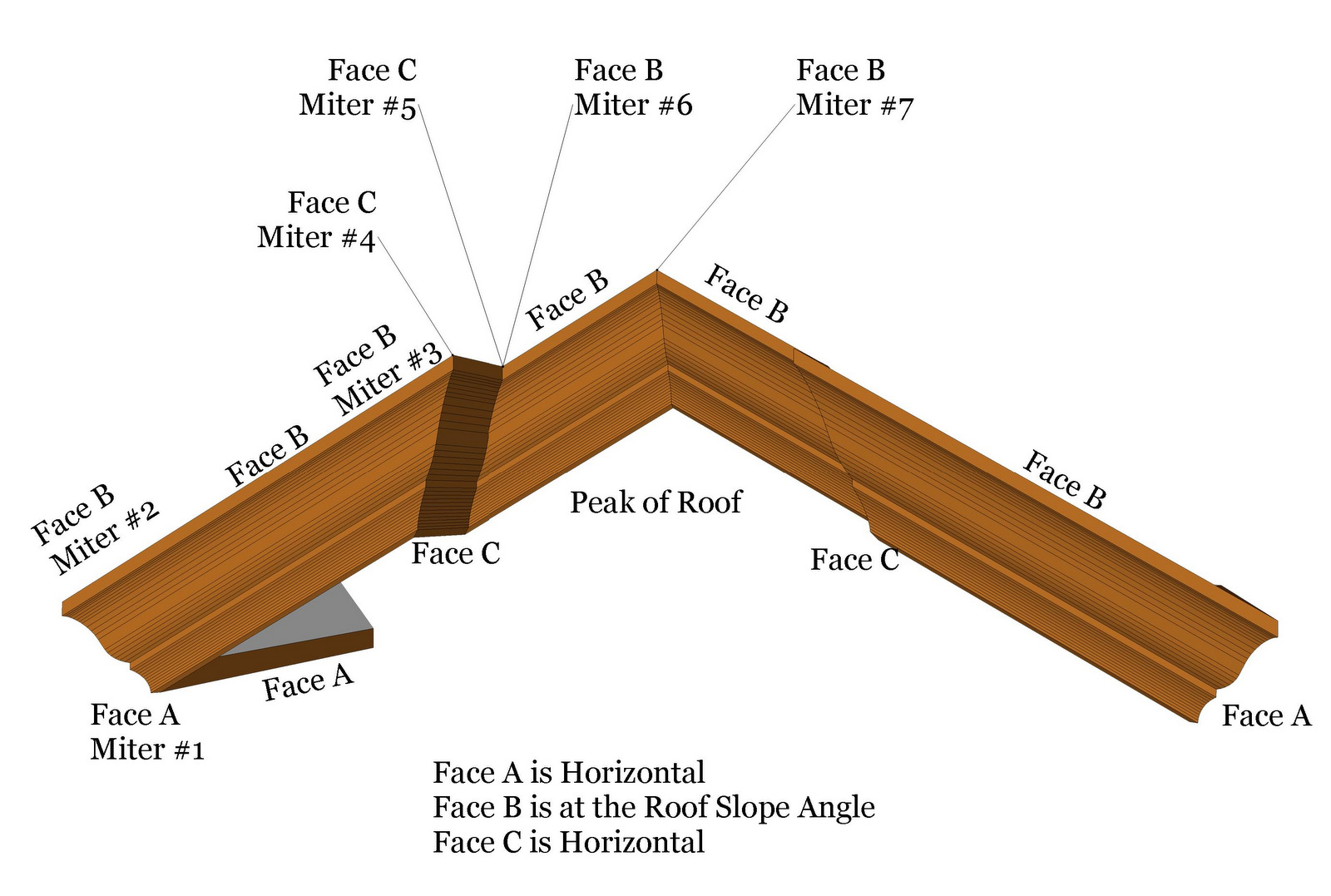

Roof Framing Geometry Rake Crown Moulding Geometry

Cutting Crown Molding Chart

How To Install Interior Crown Molding The Complete Guide To Inside

This Discussion Of Cutting Crown Molding Includes A Set Of Tables For Determining Angle And Bevel Cuts When Cutting Flat On The Saw Table.

Web There Is No More Need For Crown Molding Spring Angles.

Standard Crown Molding With 52° And 38° Angles, And Assume That The Angle Between The Wall Is 90°.

Armed With This Information, You Can Confidently Cut Your Crown Molding At The Precise Angle Required For A Flawless Installation.

Related Post: