Copper Fitting Take Off Chart

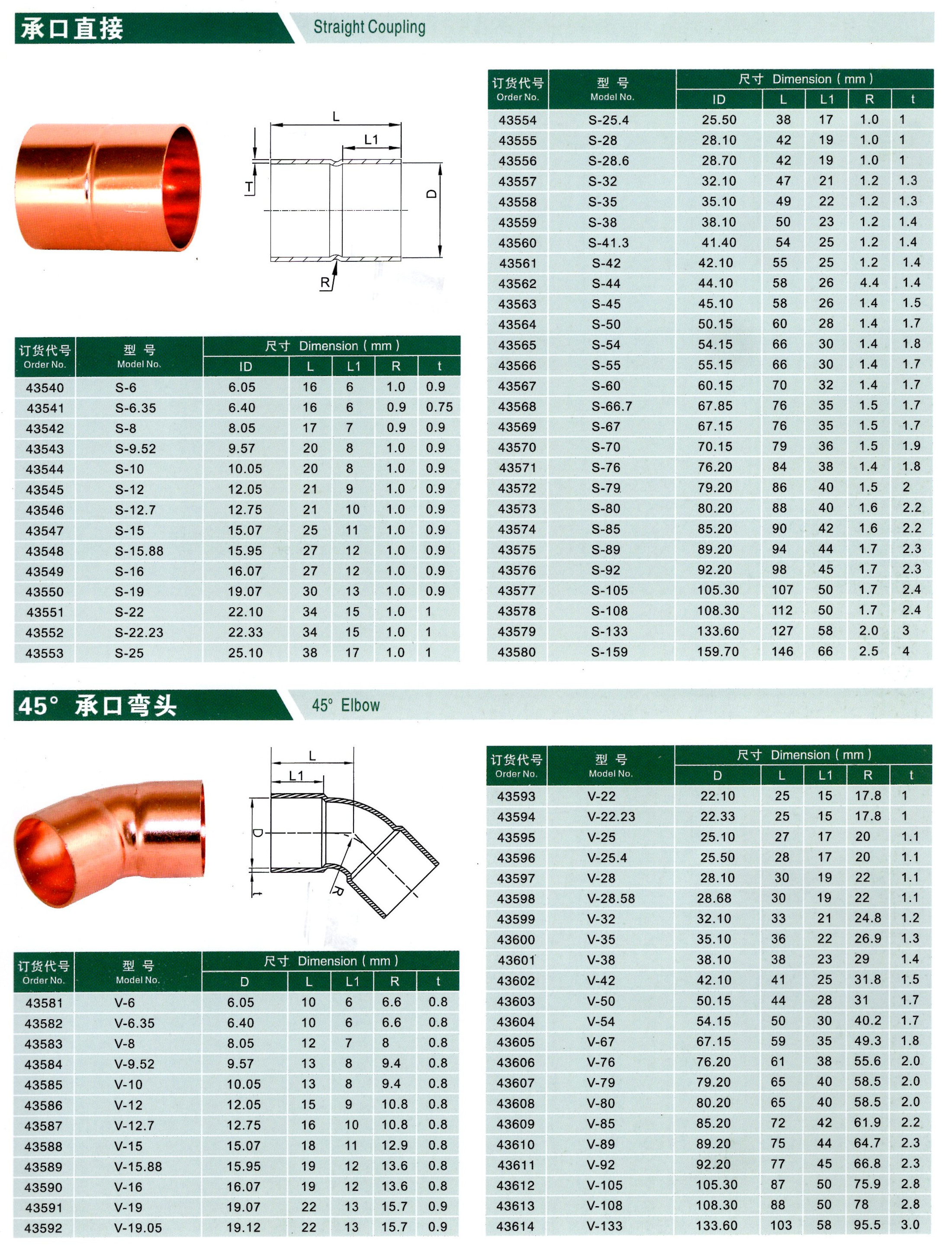

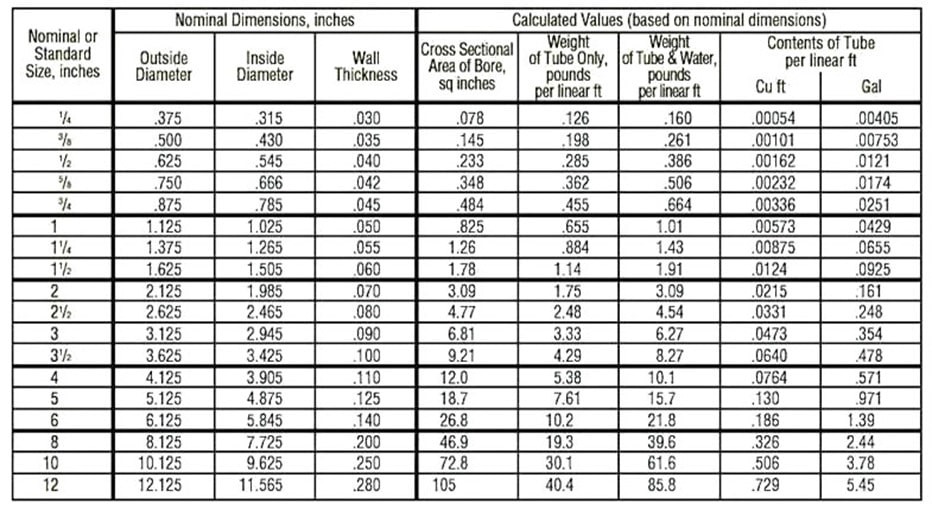

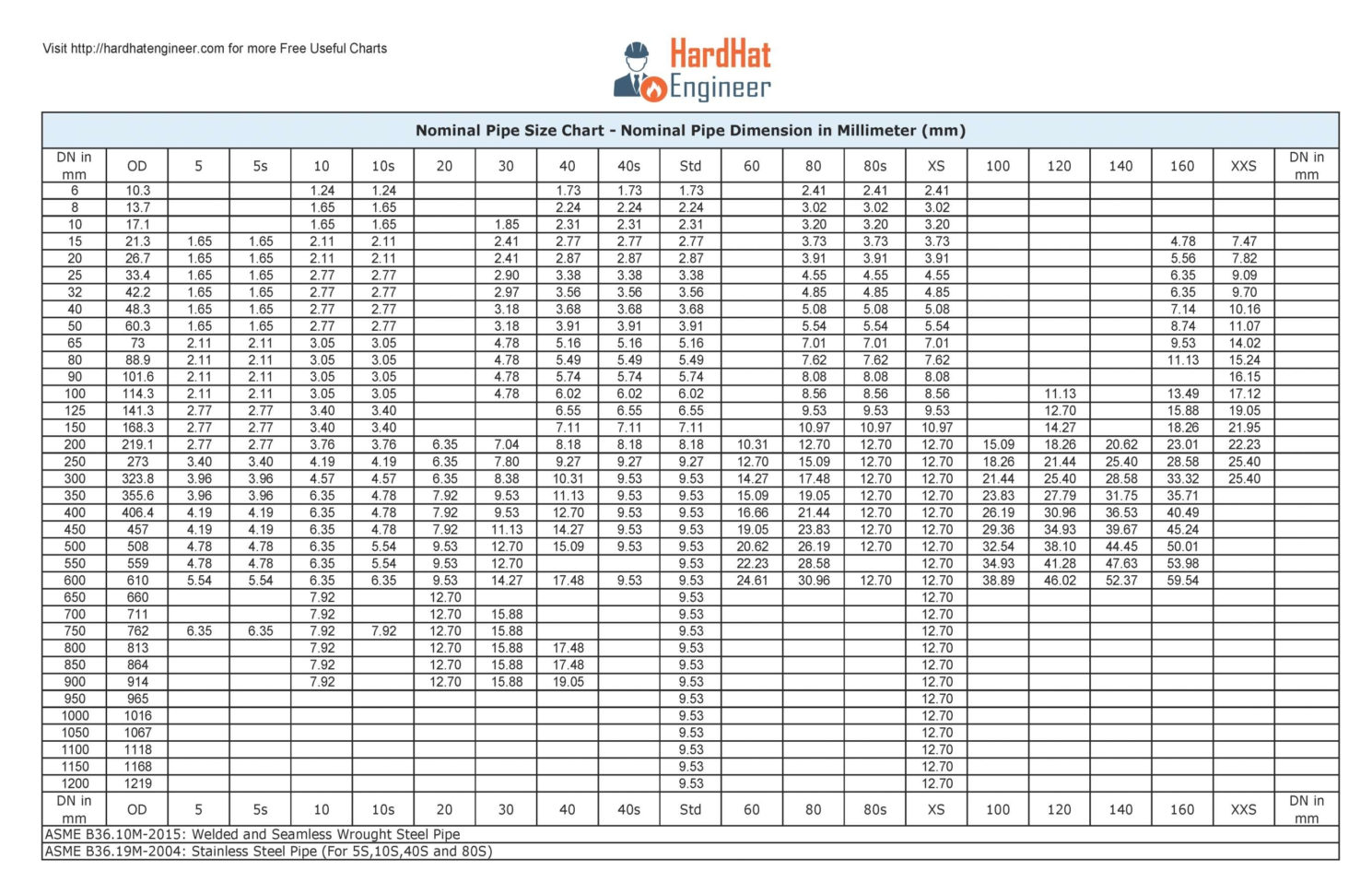

Copper Fitting Take Off Chart - It is used when velocity is not a problem. Viega products are designed to be installed by licensed and trained plumbing and mechanical professionals who are familiar with viega products and their installation. Allowances are for streamlined soldered fittings and recessed threaded fittings. Web 6 anvil® pipe fitters handbook gruvlok® installation and assembly figures 7400 & 7401 couplings 1. Propress g™ fittings also incorporate the viega patented smart connect™ feature. With edi, you can trade: Figure 14.7 brazing flux recommendations. Whether you’re working with elbows, tees, or couplings, you’ll find detailed measurements and specifications to ensure precise installations every time. Web browse copper pressure fittings in the mueller industries inc. Web find the most extensive selection of copper fittings for supply and pressurized systems in wrot copper and cast bronze. With edi, you can trade: Web nibco uses cookies to help us improve your overall experience. The capillary space between tube and fitting is approximately 0.004 in. If you wish to decline the use of persistent. Type l hard drawn copper tubing per astm b88. Web figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Web work involved in traditional order taking. Failure to remove them can interfere with capillary action and may lessen the strength of the joint and cause failure. Web 18 rows table 14.7. S purchase orders s product activity data s po acknowledgements. Type l hard drawn copper tubing per astm b88. Web 18 rows table 14.7. Available sizes range from ½” through 4” in diameter. Web a h e a d o f ®t h e f l o w www.nibco.com nibco inc. By using this site, you agree to the use of these cookies. Fittings for steel pipe screw onto tapered external threads on the end of the pipe. Download resources, view cad/bim drawings, and learn about exclusive technology and quality standards. Failure to remove them can interfere with capillary action and may lessen the strength of the joint and cause failure. Web a master copper fitting take off chart provides a comprehensive reference. This document is subject to updates. Pressure loss in fittings and valves expressed as equivalent length of tube, feet. Available sizes range from ½” through 4” in diameter. The taper jams the threads together to prevent leaks. With edi, you can trade: Check & lubricate gasket check gasket to be sure it is compatible for the intended service. Web fitting cups is crucial to proper flow of filler metal into the joint. • bronze sand cast conforming to uns c89836. Web browse copper pressure fittings in the mueller industries inc. It is used when velocity is not a problem. By using this site, you agree to the use of these cookies. The fitting provides a means of changing the pipeline direction 90 degrees. For the most current viega technical literature, please visit www.viega.us. 1 applies to 6 x 4 no. Web fitting cups is crucial to proper flow of filler metal into the joint. The taper jams the threads together to prevent leaks. Allowances are for streamlined soldered fittings and recessed threaded fittings. Figure 14.7 brazing flux recommendations. • wrought copper per astm b75 c12200 or astm b152 c110001 and ansi b16.22. Propress g™ fittings also incorporate the viega patented smart connect™ feature. World headquarters • 1516 middlebury st. Figure 14.7 brazing flux recommendations. Index of tables and figures that represent the supporting technical data. Web nibco uses cookies to help us improve your overall experience. The taper jams the threads together to prevent leaks. If you wish to decline the use of persistent. Download resources, view cad/bim drawings, and learn about exclusive technology and quality standards. Web nibco® mechanical press copper fittings for use in plumbing or mechanical applications. • wrought copper per astm b75 c12200 or astm b152 c110001 and ansi b16.22. Web figure 14.6 melting temperature ranges for copper and copper alloys,. Please refer to nibco technical data sheets and catalogs for engineering and installation information. Fittings for copper and plastic pipe slip over the end of the pipe and are soldered or glued in place. World headquarters • 1516 middlebury st. 1 applies to 6 x 4 no. Download resources, view cad/bim drawings, and learn about exclusive technology and quality standards. Allowances are for streamlined soldered fittings and recessed threaded fittings. Web how a fitting connects pipes depends on the type of pipe: • wrought copper per astm b75 c12200 or astm b152 c110001 and ansi b16.22. Check & lubricate gasket check gasket to be sure it is compatible for the intended service. Figure 14.7 brazing flux recommendations. Available sizes range from ½” through 4” in diameter. Propress g™ fittings also incorporate the viega patented smart connect™ feature. Web 18 rows table 14.7. The fitting provides a means of changing the pipeline direction 90 degrees. Web ahead of the flow® www.nibco.com nibco inc. Web a master copper fitting take off chart provides a comprehensive reference guide for all types of copper fittings.

Ac Connection Copper Fitting 90 Degree Copper Elbow Buy Copper Elbow

Copper Fitting Takeoff Chart

Refrigeration and AC copper fitting

Weld Fitting Take Off Chart

Copper Fitting Technical Info Manibhadra Fittings

Pipe Fitting Dimensions

Copper Pipe Fittings and ASTM B88 C12200 Elbow/ Coupling Manufacturer

Pipe Schedule Thickness Chart Pipe Fittings' Dimension, 54 OFF

Copper Fittings Manufacturer Threaded Copper Pipe Fittings

Piping Takeoff Spreadsheet —

For Threaded Fittings, Double The Allowances Shown In The Table.

Failure To Remove Them Can Interfere With Capillary Action And May Lessen The Strength Of The Joint And Cause Failure.

Web Figure 14.6 Melting Temperature Ranges For Copper And Copper Alloys, Brazing Filler Metals, Brazing Flux And Solders.

World Headquarters † 1516 Middlebury St.

Related Post: