Control Chart Vs Run Chart

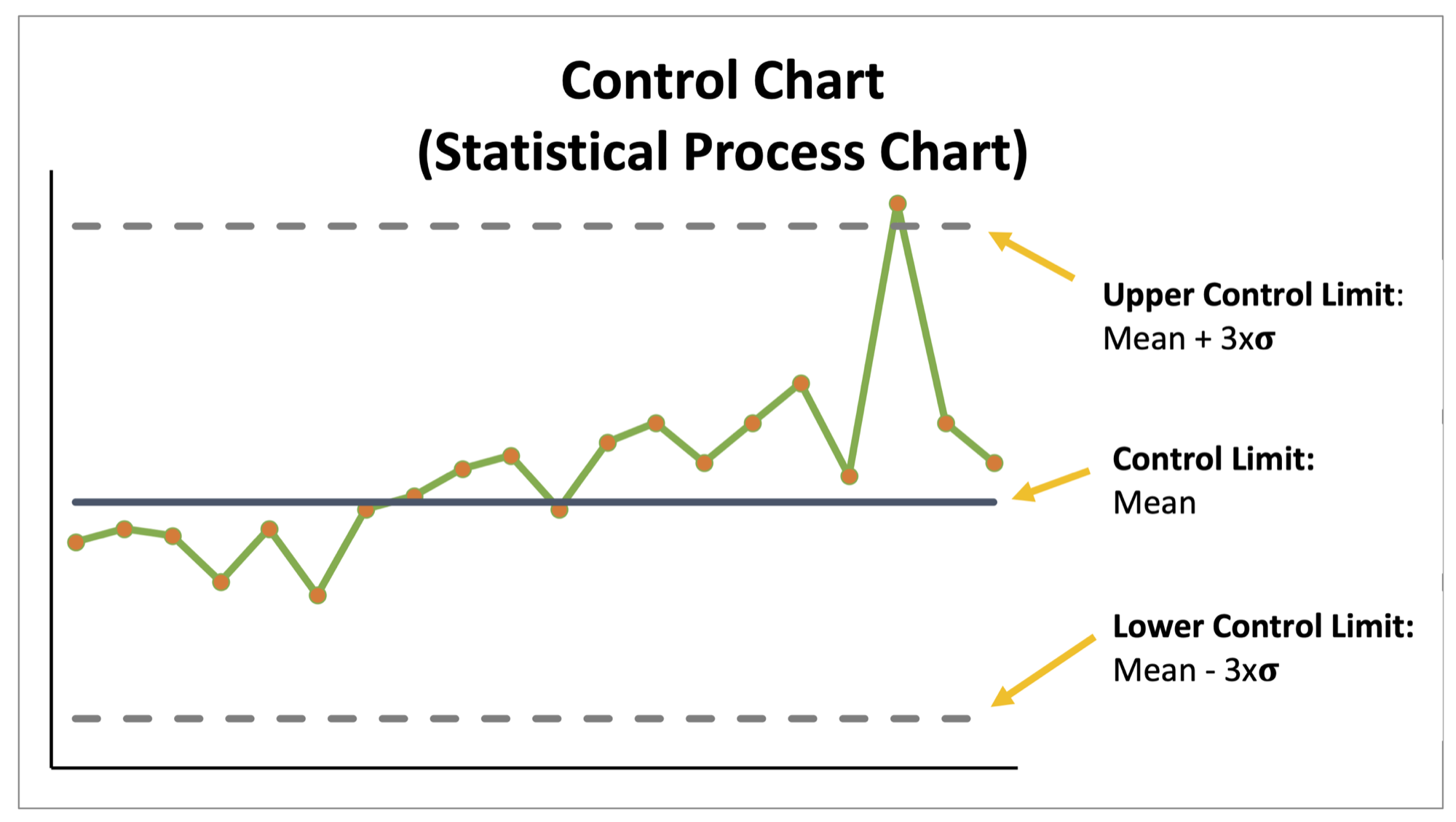

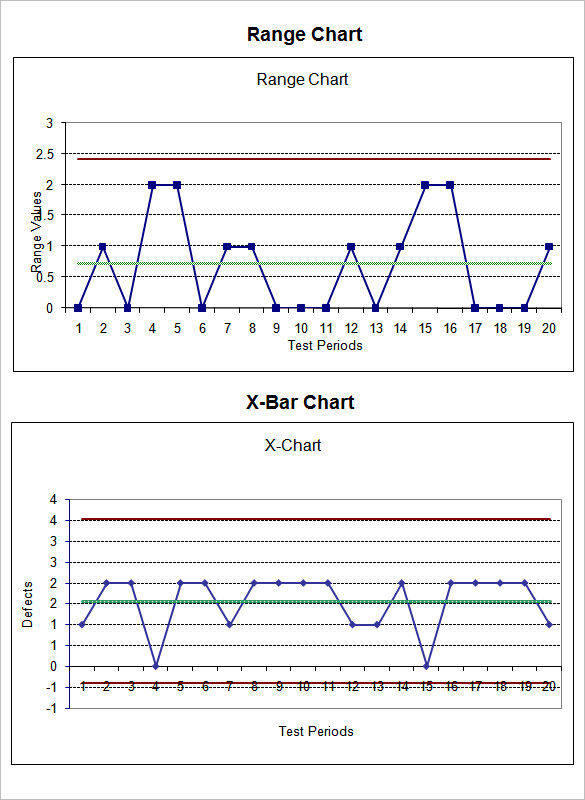

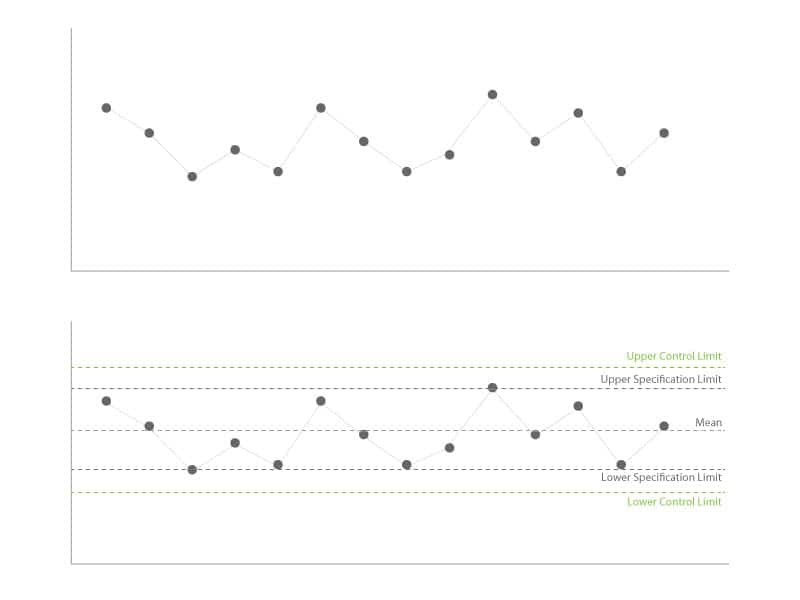

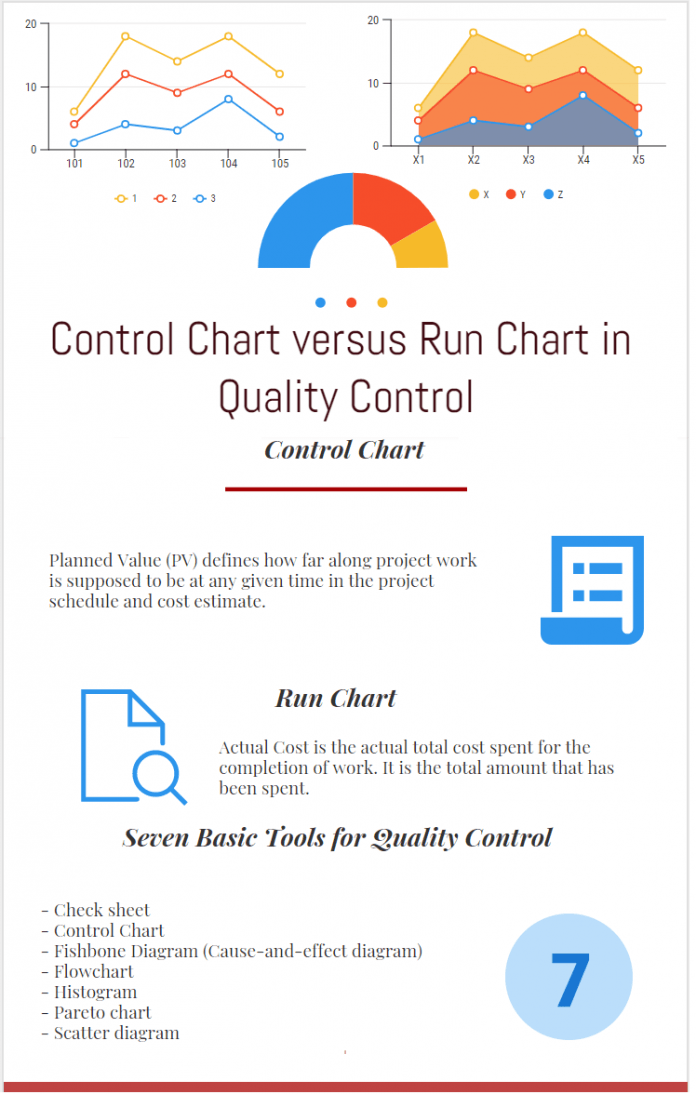

Control Chart Vs Run Chart - The control chart is a graph used to study how a process changes over time. The national assembly will choose the president for. Run charts are like control charts without the superpowers. Charting data over time helps identify trends and patterns in a process or system. If analysis of the control chart indicates that the process is currently under control (i.e., is stable, with variation only coming from sources common to the process), then no corrections or changes to process control parameters are needed or desired. On may 29, south africans will vote in national and provincial elections to elect a new national assembly and state legislatures. The first step in choosing an appropriate control chart is to determine whether you have continuous or attribute data. This post will answer the question: They show data over time, sure, but they’re missing the control limits. Web a control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts are used to monitor the stability of the process. Web however, where a run chart is concerned with showing how a process has been evolving through time with no regard to any target parameters, a control chart can give you a good overview of the current situation while taking some limits into account. Charting data over time helps. Web they plot the values of a quality measure against a time scale, and show three horizontal lines: Charting data over time helps identify trends and patterns in a process or system. Run charts show variation over time, while control charts add control limits to indicate process stability and performance. The first step in choosing an appropriate control chart is. Web learn the similarities and differences between run charts and control charts, two essential tools for quality management. In other words, they measure any type of output variable over time. Data are plotted in time order. The center line, which represents the average or median of the data; Web but there are many different types of control charts: This post will answer the question: Web a control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. The center line, which represents the average or median of the data; Typically, a run chart can be made into a. Web learn the difference between run charts. Data are plotted in time order. Estimating the standard deviation, σ, of the sample data. And the upper and lower. The goal is to see the results consistently fall within the control limits. Statistical formulas use historical records or sample data to calculate the control limits. The control chart is a graph used to study how a process changes over time. The run chart can be a beneficial tool at the beginning of a project as it reveals key information about a process or system before the data gathering process begins. Estimating the standard deviation, σ, of the sample data. Web they plot the values of. Web they plot the values of a quality measure against a time scale, and show three horizontal lines: Web a run chart is a line graph of data plotted over time. Charting data over time helps identify trends and patterns in a process or system. The first step in choosing an appropriate control chart is to determine whether you have. Web a control chart is a run chart, but a run chart isn’t always a control chart. Which control chart matches your data type? Web learn the differences and uses of run charts and control charts in project quality management. On the control chart, both upper and control limits are defined. Web a run chart is a line graph of. Web however, where a run chart is concerned with showing how a process has been evolving through time with no regard to any target parameters, a control chart can give you a good overview of the current situation while taking some limits into account. This post will answer the question: Web but there are many different types of control charts:. Web however, where a run chart is concerned with showing how a process has been evolving through time with no regard to any target parameters, a control chart can give you a good overview of the current situation while taking some limits into account. Web difference between run chart and control chart. Control charts help in identifying and controlling process. Statistical formulas use historical records or sample data to calculate the control limits. Once i got used to these new (and super useful!) tools, there was something i noticed… Charting data over time helps identify trends and patterns in a process or system. The goal is to see the results consistently fall within the control limits. Web it didn’t take long for me to realize that pareto charts are essentially just compound column and line charts, a run chart is just a line chart with a median line, and control charts are line charts that also show mean and special standard deviations. The center line, which represents the average or median of the data; Web but there are many different types of control charts: Web learn the differences and uses of run charts and control charts in project quality management. Web they plot the values of a quality measure against a time scale, and show three horizontal lines: • the central line on a control chart is the mean of the Web learn how control charts and run charts differ in data representation, purpose, control limits, and time axis. However, control charts depict additional things, like your control limits, a central control line and other components. They show data over time, sure, but they’re missing the control limits. Run charts show variation over time, while control charts add control limits to indicate process stability and performance. Shewhart chart, statistical process control chart. And the upper and lower.

The run chart a simple analytical tool for learning from variation in

Run Charts Improvement

Run Chart Templates 11+ Free Printable Docs, Xlsx, Docs & PDF Formats

Run Chart vs Control Chart

Quality Control Run Chart vs Control Chart for PMP Exam Updated PMP

Control Chart versus Run Chart in Quality Control projectcubicle

Run Chart vs Control Chart

Control Chart Out Of Control

Project Management Concept 28 Control Chart vs Run Chart YouTube

A Complete Guide on Control Chart vs. Run Chart

Web Use A Control Chart When You Have More Than 15 Data Points And Want More Insight Into Your Data.

The Run Chart Can Be A Beneficial Tool At The Beginning Of A Project As It Reveals Key Information About A Process Or System Before The Data Gathering Process Begins.

Run Charts Track Process Performance Over Time, While Control Charts Monitor Process Variation And Identify Special Causes.

Now, Don’t Confuse Control Charts With Their Distant Cousin, The Run Chart.

Related Post: