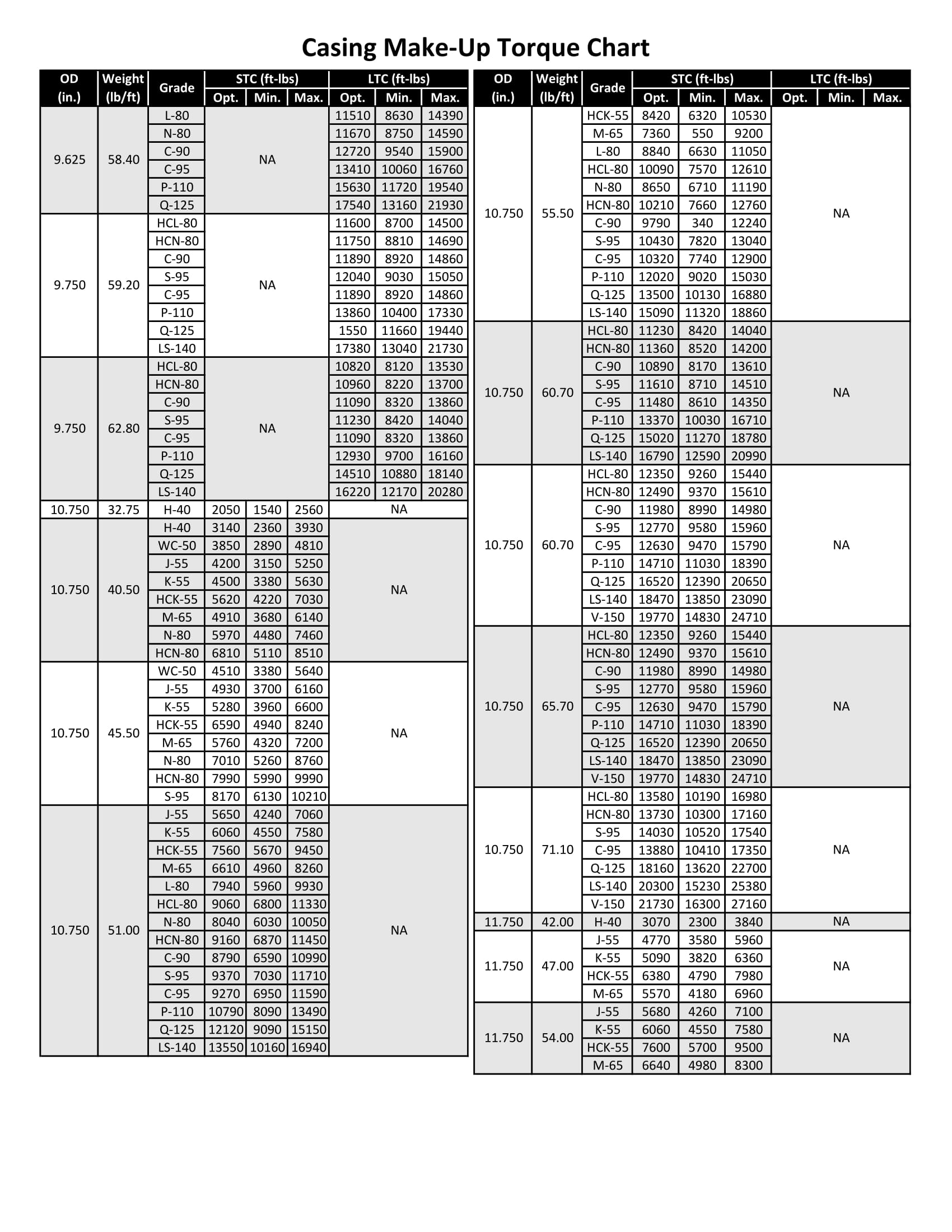

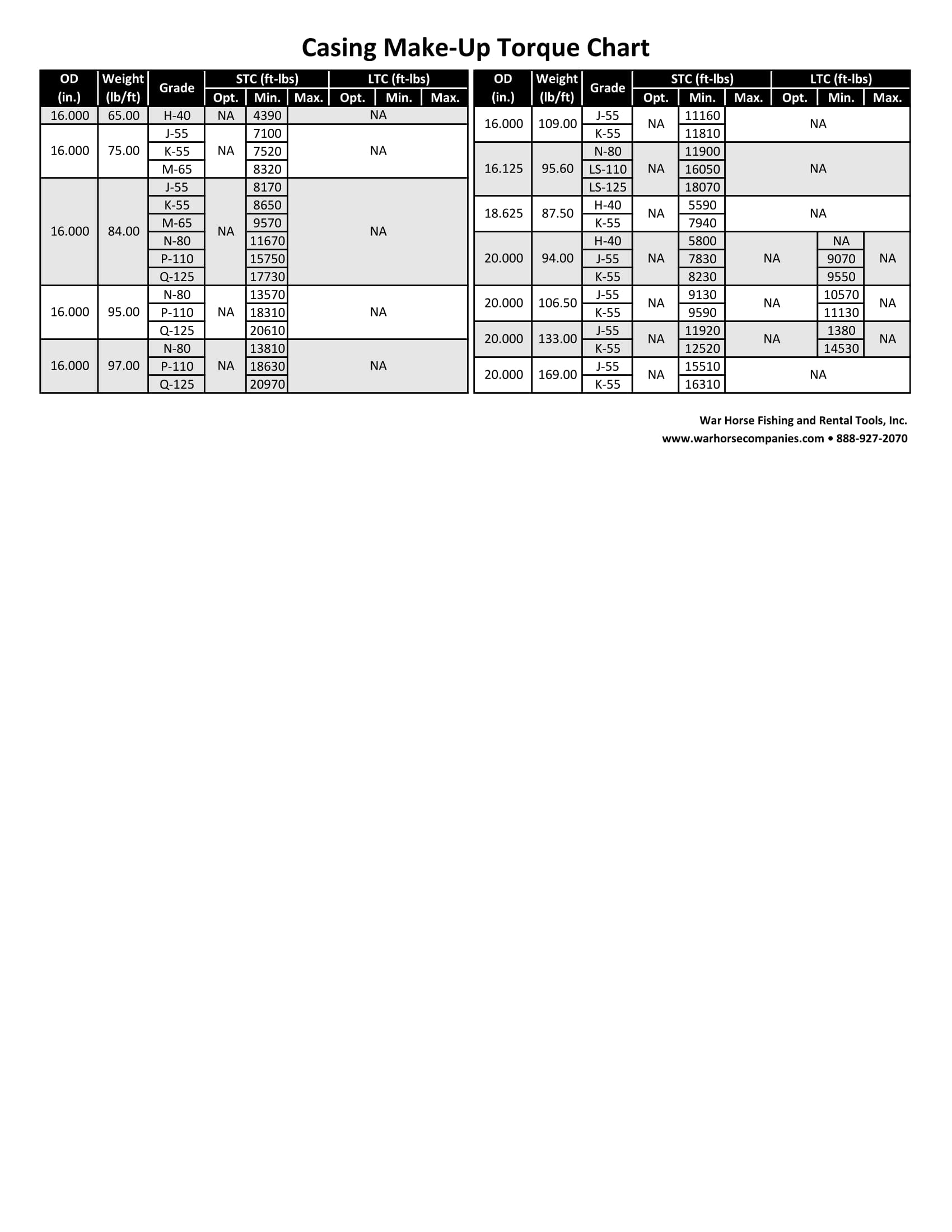

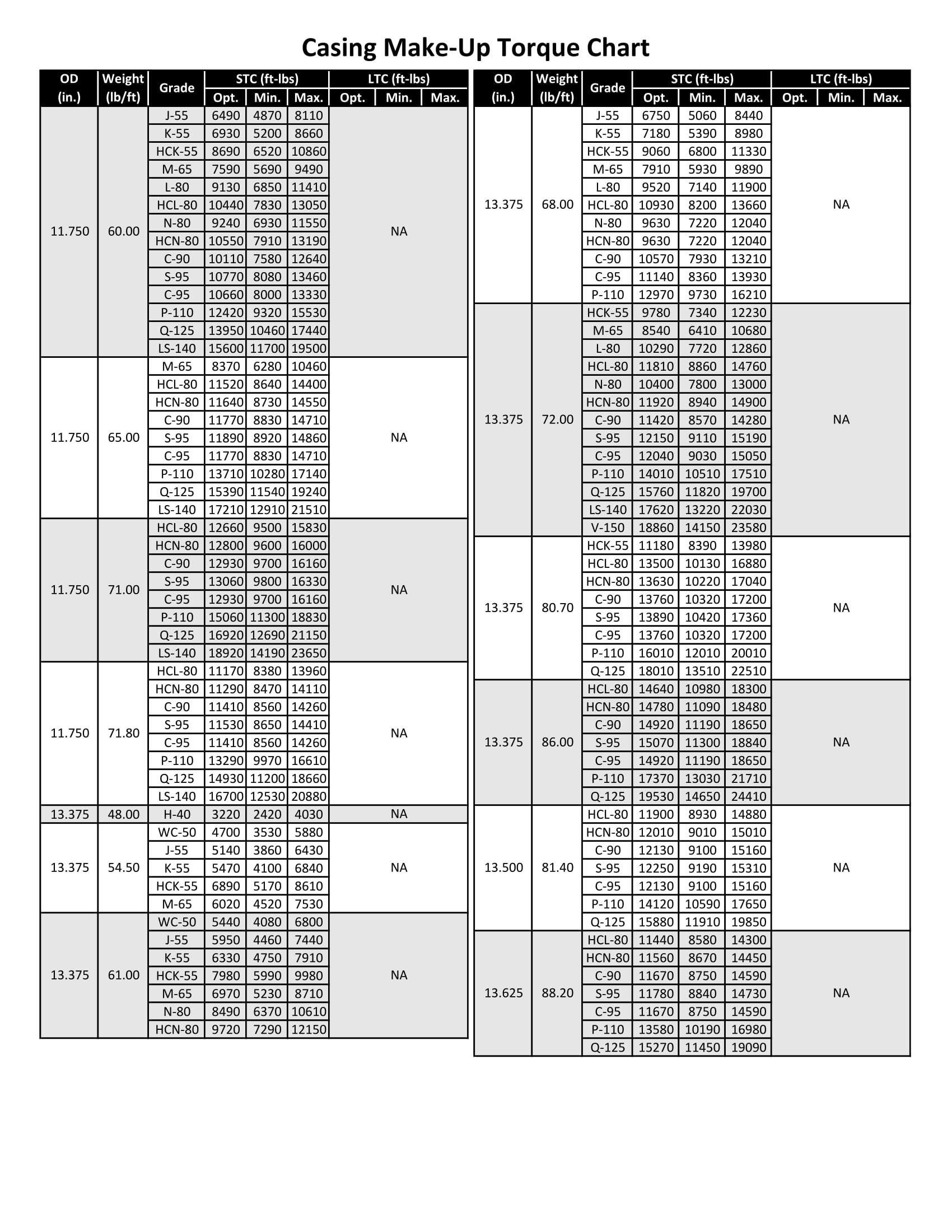

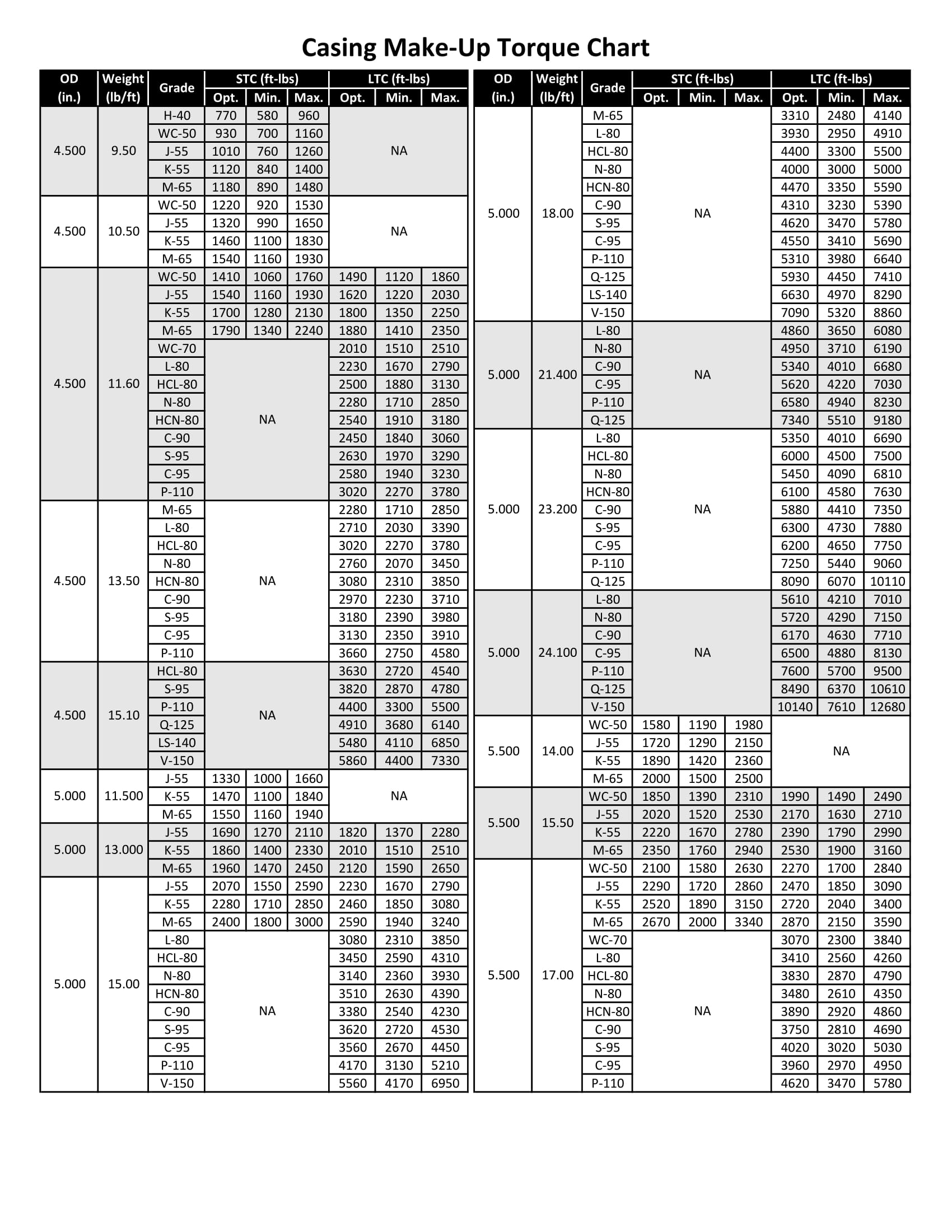

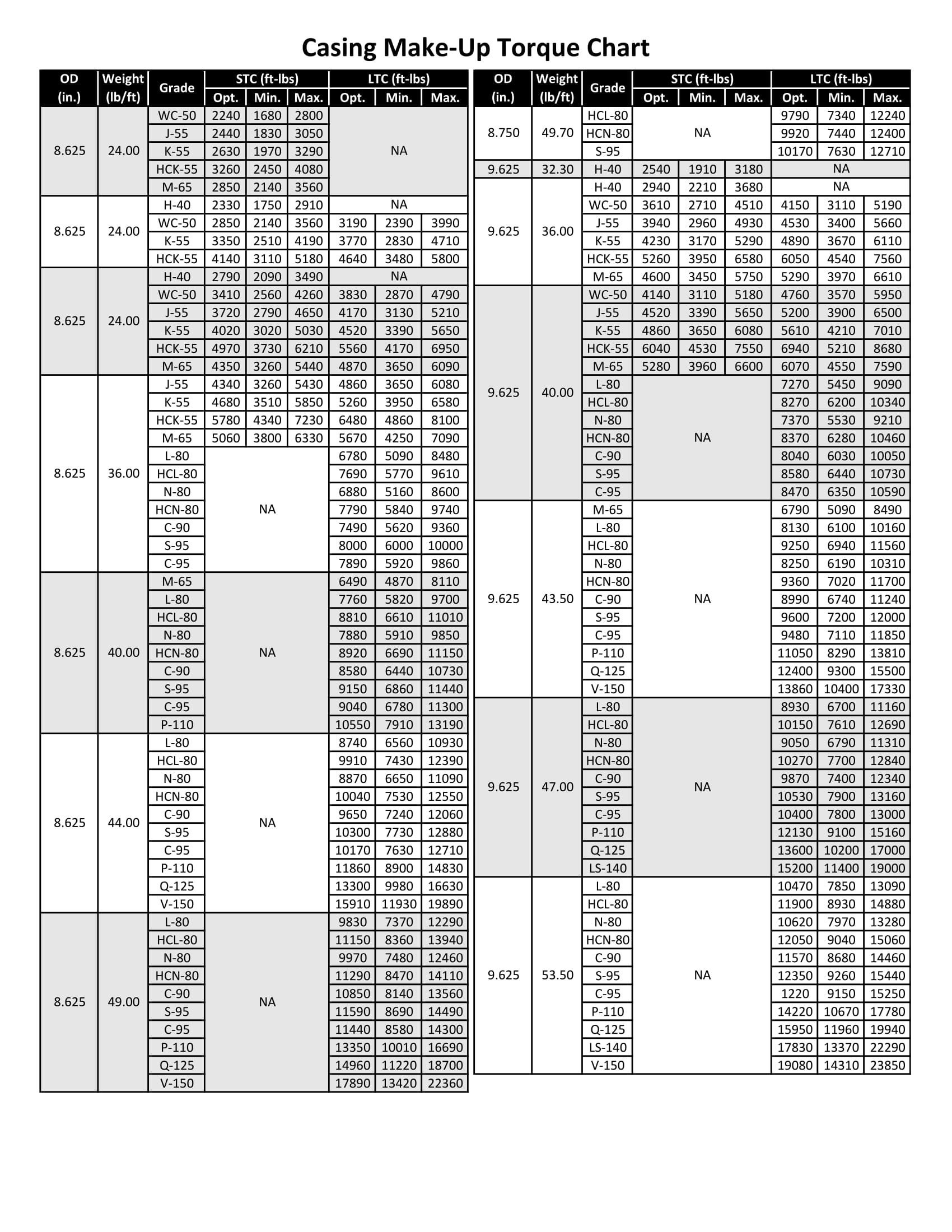

Casing Makeup Torque Chart

Casing Makeup Torque Chart - 46*1.67 = 77g with a dope having a gravity of 1.67 g/cm3 and 2.8*1.00 = 2.8 oz with a dope having a gravity of 1.00 oz/in3. There is no torque specification for api buttress however torque values required to reach an acceptable make up tend to be similar within the same batch of pipe. Api buttress casing connections make up loss datasheet. Data sheet | coupling of the api buttress connection dimensions. Threads per inch and a sharp. After reaching this value, it is necessary to verify the box face position reaches the vanish point of the pin, with a tolerance of ± two threads from the box face. Web a torque turn specialist will be able to distinguish three different characters in a graph: Making up the buttress connection. Make up the first 15 joints to the base of the stamped triangle, taking note of the required torque for each joint. Provided the position falls within. Web a torque turn specialist will be able to distinguish three different characters in a graph: Making up the buttress connection. Make up with maximum torque In order to determine make up torque for the string to be run:. Web bit diameter api connection recommended torque. Api buttres connection selection do's & dont's in data sheet. Web torque should never exceed 25% over minimum. Provided the position falls within. Threads per inch and a sharp. Dope volume (in.) (cm³) (in.³) 2 3/8 9 0.5 2 7/8 10 0.6 3 1/2 13 0.8 4 14 0.9 4 1/2 16 1.0 5 24 1.5 5 1/2 26 1.6. Threads per inch and a sharp. There is no torque specification for api buttress however torque values required to reach an acceptable make up tend to be similar within the same batch of pipe. Web make up process and torque values are referenced in api rp 5c1. Dope volume (in.) (cm³) (in.³) 2 3/8 9 0.5 2 7/8 10 0.6. Web torque should never exceed 25% over minimum. Dope volume (in.) (cm³) (in.³) 2 3/8 9 0.5 2 7/8 10 0.6 3 1/2 13 0.8 4 14 0.9 4 1/2 16 1.0 5 24 1.5 5 1/2 26 1.6 6 5/8 32 1.9 7 42 2.6 7 5/8 46 2.8 8 1/8 57 3.48 8 5/8 62 3.8 9 3/8. This extra torque capability is provided by the torque shoulder. In order to determine make up torque for the string to be run:. 46*1.67 = 77g with a dope having a gravity of 1.67 g/cm3 and 2.8*1.00 = 2.8 oz with a dope having a gravity of 1.00 oz/in3. There is no torque specification for api buttress however torque values. Dope volume (in.) (cm³) (in.³) 2 3/8 9 0.5 2 7/8 10 0.6 3 1/2 13 0.8 4 14 0.9 4 1/2 16 1.0 5 24 1.5 5 1/2 26 1.6 6 5/8 32 1.9 7 42 2.6 7 5/8 46 2.8 8 1/8 57 3.48 8 5/8 62 3.8 9 3/8 67 4.1 9 5/8 69 4.2 9 7/8. Web bit diameter api connection recommended torque. Web torque should never exceed 25% over minimum. Web locate the appropriate chart for the tool joint of interest. In order to determine make up torque for the string to be run:. Web gbc strongly recommends that the procedure be followed closely to determine the proper running torque at the beginning of each. There is no torque specification for api buttress however torque values required to reach an acceptable make up tend to be similar within the same batch of pipe. In order to determine make up torque for the string to be run:. Making up the buttress connection. Api buttress casing connections make up loss datasheet. Dope volume (in.) (cm³) (in.³) 2. Web gbc strongly recommends that the procedure be followed closely to determine the proper running torque at the beginning of each casing run. This extra torque capability is provided by the torque shoulder. In order to determine make up torque for the string to be run:. Threads per inch and a sharp. Web bit diameter api connection recommended torque. Threads per inch and a sharp. Web a torque turn specialist will be able to distinguish three different characters in a graph: In order to determine make up torque for the string to be run:. Data sheet | coupling of the api buttress connection dimensions. Web bit diameter api connection recommended torque. Web a torque turn specialist will be able to distinguish three different characters in a graph: Web the weight of dope to apply on a connection depends of the specific gravity of the used dope. Web bit diameter api connection recommended torque. In order to determine make up torque for the string to be run:. Threads per inch and a sharp. Api buttress casing connections make up loss datasheet. Web locate the appropriate chart for the tool joint of interest. Web gbc strongly recommends that the procedure be followed closely to determine the proper running torque at the beginning of each casing run. For example, the make up dope quantity in 7 5/8 will be: Web torque should never exceed 25% over minimum. Make up the first 15 joints to the base of the stamped triangle, taking note of the required torque for each joint. Provided the position falls within. Web make up process and torque values are referenced in api rp 5c1. Dope volume (in.) (cm³) (in.³) 2 3/8 9 0.5 2 7/8 10 0.6 3 1/2 13 0.8 4 14 0.9 4 1/2 16 1.0 5 24 1.5 5 1/2 26 1.6 6 5/8 32 1.9 7 42 2.6 7 5/8 46 2.8 8 1/8 57 3.48 8 5/8 62 3.8 9 3/8 67 4.1 9 5/8 69 4.2 9 7/8 71 4.3 10 3/4 77 4.7 11 3/4 99 6.0 After reaching this value, it is necessary to verify the box face position reaches the vanish point of the pin, with a tolerance of ± two threads from the box face. A recommended minimum makeup torque referred to in the running procedure is specified on the data sheet.

Casing MakeUp Torque Chart.

Casing MakeUp Torque Chart.

Casing MakeUp Torque Chart PDF

Casing MakeUp Torque Chart.

Casing MakeUp Torque Chart.

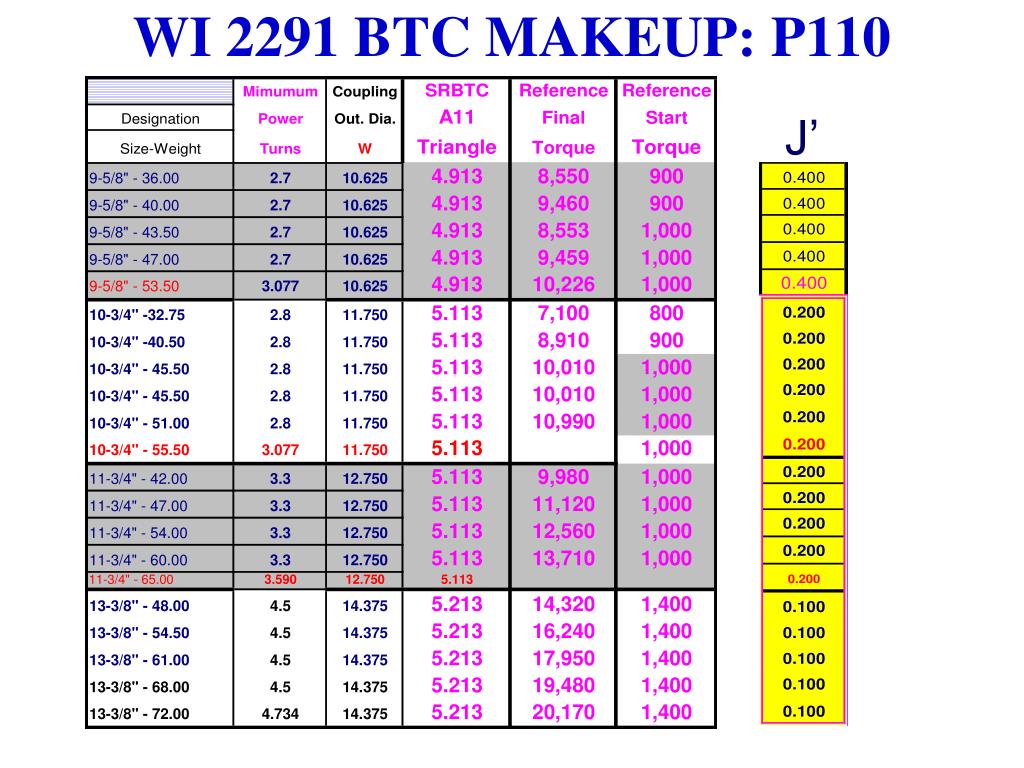

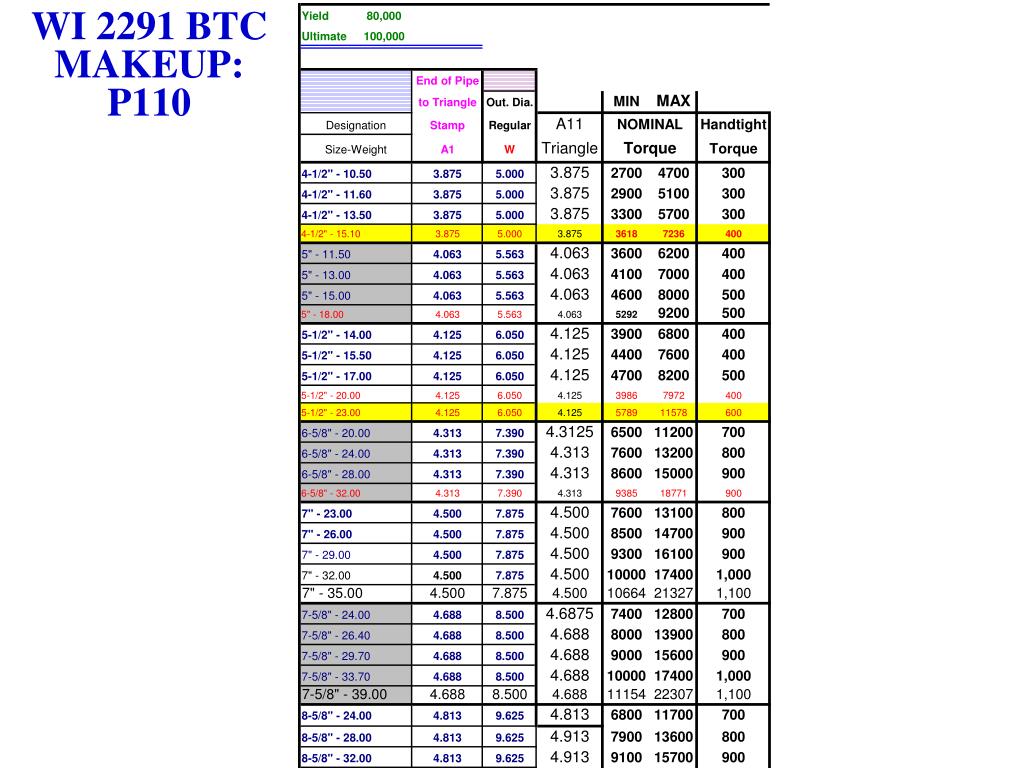

Btc Make Up Torque Mugeek Vidalondon

Casing MakeUp Torque Chart.

4 Flush Joint Casing Specs

Btc Make Up Torque Mugeek Vidalondon

Make Up Torque LTC Trpon Pipe

46*1.67 = 77G With A Dope Having A Gravity Of 1.67 G/Cm3 And 2.8*1.00 = 2.8 Oz With A Dope Having A Gravity Of 1.00 Oz/In3.

Making Up The Buttress Connection.

There Is No Torque Specification For Api Buttress However Torque Values Required To Reach An Acceptable Make Up Tend To Be Similar Within The Same Batch Of Pipe.

Api Buttres Connection Selection Do's & Dont's In Data Sheet.

Related Post: