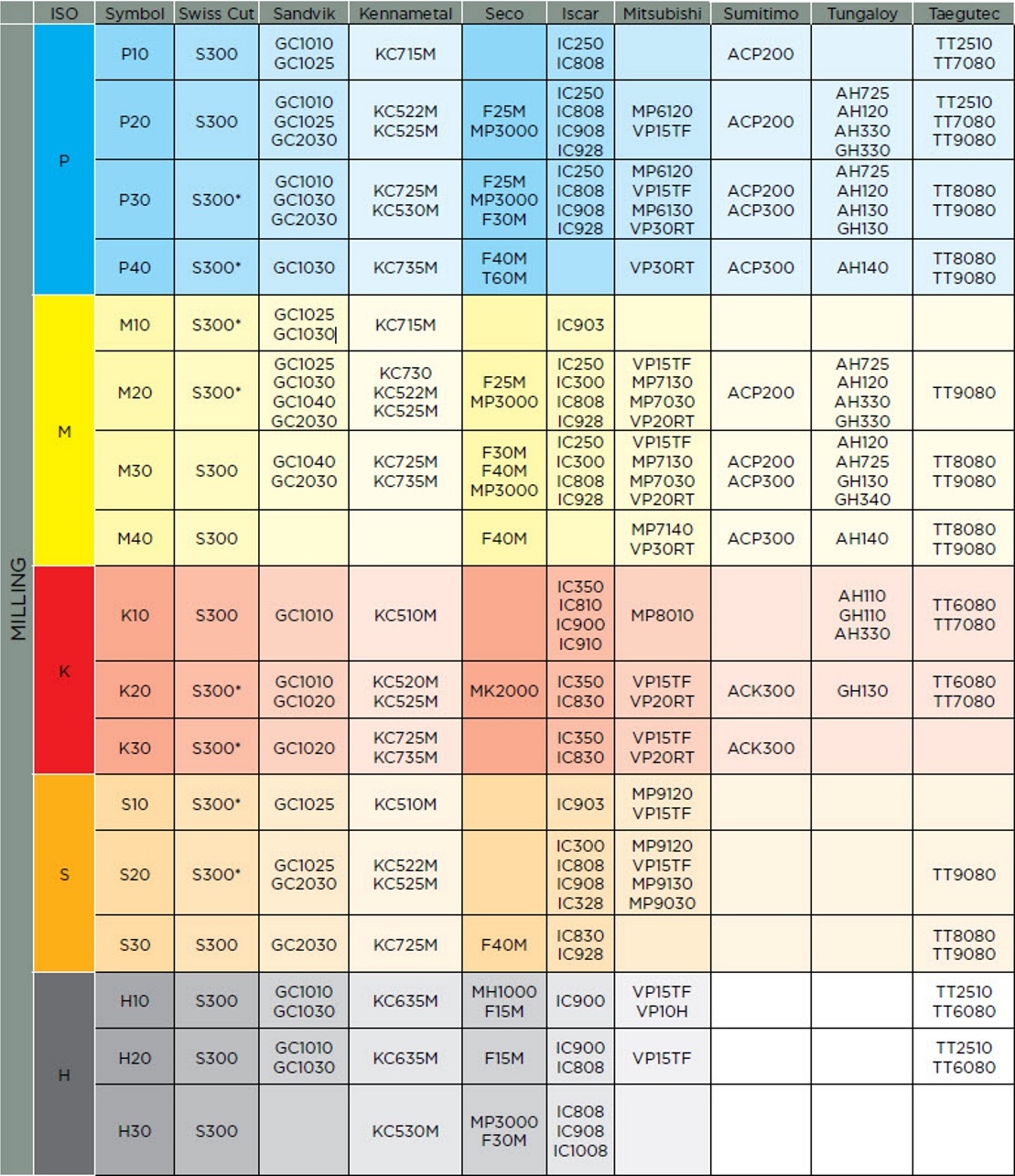

Carbide Grade Chart

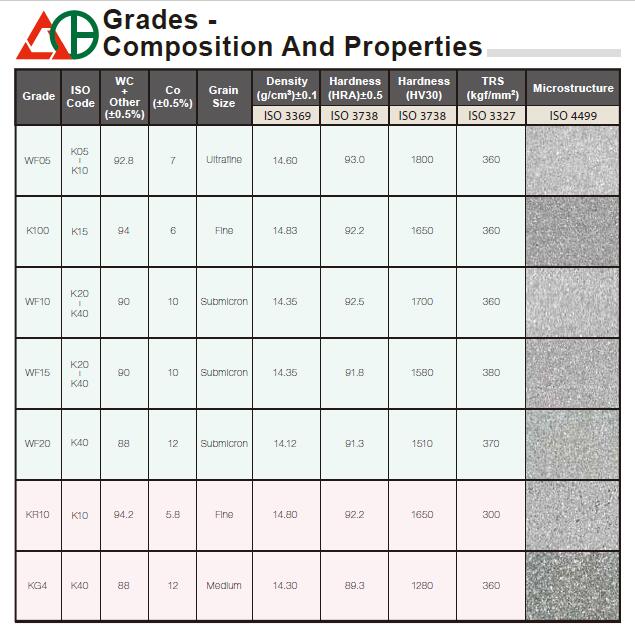

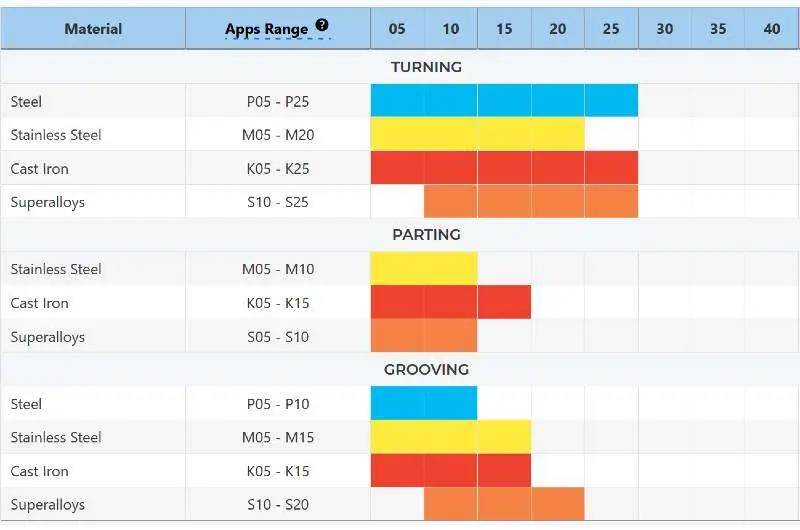

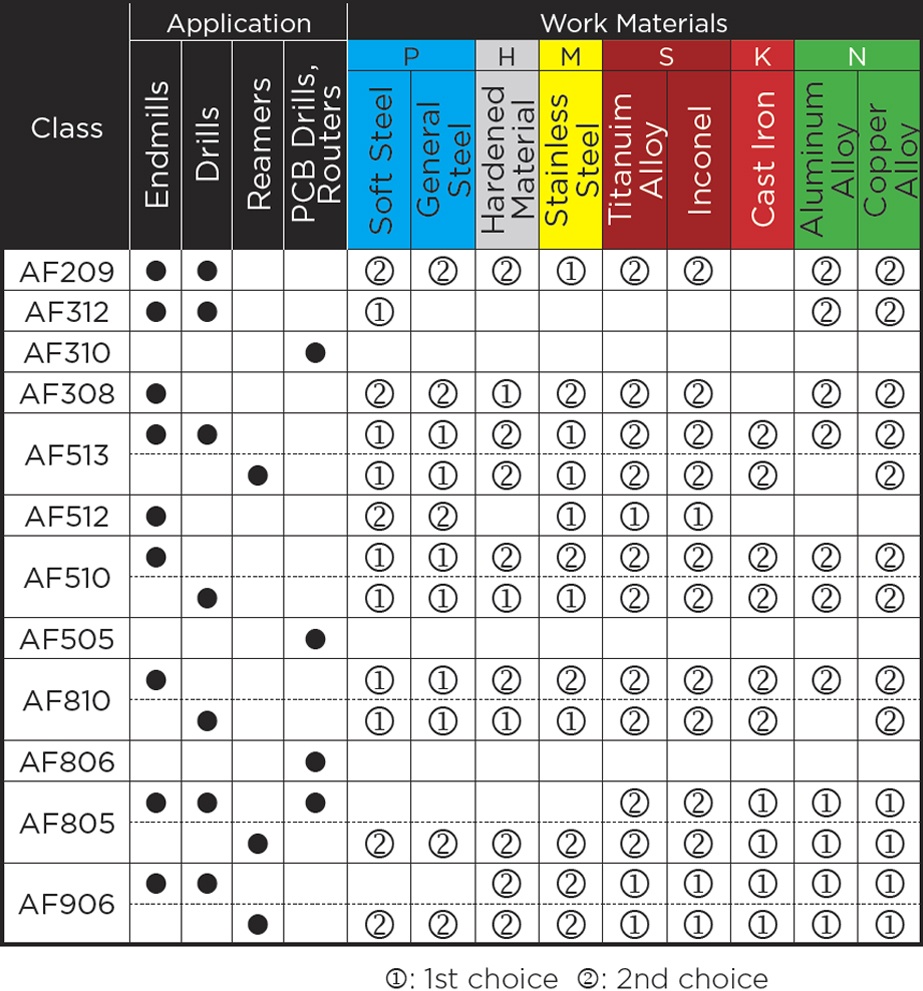

Carbide Grade Chart - Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Web regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Web grade selection is crucial to meeting today’s strict quality requirements and technical challenges, while maximizing productivity. Web look up grade descriptions and application ranges for grades from carbide insert manufacturers These are approximate grade conversions. Web general carbide manufactures tungsten carbide tooling in a wide range of grades. Compare different grades from sandvik and other brands based on substrate, coating, and toughness. Special grades to meet specific requirements are also available. Your hyperion sales person can offer their expertise in selecting the carbide or cermet insert blank best suited to solve your metal cutting application needs. Bold type = standard horizon grades and competitive equivalents. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Web grade comparison table cemented carbide note 1) the above table is selected from a publication. See charts and examples of different carbide grades and their suitability for various materials and cutting conditions. “first choice” grade for stainless steel (iso m materials). These. Web look up grade descriptions and application ranges for grades from carbide insert manufacturers Web the chart below offers an overview of our standard cemented carbide and specialty cermet grades. Please visit our website for the latest grade specification information. Web grade selection is crucial to meeting today’s strict quality requirements and technical challenges, while maximizing productivity. 800.547.2659 +1 724.836.6274. Additional and special tungsten carbide grades are available upon enquiry. Web general carbide manufactures tungsten carbide tooling in a wide range of grades. Web these grades range from 6% to 25% to meet any of your toughest wear and impact demands. See charts and examples of different carbide grades and their suitability for various materials and cutting conditions. Web regardless. We have not obtained approval from each company. See charts and examples of different carbide grades and their suitability for various materials and cutting conditions. Your hyperion sales person can offer their expertise in selecting the carbide or cermet insert blank best suited to solve your metal cutting application needs. Compare different grades from sandvik and other brands based on. Web carbide grade selection describes the different carbide tool grades and explains how to select the proper grade for a cutting operation. Web these grades range from 6% to 25% to meet any of your toughest wear and impact demands. Additional and special tungsten carbide grades are available upon enquiry. Please visit our website for the latest grade specification information.. All data shown are typical values. See charts and examples of different carbide grades and their suitability for various materials and cutting conditions. Web regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Web these grades range from 6% to 25% to meet any of your toughest. We have not obtained approval from each company. Additional and special tungsten carbide grades are available upon enquiry. Web the dymet alloys tungsten carbide grade chart illustrates the range of standard cobalt and nickel binder grades which are available together with information on the basic material composition and where applicable, the appropriate iso application codes. Carbide grades are classified by. Please visit our website for the latest grade specification information. Ask one of our engineers to explain the process.) These are approximate grade conversions. 800.547.2659 +1 724.836.6274 [email protected] • www.generalcarbide.com. Heavy shock, rotary drilling and mining. Your hyperion sales person can offer their expertise in selecting the carbide or cermet insert blank best suited to solve your metal cutting application needs. Special grades to meet specific requirements are also available. All data shown are typical values. 800.547.2659 +1 724.836.6274 [email protected] • www.generalcarbide.com. Ask one of our engineers to explain the process.) The tooling is used for industrial wear and metal forming applications. Web regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Bold type = standard horizon grades and competitive equivalents. Please visit our website for the latest grade specification information. “first choice” grade for stainless steel (iso. 800.547.2659 +1 724.836.6274 [email protected] • www.generalcarbide.com. Web grade comparison table cemented carbide note 1) the above table is selected from a publication. Bold type = standard horizon grades and competitive equivalents. Web the chart below offers an overview of our standard cemented carbide and specialty cermet grades. Web carbide grade selection describes the different carbide tool grades and explains how to select the proper grade for a cutting operation. Web grade selection is crucial to meeting today’s strict quality requirements and technical challenges, while maximizing productivity. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Metal forming, wear and impact. These are approximate grade conversions. Please visit our website for the latest grade specification information. Carbide grades are classified by two systems. See charts and examples of different carbide grades and their suitability for various materials and cutting conditions. Your hyperion sales person can offer their expertise in selecting the carbide or cermet insert blank best suited to solve your metal cutting application needs. Ask one of our engineers to explain the process.) Web 452 rows find out the technical information on any carbide grade, such as cutting speed, application range, and coating type. Use our grade selection tool to find a match for your project needs.

Carbide Grades Chart A Visual Reference of Charts Chart Master

Carbide Insert Grade Comparison Chart

Carbide Grades For Machining Machining Doctor

Carbide Rods

Carbide Grades Revolver Carbide

COMPARISON CHART— CARBIDE GRADES FOR Competitor... · COMPARISON CHART

Cemented Tunsten Carbide Metalforming Grades Chart Steel Stainless

Tungsten Carbide Grade Chart A Visual Reference of Charts Chart Master

Carbide Rod Blanks Materials Group Details

Carbide Insert Grade Comparison Chart Images

Web General Carbide Manufactures Tungsten Carbide Tooling In A Wide Range Of Grades.

Web Regardless Of Component Size, Material Or Design, The Carbide Insert Grade You Use Can Make All The Difference In Your Manufacturing Productivity.

All Data Shown Are Typical Values.

Heavy Shock, Rotary Drilling And Mining.

Related Post: