Brake Rotor Wear Chart

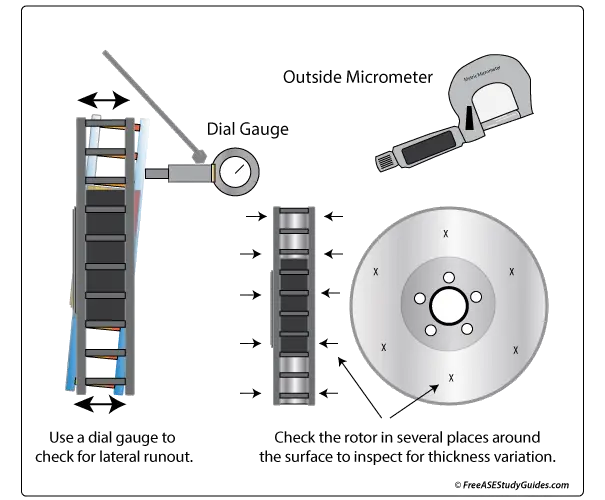

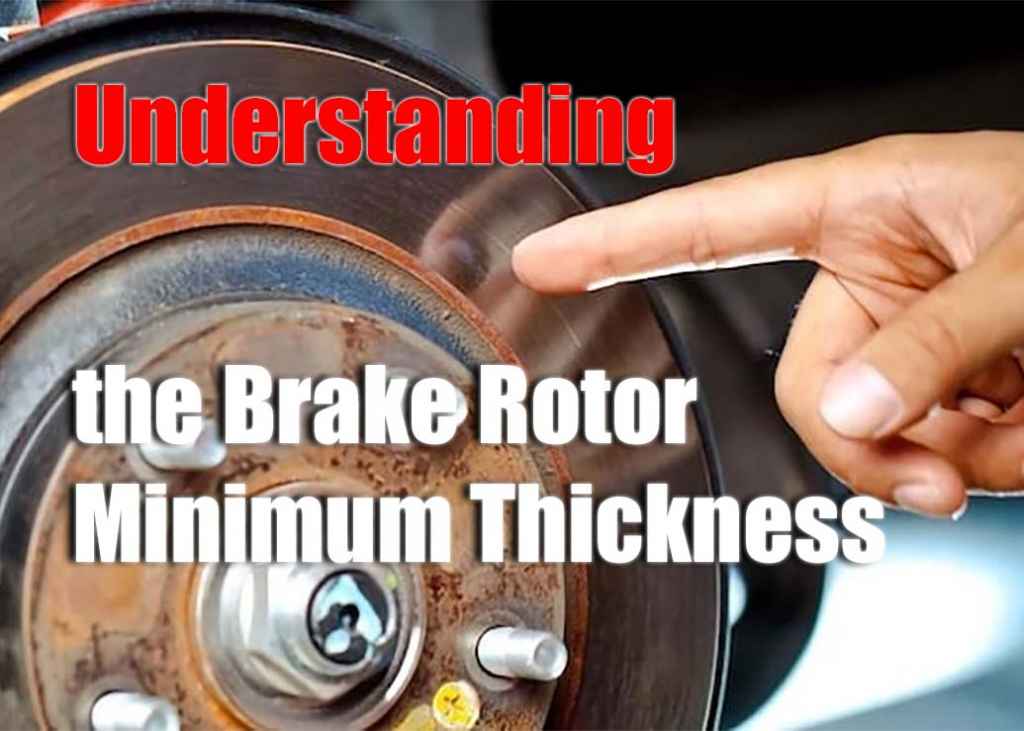

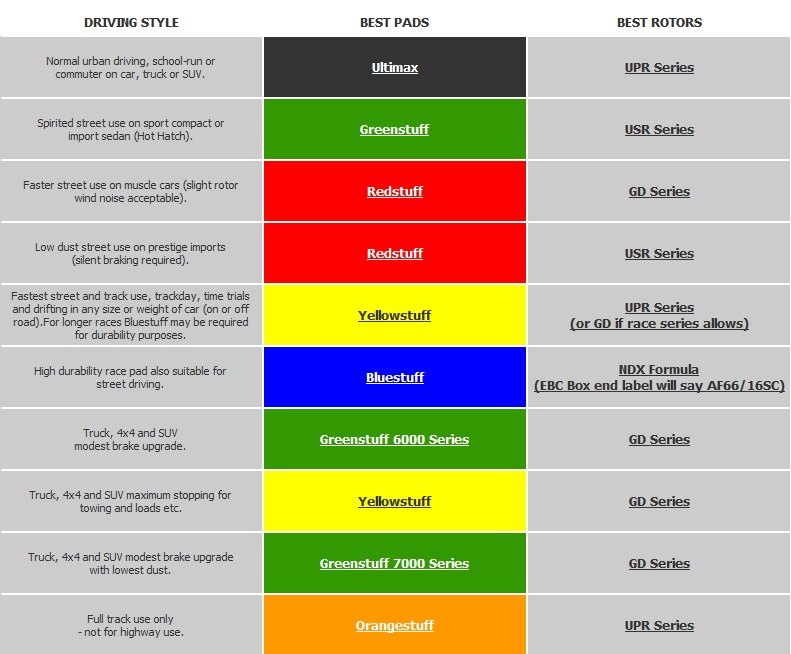

Brake Rotor Wear Chart - These edges and surfaces can create high pitch sounds when you drive normally, but this happens most often when you apply some force to your brakes. Replace if damaged or corroded. Most manufacturers and mechanics will also agree that you should probably replace your brake pads once they reach 75% worn, or 3mm thick. Web the midland line of air disc brake rotors delivers quality, value, and long service life. Web it is important to know the wear limit of your brake rotor to avoid any damage and breakages, but how do you measure this value? Rotors will become coned or dished from normal wear. Web reasons for uneven brake pad wear. Be sure to see a professional to determine when to change brake pads and components. Use an outside micrometer to measure rotor thickness in several places around the rotor. This type of wear pattern is a sure sign of a worn seal, damage to the caliper, or. • service caliper slides and lubricate. The brake pads may wear unevenly because of a stuck slide pin or stuck brake pads in the mounting bracket. Web learn how to understand and interpret brake pad wear charts, identify different wear patterns, and determine when to replace your brake pads. Replace if damaged or corroded. Web the midland line of air. It is essential that your rotor mounting matches your hub mounting for optimal placement, performance and operation. Web three main types of brake pads are available on the market today: Find tips for maintaining brake pads and choosing the best ones. Rely on raybestos® for the best in brakes®. • service caliper guide pins and bushings. Use an outside micrometer to measure rotor thickness in several places around the rotor. Modern road bikes, mountain bikes, and gravel bikes all rely on disc brakes. These edges and surfaces can create high pitch sounds when you drive normally, but this happens most often when you apply some force to your brakes. Web brake rotor thickness is a critical. Web this section usually contains a chart indicating all specifications for the complete brake system. It could also be due to bad brake pad quality, or a bad brake caliper piston, as well as rotor thickness variation. Everything you need to know about disc brake rotors. “which is the best time to check rotor thickness and how to do it?”. Rely on raybestos® for the best in brakes®. Web brake rotor thickness is a critical measurement for automotive safety. Web check the rotor for runout using a dial gauge and compare it with the manufacturer's specifications. It could also be due to bad brake pad quality, or a bad brake caliper piston, as well as rotor thickness variation. However, that. Web this section usually contains a chart indicating all specifications for the complete brake system. These edges and surfaces can create high pitch sounds when you drive normally, but this happens most often when you apply some force to your brakes. “which is the best time to check rotor thickness and how to do it?” Be sure to see a. Web check the rotor for runout using a dial gauge and compare it with the manufacturer's specifications. Use an outside micrometer to measure rotor thickness in several places around the rotor. Most manufacturers and mechanics will also agree that you should probably replace your brake pads once they reach 75% worn, or 3mm thick. Most rotors are cast iron, and. It is essential that your rotor mounting matches your hub mounting for optimal placement, performance and operation. Web one of the benefits of running disc brakes is that there's no wear to your wheel rims when you brake, but the disc brake rotors will gradually wear with use. Web three main types of brake pads are available on the market. Web in this powerstop guide, we discuss the common signs that indicate it’s time to replace your rotors and the consequences of failing to get new rotors when you need them. Web check the rotor for runout using a dial gauge and compare it with the manufacturer's specifications. Web learn how to understand and interpret brake pad wear charts, identify. I know it’s commonly reported around here, by myself included, that t1n rotors are generally one time use, and replaced with pads due to minimum wear thickness tolerances. Web it is important to know the wear limit of your brake rotor to avoid any damage and breakages, but how do you measure this value? This is for a 140” high. First, we’ll explain the importance of understanding brake rotor thickness and why it matters to your braking performance. Most rotors are cast iron, and the brake pads are a much softer material. The inboard pad shows increased wear when compared to the outboard pad. Web if you have questions about brake wear, use this handy brake pad replacement indicator chart to help identify disc brake problems and their causes, effects and solutions. Most manufacturers and mechanics will also agree that you should probably replace your brake pads once they reach 75% worn, or 3mm thick. I know it’s commonly reported around here, by myself included, that t1n rotors are generally one time use, and replaced with pads due to minimum wear thickness tolerances. Let’s look at some essential things about the brake rotors, and find answers to the questions: Ceramic brake pads are known for their exceptional performance and low noise levels. However, your car is no longer safe to drive once the brake pads get this thin. • service caliper slides and lubricate. Rotors will become coned or dished from normal wear. When the brake rotors get worn, it creates an uneven surface and edges on the inside and outside of the brake rotor surface. Web the midland line of air disc brake rotors delivers quality, value, and long service life. Find your existing rotor size. Be sure to see a professional to determine when to change brake pads and components. Web signs of excessive wear on the inner brake pad are a strong indicator that the pad is resting against the rotor even after the caliper has released.

Brake Pad Wear Percentage Chart

Brake Rotor Cross Reference Chart

FIXES FOR COMMON BRAKE PROBLEMS

Repair Guides Specifications Charts Specifications Charts

How do I tell if I need new brake pads World

Minimum Rotor Thickness Honda Odyssey / Repair Guides Measure the

Brake Rotor Wear Patterns

How To Tell If Your Brakes Are Worn The Filter Blog MicksGarage

Understanding the Brake Rotor Minimum Thickness Chart

Brake Selector Chart

This Type Of Wear Pattern Is A Sure Sign Of A Worn Seal, Damage To The Caliper, Or.

Web This Section Usually Contains A Chart Indicating All Specifications For The Complete Brake System.

Use An Outside Micrometer To Measure Rotor Thickness In Several Places Around The Rotor.

It Could Also Be Due To Bad Brake Pad Quality, Or A Bad Brake Caliper Piston, As Well As Rotor Thickness Variation.

Related Post: