Brake Press Tonnage Chart

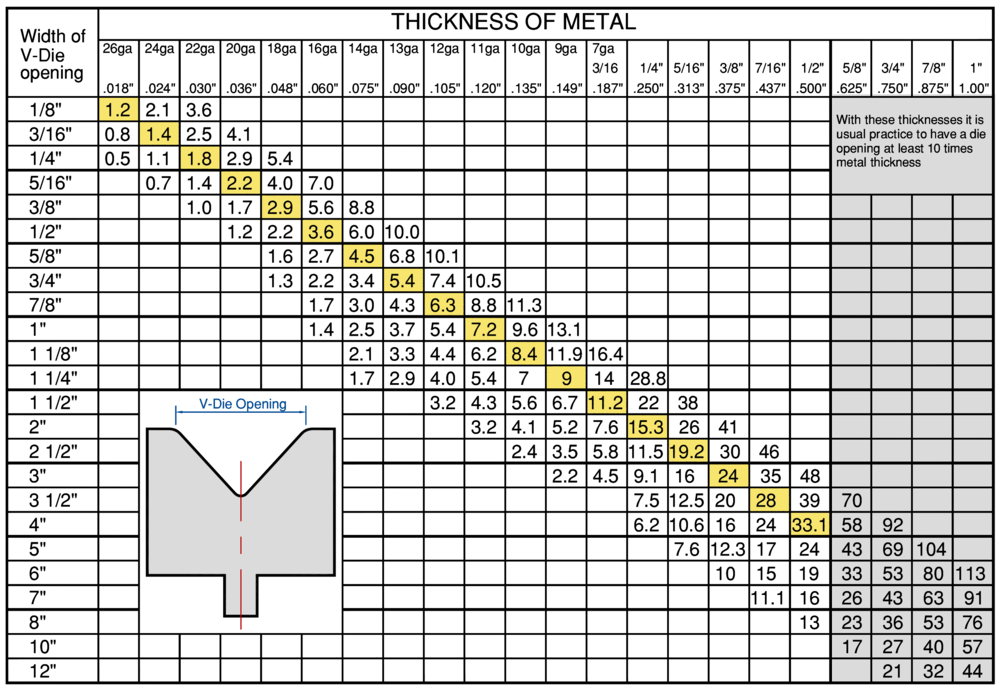

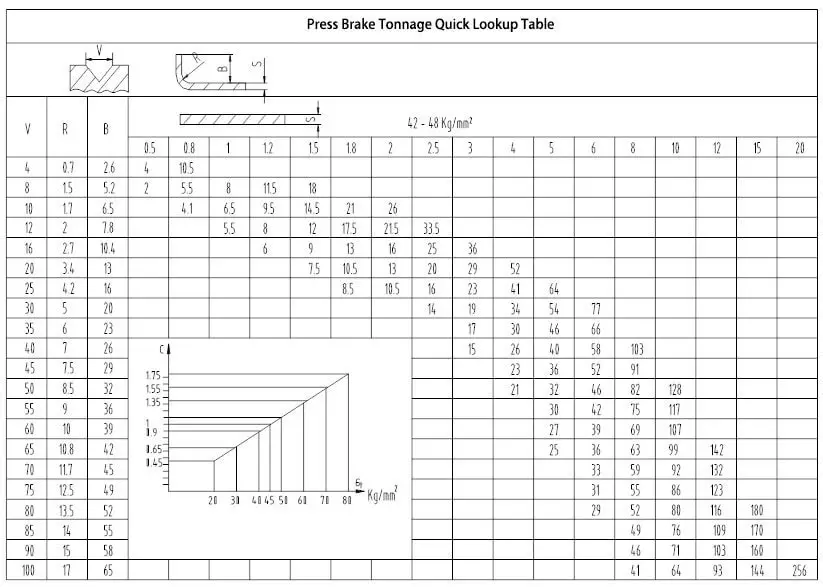

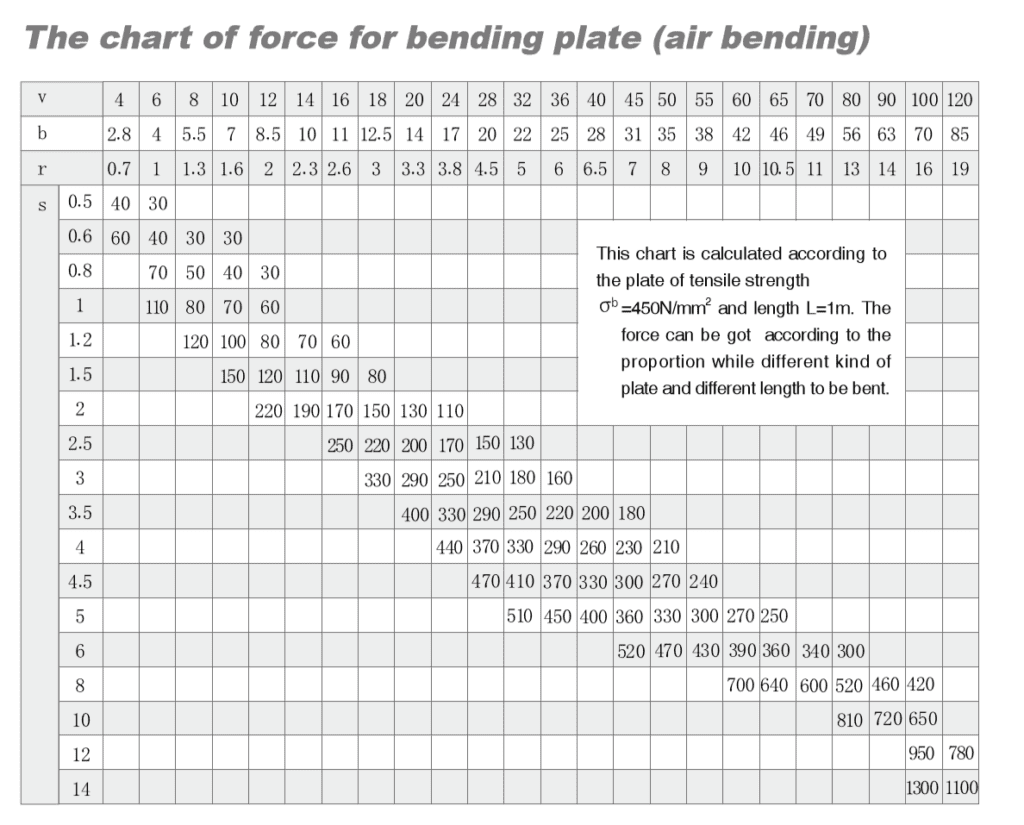

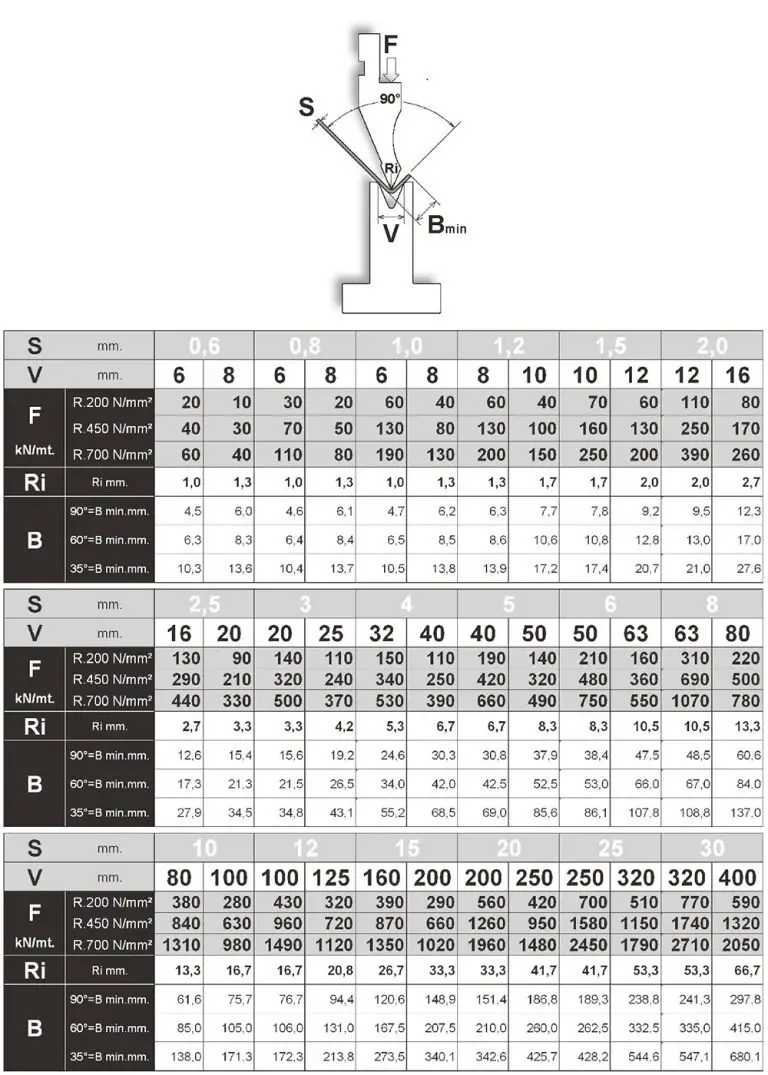

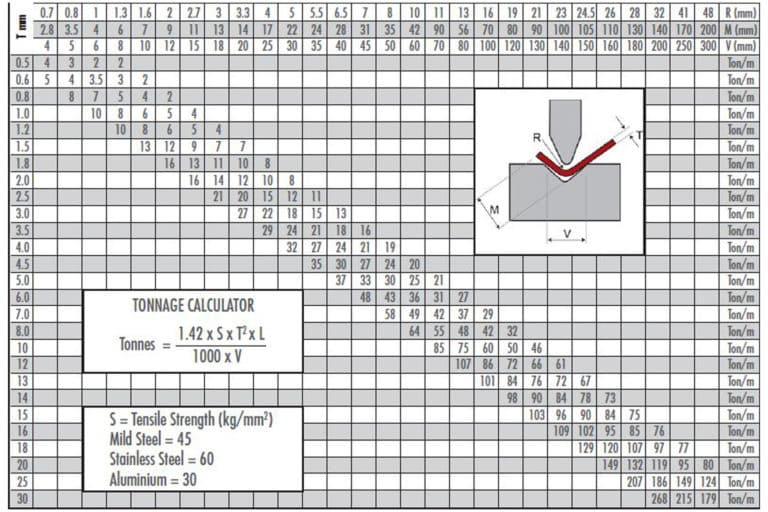

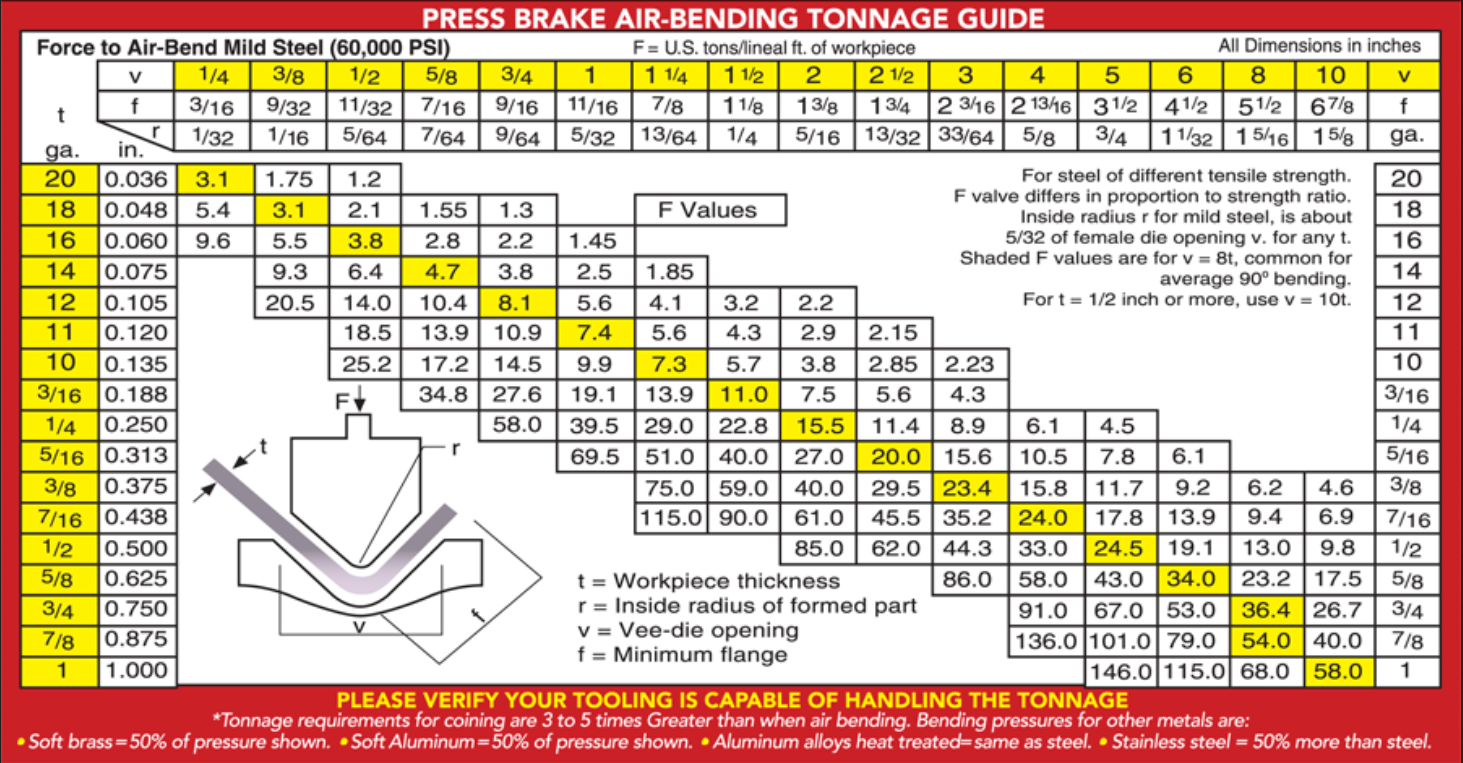

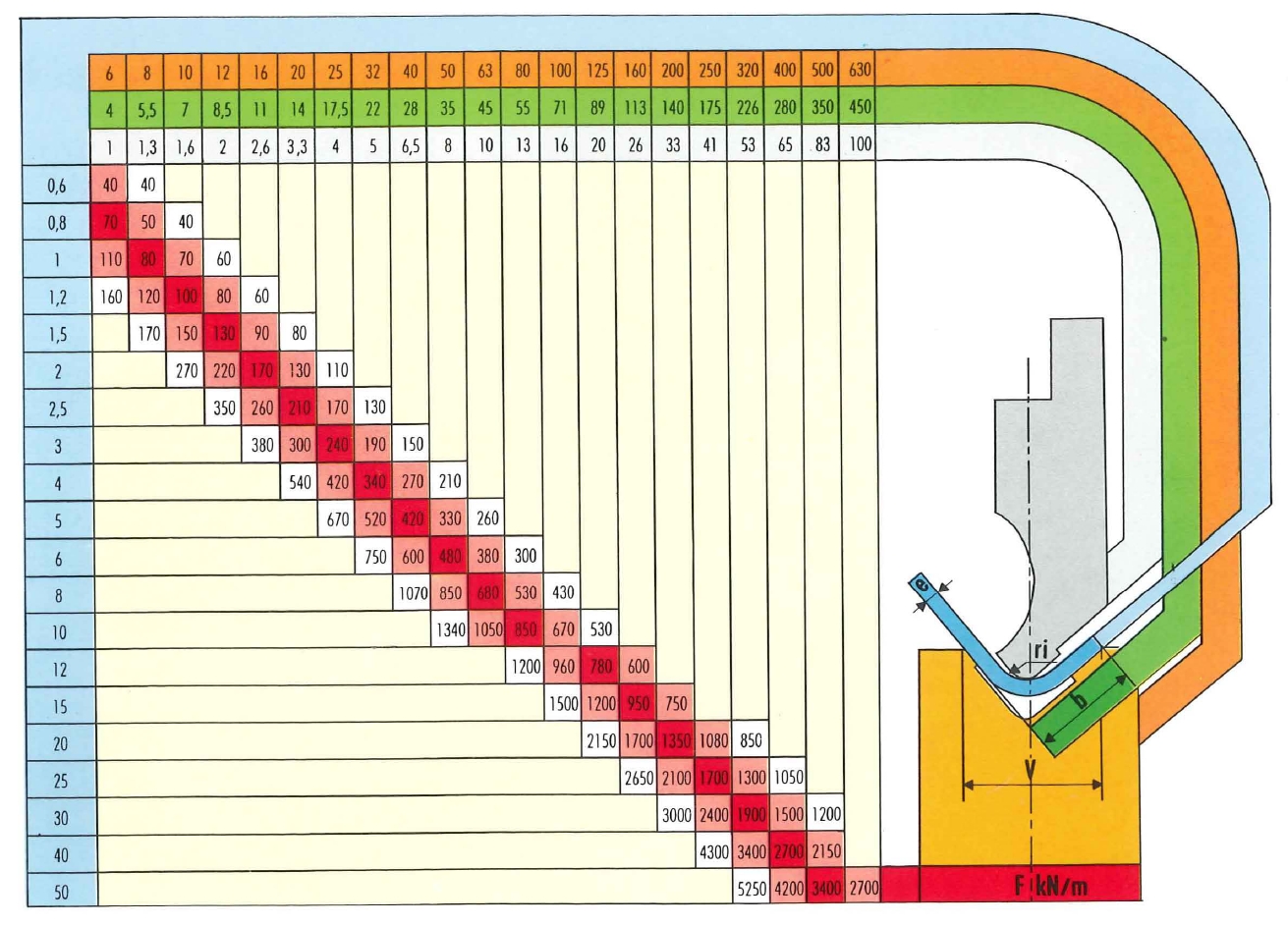

Brake Press Tonnage Chart - Accurate calculation of this force is crucial for precision bending and machine safety. Of bend @ specific die opening / radius) thickness. Width of lower die opening. Does the complexity of my bends matter when selecting a brake press? When using material over 1/2”, it is usual practice to have die opening 10 times the metal thickness. 72,000 psi tensile strength and max. Exceeding the maximum allowable tonnage could result in significant damage to the part, the press brake, or the tooling itself. Web information chart for necessary tonnage for 1 meter bending width (l) for mild steel material: From an efficiency standpoint, using the correct tonnage minimizes wear and tear on the press brake, preserving its lifespan and performance. Web use this quick bending calculator tool to input material type and thickness, die and punch parameters, and overall bending length. Locate the corresponding values for bend length, angle, and material thickness on. Potential issues with using insufficient tonnage. Web a press brake tonnage chart is a valuable tool that provides a quick reference for determining the required tonnage based on various factors, such as material type, thickness, and bend length. To lessen downtime ashmores can offer a tool 24 hour. You can use this calculator to work out the necessary press brake tonnage and tooling requirements to perform the bending of your parts. By utilizing this chart, fabricators can ensure accurate and precise bends,. Then press a button and the exact tonnage is revealed to process a 90 degree air bend. The bending force is not the same thing as. 11 16 10 12 18 20 25 1.3 12 17 10 1.6 10 15 27 12 8.5 13 22 35 16 11 2.6 17 26 38 20 14 3.3 13 21 30 54 1. Of bend @ specific die opening / radius) thickness. The risks of using too much tonnage. Web press brake bending tonnage chart. Locate the corresponding values. From an efficiency standpoint, using the correct tonnage minimizes wear and tear on the press brake, preserving its lifespan and performance. Web press brake metric calculator of bending force and tonnage online with tonnage force chart and formulas to use. Web whether you look at the tonnage force chart or calculate the numbers yourself, those values represent the estimated tonnage. Web consult the press brake tonnage chart to determine the required tonnage based on the material properties and bend specifications. Web press brake tonnage calculator is a measure of the amount of force a press brake can exert on a piece of metal during the bending process. Tons required per linear foot to bend mild steel having max. Then press. Potential issues with using insufficient tonnage. From an efficiency standpoint, using the correct tonnage minimizes wear and tear on the press brake, preserving its lifespan and performance. Web overloading a press brake can lead to mechanical failures, posing serious risks. It is an indispensable resource for any press brake operator, as it helps streamline the bending process and ensures optimal. Web ashmores press brake tooling limited. It is an indispensable resource for any press brake operator, as it helps streamline the bending process and ensures optimal results. When using material over 1/2”, it is usual practice to have die opening 10 times the metal thickness. 11 16 10 12 18 20 25 1.3 12 17 10 1.6 10 15 27. Web consult the press brake tonnage chart to determine the required tonnage based on the material properties and bend specifications. Web the cincinnati press brake load calculator will calculate the tonnage to form a part with the variables of material type, vee die opening, bend length, and material thickness inputted. To lessen downtime ashmores can offer a tool 24 hour. Web ashmores press brake tooling limited. 11 16 10 12 18 20 25 1.3 12 17 10 1.6 10 15 27 12 8.5 13 22 35 16 11 2.6 17 26 38 20 14 3.3 13 21 30 54 1. When using material over 1/2”, it is usual practice to have die opening 10 times the metal thickness. Web to. Press brake tonnage is the measure of force required to bend metal in a press brake machine. Bending pressures required for other metals compared to 60,000 p.s.i. Web use this quick bending calculator tool to input material type and thickness, die and punch parameters, and overall bending length. Locate the corresponding values for bend length, angle, and material thickness on.. Tons required per linear foot to bend mild steel having max. From an efficiency standpoint, using the correct tonnage minimizes wear and tear on the press brake, preserving its lifespan and performance. Exceeding the maximum allowable tonnage could result in significant damage to the part, the press brake, or the tooling itself. Web selecting the right press brake tooling for your application requires careful consideration of not only how much tonnage a job requires, but how much tonnage your press brake and tooling can safely withstand. Web press brake tonnage calculator is a measure of the amount of force a press brake can exert on a piece of metal during the bending process. Web overloading a press brake can lead to mechanical failures, posing serious risks. When using material over 1/2”, it is usual practice to have die opening 10 times the metal thickness. Web to determine the required press brake tonnage, we need to refer to the press brake tonnage chart. First, find the row with a thickness value of “4” and then determine the corresponding vee opening value of 32 (4 * 8). Web press brake bending tonnage chart. The bending force is not the same thing as machine capacity. Web tonnage chart material thickness width of female vee die opening approximate tons per lineal foot of forming based on air bending 90° bend in mild steel. Web calculate tonnage needed to bend your metal thickness using the press brake tonnage chart from american machine tools company. To lessen downtime ashmores can offer a tool 24 hour refurbishment service. Web consult the press brake tonnage chart to determine the required tonnage based on the material properties and bend specifications. By utilizing this chart, fabricators can ensure accurate and precise bends,.

FAQ — Power Brake Dies

What is a press brake and why do I need one?

How to Calculate Press Brake Tonnage BLMA machinery

Press brake bending basics Die angles, tonnage, and Kfactors

Press Brake Tonnage Calculator & Free) MachineMFG

How to calculate press brake working tonnage?

How to Calculate Press Brake Bending Force? MachineMFG

Press Brake Toolings, A Guide to Punches and Dies Selmach™

1020680, Baileigh BP3305CNC 63 inch CNC Press Brake, 33 ton

Hydraulic PressBrake

Web A Press Brake Tonnage Chart Is A Valuable Tool That Provides A Quick Reference For Determining The Required Tonnage Based On Various Factors, Such As Material Type, Thickness, And Bend Length.

Web Always Consult A Tonnage Chart And Consider The Types Of Materials You’ll Primarily Work With.

Does The Complexity Of My Bends Matter When Selecting A Brake Press?

It Is An Indispensable Resource For Any Press Brake Operator, As It Helps Streamline The Bending Process And Ensures Optimal Results.

Related Post: