Blower Motor Size Chart

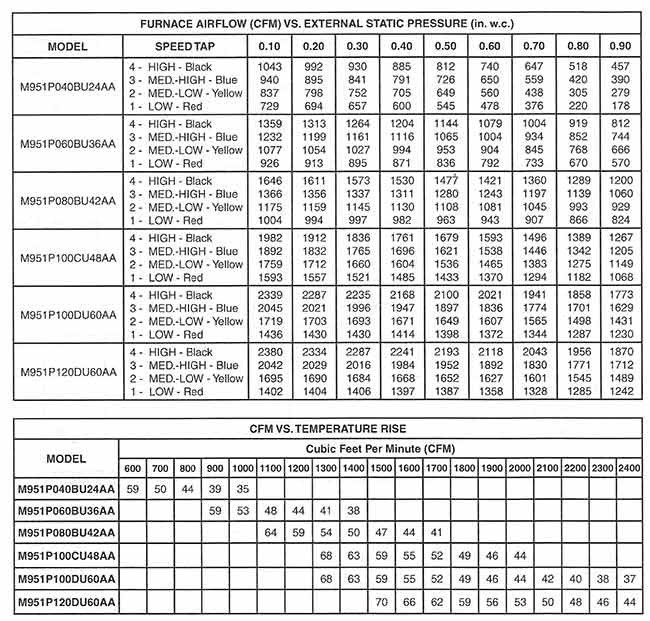

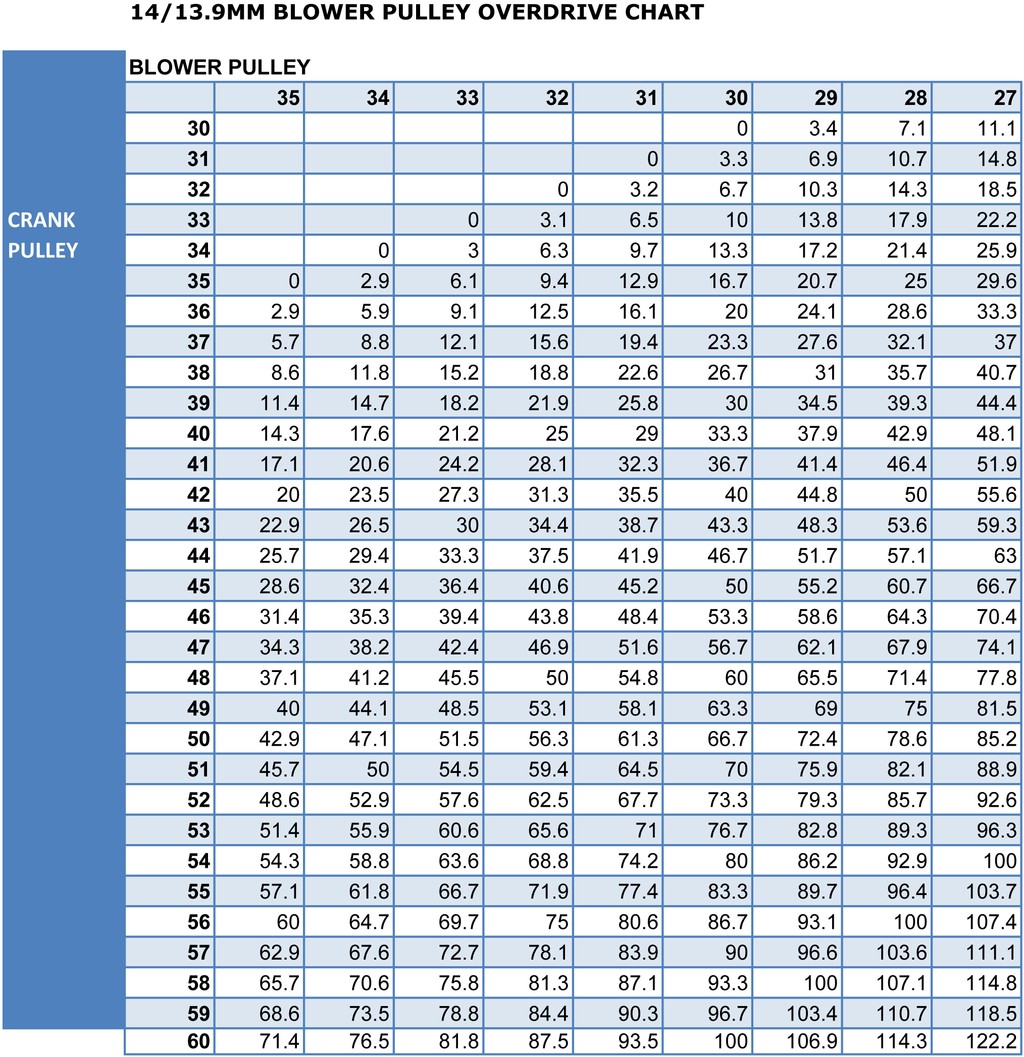

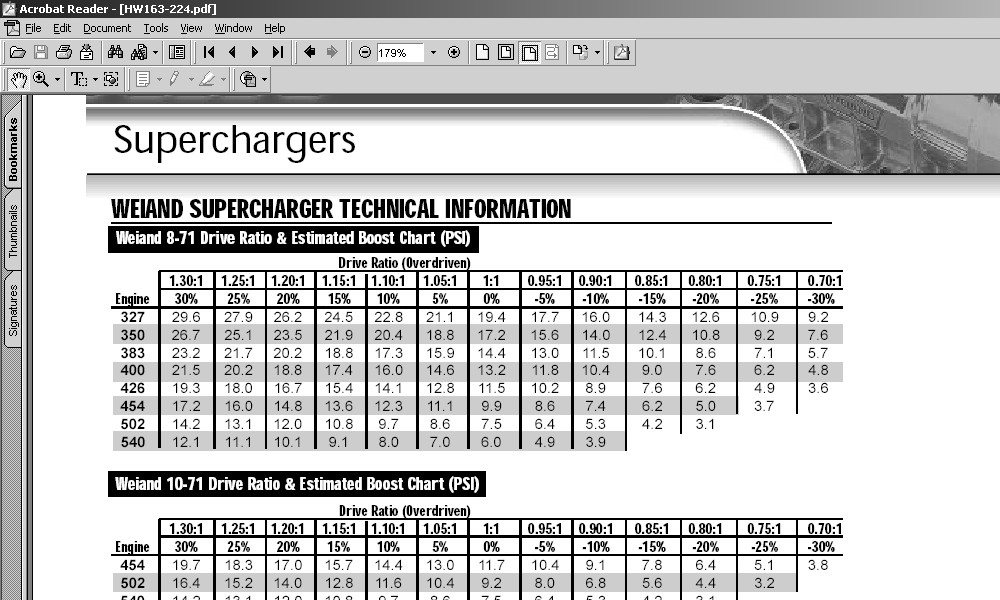

Blower Motor Size Chart - Blower motor sizes cannot be interchanged, as they are sized to things like the supply opening, the blower wheel, and the return. Notice i said mounting dimensions. Web measure and record the distance between the motor shaft and the pulley shaft, and then measure the diameter of the motor pulley (also called the drive pulley or sheave) and the fan pulley (called the driven pulley). Web below are three blower motor options, each with an increasing level of comfort control. Changing a motor lead is all that is necessary to change speeds. The article guides electrical engineers on electric motor sizing and selection to satisfy their power system requirements. Web motors speed control systems stepping motors gearheads linear motion cooling f ans motor and f an sizing fan sizing calculations selecting a fan this section describes basic methods of selecting typical ventilation and cooling products based on their use. Web oil and gas furnace direct drive blower motors are usually 115 volts. It is perfectly fine to run a larger blower on a small engine as long as you use the proper underdrive pulleys to create safe boost levels. When on, the blower is designed to push a specific volume of air through the ductwork. Notice i said mounting dimensions. By looking at this chart, you can determine the correct horsepower for the replacement motor based on the specification of the fan blade. The length & diameter, shaft sizes, mounting type, etc are very important for choosing the motor size. Web how to properly select a fan or blower. Device specifications and conditions determine the. A centrifugal blower wheel draws air into the inlet of the blower housing, through the wheel, and discharges it at 90° out through the discharge of the blower housing. Select a blower for 1500 cfm at 7 wg at 250°f. At 1000 cfm, your blower draws 1.5a. The article guides electrical engineers on electric motor sizing and selection to satisfy. Web all you can do is measure the current fan and it is a four blade 18” fan with a 30 degree angle. It is perfectly fine to run a larger blower on a small engine as long as you use the proper underdrive pulleys to create safe boost levels. Apply the following formula to determine a new replacement belt. Web chart found on page 5 of instructions for how to properly select a fan or blower. Web oil and gas furnace direct drive blower motors are usually 115 volts. Web to accommodate the larger mechanical horsepower capability, shaft and bearing sizes had to be increased. Web all you can do is measure the current fan and it is a. Learn about dimensions for leeson, century, & marathon motors. Web all you can do is measure the current fan and it is a four blade 18” fan with a 30 degree angle. Notice i said mounting dimensions. It is perfectly fine to run a larger blower on a small engine as long as you use the proper underdrive pulleys to. Apply the following formula to determine a new replacement belt length: Web the size of your furnace blower motor depends on its physical and electrical specifications. Belt length = 2c + 1.57 x (d1 + d2) + 1” where. You need to know how much hp it is using now and what your. Web highly efficient designs for furnaces and. And at 6500 feet elevation. When on, the blower is designed to push a specific volume of air through the ductwork. Web chart found on page 5 of instructions for how to properly select a fan or blower. Web how to properly select a fan or blower. It is perfectly fine to run a larger blower on a small engine. The length & diameter, shaft sizes, mounting type, etc are very important for choosing the motor size. Web blower diameter 9½ 9½ 9½ 10⅝ 10⅝ 10⅝ 10⅝ 11¹⁵⁄₁₆ 11¹⁵⁄₁₆ width 6 6 6 8 10⅝ 10⅝ 10⅝ 10⅝ 10⅝ coil connections liquid ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ suction ¾ ⅞ ⅞ ⅞ ⅞ ⅞ ⅞ ⅞. Additionally, to ensure compatibility, you’ll need to know the hp, rpm, amp & voltage limits. Web final compression ratio chart; For an electric power system to work well, the secret lies in the proper sizing and. Notice i said mounting dimensions. When on, the blower is designed to push a specific volume of air through the ductwork. When selecting a model with a 3 speed motor, it is recommended that the g speed be chosen whenever possible. Web blower diameter 9½ 9½ 9½ 10⅝ 10⅝ 10⅝ 10⅝ 11¹⁵⁄₁₆ 11¹⁵⁄₁₆ width 6 6 6 8 10⅝ 10⅝ 10⅝ 10⅝ 10⅝ coil connections liquid ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ suction ¾ ⅞ ⅞ ⅞ ⅞. The three speeds are 1550 rpm (d), 1300 rpm (g) and 1050 rpm (e). It is perfectly fine to run a larger blower on a small engine as long as you use the proper underdrive pulleys to create safe boost levels. Additionally, to ensure compatibility, you’ll need to know the hp, rpm, amp & voltage limits. When on, the blower is designed to push a specific volume of air through the ductwork. Web motors speed control systems stepping motors gearheads linear motion cooling f ans motor and f an sizing fan sizing calculations selecting a fan this section describes basic methods of selecting typical ventilation and cooling products based on their use. Electric furnace direct drive blower motors are usually 230 volts. Belt length = 2c + 1.57 x (d1 + d2) + 1” where. Select a blower for 1500 cfm at 7 wg at 250°f. Web if your motor is already close to its rated hp, a small airflow increase can overload it. Apply the following formula to determine a new replacement belt length: Web chart found on page 5 of instructions for how to properly select a fan or blower. Most furnace blower motors have a ½ inch shaft size. When selecting a model with a 3 speed motor, it is recommended that the g speed be chosen whenever possible. Web blower diameter 9½ 9½ 9½ 10⅝ 10⅝ 10⅝ 10⅝ 11¹⁵⁄₁₆ 11¹⁵⁄₁₆ width 6 6 6 8 10⅝ 10⅝ 10⅝ 10⅝ 10⅝ coil connections liquid ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ ⅜ suction ¾ ⅞ ⅞ ⅞ ⅞ ⅞ ⅞ ⅞ ⅞ coil drain connect (fpt). Web highly efficient designs for furnaces and air handlers residential and commercial applications •extended studs for mounting flexibility on most motors •2.5 diameter hub rings included •24 leads with 5 long shafts with flat •designed for 370v capacitors minimum 42 frame (5.0 dia.) shaded pole designs, ccw lead end rotation only. Apply it in the field:

New Blower Charts for G7 SingleStage Furnaces YouTube

blowercharts HPAC Magazine

Blower Sizing Chart

Blower Sizing Waterway Plastics

Single Phase Motor Chart

Blower Motor Size Chart

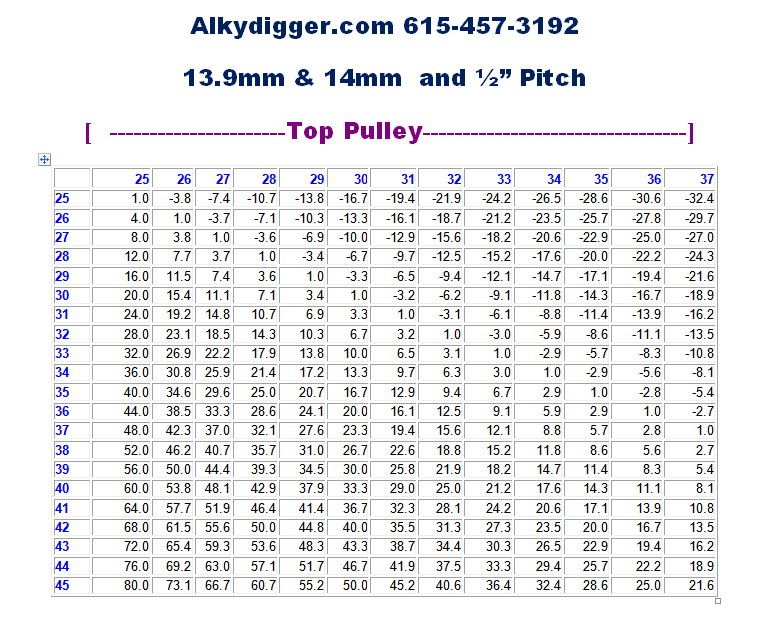

Blower Ratio Chart For 13.9mm, 14mm and 1/2" Pitch Pulleys

Hot Rods Engine Advise for a 671 Blower. The H.A.M.B.

Blower Sizing Chart

blower pulley size charts

You Can Find All Of These Details On Your Old Blower Motor’s Faceplate.

Web Final Compression Ratio Chart;

1 Speed, 2 Speed, Or 3 Speed.

Changing A Motor Lead Is All That Is Necessary To Change Speeds.

Related Post: