Beginner Welding Rod Chart

Beginner Welding Rod Chart - A consumable electrode is effective when the electrode and the filler metal are the same. Web welding rod sizes vary in electrodes of the same diameter. Welding electrodes & filler rods explained. Web one of the things you may ask yourself when using stick welding (smaw) is which is the easiest welding electrode (or rod) to use. Chart for different welding positions. Your guide to welding rod selection & numbers. Determining rod size from metal thickness. 298k views 1 year ago how to stick weld course. It is made out of materials with a similar composition to the metal being welded. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Determining rod size from metal thickness. How to choose a correct welding rod size. Web this guide aims to provide insights into the best welding rods for beginners, focusing on types that offer ease of use, forgiveness in application, and compatibility with common welding tasks. Web this guide will help you understand the basics of stick electrode selection. Web the. These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. Each one has different properties and applications. Additionally, we made the most complete stick welding rod chart pdf on the internet with over 220 electrodes. 1.1 how do welding rods differ? Understanding stick welding rod classification is essential in selecting the correct electrode for your. The chart helps welders understand the correct techniques, tools, and types of welds for each position. Diameters range from 1/16″ to 1/4″, the most common diameters being 3/32″, 1/8″, and 5/32″. The easiest welding rod to use is a 1/8″ (3.2 mm) e6013 rod. So, what welding rod to use for your application? It serves as a foundational resource for. Click here to see the welding rod chart in pdf format. Web one of the things you may ask yourself when using stick welding (smaw) is which is the easiest welding electrode (or rod) to use. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. Welding rods &. Welding rods vs electrodes vs filler metals; It serves as a foundational resource for novice welders looking to. It’s because of the amount of flux or coating each one has. Web one of the things you may ask yourself when using stick welding (smaw) is which is the easiest welding electrode (or rod) to use. Different electrode charts/tables below should. These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. It is made out of materials with a similar composition to the metal being welded. You will also get the required polarity, position, and other related information. Web welding rod size chart. Choosing what welding rod to use is crucial to the success of your. How to understand welding rod numbers; How to choose a correct welding rod size. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. 2.1 how is welding rod diameter measured? Click here to see the welding rod chart in pdf format. Different electrode charts/tables below should give you a pretty good idea of which rod to use, when, and on which settings. Determining rod size from metal thickness. Below is a chart that will give you a starting point for choosing the correct welding rod size. The calculator below pinpoints exactly which electrode you need for the metal you are welding.. What are the welding rods? We have gone into this in more detail below. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. How to choose a correct welding rod size. These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. 298k views 1 year ago how to stick weld course. Click here to see the welding rod chart in pdf format. Web a welding position chart is a comprehensive guide outlining the positions in which a welder can operate. Many factors go into the decision of picking the right rod, like the tensile strength, the base metal properties, the welding. Each one has different properties and applications. 2.1 how is welding rod diameter measured? You will also get the required polarity, position, and other related information. How to understand welding rod numbers; 3.1 thickness of the metal and electrode size. The chart helps welders understand the correct techniques, tools, and types of welds for each position. Web welding rod sizes vary in electrodes of the same diameter. You should not be perplexed with these numbers for these numbers correspond to certain values. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. Web this guide will help you understand the basics of stick electrode selection. Web if you are a beginner in the welding industry, you may be confused upon looking at the welding rod classification, for you would readily notice that the welding rod chart have numerical digits. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. Welding rods vs electrodes vs filler metals; Welding electrodes & filler rods explained. Contents [ show] common stick welding rods. 298k views 1 year ago how to stick weld course.

Welding rod chart, Welding rods, Welding and fabrication

Welding Rod Chart

Beginner Welding Rod Chart

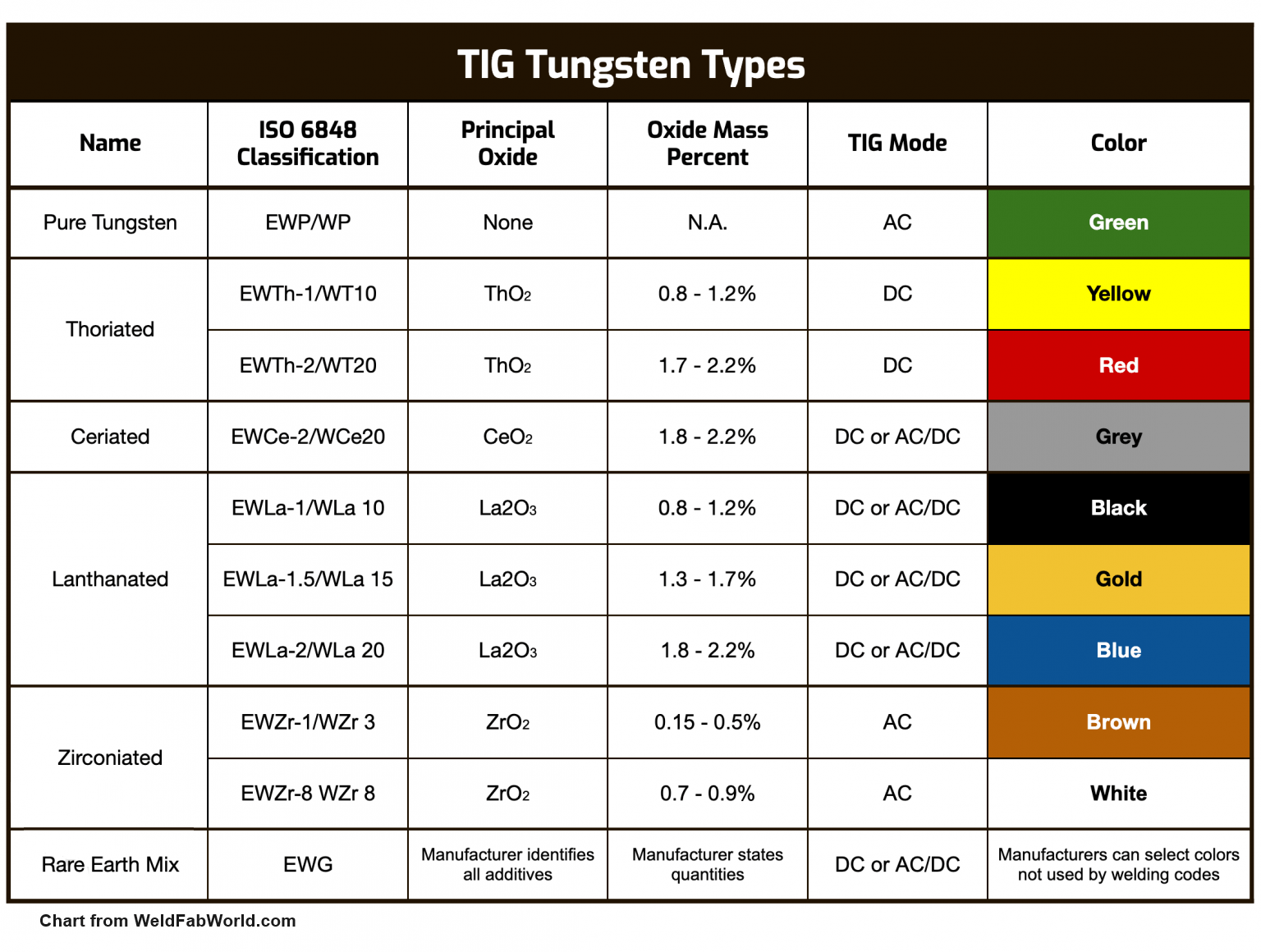

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World

How Do I Calculate How Much Welding Rod I Need

Welding Rod List

Welding Rod Chart

Welding Rod Sizes Here's The Complete Guide

The ultimate guide to welding rod sizes and classifications, including

![Different Types of Welding Rods & Their Uses [Explained] PDF](https://www.theengineerspost.com/wp-content/uploads/2022/07/Welding-Rods-1.jpg)

Different Types of Welding Rods & Their Uses [Explained] PDF

How To Choose A Correct Welding Rod Size.

Web The E6013 Welding Rod Is A Versatile Electrode Favored By Both Beginners And Professionals In Welding Due To Its Excellent Arc Stability And Ability To Produce Smooth, Clean Welds With Minimal Spatter.

The Calculator Below Pinpoints Exactly Which Electrode You Need For The Metal You Are Welding.

The Welding Rod You Select Can Affect The Strength, Penetration, And Position Of The Weld,.

Related Post: