Attribute Control Chart

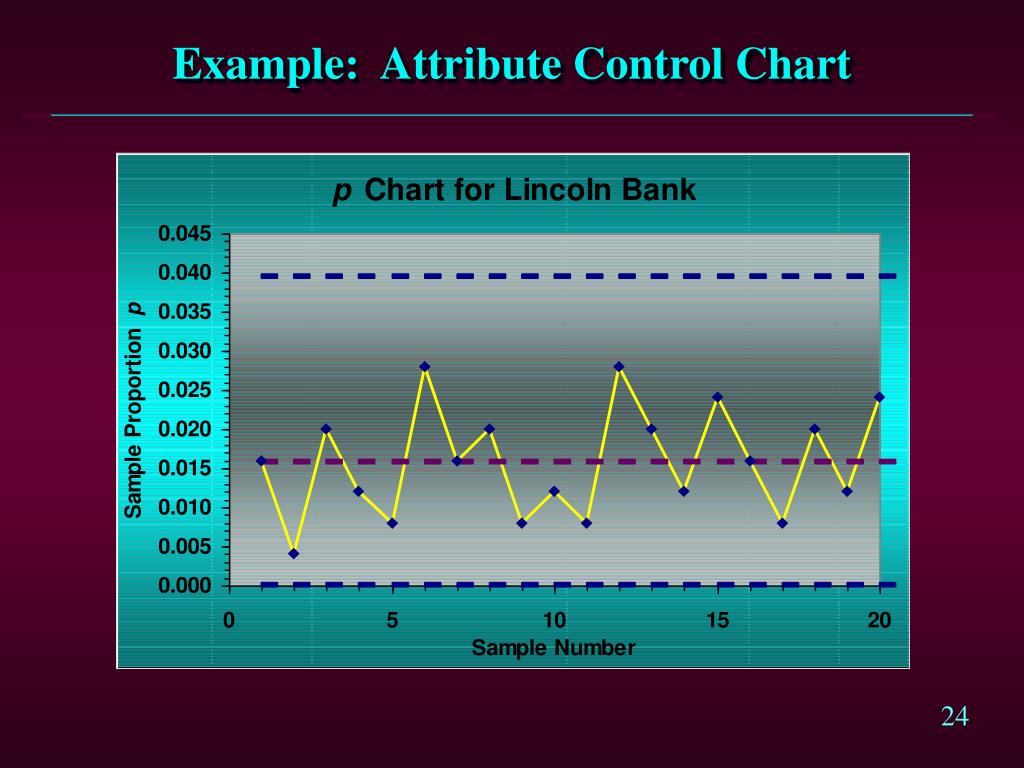

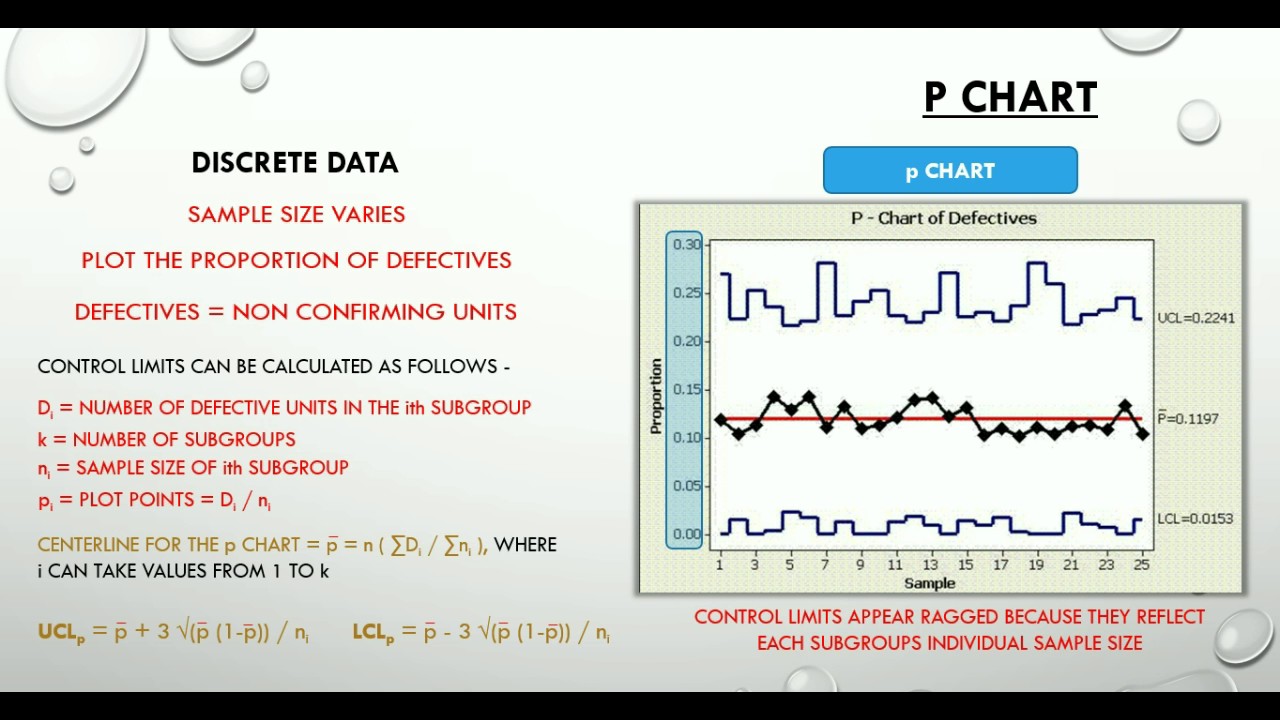

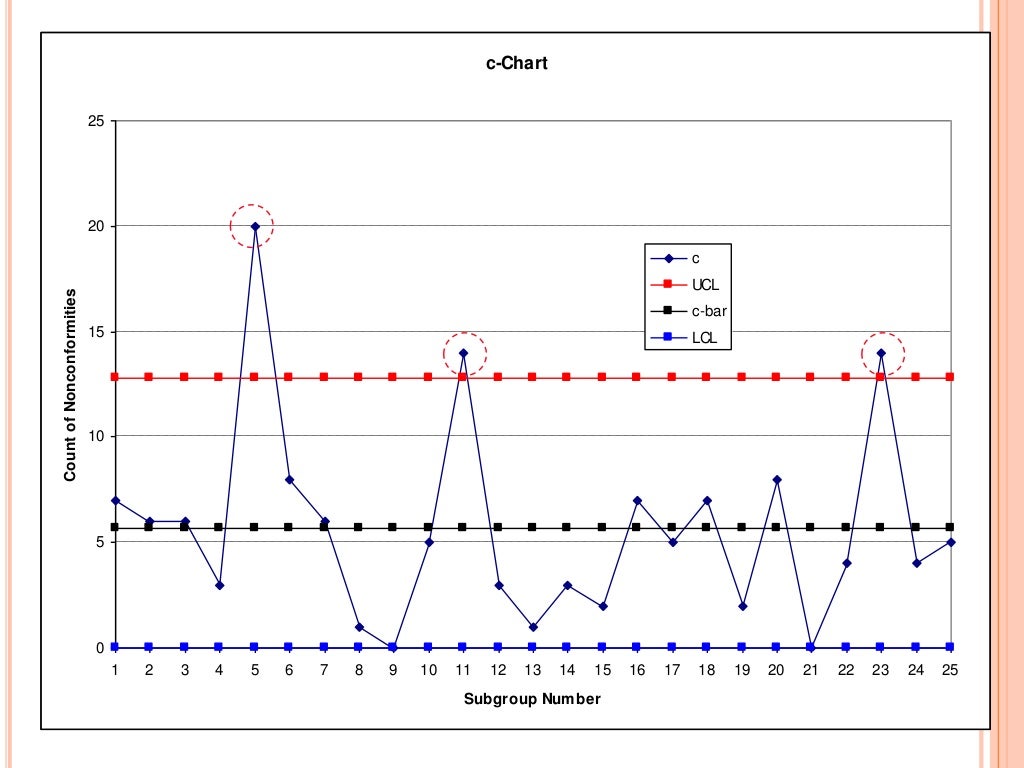

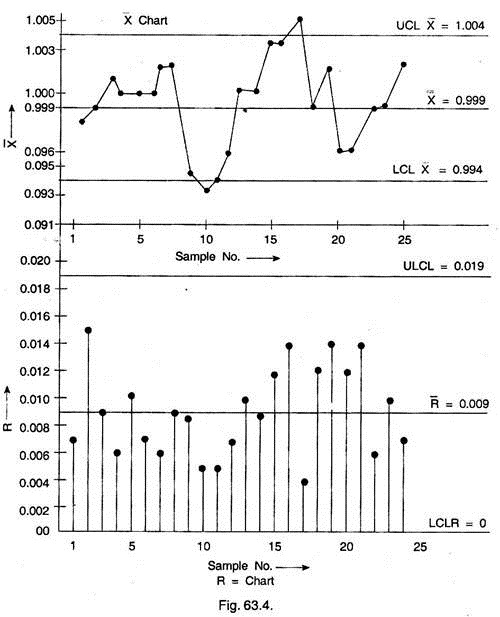

Attribute Control Chart - The family of attribute charts include the: February 18, 2013 by carl berardinelli. Web what is a p chart? Merely look for out of control points. A defect refers to a quality characteristic and a defective unit refers to the overall product. Web attribute control charts are fairly simple to interpret: Web what is an attributes control chart? A process can be called stable or under statistical control if it has only one average and one standard. Control charts have two general uses in an improvement project. Web attribute charts are a set of control charts specifically designed for attributes data (i.e. Web an attribute control chart is a way to track the production of defective items. It is important, however, to not lose sight of the primary goal: Excerpted from the quality toolbox, asq quality press. These types of defects are binary in nature (yes/no), where a part has one or more defects, or it doesn’t. Attributes data arise when classifying. That’s why analysts need to be careful and thorough when setting up this kind of study. P chart is also known as the control chart for proportions. What capabilities you care about and what counts as a success depends on the demands of the situation. Web this month’s publication reviewed the four basic attribute control charts: The charts help us. The most common application is as a tool to monitor process stability and control. Control limits for these charts are determined through a repetitive sampling procedure. Statistical formulas use historical records or sample data to calculate the control limits. P chart is also known as the control chart for proportions. A process can be called stable or under statistical control. Control charts have two general uses in an improvement project. Web attribute data on a control chart is simply the count of products or characteristics of a product that do not conform to some established criteria. The chart becomes a line graph showing the variation in the quality of the process over a period of time. Certain quality characteristics are. A control chart for attributes can provide overall quality information at a. Two inner and outer control limits are established based on the desired. The control chart is a graph used to study how a process changes over time with data plotted in time order. We measure weight, height, position, thickness, etc. A unit may have many defects, but the. Web attribute charts are a set of control charts specifically designed for attributes data (i.e. A control chart for attributes can provide overall quality information at a. Web how are attribute & variable data used to create control charts? A control chart always has a central line for the average, an upper line for the upper control limit, and the. It is important, however, to not lose sight of the primary goal: Control charts have two general uses in an improvement project. Control limits are drawn on the control chart to aid in analyzing the variation of the. Attributes data arise when classifying or counting observations. We measure weight, height, position, thickness, etc. A unit may have many defects, but the unit itself is. A control chart for attributes can provide overall quality information at a. What capabilities you care about and what counts as a success depends on the demands of the situation. Web control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process.. Two inner and outer control limits are established based on the desired. Minitab offers several attribute control charts that plot defects or defectives. The equations for the average and control limits were given as well as the underlying assumptions for each type of control chart. Web what is a p chart? It is important, however, to not lose sight of. It visually displays process data over time and allows you to detect whether a. Improve quality, and in so doing, improve customer satisfaction and the company’s profitability. P chart is also known as the control chart for proportions. Web attribute charts are a set of control charts specifically designed for attributes data (i.e. Statistical formulas use historical records or sample. Web for these situations, we need to use attributes control charts. A unit may have many defects, but the unit itself is. Web how are attribute & variable data used to create control charts? The equations for the average and control limits were given as well as the underlying assumptions for each type of control chart. The shewhart control chart plots quality characteristics that can be measured and expressed numerically. It is important, however, to not lose sight of the primary goal: A control chart, also known as a statistical process control chart, is a statistical tool used to monitor, control, and improve the quality of processes. Two inner and outer control limits are established based on the desired. The complete guide to understanding control charts. These limits let you know when unusual variability occurs. A control chart for attributes can provide overall quality information at a. The chart becomes a line graph showing the variation in the quality of the process over a period of time. Web control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Web what is an attributes control chart? We measure weight, height, position, thickness, etc. Web this month’s publication reviewed the four basic attribute control charts:

Types Of Attribute Control Charts Minga

Attribute Control Charts Example 1 Multiple Choice Questions YouTube

Types of Attribute Control Charts The P Chart VS C Chart

Lecture 12 Attribute Control Charts and Process Capability YouTube

Control Charts For Variable Normal Curve Control Charts

PPT Chapter 17 PowerPoint Presentation, free download ID3422491

1.8.4 Attribute Control Charts YouTube

Control charts for attributes

Control Charts for Variables and Attributes Quality Control

PPT SPC PowerPoint Presentation, free download ID6115362

Web Chapter 7 Attribute Control Charts.

The Chart Doesn’t Tell You Why The Defects Happened, But It Does Give You The Total Or Average Counts Per Unit.

Control Charts Are Used To Regularly Monitor A Process To Determine Whether It Is In Control.

A Process Can Be Called Stable Or Under Statistical Control If It Has Only One Average And One Standard.

Related Post: