Asme Flange Bolt Torque Chart

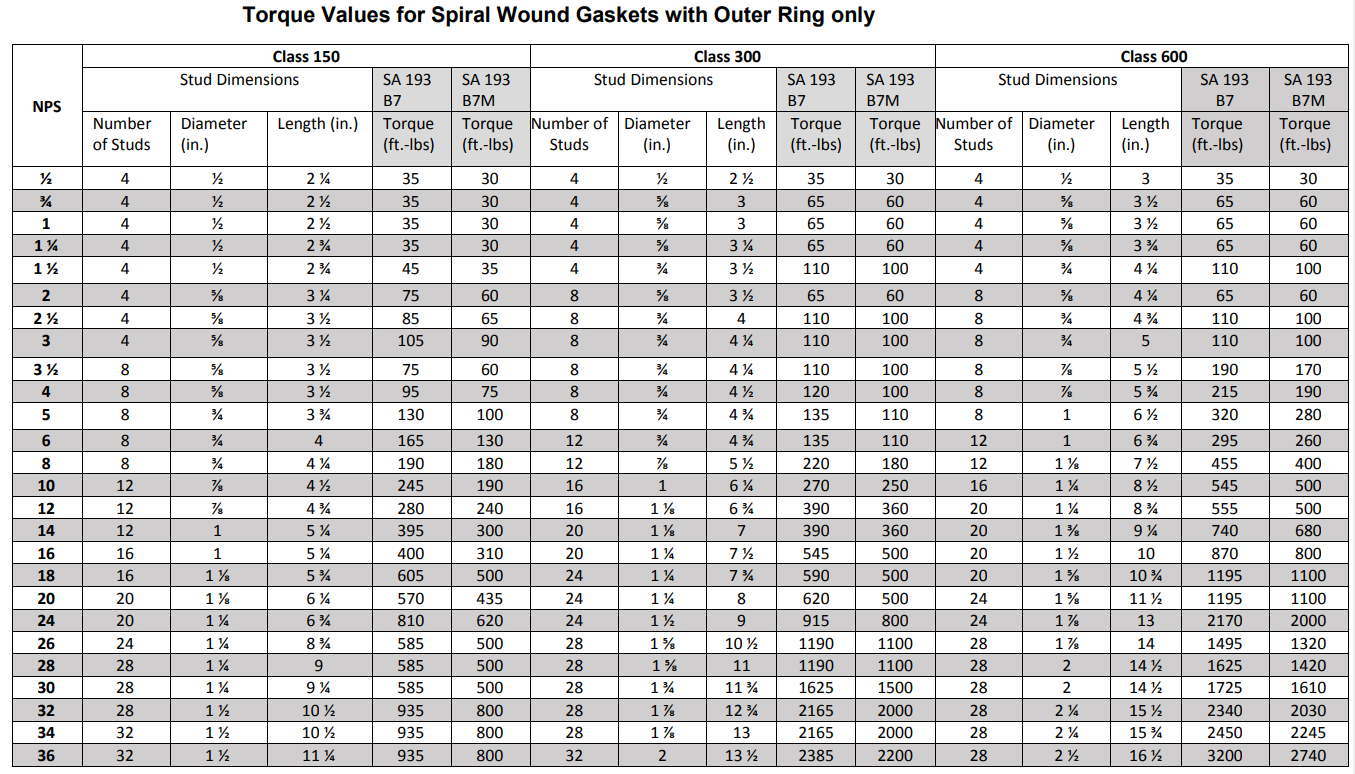

Asme Flange Bolt Torque Chart - K = 0.15 k = 0.17 k = 0.20. Web allways wear safety equipment. Web find bolt torque values for asme b16.47 and b16.5 flanges with different pipe sizes, bolt sizes and gasket types. The tables are based on astm standards and include factors for lubricant, material,. Web if conditions different from these exist, we suggest that further analysis be performed to determine the proper solution. Web bolt reference charts for asme b16.5 flanges. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Recommended torque values lubricated stud bolts w/0.15 friction value. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Web minimum torque recommended per bolt = (2,500 psi) (4,844 psi) x (120 ft.lbs.) minimum torque recommended per bolt = 62 ft.lbs. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web if conditions different from these exist, we suggest that further analysis be performed to determine the proper solution. Asme (mechanical) code issues forum. Key charts for stud bolts: #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. For full face homogenous elastomeric gaskets 70. Use of 6 mm (1/4 in) gasket thickness is recommended torque values requirements. Web bolt torque values for asme b16.47 series a class 150# flat flanges with a193 grade b7 bolts. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) edge®. Diameter diameter number diameter length of stud bolts [note (1)] raised ring face joint. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. The tables are based on astm standards and include factors for lubricant, material,. Minimum preferred torque torque (ft.lbs.) (ft.lbs.). Web stud bolts charts: Web minimum torque recommended per bolt = (2,500 psi) (4,844 psi) x (120 ft.lbs.) minimum torque recommended per bolt = 62 ft.lbs. Use of 6 mm (1/4 in) gasket thickness is recommended torque values requirements. Minimum preferred torque torque (ft.lbs.) (ft.lbs.). Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. For full face homogenous elastomeric gaskets 70. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web find torque values for different sizes and types of stud bolts used in flange connections. Web bolt torque values for asme b16.47 series a class 150# flat flanges with a193 grade b7 bolts. Asme (mechanical) code issues forum. The tables are based on astm standards and include factors for lubricant, material,. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Use of 6 mm (1/4 in) gasket thickness is recommended torque values requirements. See minimum and preferred torque values, as well as notes and. Web. Diameter diameter number diameter length of stud bolts [note (1)] raised ring face joint 0.06. Use of 6 mm (1/4 in) gasket thickness is recommended torque values requirements. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. Recommended torque values lubricated stud bolts w/0.15 friction value. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. The tables are based on astm standards and include factors for lubricant, material,. Flanges bolting table, weights, and torque sequences & requirements. Web find bolt torque values for asme b16.47 and b16.5 flanges with different pipe sizes, bolt sizes and gasket types. Web find torque values for different sizes and types of stud bolts used in flange connections. Web torque. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web bolt torque values for asme b16.47 series a class 150# flat flanges with a193 grade b7 bolts. Web stud bolts charts: Swg (type 913 and 913m). For full face homogenous elastomeric gaskets 70. Flanges bolting table, weights, and torque sequences & requirements. Asme (mechanical) code issues forum. Engineering codes, standards & certifications. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Web torque bolts in stages according to torque tables using a calibrated torque wrench or impact wrench, following the specified. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Swg (type 913 and 913m). Flange dimensions are determined by the pipe size and the pressure class. Web find bolt torque values for asme b16.47 and b16.5 flanges with different pipe sizes, bolt sizes and gasket types. Minimum preferred torque torque (ft.lbs.) (ft.lbs.). Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Use of 6 mm (1/4 in) gasket thickness is recommended torque values requirements. Engineering codes, standards & certifications. Web find torque values for different sizes and types of stud bolts used in flange connections. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) edge®. Key charts for stud bolts: Web stud bolts charts: K = 0.15 k = 0.17 k = 0.20. Web if conditions different from these exist, we suggest that further analysis be performed to determine the proper solution. Web bolt torque values for asme b16.47 series a class 150# flat flanges with a193 grade b7 bolts.ASME Flange B16.5 Chart 150 LB Plumbing Mechanical Engineering

Asme Flange Bolt Torque Chart

ASME Bolting Assembly Torque Values

Asme Flange Bolt Torque Chart

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

ASME Flange Chart

Technical Info Flange BoltUp Charts

Asme Flange Bolt Torque Chart

Bolt Torque ASME B16.5 Flanges Sheet Gaskets 02 Screw Nut (Hardware)

ASME Flange B16.5 Chart 300 LB Mechanical Engineering Nature Free

For Full Face Homogenous Elastomeric Gaskets.

Web Torque Bolts In Stages According To Torque Tables Using A Calibrated Torque Wrench Or Impact Wrench, Following The Specified Tightening Pattern.

For Full Face Homogenous Elastomeric Gaskets 70.

See Minimum And Preferred Torque Values, As Well As Notes And.

Related Post: