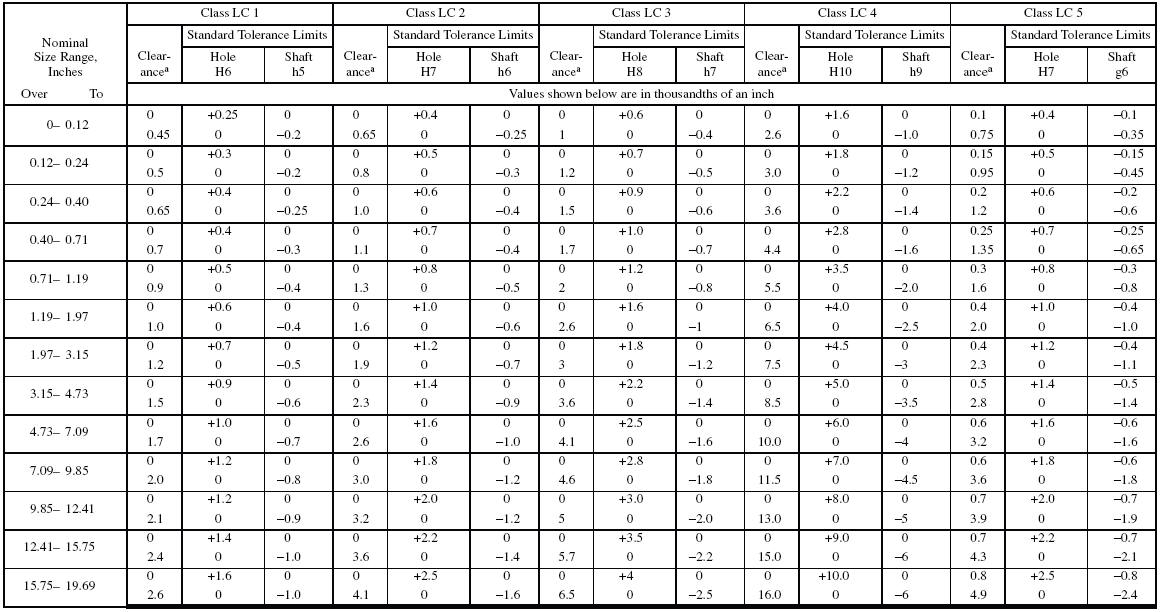

Ansi Tolerance Chart

Ansi Tolerance Chart - Web all limits shown in chart below are in thousandths of an inches. The schematic representation of the fit is also drawn. Web find the ansi b4.1 standard for running, sliding, locational and force fits for cylindrical parts. Find interactive charts, terminology explanations, and a calculator for different. Compare the clearance, transition and interference fits. Ansi b4.1 tolerance table provides a suitable range from which appropriate tolerance. This munsell color tolerance chart has ansi #70 as its main hue (target color). If an rx is great than 6.50. Popular internal searches in the engineering toolbox. Web the following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide machining tolerances. Find interactive charts, terminology explanations, and a calculator for different. Limits for sizes above 19.69 inches are not covered by abc agreements but are given in the ansi. Web symbols h6, h7, s6, etc. Web ansi b4.1 system of tolerances is prescribed by the standard for basic sizes up to 200 in. Compare the clearance, transition and interference fits. Web symbols h6, h7, s6, etc. Web drilled hole locations and size variations are cumulative of several manufacturing variables. Find interactive charts, terminology explanations, and a calculator for different. 1 in (inch) = 25.4 mm. Popular internal searches in the engineering toolbox. Fastener and screw / bolt design, formula and calculations. Web drilled hole locations and size variations are cumulative of several manufacturing variables. These tolerances are used where size tolerances. Web this section explains how to properly state tolerances for straightness, flatness, circularity, and cylindricity. Web symbols h6, h7, s6, etc. This munsell color tolerance chart has ansi #70 as its main hue (target color). See schematic representation of the fit and definitions of terms such as deviation,. Cylindrical fits and tolerances table for ip and metric. Web all limits shown in chart below are in thousandths of an inches. Web ansi internal screw threads size and tolerances table chart. Fastener and screw / bolt design, formula and calculations. Web geometric tolerancing reference chart asme y14.5m and iso/tc 213. Web calculate size limits for hole/shaft based on ansi b4.1 standard and fit type selection. The size ranges given are for. Web find the ansi b4.1 standard for running, sliding, locational and force fits for cylindrical parts. Drilled hole locations and size variations are. Ansi b4.1 tolerance table provides a suitable range from which appropriate tolerance. These tolerances are used where size tolerances. Web the following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide machining tolerances. If an rx is great than 6.50. Web ansi b4.1 system of tolerances is prescribed by the standard for basic sizes up to 200 in. Web symbols h6, h7, s6, etc. Tolerances for linear and angular dimensions without individual tolerance indications. Web ansi b4.1 standard tolerances are indicated in the diagram below: Tolerance on distance refractive power (single vision & multifocal lenses) sphere meridian power (minus cylinder. Anything outside of this range would not qualify as passing ansi standards. Web drilled hole locations and size variations are cumulative of several manufacturing variables. Web calculate size limits for hole/shaft based on ansi b4.1 standard and fit type selection. These tolerances are used where size tolerances. Drilled hole locations and size variations are. Drilled hole locations and size variations are. See schematic representation of the fit and definitions of terms such as deviation,. If an rx is great than 6.50. Fastener and screw / bolt design, formula and calculations. This munsell color tolerance chart has ansi #70 as its main hue (target color). Tolerances for linear and angular dimensions without individual tolerance indications. See the fit details, symbols, clearances and tolerances for each class of fit. Limits for sizes above 19.69 inches are not covered by abc agreements but are given in the ansi. These tolerances are used where size tolerances. Web find the ansi b4.1 standard for running, sliding, locational and force. Tolerances for linear and angular dimensions without individual tolerance indications. Compare the clearance, transition and interference fits. The schematic representation of the fit is also drawn. Cylindrical fits and tolerances table for ip and metric. See the fit details, symbols, clearances and tolerances for each class of fit. Web learn how to use the iso 286 system to specify and calculate tolerances for shafts and holes. Web ansi external screw threads size & tolerances chart. Web symbols h6, h7, s6, etc. This munsell color tolerance chart has ansi #70 as its main hue (target color). See schematic representation of the fit and definitions of terms such as deviation,. Fastener and screw design, formula calculations. Ansi b4.1 tolerance table provides a suitable range from which appropriate tolerance. Web the following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide machining tolerances. Web find the preferred size and limit tolerances for different types of fits per ansi b 4.1 standard. Find interactive charts, terminology explanations, and a calculator for different. Web ansi preferred tolerances and fits charts.

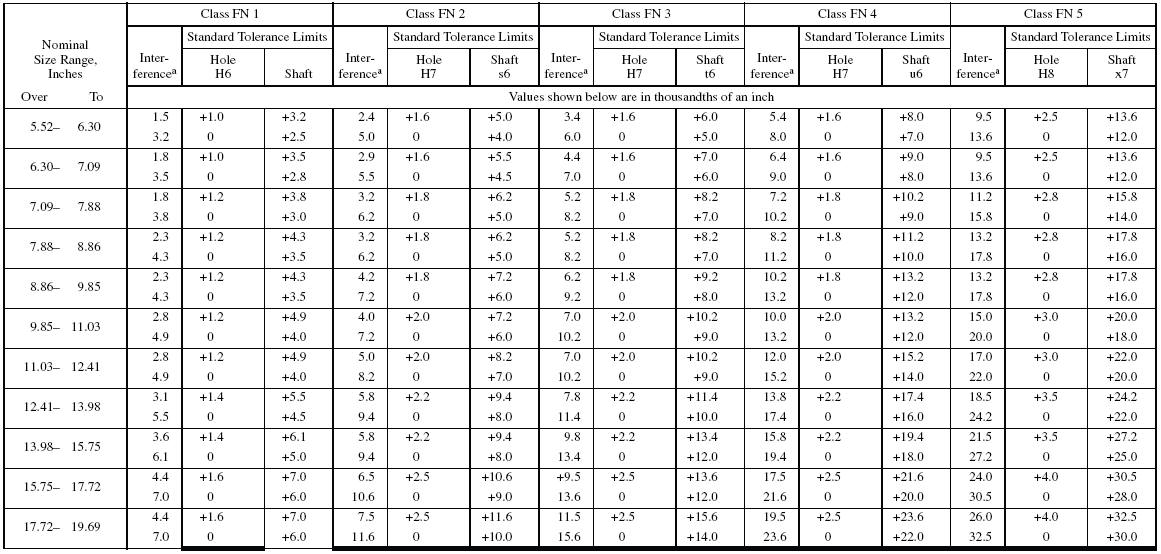

American National Standard Runni

Tolerance Table Engineering Tolerance Industrial Processes

ANSI Y14_51994 Geometric Tolerancing Cheatsheet

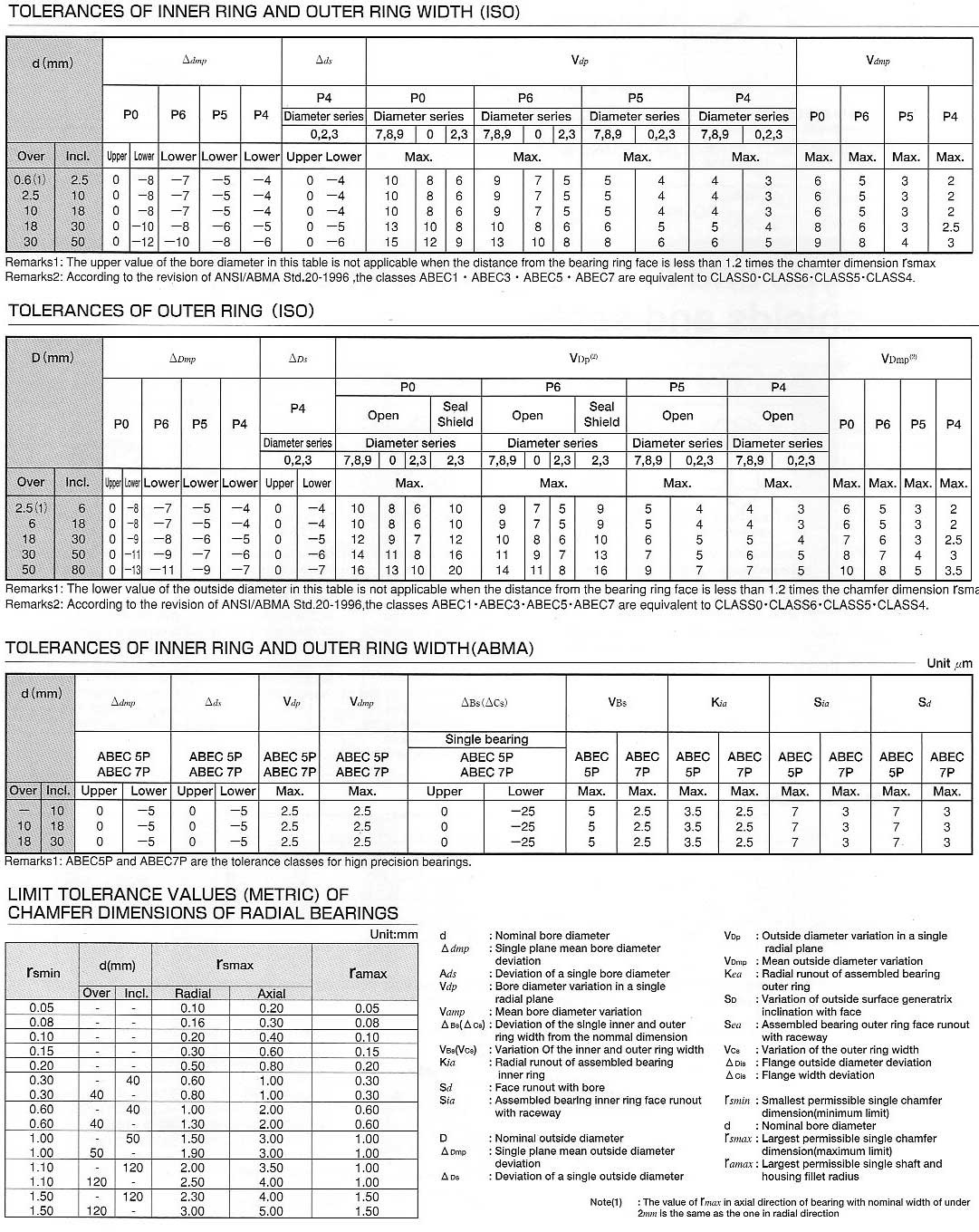

Tolerance Charts for Bearings — Electric Motor Bearings

Bearing Tolerance Chart

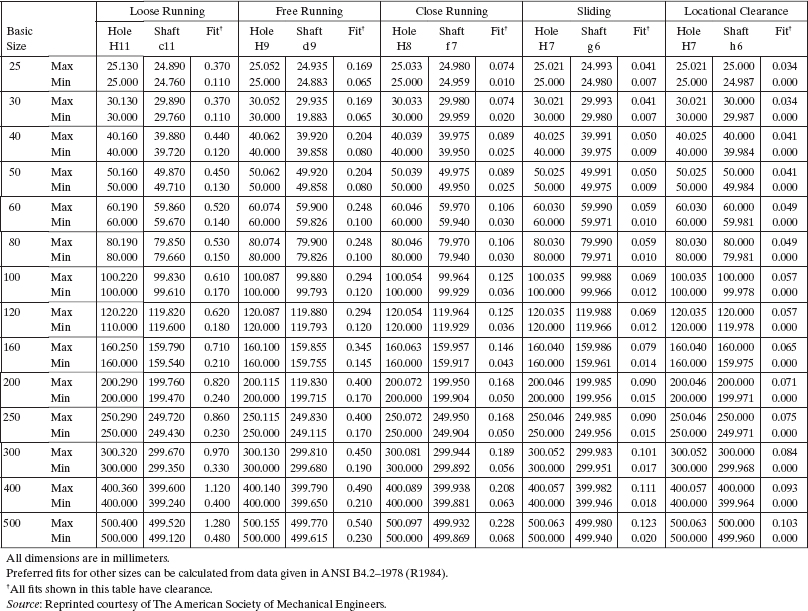

APPENDIX B ANSI PREFERRED METRIC LIMITS AND FITS Engineering Design

Iso Fits And Tolerances Chart salonenergy

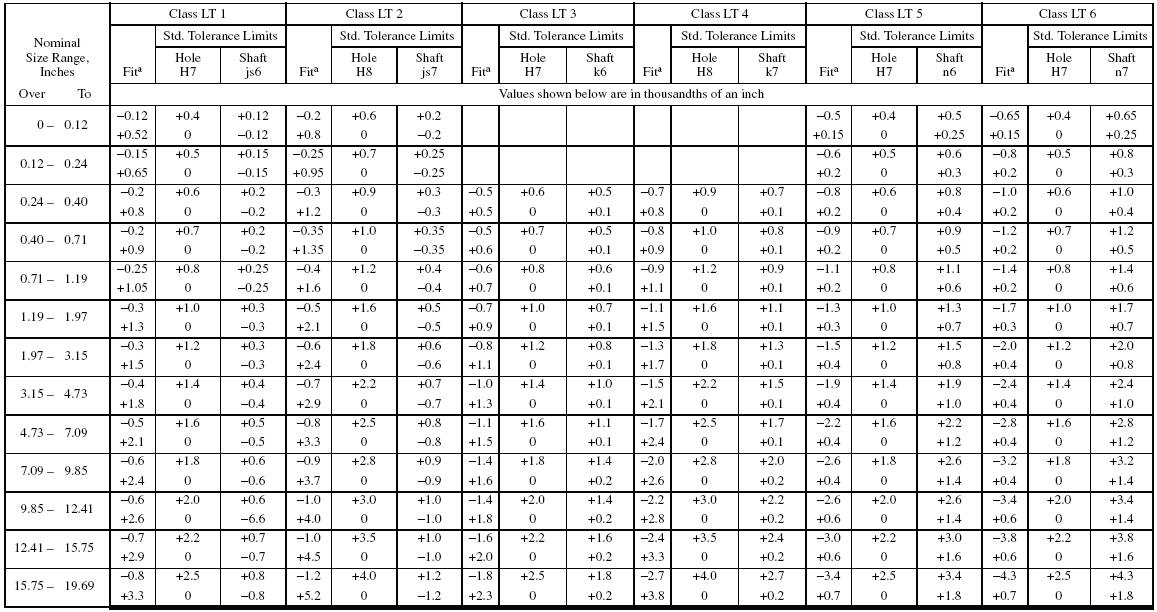

American National Standard Runni

American National Standard Runni

ANSI Tolerance Chart

Web Ansi B4.1 System Of Tolerances Is Prescribed By The Standard For Basic Sizes Up To 200 In.

Web Geometric Tolerancing Reference Chart Asme Y14.5M And Iso/Tc 213.

Anything Outside Of This Range Would Not Qualify As Passing Ansi Standards.

Web This Section Explains How To Properly State Tolerances For Straightness, Flatness, Circularity, And Cylindricity.

Related Post: