Anodize Thickness Chart

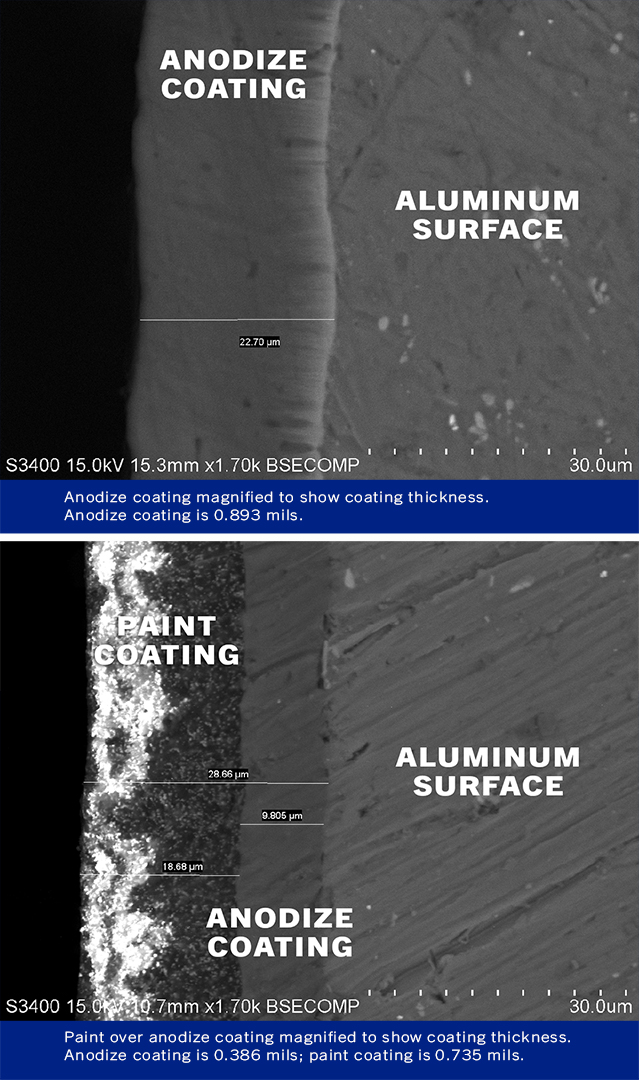

Anodize Thickness Chart - Aside from this, titanium can be anodized to take on vibrant colors that won’t fade. It may be specified as either coating thickness or coating weight, or both. There was no anodic coating thickness called out. 25 microns equals 1.0 mil; Coating thickness of 0.005 and will be gray in color. Web hardcoat anodizing provides several desirable qualities including: Mainly guideline values, list is only a recommendation which is not binding. This principle tends to hold true for most alloys and coating thicknesses. Coatings over 0.0035 tend to chip and become milky in color and should only be used in the salvage of parts. Anodizing creates a thin layer of oxide ranging from 0.08um to 80 um, depending on the type of anodizing, for a thicker anodized coating improves corrosion resistance and hardness. Anodized parts have a thin layer. Corrosion resistance is good, but recommend sealing in 5% dichromate solution where increased corrosion resistance is required. We also recommend preparing test samples before final application. 20 to 70µm for hard anodising, with thicknesses up to 100µm achievable on some alloys. It’s best for applications where a decorative finish is desired. Mainly guideline values, list is only a recommendation which is not binding. Coatings over 0.0035 tend to chip and become milky in color and should only be used in the salvage of parts. This principle tends to hold true for most alloys and coating thicknesses. Abrasion resistance will vary with alloy and thickness of coating. Hardcoat thicknesses can vary from. Natural oxide layers are generally 2 to 3 nanometers thick—with type iii anodizing, this layer can be increased to or above 50 μm* (0.002”). There was no anodic coating thickness called out. Anodized thickness.“the 50/50 rule” — a hard anodized finish is divided approximately 50% as a coating above the base metal (called “growth”), and 50% penetration below the surface. The eddy current method uses a probe that contains a coil. An example of a hard anodized and black dyed finish designated by this specification would be: Up to 5µm for chromic acid anodising. We have produced some recommendations based on what we find is suitable for most of our customers. Web coating thickness, color and alloys. Web typical coating thicknesses are as follows: For the threaded rod on the right, the diameter increased by 0.002″ since half of the coating thickness (0.001″) built up the diameter on each side of the rod. Abrasion resistance will vary with alloy and thickness of coating. Web the most common means of measuring the thickness of anodized aluminum is the. Web abrasion resistance will vary with alloy and thickness of coating. Coating thickness of 0.005 and will be gray in color. 10 to 25µm for dyed (coloured) sulphuric acid anodising. Web hardcoat anodize is type iii which is done under more exacting process conditions resulting in a harder, denser, thicker, and more abrasion resistant coating. For the threaded rod on. Web typical coating thicknesses are as follows: However, it can incur a high cost, leading to relying on other processes. Coatings over 0.0035 tend to chip and become milky in color and should only be used in the salvage of parts. Mainly guideline values, list is only a recommendation which is not binding. The corrosion resistance and long term performance. Corrosion resistance is good, but recommend sealing in 5% dichromate solution where increased corrosion resistance is required. Hardcoat thicknesses can vary from 0.0005 to 0.0030” and beyond but is dependent on the specific alloy being anodized. The three most common variations of aluminum anodizing include chromic anodizing (type i), sulfuric anodizing (type ii) and hard anodizing (type iii). Mainly guideline. The corrosion resistance and long term performance of the anodising depends on two things: While paints and plating sit on top of the surface of the aluminum, anodizing converts the outer layer of aluminum to aluminum oxide, so the coating is fully integrated with the aluminum substrate. Up to 5µm for chromic acid anodising. For type i and type ii. Corrosion resistance is good, but recommend sealing in 5% dichromate solution where increased corrosion resistance is required. Web the term thickness includes both the buildup and penetration. There was no anodic coating thickness called out. Web anodizing (guidelines ˚ r direct current method). Mainly guideline values, list is only a recommendation which is not binding. My company fabricates aluminum and steel pedestrian bridge railing among other bridge parts. There was no anodic coating thickness called out. Web hardcoat anodizing provides several desirable qualities including: Web typical coating thicknesses are as follows: 5 to 15µm for clear (natural) sulphuric acid anodising. Anodized thickness.“the 50/50 rule” — a hard anodized finish is divided approximately 50% as a coating above the base metal (called “growth”), and 50% penetration below the surface of the part. However, it can incur a high cost, leading to relying on other processes. 25 microns equals 1.0 mil; For the threaded rod on the right, the diameter increased by 0.002″ since half of the coating thickness (0.001″) built up the diameter on each side of the rod. 10 to 25µm for dyed (coloured) sulphuric acid anodising. Web hardcoat anodize is type iii which is done under more exacting process conditions resulting in a harder, denser, thicker, and more abrasion resistant coating. We have produced some recommendations based on what we find is suitable for most of our customers. Web anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. This principle tends to hold true for most alloys and coating thicknesses. Web 14 min read. Corrosion resistance is good, but recommend sealing in 5% dichromate solution where increased corrosion resistance is required.

Your Basic Guide on How to Anodize Aluminum Parts rapiddirect

ANODISING OF ALUMINIUM Tag

Aluminum Anodizing Colors Chart

Titanium Anodizing ChemTalk

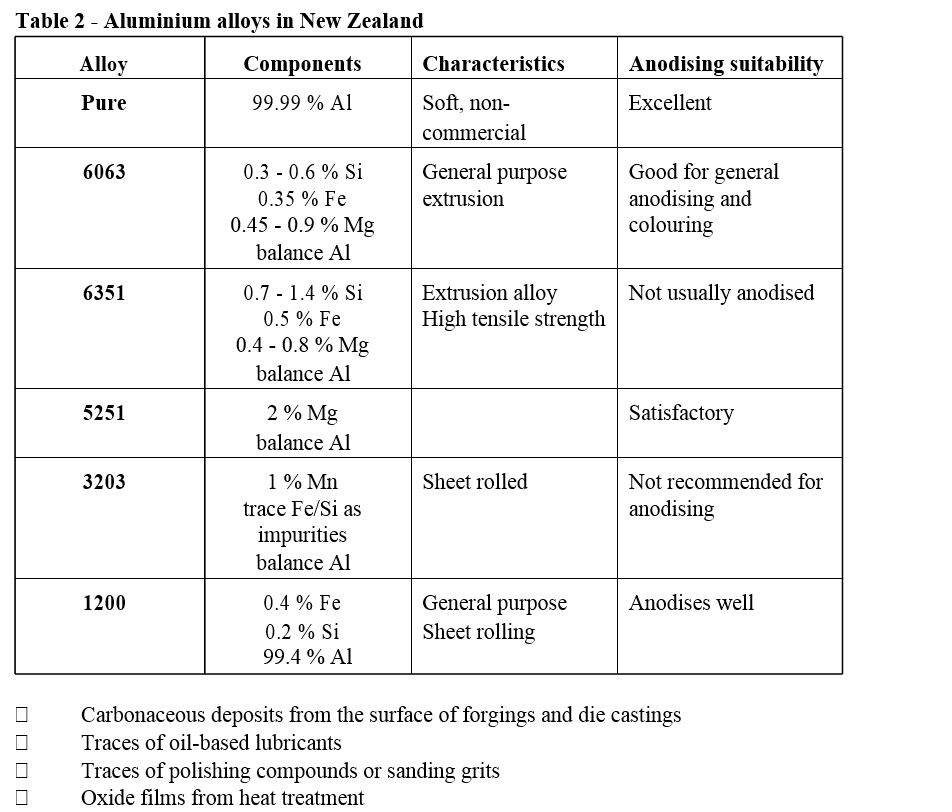

Anode CompositionAluminium AlloysStandards CivilWeb Spreadsheets

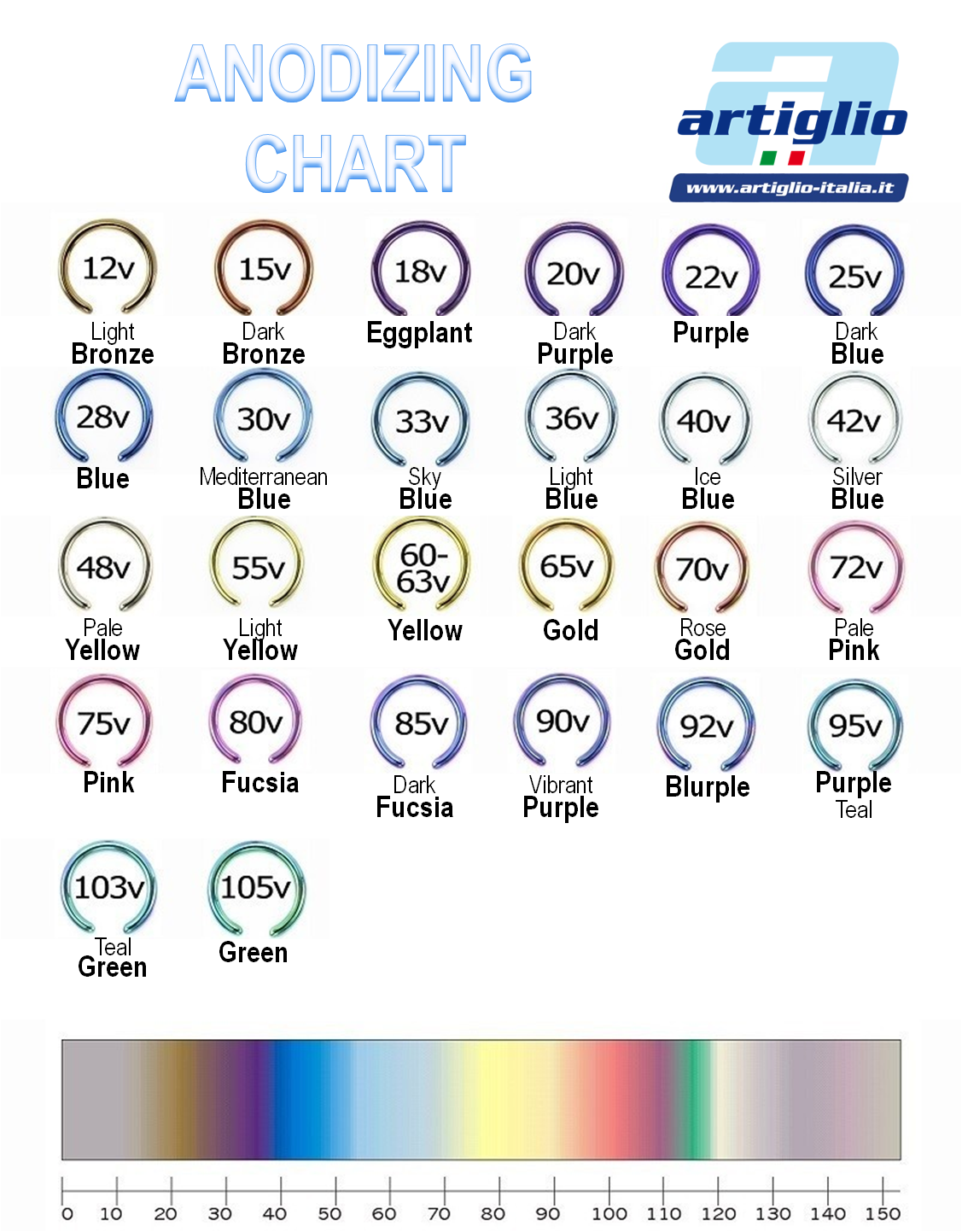

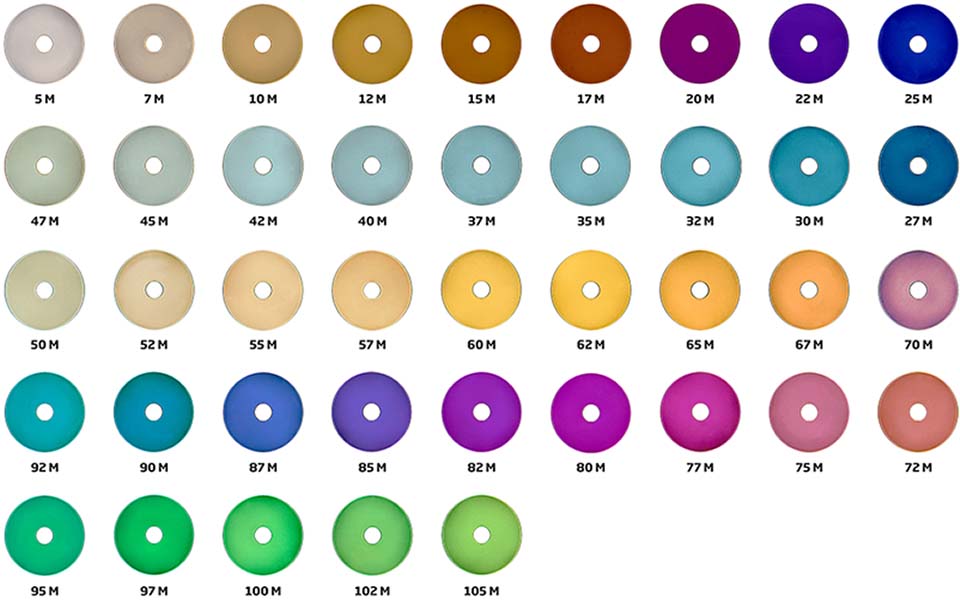

Anodizing Color Chart

Titanium Anodizing Chart — 11 X 17 Poster ubicaciondepersonas.cdmx.gob.mx

Anodizing Color Chart

Titanium Anodizing Voltage Color Chart

When durability matters most, choose highperformance finishes to meet

Anodizing Creates A Thin Layer Of Oxide Ranging From 0.08Um To 80 Um, Depending On The Type Of Anodizing, For A Thicker Anodized Coating Improves Corrosion Resistance And Hardness.

For Type I And Type Ii Anodize, The Rule Of Thumb We Use At Anoplate Is.

How Will Strip And Reanodise Affect The Dimensions?

Up To 5Μm For Chromic Acid Anodising.

Related Post: