Aluminum Tig Welding Settings Chart

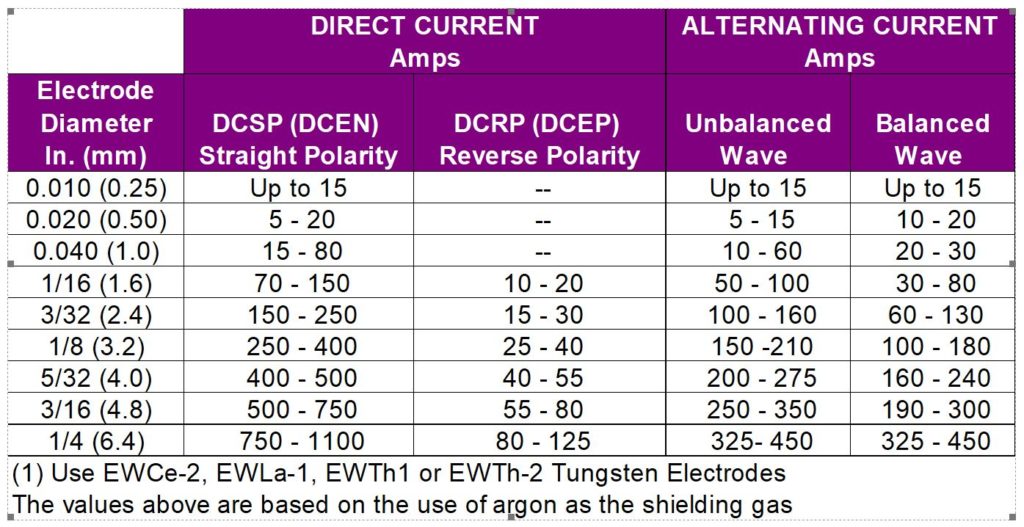

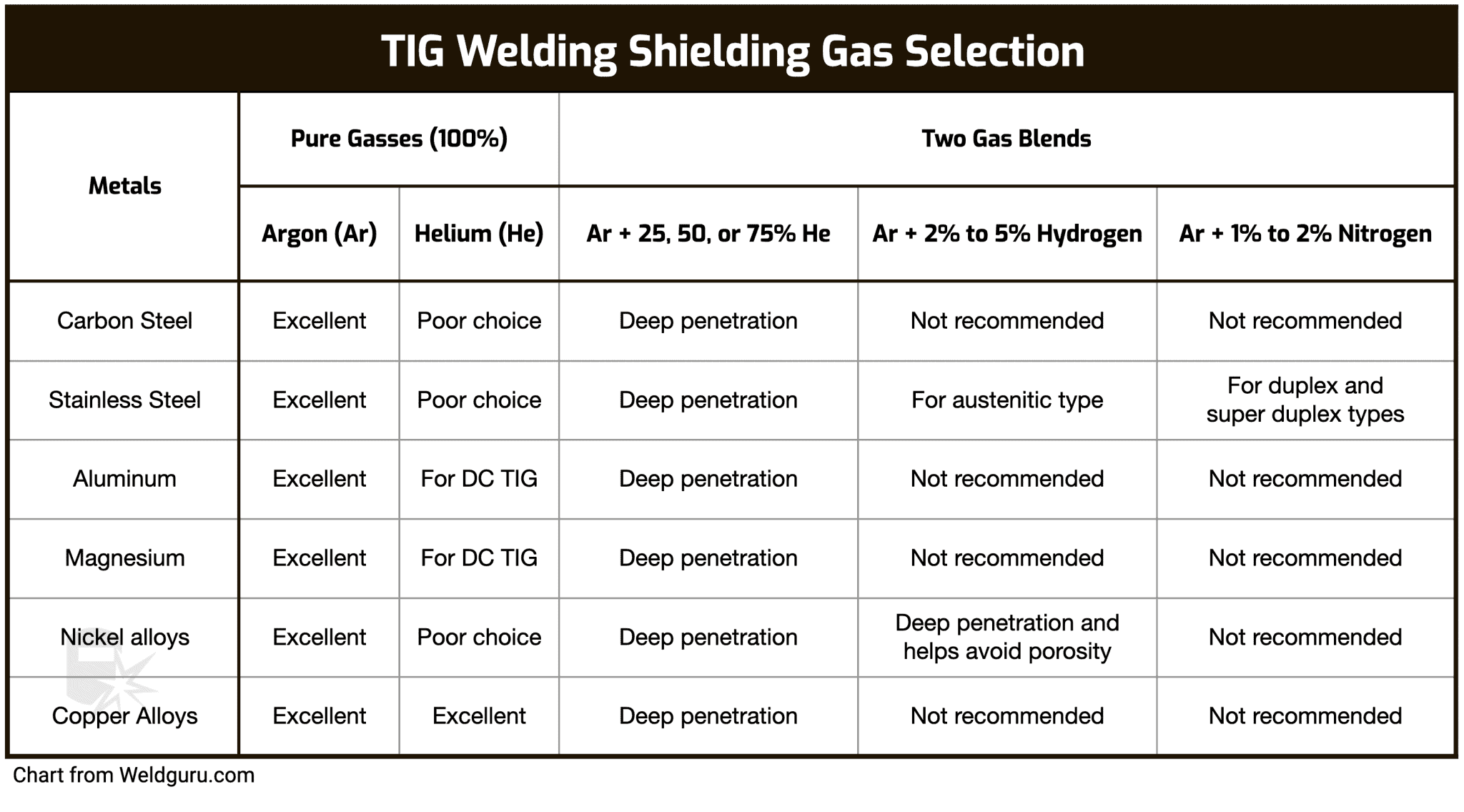

Aluminum Tig Welding Settings Chart - The diagrams below show arc. It is not merely the innovative manufacturing methods and techniques which make the hobart product “best in class”. Web the tig welding parameters for aluminum are set forth in the table below. Gas flow rates for tig welding. With a little practice — and some basic best practices to help beginning welders — you can produce the results you want. Tig (gtaw) welding is one of the cleanest and best ways to weld aluminum. Web in tig aluminum, amperage is controlled with a foot pedal or fingertip control. I recommend getting in the habit of using a degreaser, since even the invisible oil from your hands can cause. Like any other type of welding, it is critical to understand tig welding settings and requirements to create a sustainable and quality weld. Web how to read the chart. There has been a quiet revolution in tig welder design over the last 20 years. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Tig welding aluminum requires that everything be squeaky clean, and this is particularly important with aluminum. It outlines the optimal settings based on material thickness and joint type. Web the. Gas flow rates for tig welding. Filler metal can be either wire or rod and should be compatible with the base alloy. The quality and meticulous attention to detail in every facet of delivering the product into the customer’s hands are also a. View full size chart here. Web tig welding aluminum doesn’t need to be intimidating. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. Web the tig welding parameters for aluminum are set forth in the table below. The issue with tig welding aluminum is that it can be daunting for beginner welders. Choosing the right gas & connecting the gas supply. They can then look up. Many operators, especially those new to aluminum welding, may not. Web setting up the tig welder for aluminum will require you to go through the following steps: Tig welding aluminum requires that everything be squeaky clean, and this is particularly important with aluminum. Filler metal can be either wire or rod and should be compatible with the base alloy. 2t. There has been a quiet revolution in tig welder design over the last 20 years. Filler metal must be dry, free of oxides, grease, or other foreign matter. The type of current used will have a great effect on the penetration pattern as well as the bead configuration. The diagrams below show arc. Very large cup sizes will require more. Choosing the right gas & connecting the gas supply. The diagrams below show arc. It outlines the optimal settings based on material thickness and joint type. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. To use the tig welding chart, the welder must determine the material’s type and thickness. Web in tig aluminum, amperage is controlled with a foot pedal or fingertip control. Quick pointers to refine your skills and results. It is not merely the innovative manufacturing methods and techniques which make the hobart product “best in class”. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each. The diagrams below show arc. Navigate the difficulties unique to aluminum welding. Tig (gtaw) welding is one of the cleanest and best ways to weld aluminum. 2t means you need to retain pressure on the trigger while welding, 4t, which means after you press the trigger the arc will continue on its own until the trigger is pressed again. By. The type of current used will have a great effect on the penetration pattern as well as the bead configuration. View full size chart here. Choosing the right gas & connecting the gas supply. There has been a quiet revolution in tig welder design over the last 20 years. Filler metal must be dry, free of oxides, grease, or other. Choosing the right equipment (right type of tig welder) selecting the right tungsten electrode. 2t means you need to retain pressure on the trigger while welding, 4t, which means after you press the trigger the arc will continue on its own until the trigger is pressed again. I recommend getting in the habit of using a degreaser, since even the. Web the tig welding parameters for aluminum are set forth in the table below. There has been a quiet revolution in tig welder design over the last 20 years. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each application. View full size chart here. Filler metal must be dry, free of oxides, grease, or other foreign matter. It is not merely the innovative manufacturing methods and techniques which make the hobart product “best in class”. Web in tig aluminum, amperage is controlled with a foot pedal or fingertip control. Web a flow of 15 to 25 cfh will cover most applications. Web a look at each type and its uses will help the operator select the best current type for the job. It outlines the optimal settings based on material thickness and joint type. Navigate the difficulties unique to aluminum welding. Web in addition to properly controlling heat, consider these seven tips to optimize results when welding aluminum with gtaw. With a little practice — and some basic best practices to help beginning welders — you can produce the results you want. Gas flow rates for tig welding. However, it is best to set the right maximum amperage to obtain the best results. By following the chart’s recommended settings, welders can achieve optimal weld quality.

Aluminum Tig Welding Settings Chart

Tig Weld Amp Chart

Aluminum Tig Welding Settings Chart

TIG Welding Charts ILMO Products Company

Aluminum Tig Welding Settings Chart

TIG Welding Charts ILMO Products Company

Download Tig Welding Aluminum Amperage Chart Pics All About Welder

Aluminum Tig Welding Settings Chart

Aluminum Tig Welding Settings Chart

Tig Welding Settings Chart

Many Operators, Especially Those New To Aluminum Welding, May Not.

You Can Then Choose Between 2T, 4T Or Spot.

Web To Start, Make Sure Your Selector Switch Is Turned To Ac.

For A 1/1Ch Inch Aluminum, The Amperage Required Is Between 60 To 90 Amps.

Related Post: