Aluminum Anodizing Color Chart

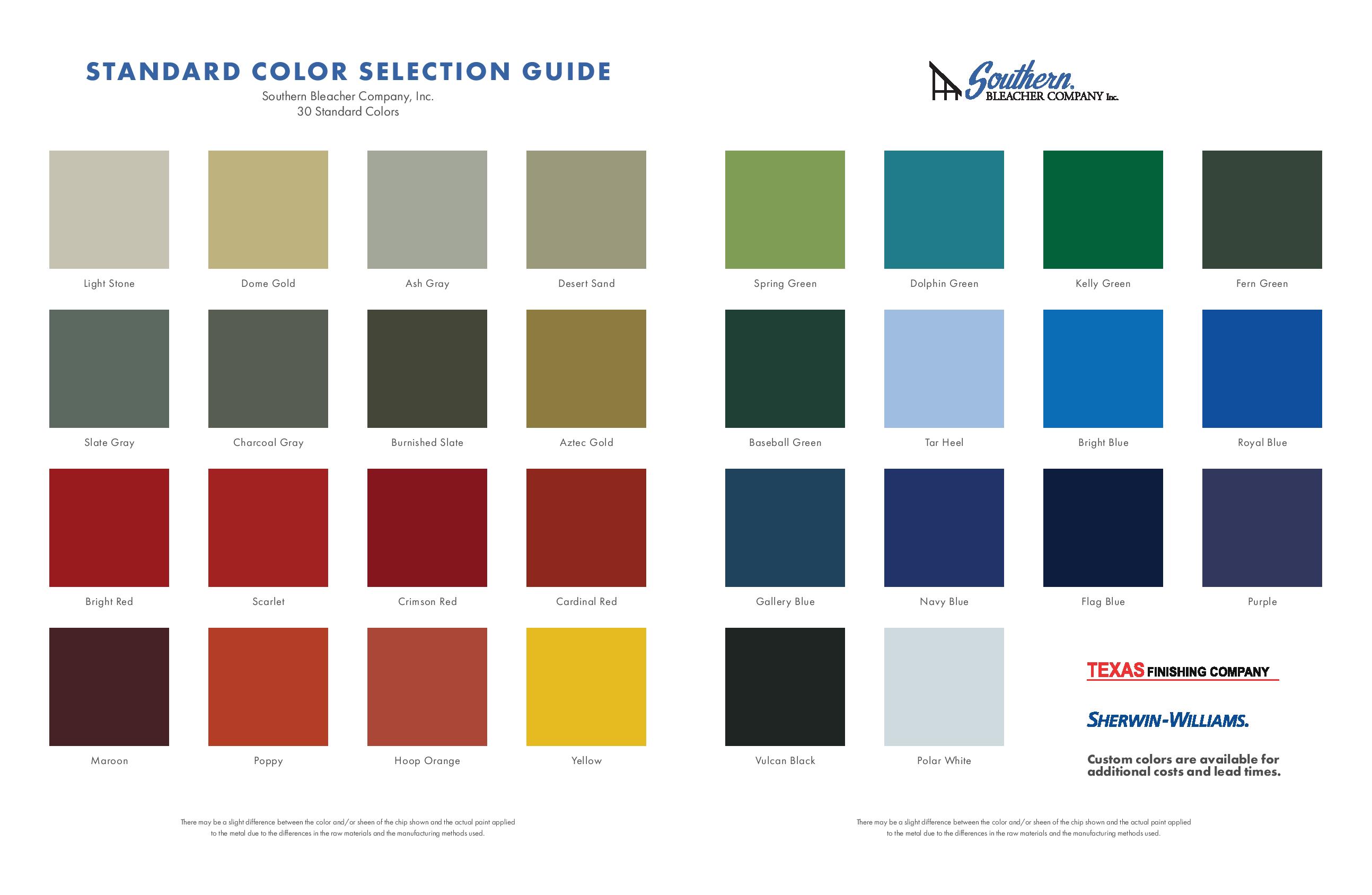

Aluminum Anodizing Color Chart - Web the anodization of colors into metals, including aluminum components, has proven reliable in not just maintaining but improving the overall quality of the materials. Web aac provides members and users with a helpful reference guide including various finishing and testing methods. Web home careers about services gallery type ii anodize type iii hardcoat media blasting masking color chart aluminum color chart testimonials ffl/certifications contact. Custom colors can also be created by using different dyes and processes. Alloy constituents, temper, extruded temperature, grain, rolled temperature, etc. The color obtained in the anodizing process is dependent on many factors such as aluminum alloy, temper, shape, etc., therefore it is not possible to produce an exact color match. Web anodized aluminum colors: Choose an aluminum finish that brings your vision to life. Web linetec offers anodize color cards, with our 7 standards, and individual color samples. These are our standard shades, custom colors available. Kawneer gives you a wide variety of anodized finishes with attractive alternatives. These are our standard shades, custom colors available. The anodized color samples indicate winco’s anodized color range; Web the anodization of colors into metals, including aluminum components, has proven reliable in not just maintaining but improving the overall quality of the materials. Web to choose a color option,. Hard anodization helps in the functional refinement of aluminum alloys and other metals. The principle of the aluminum anodizing process. Let’s get right on it so you can understand how the process works. For example, material from one lot anodized light bronze might produce a color to the light side of a range. Web the anodization of colors into metals,. Pink, blue, black, silver, gold, green, orange, red, and purple. The principle of the aluminum anodizing process. Custom colors can also be created by using different dyes and processes. These slight differences can have a big effect on anodizing color. Web what colors are available for anodized aluminum? Textured face sheets are available in any stock or optional anodized color. Anodizing process forms a layer of oxide on the metal surface, which helps to resist corrosion, scratches, and fading. Let’s get right on it so you can understand how the process works. Web anodized aluminum colors: How do they color anodized aluminum? These colors are permanently applied through the anodization process to improve stability, durability, surface finish, and abrasion resistance. How do they color anodized aluminum? Includes a wide selection of bronze anodizing finishes. How to make ideal and matching anodized color. The color options for anodized aluminum are virtually limitless. Hard anodization helps in the functional refinement of aluminum alloys and other metals. For example, material from one lot anodized light bronze might produce a color to the light side of a range. The resulting hard anodic oxide layer protects aluminum from corrosion. Web the anodization of colors into metals, including aluminum components, has proven reliable in not just maintaining. Eagle mouldings offers a variety of aluminum finishing services and options allowing you to perfectly customize your project. Through an electrochemical process, the natural oxide layer on aluminum is thickened, offering protection from wear and corrosion and enabling the metal to be dyed in a variety of colors. The color options for anodized aluminum are virtually limitless. Textured face sheets. Web aluminum can accept a wide spectrum of anodized colors, including: Through an electrochemical process, the natural oxide layer on aluminum is thickened, offering protection from wear and corrosion and enabling the metal to be dyed in a variety of colors. Web saf anodizing color samples on saf aluminum sheet may be available by customer request to help confirm anodizing. The resulting hard anodic oxide layer protects aluminum from corrosion. Eagle mouldings offers a variety of aluminum finishing services and options allowing you to perfectly customize your project. Web experience the captivating enchantment of lorin anodized aluminum as it unveils a mesmerizing interplay of light, shadows, and breathtaking reflections, effortlessly capturing refined beauty and elevating projects to artistic masterpieces. Type. Alloy constituents, temper, extruded temperature, grain, rolled temperature, etc. Custom colors can also be created by using different dyes and processes. Aluminum finishing services for added protection and performance. Let’s get right on it so you can understand how the process works. Anodized aluminum face sheets, door extrusions and framing are available in the colors shown. Anodization improves the durability, stability, abrasion resistance, and surface polish of these colors by permanently binding them to the metal’s surface and encasing them in a protective oxide layer. They are not intended for color selection. The color options for anodized aluminum are virtually limitless. Web anodized aluminum colors include blue, red, green, black, silver, gold, orange, purple, pink, etc. Choose an aluminum finish that brings your vision to life. From bronze to black, this process is called anodizing, and it’s used to color aluminium without painting or powder coating. Have you ever seen a piece of aluminum coloured by heat? Type ii anodize color chart. Textured face sheets are available in any stock or optional anodized color. Alumet supply provides customers with a wide variety of anodized colors and finishes to create alternative metal looks with options in finish. Kawneer gives you a wide variety of anodized finishes with attractive alternatives. Aluminum finishing services for added protection and performance. These colors are permanently applied through the anodization process to improve stability, durability, surface finish, and abrasion resistance. January 17, 2023 | 12:54 pm. Anodized aluminum is a popular choice for product developers due to its attractive appearance and physically durable finish. Web to choose a color option, you need to look out for the aluminum grade, as every aluminum grade has its color and shades, type of finish, the type of dyes available, layering, and parts of crystalline nature, which affect the reflection of light.

Anodizing Color Choices SAF Southern Aluminum Finishing Co, Inc.

Aluminum Anodizing Colors Chart

Anodized Aluminum Finish Color Chart GSA

anodized aluminum colors chart WhizzBang Blogger Photos

Alumet Anodized Finishes Color Chart by Alice Buchman Creative Design

Anodized Aluminum Colors Chart

anodized aluminum color fade Items EZine Picture Gallery

Aluminum Anodizing Colors Chart

Anodized Aluminum Colors Chart Warehouse of Ideas

anodised aluminium colours

The Color Obtained In The Anodizing Process Is Dependent On Many Factors Such As Aluminum Alloy, Temper, Shape, Etc., Therefore It Is Not Possible To Produce An Exact Color Match.

Web A N O D I Z E D.

Anodizing Process Forms A Layer Of Oxide On The Metal Surface, Which Helps To Resist Corrosion, Scratches, And Fading.

Saf Offers Metal Anodizing That Can Create A Variety Of Looks That Last.

Related Post: