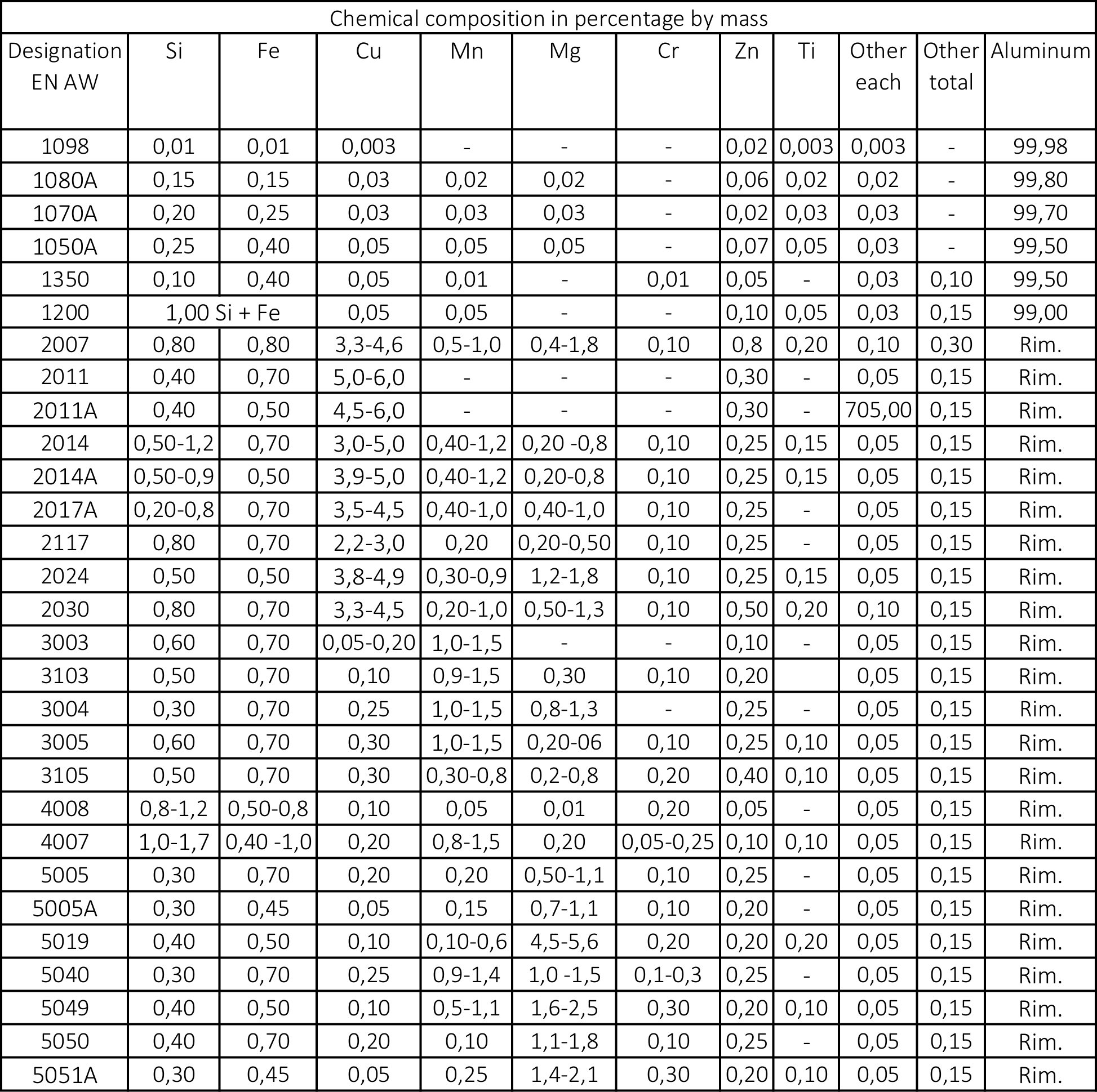

Aluminum Alloys Chart

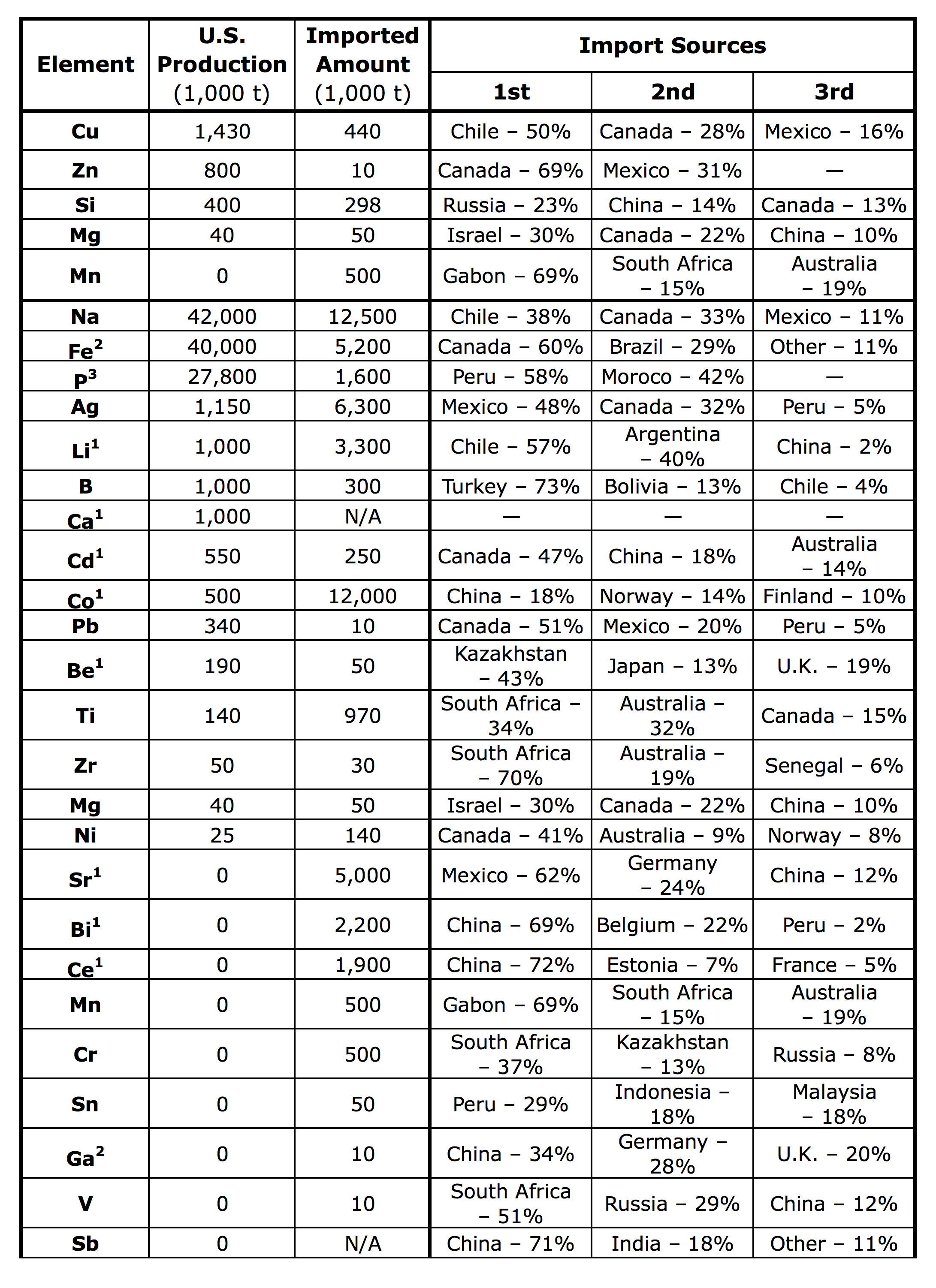

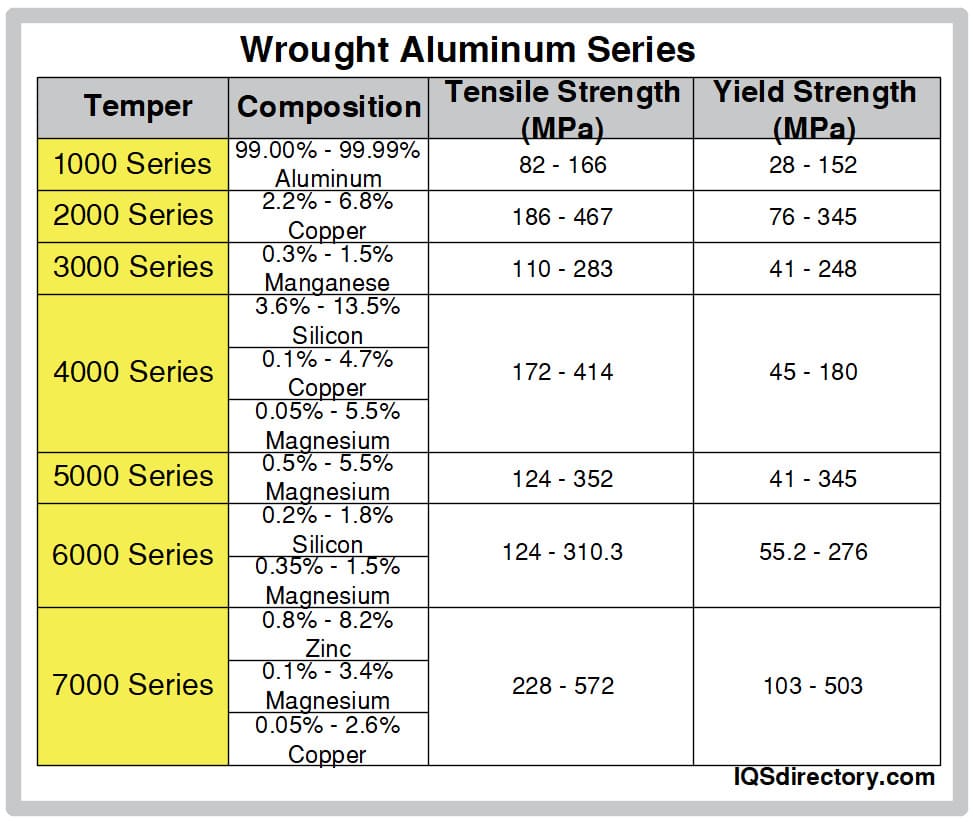

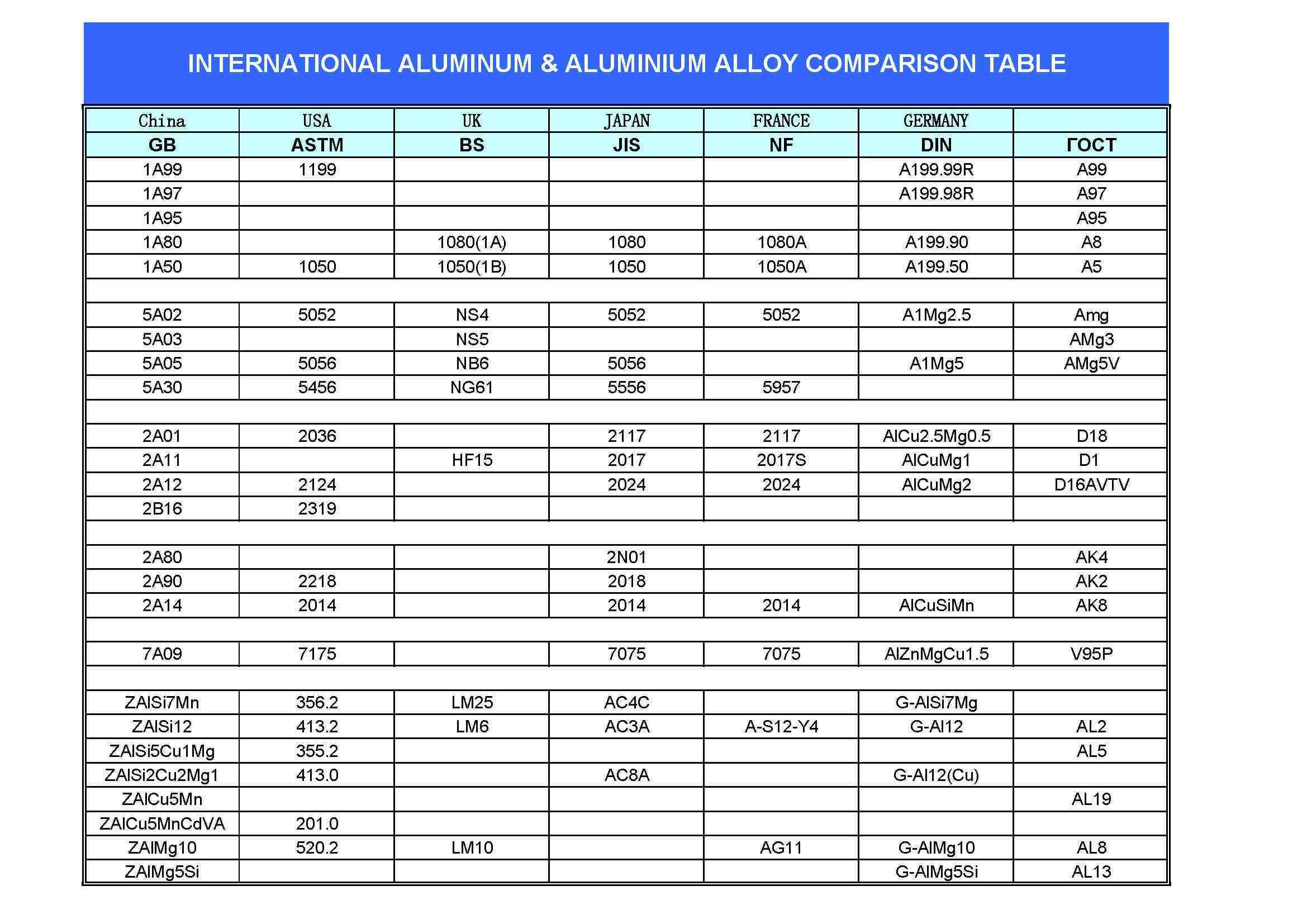

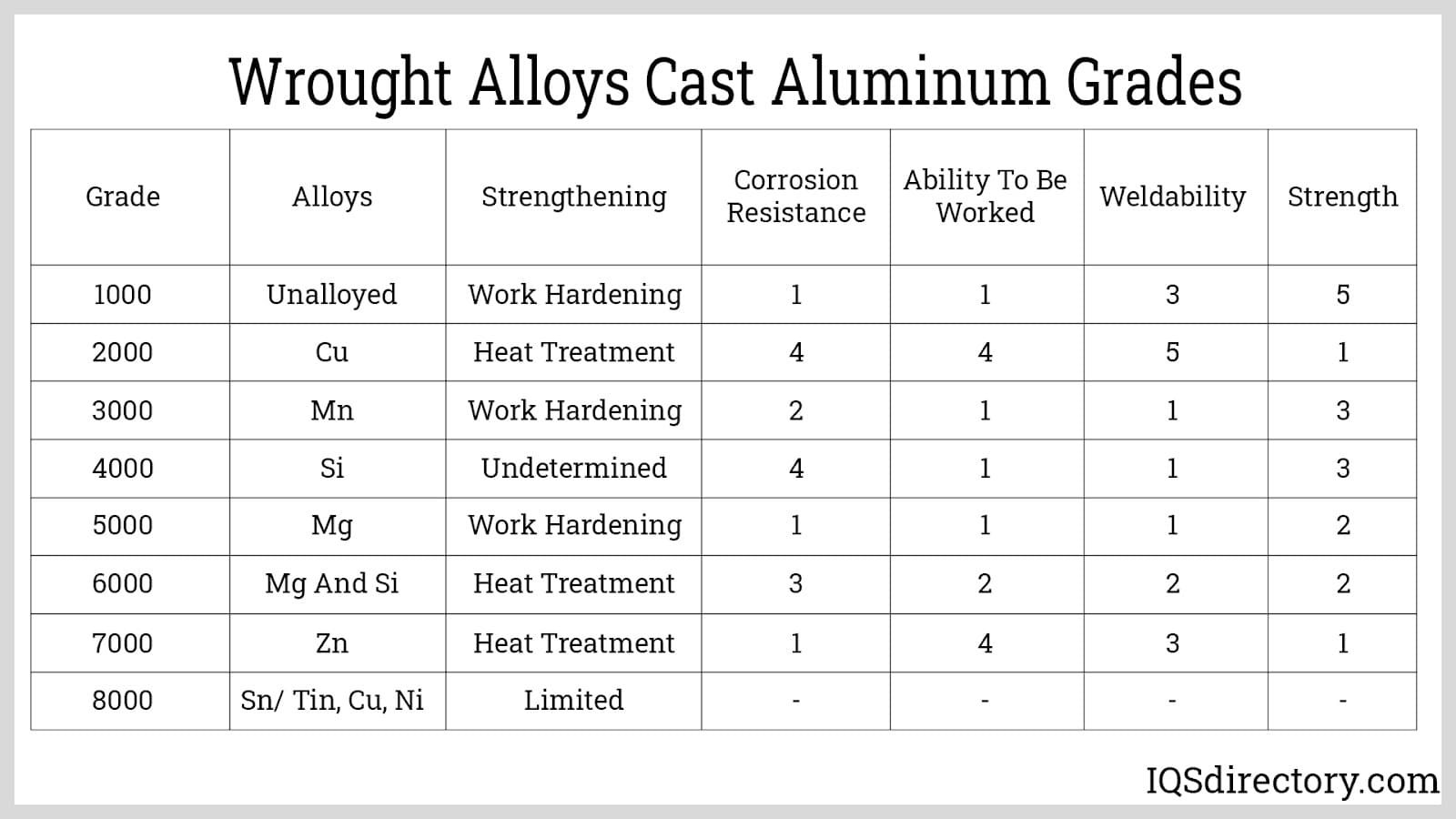

Aluminum Alloys Chart - There are two principal classifications, namely casting alloys and wrought alloys, both of which are. Web list of aluminum alloys. Numerical designations are assigned in accordance with the recommendation—international designation system for wrought aluminum and wrought aluminum alloys, which is printed on pages 28 through 30. These classes have distinct identification numbering systems for differentiation. Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. The aluminum association describes how there are more than 530 registered active compositions of aluminum alloys and that number continues to grow. Web complete property data on aluminium includes density, hardness, shear strength, shear modulus, heat capacity, solidus, liquidus, elongation, poisson's ratio, hardness, fatigue etc. Web wrought aluminum alloys registered with the aluminum association. The various combinations of alloying additions and strengthening mechanisms used for wrought aluminum alloys are shown in table 1. It comes in a range of grades, each tailored for specific uses and scenarios. Let’s take a look at each of them. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. The strength ranges achievable with various classes of wrought and cast alloys are given in tables 2 and 3. There are two principal classifications, namely casting alloys and wrought alloys, both of which are. The chart below shows different. Here are some of the most notable ones: The aluminum association describes how there are more than 530 registered active compositions of aluminum alloys and that number continues to grow. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. Web aluminum is typically alloyed with other elements to produce different strengths. Web grades of aluminum. These classes have distinct identification numbering systems for differentiation. Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; The chart below shows different alloy series and what makes them unique. Web aluminum alloys fall into two main classifications: Here are some of the most notable ones: Here are some of the most notable ones: The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. These classes have distinct identification numbering systems for differentiation. See spelling differences) is an alloy in which aluminium (al) is the predominant metal. Web complete property data on aluminium includes density, hardness, shear strength, shear modulus, heat capacity, solidus,. It comes in a range of grades, each tailored for specific uses and scenarios. Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. The strength ranges achievable with various classes of wrought and cast alloys are given in tables 2 and 3. The aluminum association describes how there are more than 530 registered active compositions of. Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. Web aluminum alloys include the 2xxx, 6xxx, 7xxx, and some of the 8xxx alloys. Here are some of the most notable ones: The various combinations of alloying additions and strengthening mechanisms used for wrought. These classes have distinct identification numbering systems for differentiation. It comes in a range of grades, each tailored for specific uses and scenarios. Web list of aluminum alloys. Web grades of aluminum. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. See spelling differences) is an alloy in which aluminium (al) is the predominant metal. Web wrought aluminum alloys registered with the aluminum association. Here are some of the most notable ones: Web list of aluminum alloys. These classes have distinct identification numbering systems for differentiation. Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. Let’s take a look at each of them. Web aluminum alloys fall into two main classifications: There are two principal classifications, namely casting alloys and wrought alloys, both of which are. The strength ranges achievable with various classes of wrought and cast alloys are given in tables 2 and 3. Web grades of aluminum. Web aluminum alloys fall into two main classifications: Web list of aluminum alloys. Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; Web aluminum alloys include the 2xxx, 6xxx, 7xxx, and some of the 8xxx alloys. It comes in a range of grades, each tailored for specific uses and scenarios. Web aluminum is typically alloyed with other elements to produce different strengths. Web complete property data on aluminium includes density, hardness, shear strength, shear modulus, heat capacity, solidus, liquidus, elongation, poisson's ratio, hardness, fatigue etc. See spelling differences) is an alloy in which aluminium (al) is the predominant metal. The aluminum association describes how there are more than 530 registered active compositions of aluminum alloys and that number continues to grow. These classes have distinct identification numbering systems for differentiation. Web aluminum alloys fall into two main classifications: Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. That’s a lot of aluminum alloys! Web wrought aluminum alloys registered with the aluminum association. Here are some of the most notable ones: Wrought aluminum possesses remarkable mechanical strength and it can take on various shapes. They’re also available in various formats including sheet, plate, tube, and bar. There are two principal classifications, namely casting alloys and wrought alloys, both of which are.Comparison Table of Cast Aluminum Alloy Grades Metals Industrial

Aluminum Alloys Chart Properties

ARTICLE The Importance of Aluminum Alloying Elements and Their Sources

Aluminum Filler Alloy Selection Chart PDF Welding Construction

The Element Aluminum

Types of Aluminum Types, Uses, Features and Benefits

Aluminium Grade Comparison PDF Industries Building, 41 OFF

What Is It? How Is it Made? Advantages (2022)

Aluminum and his alloys Custom Online Laser Cutting

Which Aluminum Alloy Bends Best? Clinton Aluminum

The Strength Ranges Achievable With Various Classes Of Wrought And Cast Alloys Are Given In Tables 2 And 3.

The Chart Below Shows Different Alloy Series And What Makes Them Unique.

Numerical Designations Are Assigned In Accordance With The Recommendation—International Designation System For Wrought Aluminum And Wrought Aluminum Alloys, Which Is Printed On Pages 28 Through 30.

Web List Of Aluminum Alloys.

Related Post: