A2 Heat Treat Chart

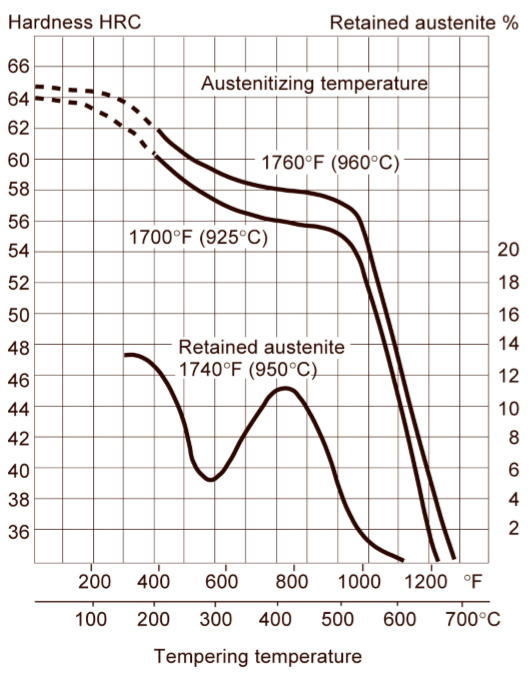

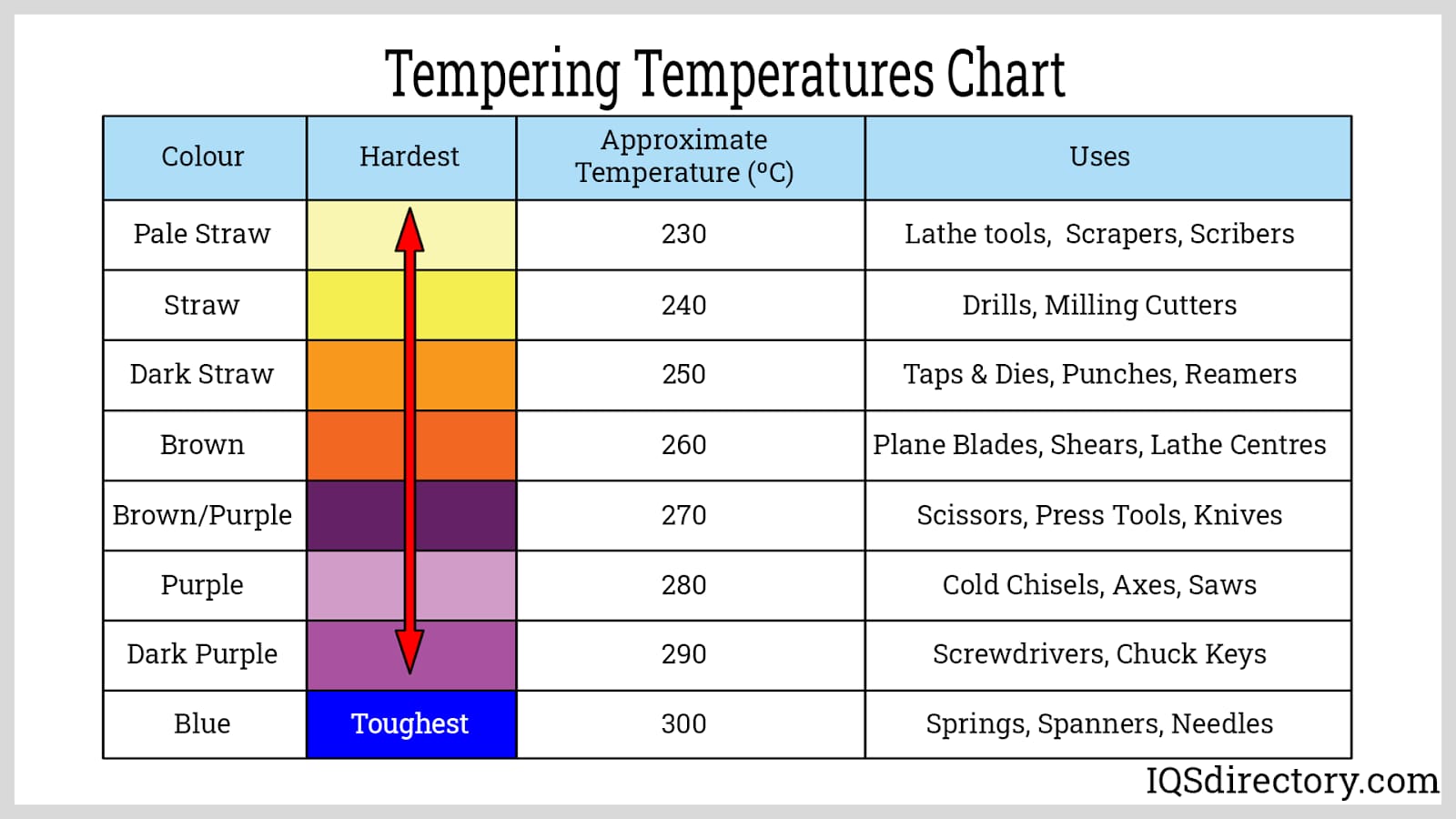

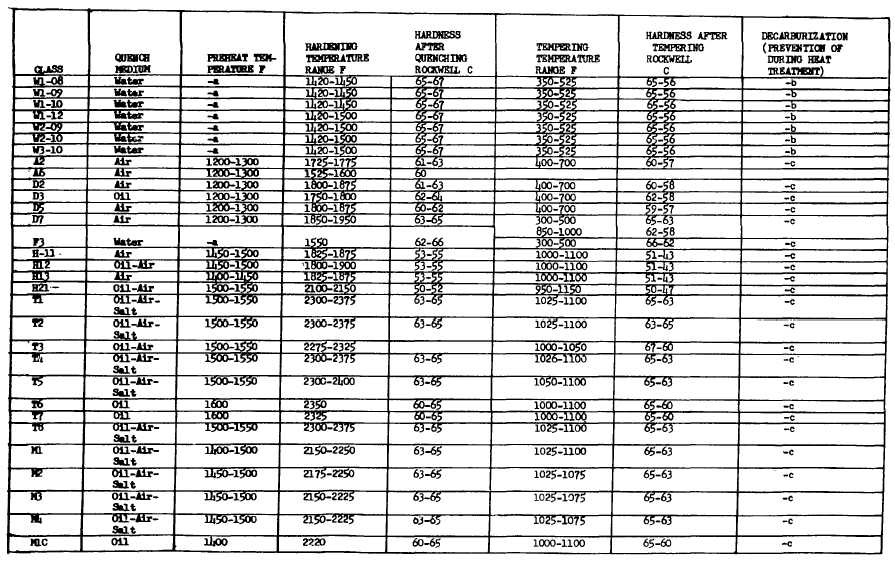

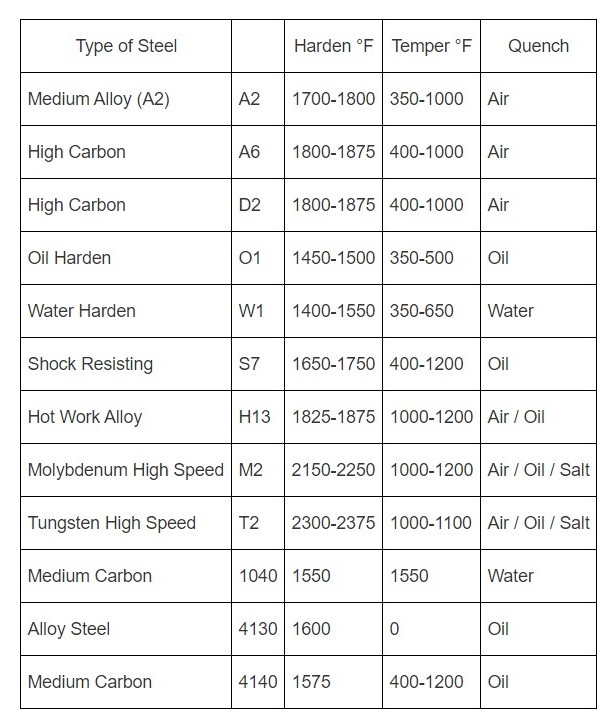

A2 Heat Treat Chart - Use high side of hardening range for thicker sections. Web this widely used tool steel has low distortion in heat treatment, good machinability, good toughness for severe service, high abrasion resistance, and deep hardening properties. Web d2 tool steel properties combine minimal distortion in heat treatment, high toughness and wear resistance at the expense of grindability and machinability compared to other. 2 should be heated thoroughly to 1550°f in an atmosphere controlled furnace. Read about the variables that can affect dimensional change and refer to heat treating steel charts. Web recommended heat treatments for specific tool steels are described thoroughly in the individual data sheets. Web on the initial heat treat cycle i always let the tool rise in temperature slowly to prevent introducing large temperature gradients within the part that can then lead to. Web a2 is noted for its good toughness and excellent dimensional stability in heat treatment. Heat at a rate not exceeding 400°f per hour (222°c per hour) to. The chart below describes various types of tool steels, their composition and appropriate heat treating applications. Hold 2 hours, furnace cool at 25°f per/hr to 1100°f,. Learn about the chemical composition, physical properties, mechanical properties and heat treating of a2 tool steel. Web begin the heat treatment journey by ensuring your a2 steel is clean and free from contaminants. Web a2 tool steels are heat treated at temperatures ranging from 177°c (350°f) for rockwell c 62. Web this widely used tool steel has low distortion in heat treatment, good machinability, good toughness for severe service, high abrasion resistance, and deep hardening properties. Web figure 1 temperature chart indicating conversion of centigrade to fahrenheit or vice versa, color temperature scale for hardening temperature range, and tempering temperature. The chart below describes various types of tool steels, their. Web a2 is noted for its good toughness and excellent dimensional stability in heat treatment. Heat at a rate not exceeding 400°f per hour (222°c per hour) to. Web begin the heat treatment journey by ensuring your a2 steel is clean and free from contaminants. Web figure 1 temperature chart indicating conversion of centigrade to fahrenheit or vice versa, color. It has wear resistance intermediate between the oil hardening. Web this widely used tool steel has low distortion in heat treatment, good machinability, good toughness for severe service, high abrasion resistance, and deep hardening properties. Web figure 1 temperature chart indicating conversion of centigrade to fahrenheit or vice versa, color temperature scale for hardening temperature range, and tempering temperature. Read. Learn about the chemical composition, physical properties, mechanical properties and heat treating of a2 tool steel. 2 should be heated thoroughly to 1550°f in an atmosphere controlled furnace. Hold 2 hours, furnace cool at 25°f per/hr to 1100°f,. Web relieving heat treatment is always recommended. Use high side of hardening range for thicker sections. A2 is intermediate in wear. Heat at a rate not exceeding 400°f per hour (222°c per hour) to. Read about the variables that can affect dimensional change and refer to heat treating steel charts. Web recommended heat treatments for specific tool steels are described thoroughly in the individual data sheets. Find the hardness, tensile strength and elongati… Learn about the chemical composition, physical properties, mechanical properties and heat treating of a2 tool steel. Web steel part size change can occur during heat treating. Web recommended heat treatments for specific tool steels are described thoroughly in the individual data sheets. Web the heat treating process alters the alloy distribution and transforms the soft matrix into a hard matrix. Web this widely used tool steel has low distortion in heat treatment, good machinability, good toughness for severe service, high abrasion resistance, and deep hardening properties. Use high side of hardening range for thicker sections. Web d2 tool steel properties combine minimal distortion in heat treatment, high toughness and wear resistance at the expense of grindability and machinability compared to. Read about the variables that can affect dimensional change and refer to heat treating steel charts. These characteristics make it a versatile tool steel that combines good performance and. Web steel part size change can occur during heat treating. Web relieving heat treatment is always recommended. Web on the initial heat treat cycle i always let the tool rise in. 2 should be heated thoroughly to 1550°f in an atmosphere controlled furnace. Web a2 tool steels are heat treated at temperatures ranging from 177°c (350°f) for rockwell c 62 to 538°c (1000°f) for rockwell c 56 and then tempered. Web relieving heat treatment is always recommended. Learn about the chemical composition, physical properties, mechanical properties and heat treating of a2. Learn about the chemical composition, physical properties, mechanical properties and heat treating of a2 tool steel. The chart below describes various types of tool steels, their composition and appropriate heat treating applications. Web a2 is noted for its good toughness and excellent dimensional stability in heat treatment. Web figure 1 temperature chart indicating conversion of centigrade to fahrenheit or vice versa, color temperature scale for hardening temperature range, and tempering temperature. Web on the initial heat treat cycle i always let the tool rise in temperature slowly to prevent introducing large temperature gradients within the part that can then lead to. A2 is intermediate in wear. Heat at a rate not exceeding 400°f per hour (222°c per hour) to. Proper preparation sets the stage for a successful heat treatment. Read about the variables that can affect dimensional change and refer to heat treating steel charts. 2 should be heated thoroughly to 1550°f in an atmosphere controlled furnace. Web a2 tool steels are heat treated at temperatures ranging from 177°c (350°f) for rockwell c 62 to 538°c (1000°f) for rockwell c 56 and then tempered. Web relieving heat treatment is always recommended. These characteristics make it a versatile tool steel that combines good performance and. Web recommended heat treatments for specific tool steels are described thoroughly in the individual data sheets. Hold 2 hours, furnace cool at 25°f per/hr to 1100°f,. Use high side of hardening range for thicker sections.

A2 Heat Treat Chart

1.2363 Tool Steel AISI A2 Tool Steel Specification and Information

Heat Treating Function, Types, Applications, and Benefits

A2 Tool Steel Heat Treat Chart chartdevelopment

A2 Heat Treat Chart

Tool Steel Potential Dependent Upon Heat Treating Heat Treat Today

Heat Treating D2

A2 Tool Steel Heat Treat Chart chartdevelopment

TemperatureGuidetoHeatTreatingSteel Metal working, Blacksmithing

A2 Tool Steel Heat Treat Chart chartdevelopment

Web Steel Part Size Change Can Occur During Heat Treating.

Web This Widely Used Tool Steel Has Low Distortion In Heat Treatment, Good Machinability, Good Toughness For Severe Service, High Abrasion Resistance, And Deep Hardening Properties.

It Has Wear Resistance Intermediate Between The Oil Hardening.

Web D2 Tool Steel Properties Combine Minimal Distortion In Heat Treatment, High Toughness And Wear Resistance At The Expense Of Grindability And Machinability Compared To Other.

Related Post: