309 Welding Rod Amperage Chart

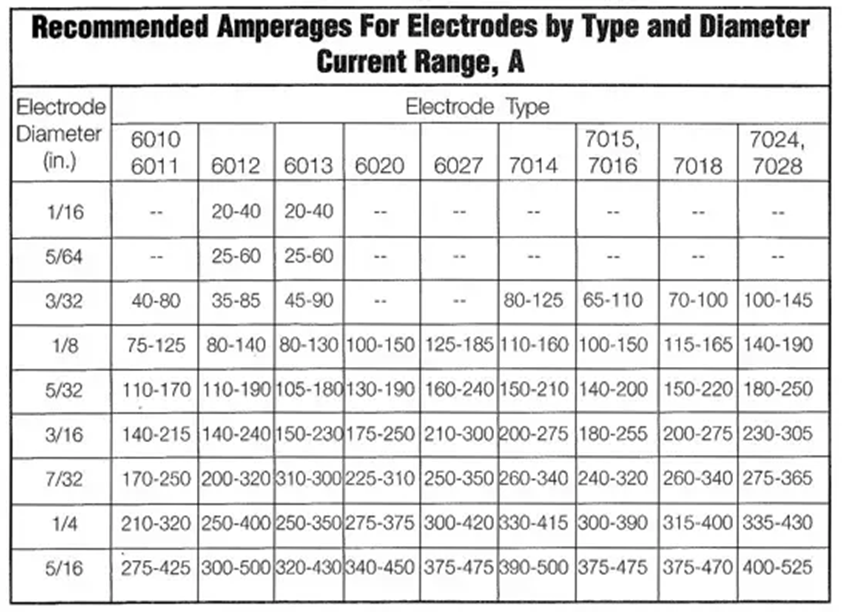

309 Welding Rod Amperage Chart - The 309lsi grade of wire has a low carbon content and a higher silicon content, hence the lsi in the. 6013 welding rod amperage chart. Web in most cases when welding dissimilar metals or, more specifically, carbon to ss, we recommend you use a 309 filler metal because of its higher ferrite content. Web stick welding rod size, amperage & metal thickness chart: No data is to be construed as a recommendation for any welding condition or technique not controlled by hobart brothers company. Other tests and procedures may produce different results. Hobart brothers company 101 trade square east troy, oh 45373 ph: Welding positions 5/32 in (4.0 mm) and smaller diameter all except, 3/16 in (4.8 mm) diameter flat and horizontal only vertical down. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Additionally, we made the most complete stick welding rod chart pdf on the internet with over 220 electrodes. Flux composition & current chart; Arc length = short arc, flat use 15°angle from 90°, vertical up & overhead use weaving techniques withinpuddle. Procedures may vary with change in position, base metals, filler metals, equipment and other changes. All, welding positions except vertical down (stainless) Web what material are you welding? 6013 welding rod amperage chart. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Welding positions 5/32 in (4.0 mm) and smaller diameter all except, 3/16 in (4.8 mm) diameter flat and horizontal only vertical down. You might also find our welding calculators useful. No data is. The 309lsi grade of wire has a low carbon content and a higher silicon content, hence the lsi in the. Direct current electrode positive (dcep) or ac. Browse suggested weld parameter settings for stick welding. Arc length = short arc, flat use 15°angle from 90°, vertical up & overhead use weaving techniques withinpuddle. Flux composition & current chart; Flux composition & current chart; Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Other tests and procedures may produce different results. You will also get the required polarity, position, and other related information. Once you determine these three main variables, you can set your welding machine. You will also get the required polarity, position, and other related information. Web what material are you welding? Web e308l stainless steel welding rod chart; This higher ferrite content can minimize weld dilution and prevent weld cracking. All, welding positions except vertical down (stainless) 6013 welding rod amperage chart. This higher ferrite content can minimize weld dilution and prevent weld cracking. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Arc length = short arc, flat use 15°angle. Once you determine these three main variables, you can set your welding machine and start. Welding positions 5/32 in (4.0 mm) and smaller diameter all except, 3/16 in (4.8 mm) diameter flat and horizontal only vertical down. Flux composition & current chart; This higher ferrite content can minimize weld dilution and prevent weld cracking. Once you’ve chosen your welding rod. Web in most cases when welding dissimilar metals or, more specifically, carbon to ss, we recommend you use a 309 filler metal because of its higher ferrite content. 7014 welding rod amperage chart. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. This higher ferrite content can. You will also get the required polarity, position, and other related information. You might also find our welding calculators useful. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. The welding parameter range given in the below table will provide the necessary welding. All, welding positions except. The calculator below pinpoints exactly which electrode you need for the metal you are welding. Arc length = short arc, flat use 15°angle from 90°, vertical up & overhead use weaving techniques withinpuddle. Web in most cases when welding dissimilar metals or, more specifically, carbon to ss, we recommend you use a 309 filler metal because of its higher ferrite. The welding parameter range given in the below table will provide the necessary welding. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Direct current electrode positive (dcep) or ac. Once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. 6013 welding rod amperage chart. This higher ferrite content can minimize weld dilution and prevent weld cracking. No data is to be construed as a recommendation for any welding condition or technique not controlled by hobart brothers company. You might also find our welding calculators useful. The 309lsi grade of wire has a low carbon content and a higher silicon content, hence the lsi in the. All, welding positions except vertical down (stainless) Flux composition & current chart; Hobart brothers company 101 trade square east troy, oh 45373 ph: Procedures may vary with change in position, base metals, filler metals, equipment and other changes. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low. 7014 welding rod amperage chart. Once you determine these three main variables, you can set your welding machine and start.

309 Welding Rod Overview » Weld Faqs

Welding Rod Amperage Chart Pdf

Welding Rod Amp Chart

Pin by Bill Poole on Metal fabrication Welding and fabrication

Welders Discount Warehouse, , STAINLESS STEEL 309 MIG WIRE

Welding Rod Amp Chart

Tig Welding Amperage Chart

309 Welding Rod Amperage Chart

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

Welding Rods By Flux Composition, Welding Position, Compatible Currents & Penetration Level;

Browse Suggested Weld Parameter Settings For Stick Welding.

Arc Length = Short Arc, Flat Use 15°Angle From 90°, Vertical Up & Overhead Use Weaving Techniques Withinpuddle.

Other Tests And Procedures May Produce Different Results.

Related Post: