174 Heat Treat Chart

174 Heat Treat Chart - A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. The present research focuses on the optimized heat treatment of. Material performance and composition is impacted by certain factors. Its mechanical properties can be optimized with heat treatment where very. Markforged represent typical tested values values, while mim h900 and wrought h900. It can be further hardened to various strength levels by a. Web astm a564 h900 heat treated. Its density ranges from 7,800 to. I had a part heated to 1900 for an hour then cooled, i. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. Web heat treatment designation processing condition a** heated at 1900°f + 25°f for 1/2 hour, air (solution treated) cooled or oil quenched. The present research focuses on the optimized heat treatment of. Markforged represent typical tested values values, while mim h900 and wrought h900. Web s17400 alloy requires a simple heat treatment; I had a part heated to 1900 for an hour then cooled, i. Web s17400 alloy requires a simple heat treatment; Markforged represent typical tested values values, while mim h900 and wrought h900. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. It can be further hardened to various strength levels by a. Markforged represent typical tested values, while mim h900 and wrought h900. Web s17400 alloy requires a simple heat. Markforged represent typical tested values values, while mim h900 and wrought h900. Web astm a564 h900 heat treated. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. I had a part heated to 1900 for an hour then cooled, i. Its density ranges from 7,800 to. Ultimate tensile strength (mpa) 650. I had a part heated to 1900 for an hour then cooled, i. Its mechanical properties can be optimized with heat treatment where very. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. Markforged represent typical tested values values, while mim h900 and wrought h900. Markforged represent typical tested values values, while mim h900 and wrought h900. Web astm a564 h900 heat treated. Markforged represent typical tested values, while mim h900 and wrought h900. Its mechanical properties can be optimized with heat treatment where very. Web s17400 alloy requires a simple heat treatment; Ultimate tensile strength (mpa) 650. Its mechanical properties can be optimized with heat treatment where very. Markforged represent typical tested values, while mim h900 and wrought h900. Web heat treatment designation processing condition a** heated at 1900°f + 25°f for 1/2 hour, air (solution treated) cooled or oil quenched to below 90°f. It can be further hardened to various strength. Markforged represent typical tested values, while mim h900 and wrought h900. Markforged represent typical tested values values, while mim h900 and wrought h900. Web s17400 alloy requires a simple heat treatment; A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. Its mechanical properties can be optimized with heat treatment where. Material performance and composition is impacted by certain factors. Its density ranges from 7,800 to. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. Markforged represent typical tested values, while mim h900 and wrought h900. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f. It can be further hardened to various strength levels by a. Web s17400 alloy requires a simple heat treatment; A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. I had a part heated to 1900 for an hour then cooled, i. Ultimate tensile strength (mpa) 650. Its mechanical properties can be optimized with heat treatment where very. It can be further hardened to various strength levels by a. Markforged represent typical tested values, while mim h900 and wrought h900. Web s17400 alloy requires a simple heat treatment; I had a part heated to 1900 for an hour then cooled, i. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. Its density ranges from 7,800 to. A one step process conducted at a temperature in the range 900°f (482°c) to 1150°f (621°c) depending on the. Material performance and composition is impacted by certain factors. Web heat treatment designation processing condition a** heated at 1900°f + 25°f for 1/2 hour, air (solution treated) cooled or oil quenched to below 90°f. Web astm a564 h900 heat treated. The present research focuses on the optimized heat treatment of.

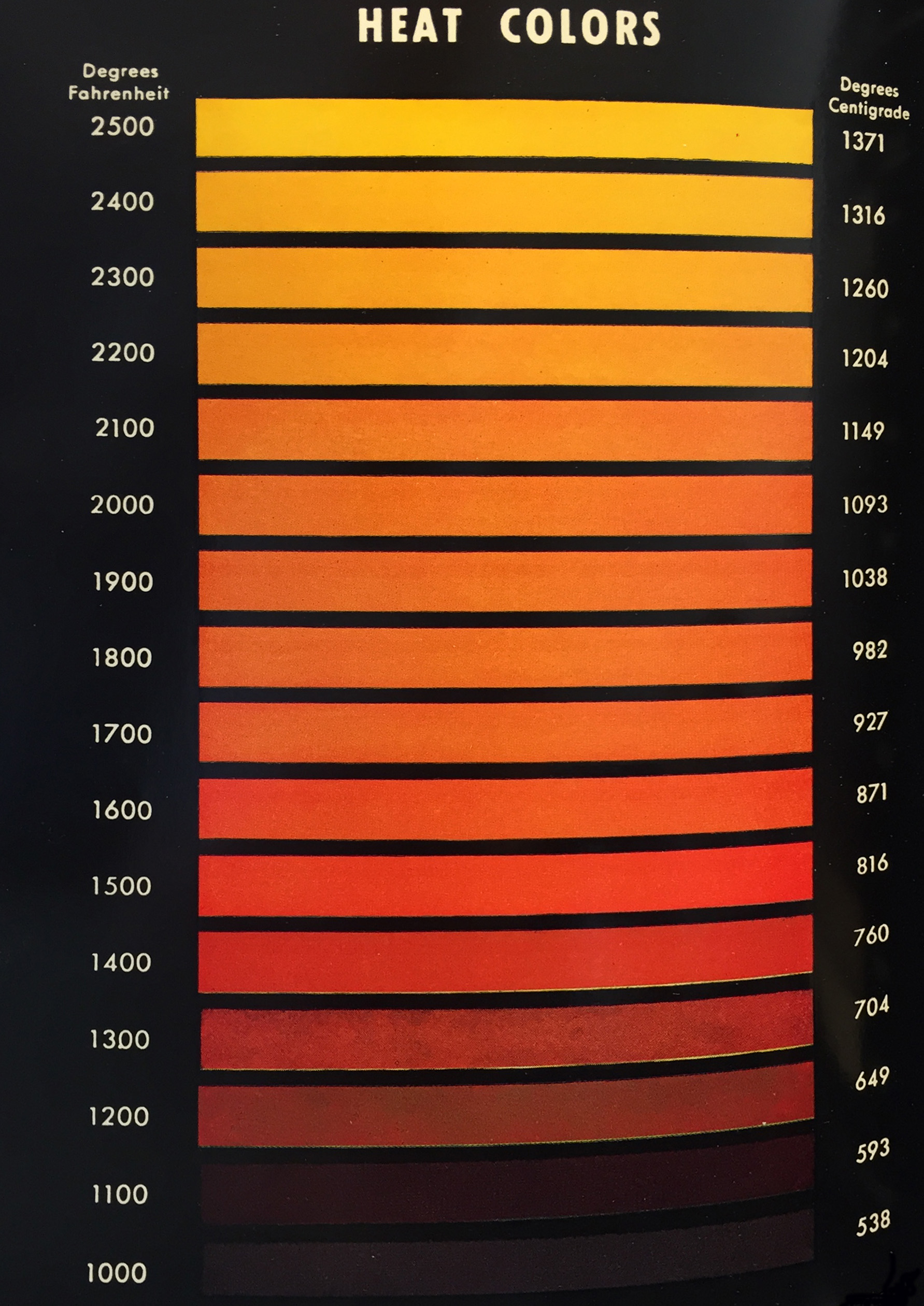

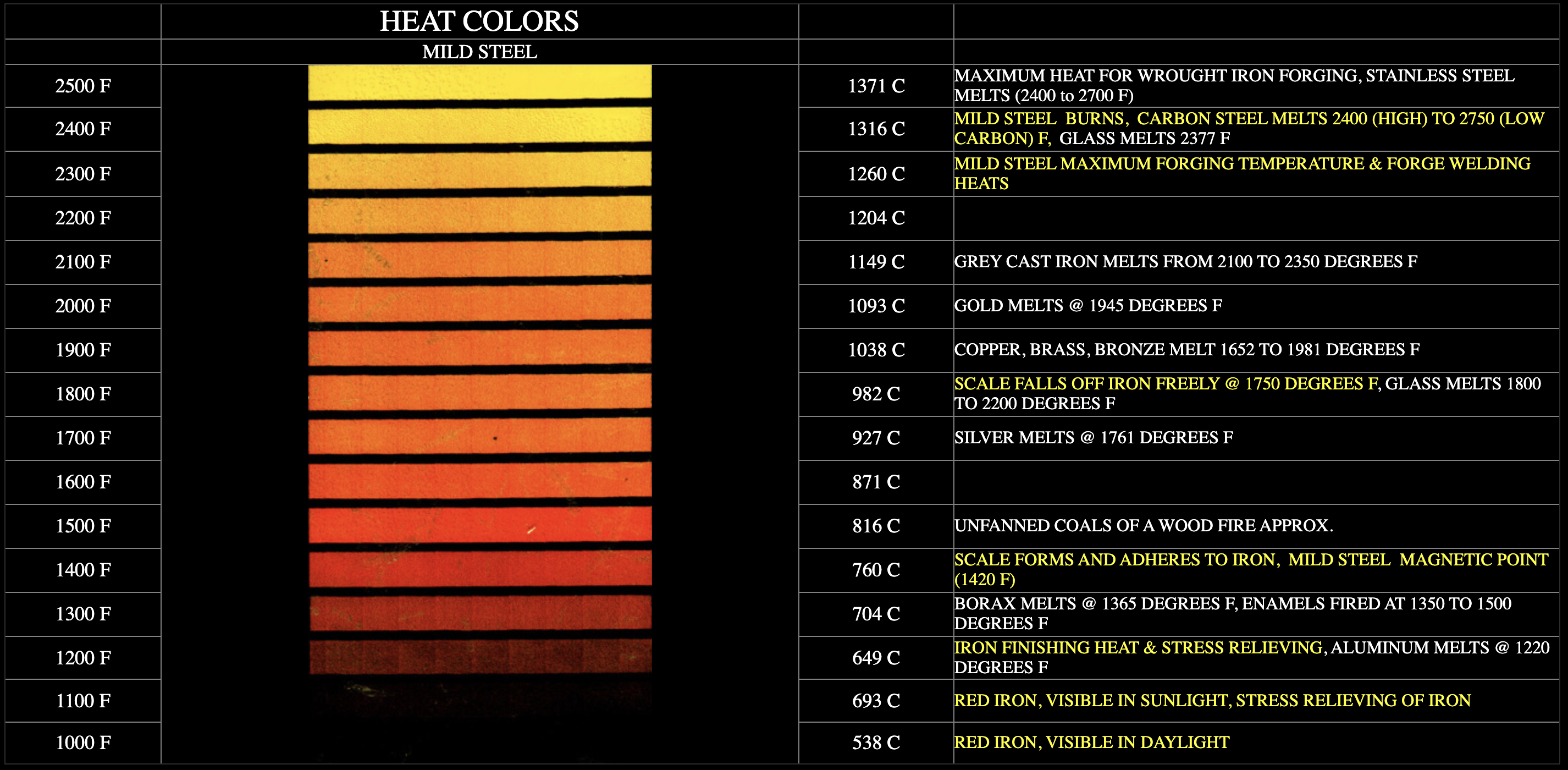

Heat Treat Colors Of Steel Chart Precision Machined Products Association

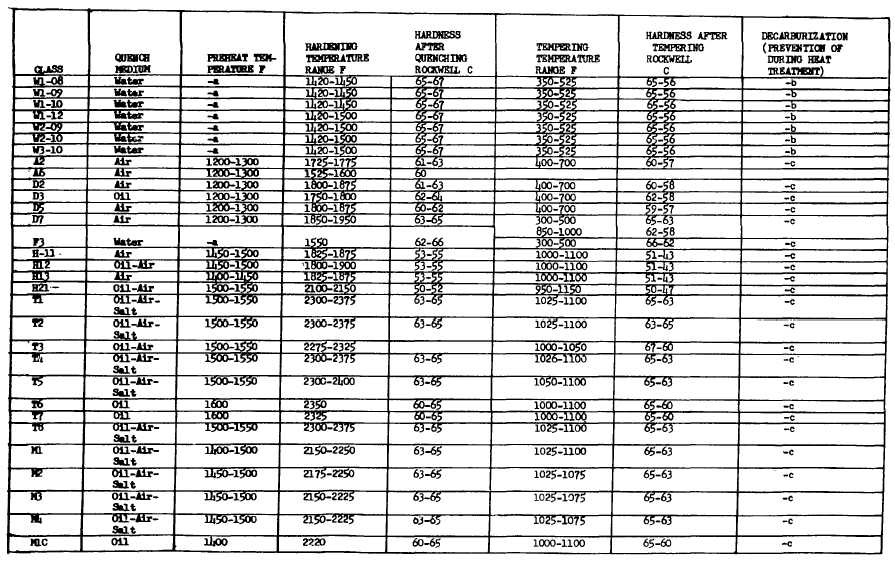

TemperatureGuidetoHeatTreatingSteel Metal working, Blacksmithing

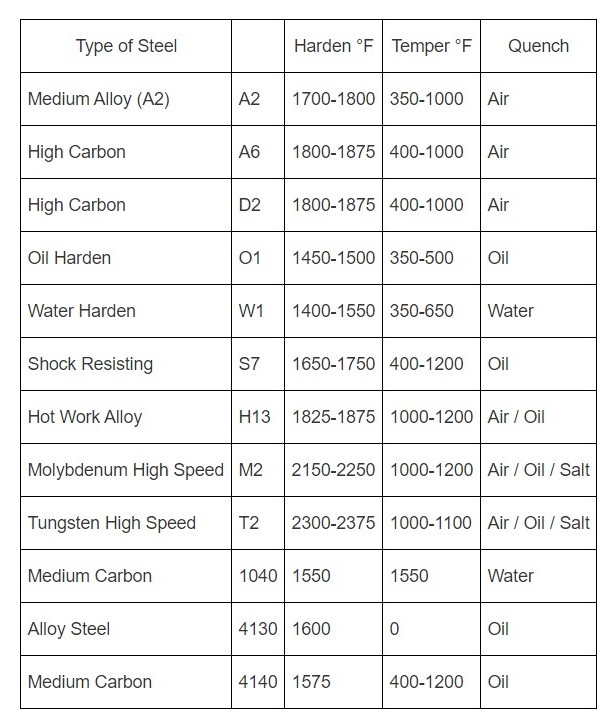

Heat Treat Chart For Steel

Heat Treat Hardness Chart

A2 Heat Treat Chart

Steel Heat Treat Temperature Color Chart

A2 Tool Steel Heat Treat Chart chartdevelopment

174 PH Data Bulletin Stainless Steel Heat Treating

The chart of heattreated colors for steel according to the temperature

Heat Treat Color Chart

Web S17400 Alloy Requires A Simple Heat Treatment;

Ultimate Tensile Strength (Mpa) 650.

Markforged Represent Typical Tested Values Values, While Mim H900 And Wrought H900.

Related Post: