3D Printable Rocket

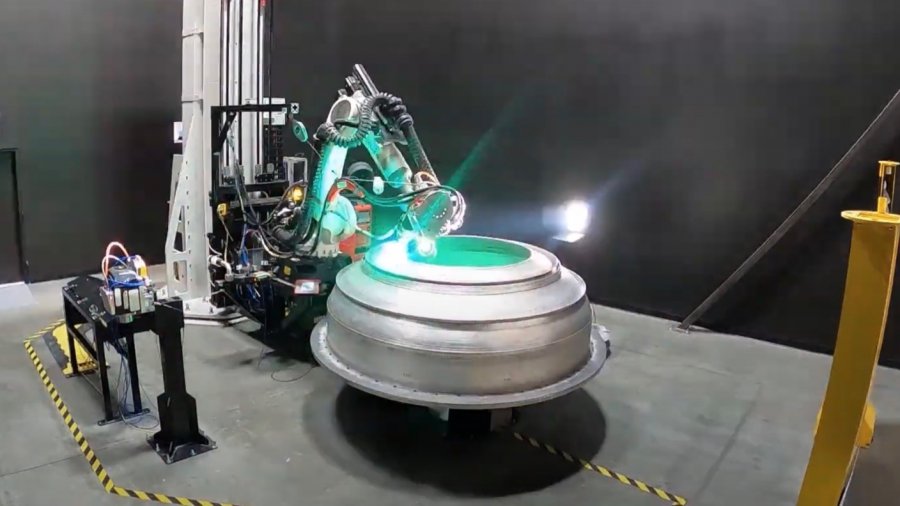

3D Printable Rocket - Web 3d printed ps4 engine the engine uses a bipropellant combination of nitrogen tetroxide as the oxidizer and mono methyl hydrazine as fuel. Next, glue the engine to the top of the flames. Web 3d printing continues to creep its way into the rocket industry. A form of additive manufacturing, 3d printing is a key technology for enhancing capabilities and reducing cost. The 3d printer does the rest of the job. Here there are 4 key features: Future lunar landers might come equipped with 3d printed rocket engine parts that help bring down overall manufacturing costs and reduce production time. We can start with any part of the rocket, but one of the simplest portions will be the section of the rocket that will connect with the lower rocket body. It is designed to lift up to 1250 kilograms. 12m views 2 years ago. Web have a fully functional, 3d printable rocket (excluding the motor) be able to recover it safely, ie tumble recovery rather than nose dive ; Web a rocket company at the core, relativity space is on a mission to become the next great commercial launch company. Do minimal gluing or cutting after printing; Future lunar landers might come equipped with. Web 3d printed ps4 engine the engine uses a bipropellant combination of nitrogen tetroxide as the oxidizer and mono methyl hydrazine as fuel. A form of additive manufacturing, 3d printing is a key technology for enhancing capabilities and reducing cost. Here there are 4 key features: Web 10000+ rocket printable 3d models. We can start with any part of the. We can start with any part of the rocket, but one of the simplest portions will be the section of the rocket that will connect with the lower rocket body. Web in this paper, we will study the commercial 3d printing wires mainly for hybrid rocket engines, analyzing their printing results, thermal analysis, and combustion performance, with the aim of. We can start with any part of the rocket, but one of the simplest portions will be the section of the rocket that will connect with the lower rocket body. Begin to create the rocket ship by gluing the inner flame to the outer flame. Web things tagged with '. Web 10000+ rocket printable 3d models. Download your favorite stl. Download your favorite stl files and make them with your 3d printer. Web it once took thousands of american engineers decades to get something into space. Click to find the best results for rocket models for your 3d printer. Web a rocket company at the core, relativity space is on a mission to become the next great commercial launch company.. I successfully launched one of these rockets twice. Download your favorite stl files and make them with your 3d printer. In these instructions i will take you thru steps needed to make really cool flying rockets. This is now a complete modular rocket system! It is designed to lift up to 1250 kilograms. Web download designs for 3d printer rocket. 3d printed rockets save on up front tooling, enable rapid iteration, decrease part count, and facilitate radically new designs. The rocket i designed is fully functional, you can actually launch it. Web things tagged with '. Web 3d printing continues to creep its way into the rocket industry. It is designed to lift up to 1250 kilograms. Download your favorite stl files and make them with your 3d printer. Web it once took thousands of american engineers decades to get something into space. The launch lug, bulkhead/ mounting hole, and upper threads. Next, glue the engine to the top of the flames. Tags pneumatic penny payload rocket (p3r or z lincoln. Now relativity space says its 3d printers can make a rocket in as little as. Download the 3d rocket template, print, and cut out the pieces you need. First, we must create the tube of the rocket. It is designed to lift up to 1250 kilograms. First, we must create the tube of the rocket. Web discover free 3d models for 3d printing related to rockets. Web discover 3d models for 3d printing related to rockets. Download files and build them with your 3d printer, laser cutter, or cnc. Here there are 4 key features: Web 3d printing offers new creativity in the world of model rocket design and fabrication. Web the rocket is about 35 metres tall, making it one of the smallest orbital rockets in the industry, and 85 per cent of it by mass is 3d printed. 12m views 2 years ago. 23k views 8 months ago #relativity #space #rocket. Web discover free 3d models for 3d printing related to rockets. Next, glue the engine to the top of the flames. It is designed to lift up to 1250 kilograms. Design the upper rocket body's lower section. 3d printers construct the desired object by using a layering method, which is the complete. 3d printed rockets save on up front tooling, enable rapid iteration, decrease part count, and facilitate radically new designs. I successfully launched one of these rockets twice. Web a rocket company at the core, relativity space is on a mission to become the next great commercial launch company. The engine that the space agency tested is the ps4 engine used in the reaction control system (rcs) of the upper stage (ps1. Begin to create the rocket ship by gluing the inner flame to the outer flame. A form of additive manufacturing, 3d printing is a key technology for enhancing capabilities and reducing cost. Take one of the rocket body pieces and glue it to the top of the engine.

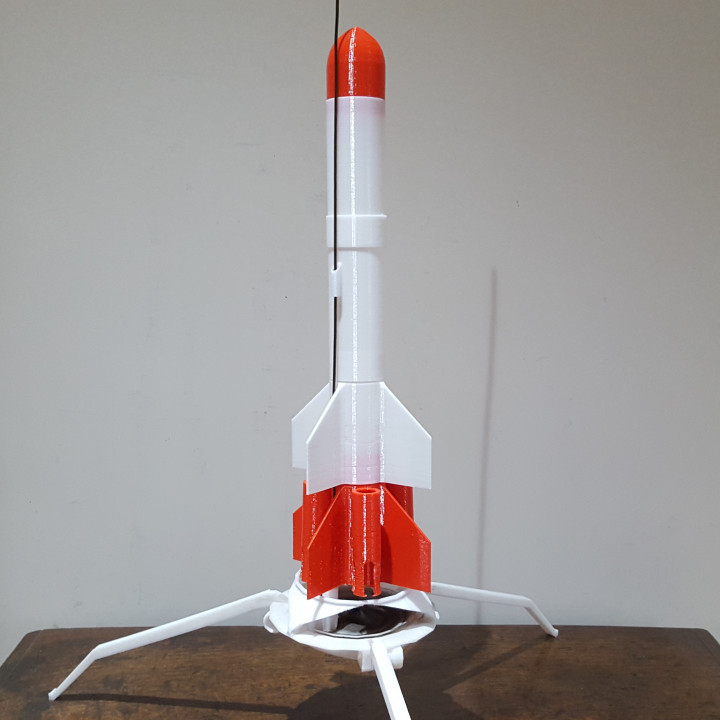

Cudacountry Rocket 3D Print

3D Printable gCreate Official Rocket Ship by gCreate

Presenting the Sky Bullet my first 3D printed rocket! rocketry

![DIY 3DPrinted Model Rocket [protofusion]](https://protofusion.org/wordpress/wp-content/uploads/2015/10/IMG_1790-e1444790094641-600x900.jpg)

DIY 3DPrinted Model Rocket [protofusion]

3D printed and assembled a model rocket. r/rocketry

3D Printable Modular Rocket for Estes motors by Leslie Kaye

My 3D Printed HO (1/87 ) Scale Model Rocket Collection r/ula

Watch a Robot 3D Printing the Rocket for Relativity Space’s First

3D Print Flying Model Rockets 20 Steps (with Pictures) Instructables

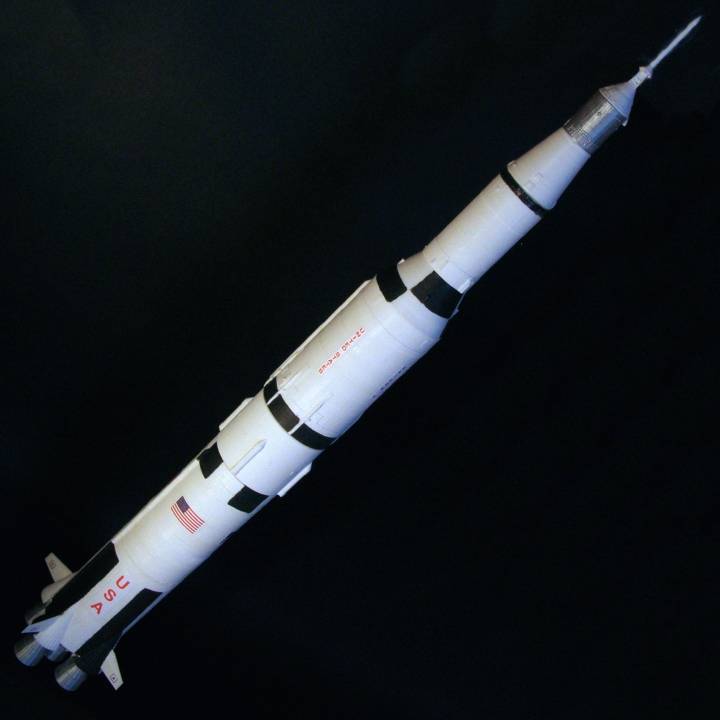

3D Printable Saturn V Rocket by NASA

Web 3D Printing Continues To Creep Its Way Into The Rocket Industry.

Every Day New 3D Models From All Over The World.

Web It Once Took Thousands Of American Engineers Decades To Get Something Into Space.

Web Launchable Mini Model Rocket.

Related Post: